Ford VSG-411 and 413 service manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

VSG-4111413

ENGINE

The

SERVICE MANUAL

I uwer...

Worldwide TM

For Engines Produced 1993 and Later

IMPORTANT SAFETY NOTICE

Appropriate service methods and proper repair procedures are essential for the safe, reliable operation of all motor

vehicles as well as the personal safety of the individual doing the work. This Shop Manual provides general direc-

tions for accomplishing service and repair work with tested, effective techniques. Following them will help assure

reliability.

There are numerous variations in procedures, techniques, tools, and parts for servicing vehicles, as well as in the

skill of the individual doing the work. This Manual cannot possibly anticipate all such variations and provide advice

or cautions as to each. Accordingly, anyone who departs from the instructions provided in this Manual must first

establish that he compromises neither his personal safety nor the vehicle integrity by his choice of methods, tools

or parts.

NOTES, CAUTIONS, AND WARNINGS

As you read through the procedures, you will come across NOTES, CAUTIONS, and WARNINGS. Each one is

there for a specific purpose. NOTES give you added information that will help you to complete a particular proce-

dure. CAUTIONS are given to prevent you from making an error that could damage the vehicle. WARNINGS

remind you to be especially careful in those areas where carelessness can cause personal injury. The following list

contains some general WARNINGS that you should follow when you work on a vehicle.

Always wear safety glasses for eye protection.

Use safety stands whenever a procedure requires you to be under the vehicle.

Be sure that the ignition switch is always in the OFF position, unless otherwise required by the procedure.

Set the parking brake when working on the vehicle. If you have an automatic transmission, set it in PARK

unless instructed otherwise for a specific operation. If you have a manual transmission, it should be in

REVERSE (engine OFF) or NEUTRAL (engine ON) unless instructed otherwise for a specific operation. Place

wood blocks (4” x 4” or larger) to the front and rear surfaces of the tires to provide further restraint from inad-

vertent vehicle movement.

Operate the engine only in a well-ventilated area to avoid the danger of carbon monoxide.

Keep yourself and your clothing away from moving parts when the engine is running, especially the fan and

belts.

To prevent serious burns, avoid contact with hot metal parts such as the radiator, exhaust manifold, tail pipe,

catalytic converter and muffler.

60 not smoke while working on the vehicle

To avoid injury, always remove rings, watches, loose hanging jewelry, and loose clothing before beginning to

work on a vehicle. Tie long hair securely behind the head.

Keep hands and other objects clear of the radiator fan blades. Electric cooling fans can start to operate at any

time by an increase in underhood temperatures, even though the ignition is in the OFF position. Therefore, care

should be taken to ensure that the electric cooling fan is completely disconnected when workina under the

hood.

The Engine Exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects or other reproductive harm.

Introduction

In general, this manual covers the servicing of the engine and asso-

ciated standard equipment. In many cases, engines are supplied

with accessories and equipment that are unique to the application. If

service information is ever required on such unique accessories or

equipment it is suggested that Power Products Division/GRI be con-

tacted. The proper information will either be forwarded or the Ser-

vice Technician will be advised where it can be obtained.

The information in this manual is grouped in sections according to

the type of work being performed. The various sections are indi-

cated in the index. In addition, each section is subdivided to include

topics such as diagnosis and testing, cleaning and inspection, over-

haul, removal and installation procedures, disassembly and assem-

bly procedures, and service specifications.

POWER PRODUCTS DIVISION/GRI

The Source for Power...

28333 TELEGRAPH ROAD - #300

Worldwide rev

SOUTHFIELD, MICHIGAN 48034

The descriptions and specifications contained in this manual were in

effect at the time the book was released for printing. Power Products

Division/GM reserves the right to discontinue models at any time, or

change specifications or design, without notice and without incurring

obligation.

NOTE: The recommendations and suggestions contained in this

___ - -- I_ I . . . . . . .I

01-l Basic Engine 01-I

SECTION TITLE PAGE SECTION TITLE PAGE

BASICENGINE ....................................... 01-l STARTING SYSTEM .................................. 051

IGNITION SYSTEM - DISTRIBUTORLESS ............... 02-l GOVERNOR ......................................... 06-l

FUEL SYSTEM ....................................... 03-I COOLING SYSTEM ................................... 07-I

EMISSION CONTROL SYSTEM ........................ 03A-1 SPECIFICATIONS .................................... 08-l

CHARGINGSYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 04-l

SECTION 01 - Basic Engine

SUBJECT PAGE

IDENTIFICATION ..................................... 01-3

DESCRIPTION ....................................... 01-4

DIAGNOSIS AND TESTING ............................ 01-6

Camshaft Lobe Lift ................................ 01-6

Compression Test ................................. 01-6

Compression Gauge Check ...................... 01-6

Test Conclusion ................................. 01-6

Crankshaft End Play ............................... 01-7

Flywheel Face Runout ............................. 01-7

Camshaft End Play ................................ 01-7

OVERHAUL .......................................... 01-8

Cylinder Head ..................................... 01-8

Reaming Valve Guides ........................... 01-8

Refacing Valve Seats ............................ 01-8

Valves.. .......................................... 01-8

Refacing Valves ................................. 01-8

Select Fitting Valves ............................. 01-9

Camshaft Repair .................................. 01-9

Crankshaft ........................................ 01-9

Refinishing Journals ............................ 01-9

Fitting Main or Connecting Rod Bearings

With Plastigage ............................... 01-9

Pistons, Pins and Rings ........................... 01-10

Fitting Pistons .................................. 01-l 0

Fitting Piston Rings ............................. 01-10

Fitting Piston Pins ............................... 01-11

Valve Rocker Arm and/or Shaft Assembly ........... 01-11

PushRods ........................................ 01-11

Cylinder Block .................................... 01-11

Refinishing Cylinder Walls ....................... 01-11

Repairing Sand Holes or Porous Engine

Castings ...................................... 01-11

CLEANING AND INSPECTION ......................... 01-l 2

Intake Manifold .................................... 01-I 2

Exhaust Manifolds ................................. 01-l 2

Valve Rocker Arm and/or Shaft Assembly ........... 01-12

PushRods.. ...................................... 01-12

SUBJECT PAGE

Cylinder Heads .................................... 01-12

Tappets ........................................... 01-14

Timing Chain and Sprockets ....................... 01-14

Camshaft ......................................... 01-14

Camshaft Bores ................................... 01-I 4

Crankshaft ........................................ 01-I 4

Flywheel .......................................... 01-l 5

Connecting Rods .................................. 01-l 5

Pistons, Pins and Rings ........................... 01-16

Main and Connecting Rod Bearings ................. 01-16

Cylinder Block .................................... 01-l 6

Oil Pan ........................................... 01-17

Oil Pump ......................................... 01-17

REMOVAL AND INSTALLATION ........................ 01-I 9

Valve Rocker Arm Cover, Rocker Arm and/or Shaft ... 01-19

Intake Manifold .................................... 01-I 9

Exhaust Manifold .................................. 01-l 9

Cylinder Head ..................................... 01-20

Valve Spring, Retainer and Stem Seal ............... 01-21

Cylinder Head Removed ......................... 01-21

Cylinder Head Installed .......................... 01-21

Water Pump ....................................... 01-22

Cylinder Front Cover and Timing Chain, or

Crankshaft Sprockets ............................ 01-22

Adjusting Valve Clearances ........................ 01-23

Crankshaft Front Oil Seal .......................... 01-24

Camshaft and/or Valve Lifters ...................... 01-24

Camshaft Bearings ................................ 01-25

Oil Pump ......................................... 01-26

Oil Pan ........................................... 01-26

Flywheel Ring Gear ................................ 01-26

Crankshaft Rear Oil Seal ........................... 01-27

Pistons and Connecting Rods ...................... 01-27

Oil Filter .......................................... 01-28

DISASSEMBLY AND ASSEMBLY ....................... 01-29

Engine Assembly .................................. 01-29

Oil Pump ......................................... 01-32

01-2 Basic Engine 01-2

BLANK

01-3 Basic Enaine 01-3

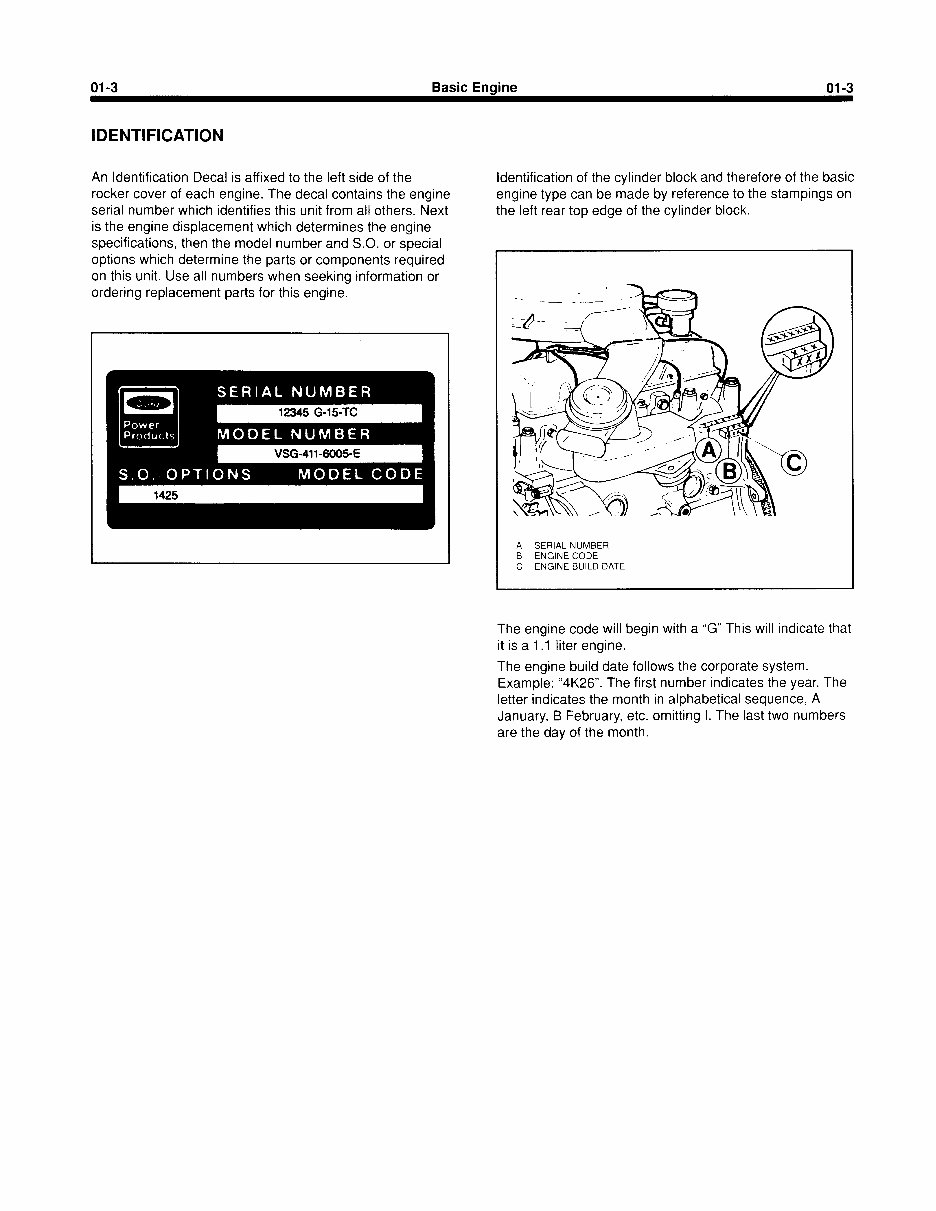

IDENTIFICATION

An Identification Decal is affixed to the left side of the

rocker cover of each engine. The decal contains the engine

serial number which identifies this unit from all others. Next

is the engine displacement which determines the engine

specifications, then the model number and S.O. or special

options which determine the parts or components required

on this unit. Use all numbers when seeking information or

ordering replacement parts for this engine.

Identification of the cylinder block and therefore of the basic

engine type can be made by reference to the stampings on

the left rear top edge of the cylinder block.

A SERIAL NUMBER

B ENGINE CODE

C ENGINE BUILD DATE

The engine code will begin with a “G” This will indicate that

it is a 1.I liter engine.

The engine build date follows the corporate system.

Example: “4K26”. The first number indicates the year. The

letter indicates the month in alphabetical sequence, A

January, B February, etc. omitting I. The last two numbers

are the day of the month.

01-4

DESCRIPTION

Basic Engine 01-4

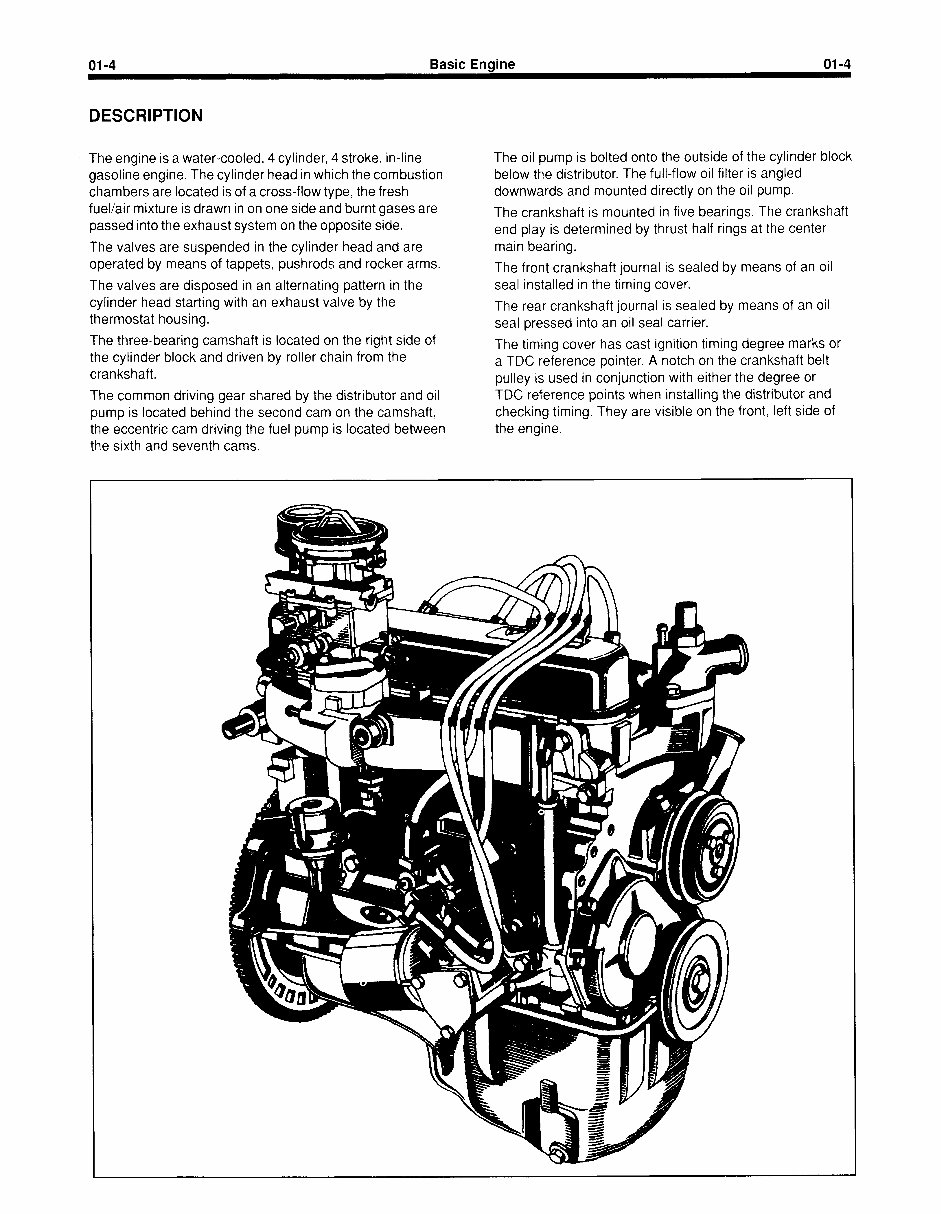

The engine is a water-cooled, 4 cylinder, 4 stroke, in-line

The oil pump is bolted onto the outside of the cylinder block

gasoline engine. The cylinder head in which the combustion

chambers are located is of a cross-flow type, the fresh

fuel/air mixture is drawn in on one side and burnt gases are

passed into the exhaust system on the opposite side.

The valves are suspended in the cylinder head and are

operated by means of tappets, pushrods and rocker arms.

The valves are disposed in an alternating pattern in the

cylinder head starting with an exhaust valve by the

thermostat housing.

The three-bearing camshaft is located on the right side of

the cylinder block and driven by roller chain from the

crankshaft.

The common driving gear shared by the distributor and oil

pump is located behind the second cam on the camshaft,

the eccentric cam driving the fuel pump is located between

the sixth and seventh cams.

below the distributor. The full-flow oil filter is angled

downwards and mounted directly on the oil pump.

The crankshaft is mounted in five bearings. The crankshaft

end play is determined by thrust half rings at the center

main bearing.

The front crankshaft journal is sealed by means of an oil

seal installed in the timing cover.

The rear crankshaft journal is sealed by means of an oil

seal pressed into an oil seal carrier.

The timing cover has cast ignition timing degree marks or

a TDC reference pointer. A notch on the crankshaft belt

pulley is used in conjunction with either the degree or

TDC reference points when installing the distributor and

checking timing. They are visible on the front, left side of

the engine.

01-5 Basic Engine 01-5

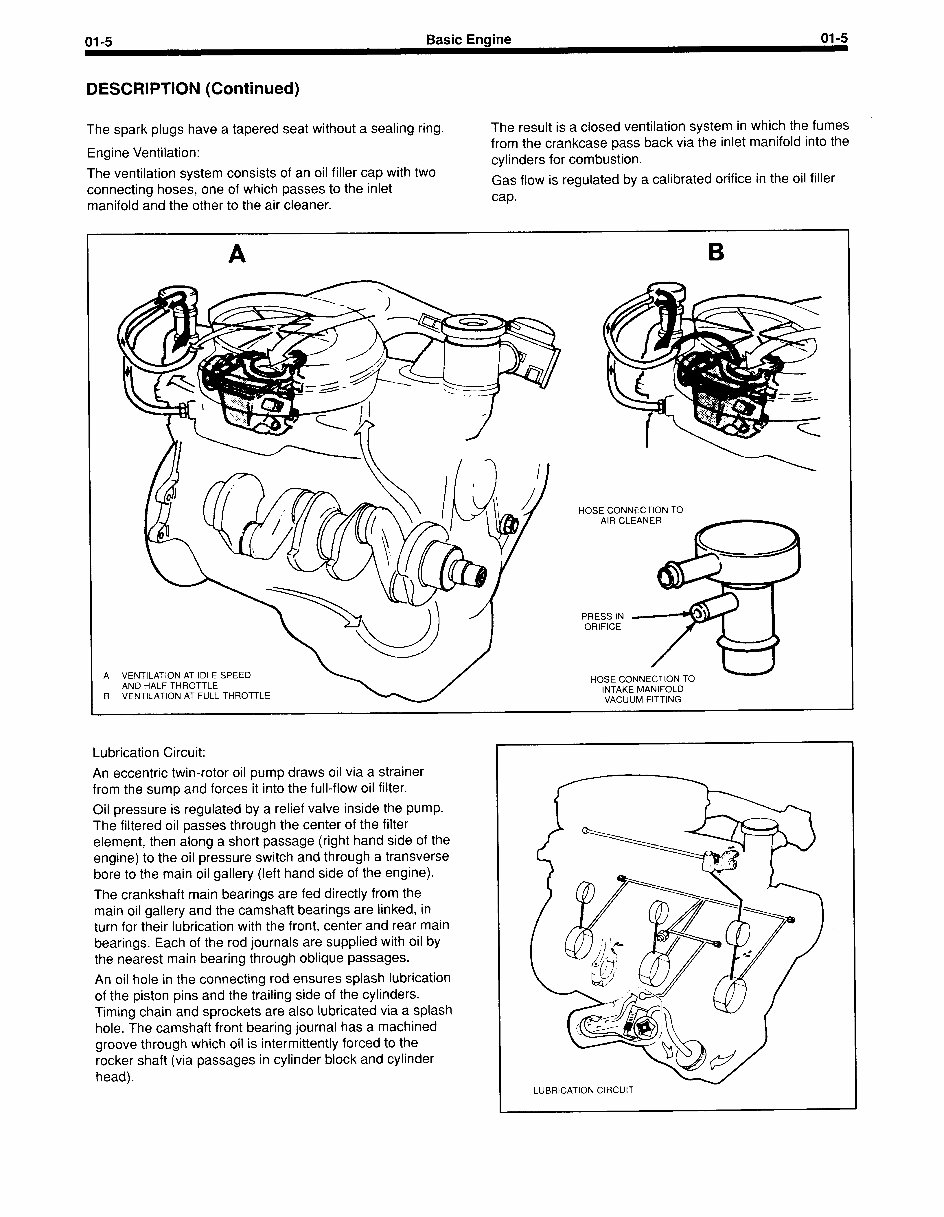

DESCRIPTION (Continued)

The spark plugs have a tapered seat without a sealing ring. The result is a closed ventilation system in which the fumes

Engine Ventilation:

from the crankcase pass back via the inlet manifold into the

The ventilation system consists of an oil filler cap with two

cylinders for combustion.

connecting hoses, one of which passes to the inlet

Gas flow is regulated by a calibrated orifice in the oil filler

manifold and the other to the air cleaner.

cap.

A VENTILATION AT IDLE SPEED

AND HALF THROTTLE

B VENTILATION AT FULL THROTTLE

HOSE CONNECTION TO

AIR C

PRESS IN

ORIFICE

HOSE C

INTAKE MANIFOLD

VACUUM FITTING

Lubrication Circuit:

An eccentric twin-rotor oil pump draws oil via a strainer

from the sump and forces it into the full-flow oil filter.

Oil pressure is regulated by a relief valve inside the pump.

The filtered oil passes through the center of the filter

element, then along a short passage (right hand side of the

engine) to the oil pressure switch and through a transverse

bore to the main oil gallery (left hand side of the engine).

The crankshaft main bearings are fed directly from the

main oil gallery and the camshaft bearings are linked, in

turn for their lubrication with the front, center and rear main

bearings. Each of the rod journals are supplied with oil by

the nearest main bearing through oblique passages.

An oil hole in the connecting rod ensures splash lubrication

of the piston pins and the trailing side of the cylinders.

Timing chain and sprockets are also lubricated via a splash

hole. The camshaft front bearing journal has a machined

groove through which oil is intermittently forced to the

rocker shaft (via passages in cylinder block and cylinder

head).

LUBRICATION CIRCUIT

01-6 Basic Enaine 01-6

DIAGNOSIS AND TESTING

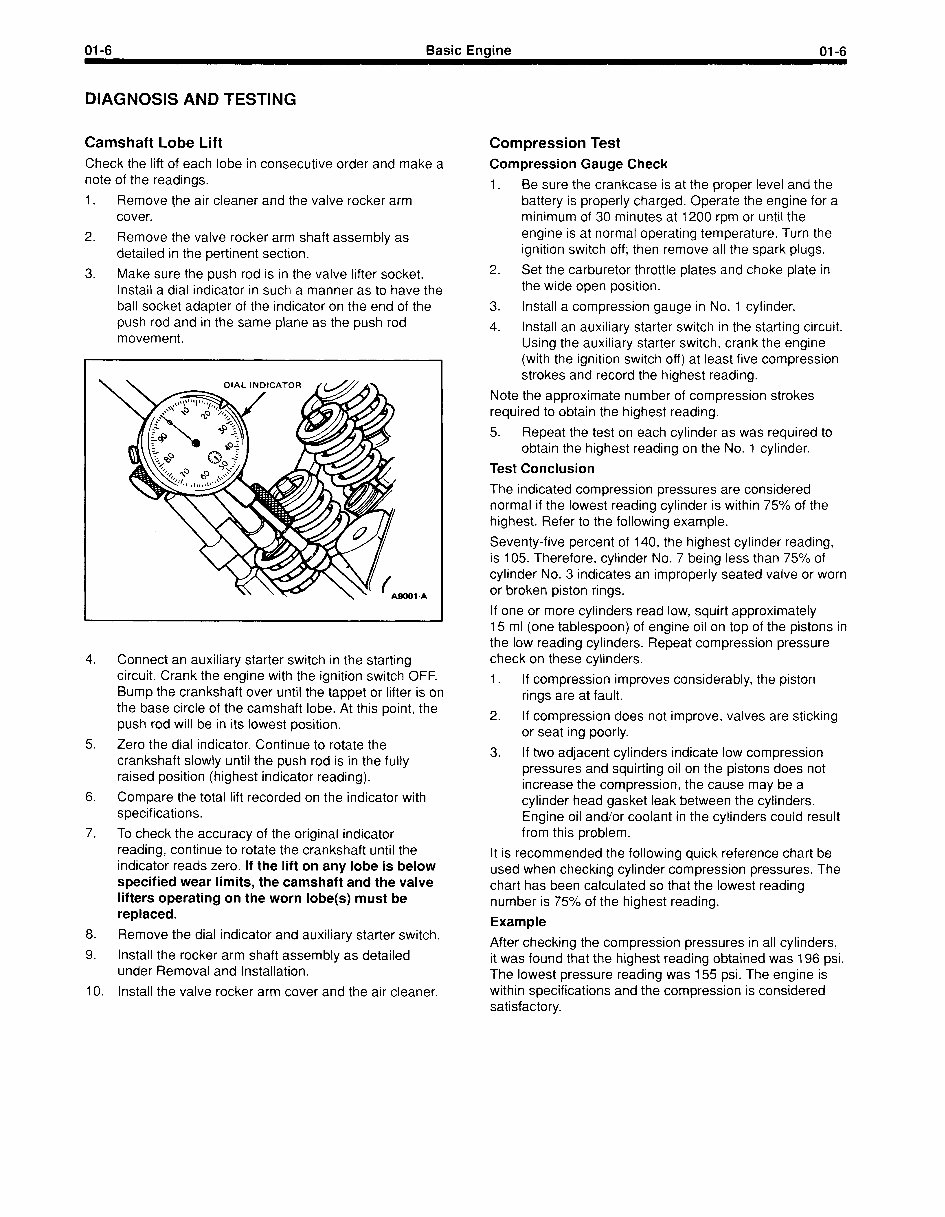

Camshaft Lobe Lift Compression Test

Check the lift of each lobe in consecutive order and make a

note of the readings.

1. Remove the air cleaner and the valve rocker arm

cover.

2. Remove the valve rocker arm shaft assembly as

detailed in the pertinent section.

3. Make sure the push rod is in the valve lifter socket.

Install a dial indicator in such a manner as to have the

ball socket adapter of the indicator on the end of the

push rod and in the same plane as the push rod

movement.

Compression Gauge Check

1. Be sure the crankcase is at the proper level and the

battery is properly charged. Operate the engine for a

minimum of 30 minutes at 1200 rpm or until the

engine is at normal operating temperature. Turn the

ignition switch off; then remove all the spark plugs.

2. Set the carburetor throttle plates and choke plate in

the wide open position.

3. Install a compression gauge in No. 1 cylinder.

4. Install an auxiliary starter switch in the starting circuit.

Using the auxiliary starter switch, crank the engine

(with the ignition switch off) at least five compression

strokes and record the highest reading.

Note the approximate number of compression strokes

required to obtain the highest reading.

5. Repeat the test on each cylinder as was required to

obtain the highest reading on the No. 1 cylinder.

Test Conclusion

1-A

4. Connect an auxiliary starter switch in the starting

circuit. Crank the engine with the ignition switch OFF.

Bump the crankshaft over until the tappet or lifter is on

the base circle of the camshaft lobe. At this point, the

push rod will be in its lowest position.

5. Zero the dial indicator. Continue to rotate the

crankshaft slowly until the push rod is in the fully

raised position (highest indicator reading).

6. Compare the total lift recorded on the indicator with

specifications.

7. To check the accuracy of the original indicator

reading, continue to rotate the crankshaft until the

indicator reads zero. If the lift on any lobe is below

specified wear limits, the camshaft and the valve

lifters operating on the worn lobe(s) must be

replaced.

8. Remove the dial indicator and auxiliary starter switch.

9. Install the rocker arm shaft assembly as detailed

under Removal and Installation.

IO. Install the valve rocker arm cover and the air cleaner.

The indicated compression pressures are considered

normal if the lowest reading cylinder is within 75% of the

highest. Refer to the following example.

Seventy-five percent of 140, the highest cylinder reading,

is 105. Therefore, cylinder No. 7 being less than 75% of

cylinder No. 3 indicates an improperly seated valve or worn

or broken piston rings.

If one or more cylinders read low, squirt approximately

15 ml (one tablespoon) of engine oil on top of the pistons in

the low reading cylinders. Repeat compression pressure

check on these cylinders.

1. If compression improves considerably, the piston

rings are at fault.

2. If compression does not improve, valves are sticking

or seat ing poorly.

3. If two adjacent cylinders indicate low compression

pressures and squirting oil on the pistons does not

increase the compression, the cause may be a

cylinder head gasket leak between the cylinders.

Engine oil and/or coolant in the cylinders could result

from this problem.

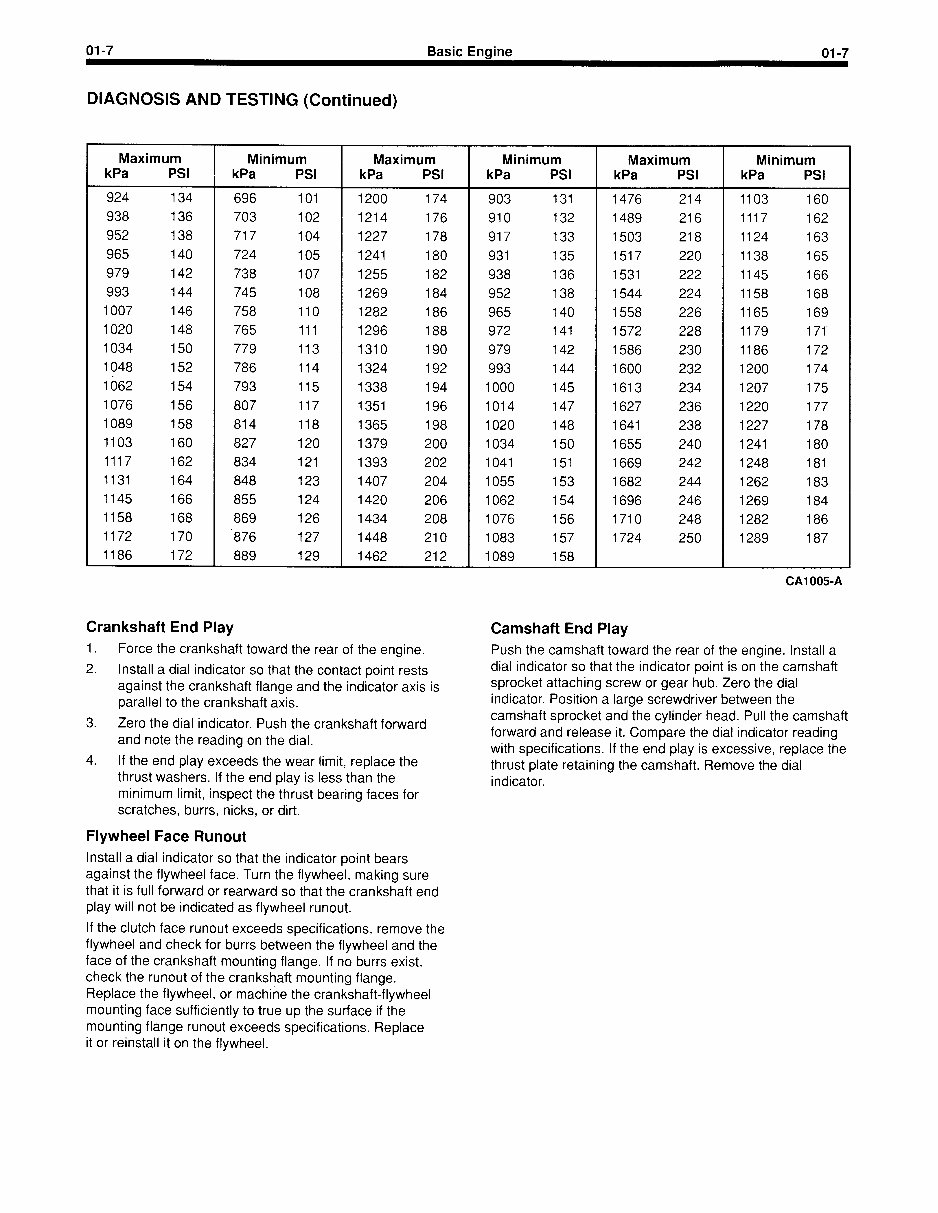

It is recommended the following quick reference chart be

used when checking cylinder compression pressures. The

chart has been calculated so that the lowest reading

number is 75% of the highest reading.

Example

After checking the compression pressures in all cylinders,

it was found that the highest reading obtained was 196 psi.

The lowest pressure reading was 155 psi. The engine is

within specifications and the compression is considered

satisfactory.

01-7 Basic Engine 01-7

DIAGNOSIS AND TESTING (Continued)

Maximum Minimum Maximum Minimum

kPa PSI kPa PSI kPa PSI kPa PSI

924 134 696 101 1200 174 903 131

938 136 703 102 1214 176 910 132

952 138 717 104 1227 178 917 133

965 140 724 105 1241 180 931 135

979 142 738 107 1255 182 938 136

993 144 745 108 1269 184 952 138

1007 146 758 110 1282 186 965 140

1020 148 765 111 1296 188 972 141

1034 150 779 113 1310 190 979 142

1048 152 786 114 1324 192 993 144

1662 154 793 115 1338 194 1000 145

1076 156 807 117 1351 196 1014 147

1089 158 814 118 1365 198 1020 148

1103 160 827 120 1379 200 1034 150

1117 162 834 121 1393 202 1041 151

1131 164 848 123 1407 204 1055 153

1145 166 855 124 1420 206 1062 154

1158 168 869 126 1434 208 1076 156

1172 170 -876 127 1448 210 1083 157

1186 172 889 129 1462 212 1089 158

Maximum Minimum

kPa PSI kPa PSI

1476 214 1103 160

1489 216 1117 162

1503 218 1124 163

1517 220 1138 165

1531 222 1145 166

1544 224 1158 168

1558 226 1165 169

1572 228 1179 171’

1586 230 1186 172

1600 232 1200 174

1613 234 1207 175

1627 236 1220 177

1641 238 1227 178

1655 240 1241 180

1669 242 1248 181

1682 244 1262 183

1696 246 1269 184

1710 248 1282 186

1724 250 1289 187

Crankshaft End Play

1. Force the crankshaft toward the rear of the engine.

2. Install a dial indicator so that the contact point rests

against the crankshaft flange and the indicator axis is

parallel to the crankshaft axis.

3. Zero the dial indicator. Push the crankshaft forward

and note the reading on the dial.

4. If the end play exceeds the wear limit, replace the

thrust washers. If the end play is less than the

minimum limit, inspect the thrust bearing faces for

scratches, burrs, nicks, or dirt.

Camshaft End Play

Push the camshaft toward the rear of the engine. Install a

dial indicator so that the indicator point is on the camshaft

sprocket attaching screw or gear hub. Zero the dial

indicator. Position a large screwdriver between the

camshaft sprocket and the cylinder head. Pull the camshaft

forward and release it. Compare the dial indicator reading

with specifications. If the end play is excessive, replace the

thrust plate retaining the camshaft. Remove the dial

indicator.

Flywheel Face Runout

Install a dial indicator so that the indicator point bears

against the flywheel face. Turn the flywheel, making sure

that it is full forward or rearward so that the crankshaft end

play will not be indicated as flywheel runout.

If the clutch face runout exceeds specifications, remove the

flywheel and check for burrs between the flywheel and the

face of the crankshaft mounting flange. If no burrs exist,

check the runout of the crankshaft mounting flange.

Replace the flywheel, or machine the crankshaft-flywheel

mounting face sufficiently to true up the surface if the

mounting flange runout exceeds specifications. Replace

it or reinstall it on the flywheel.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 55 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

The Ford VSG-411 and 413 service manual is an essential resource for anyone involved in the maintenance and repair of these engines. Whether you are a professional mechanic or a DIY enthusiast, this manual provides detailed technical information to help you understand, troubleshoot, and repair the engine effectively.

With comprehensive diagrams, step-by-step procedures, and specifications, this manual covers a wide range of topics including engine assembly, disassembly, maintenance, and troubleshooting. It is an invaluable tool for ensuring the proper functioning and longevity of the Ford VSG-411 and 413 engines.