Ford 2.5L (153 CID) LRG-425 Industrial Engine Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

LRG-425

2.5 LITER

(153 CID)

INDUSTRIAL ENGINE SERVICE MANUAL

IMPORTANT SAFETY NOTICE

Appropriate service methods and proper repair procedures are essential for the safe, reliable operation of all

industrial engines as well as the personal safety of the individual doing the work. This Service Manual provides

general directions for accomplishing service and repair work with tested, effective techniques. Following them will

help assure reliability.

There are numerous variations in procedures, techniques, tools and parts for servicing equipment, as well as in the

skill of the individual doing the work. This Manual cannot possibly anticipate all such variations and provide advice

or cautions as to each. Accordingly, anyone who departs from the instructions provided in this Manual must first

establish that he compromises neither his personal safety nor the equipment integrity by his choice of methods, tools

or parts.

NOTES, CAUTIONS, AND WARNINGS

As you read through the procedures, you will come across NOTES, CAUTIONS, and WARNINGS. Each one is

there for a specific purpose. NOTES give you added information that will help you to complete a particular

procedure. CAUTIONS are given to prevent you from making an error that could damage the equipment.

WARNINGS remind you to be especially careful in those areas where carelessness can cause personal injury. The

following list contains some general WARNINGS that you should follow when you work on the equipment.

• Always wear safety glasses for eye protection.

• Use safety stands whenever a procedure requires you to be under the equipment.

• Be sure that the ignition switch is always in the OFF position, unless otherwise required by the

procedure.

• Set the parking brake (if equipped) when working on the equipment. If you have an automatic

transmission, set it in PARK REVERSE (engine off) or NEUTRAL (engine on) unless instructed

otherwise for a specific operation. Place wood blocks (4” x 4” or larger) to the front and rear

surfaces of the tires to provide further restraint from inadvertent equipment movement.

• Operate the engine only in a well ventilated area to avoid the danger of carbon monoxide.

• Keep yourself and your clothing away from moving parts when the engine is running, especially the

fan and belts.

• To prevent serious burns, avoid contact with hot metal parts such as the radiator, exhaust manifold,

tail pipe, catalytic converter and muffler.

• Do not smoke while working on the equipment.

• To avoid injury, always remove rings, watches, loose hanging jewelry, and loose clothing before

beginning to work on the equipment. Tie long hair securely behind the head.

• Keep hands and other objects clear of the radiator fan blades. Electric cooling fans can start to

operate at any time by an increase in underhood temperatures, even through the ignition is in the

OFF position. Therefore, care should be taken to ensure that the electric cooling fan is completely

disconnected when working under the hood.

Introduction

In general, this manual covers the servicing of the engine and

associated standard equipment. In many cases, engines are

supplied with accessories and equipment that are unique to the

application. If service information is ever required on such unique

accessories or equipment it is suggested that Ford Power Products

be contacted. The proper information will either be forwarded or the

Service Technician will be advised where it can be obtained.

The information in this manual is grouped in sections according to

the type of work being performed. The various sections are indicated

in the index. In addition, each section is subdivided to include

topics such as diagnosis and testing, cleaning and inspection,

overhaul, removal and installation procedures, disassembly and

assembly procedures, and service specifications.

Special service tools called for by the procedures can be obtained by

calling:

1-800-ROTUNDA (1-800-768-8632).

The descriptions and specifications contained in this manual were in

effect at the time the book was released for printing. Ford Power

Products reserves the right to discontinue models at any time, or

change specifications or design, without notice and without incurring

obligation.

NOTE: The recommendations and suggestions contained in this

publication are made to assist the distributor in improving his

distributorship parts and/or service department operations. These

recommendations and suggestions do not supersede or override the

provisions of the Warranty and Policy Manual and in any cases

where there may be a conflict, the provisions of the Warranty and

Policy Manual shall govern.

Reroduction in any manner, in whole or in part, is prohibited without

The express permission in writing from:

Ford Power Products, Marketing Department.

TABLE OF CONTENTS

SECTION TITLE PAGE

ENGINE SERVICE - GENERAL ................................................................................................01

ENGINE SERVICE – 2.5L .........................................................................................................02

IGNITION SYSTEM ...................................................................................................................03

FUEL PUMP ..............................................................................................................................04

CARBURETOR ..........................................................................................................................05

STARTER MOTOR ....................................................................................................................06

GOVERNOR ..............................................................................................................................07

COOLING SYSTEM...................................................................................................................08

GENERATOR ............................................................................................................................09

01-1 Engine Service - General 01-1

SECTION TITLE PAGE

ENGINE SERVICE - General ................................................................................................................................ 01-01

ENGINE SERVICE - 2.5L ...................................................................................................................................... 02-01

IGNITION SYSTEM ............................................................................................................................................... 03-01

FUEL PUMP ......................................................................................................................................................... 04-01

CARBURETOR...................................................................................................................................................... 05-01

STARTER MOTOR................................................................................................................................................ 06-01

GOVERNOR .......................................................................................................................................................... 07-01

COOLING SYSTEM .............................................................................................................................................. 08-01

GENERATOR ........................................................................................................................................................ 09-01

SECTION 01 - Engine Service - General

SUBJECT PAGE

DESCRIPTION ............................................................................................................................................................. 2

Introduction .............................................................................................................................................................. 2

Engine Identification Nameplate .............................................................................................................................. 2

DIAGNOSIS .................................................................................................................................................................. 3

Inspection................................................................................................................................................................. 3

Symptom Chart ........................................................................................................................................................ 3

PCV System Malfunction ......................................................................................................................................... 5

Engine Oil Leak Check ............................................................................................................................................ 5

Compression Test .................................................................................................................................................... 7

Cylinder Leakage Test ............................................................................................................................................. 8

Oil Leak and Valve Guide Seal Test ........................................................................................................................ 8

Intake Manifold Vacuum Test .................................................................................................................................. 8

Oil Consumption Test ............................................................................................................................................ 10

Oil Pressure Test ................................................................................................................................................... 11

SERVICE PROCEDURES.......................................................................................................................................... 12

Camshaft Service................................................................................................................................................... 12

Connecting Rod Service ........................................................................................................................................ 14

Crankshaft Bearing Service ................................................................................................................................... 15

Crankshaft Service................................................................................................................................................. 18

Cylinder Block Service ........................................................................................................................................... 20

Cylinder Head Service ........................................................................................................................................... 23

Engine Block Plug Service..................................................................................................................................... 31

Exhaust Manifold Service ...................................................................................................................................... 32

Hydraulic Valve Tappet/Adjuster Service............................................................................................................... 32

Intake Manifold Service.......................................................................................................................................... 34

Oil Pan Service ...................................................................................................................................................... 34

Piston Service ........................................................................................................................................................ 34

SPECIAL TOOLS ....................................................................................................................................................... 38

01-2 Engine Service - General 01-2

DESCRIPTION

DESCRIPTION

Introduction

This section covers various engine tests, adjustments,

service procedures and cleaning/inspection

procedures. Engine assembly and service

specifications appear at the end of Section 02.

For engine disassembly, assembly, installation,

adjustment procedures and specifications, refer to

Section 02.

Most Ford Power Product engines incorporate a

closed-type crankcase ventilation system. Other than

the crankcase ventilation system there are no exhaust

emission controls or engine/emission control systems

used with industrial versions of these engines.

To maintain the required performance level, the fuel

system, ignition system and engine must be kept in

good operating condition and meet recommended

adjustment specifications.

Before replacing damaged or worn engine

components such as the crankshaft, cylinder head,

valve guide, valves, camshaft or cylinder block, make

sure part(s) is not serviceable.

WARNING: TO AVOID THE POSSIBILITY OF

PERSONAL INJURY OR DAMAGE, DO NOT

OPERATE THE ENGINE UNTIL THE FAN BLADE

HAS FIRST BEEN EXAMINED FOR POSSIBLE

CRACKS OR SEPARATION.

CAUTION: Use of abrasive grinding discs to

remove gasket material from the engine sealing

surfaces during repair procedures can contribute

to engine damage and wear. Airborne debris and

abrasive grit from the grinding disc may enter the

engine through exposed cavities causing

premature wear and eventual engine damage.

Ford Power Products does not recommend using

abrasive grinding discs to remove engine gasket

material. Use manual gasket scrapers for removing

gasket material from the engine sealing surfaces.

Take added care to prevent scratching or gouging

aluminum sealing surfaces.

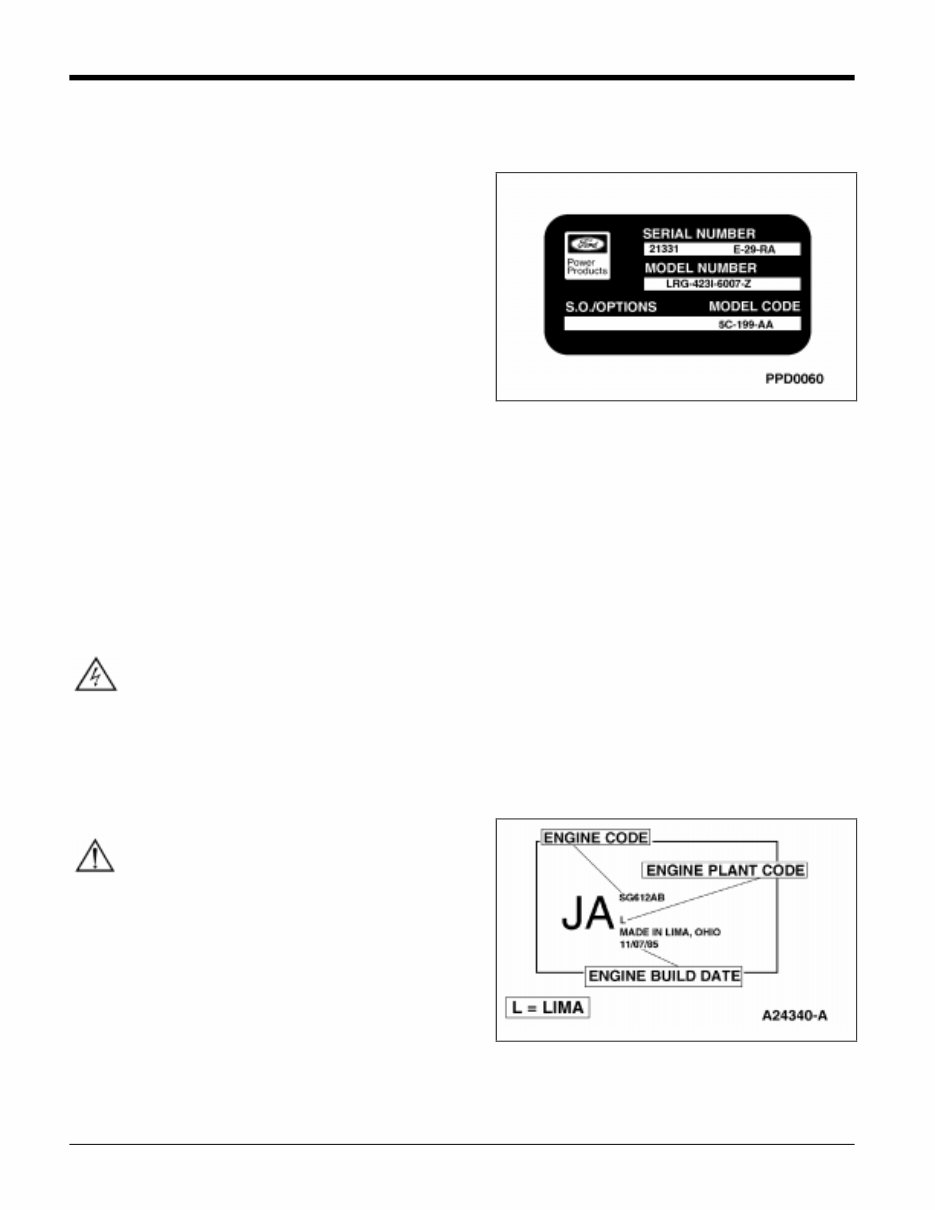

Engine Identification Nameplate

For quick engine identification, refer to the Engine

Identification Nameplate. The nameplate lists engine

information required for proper servicing of the

engine. The Engine Identification Nameplate and

identification label provide information pertaining to

engine displacement, serial number, model number,

S.O./Options, and model code.

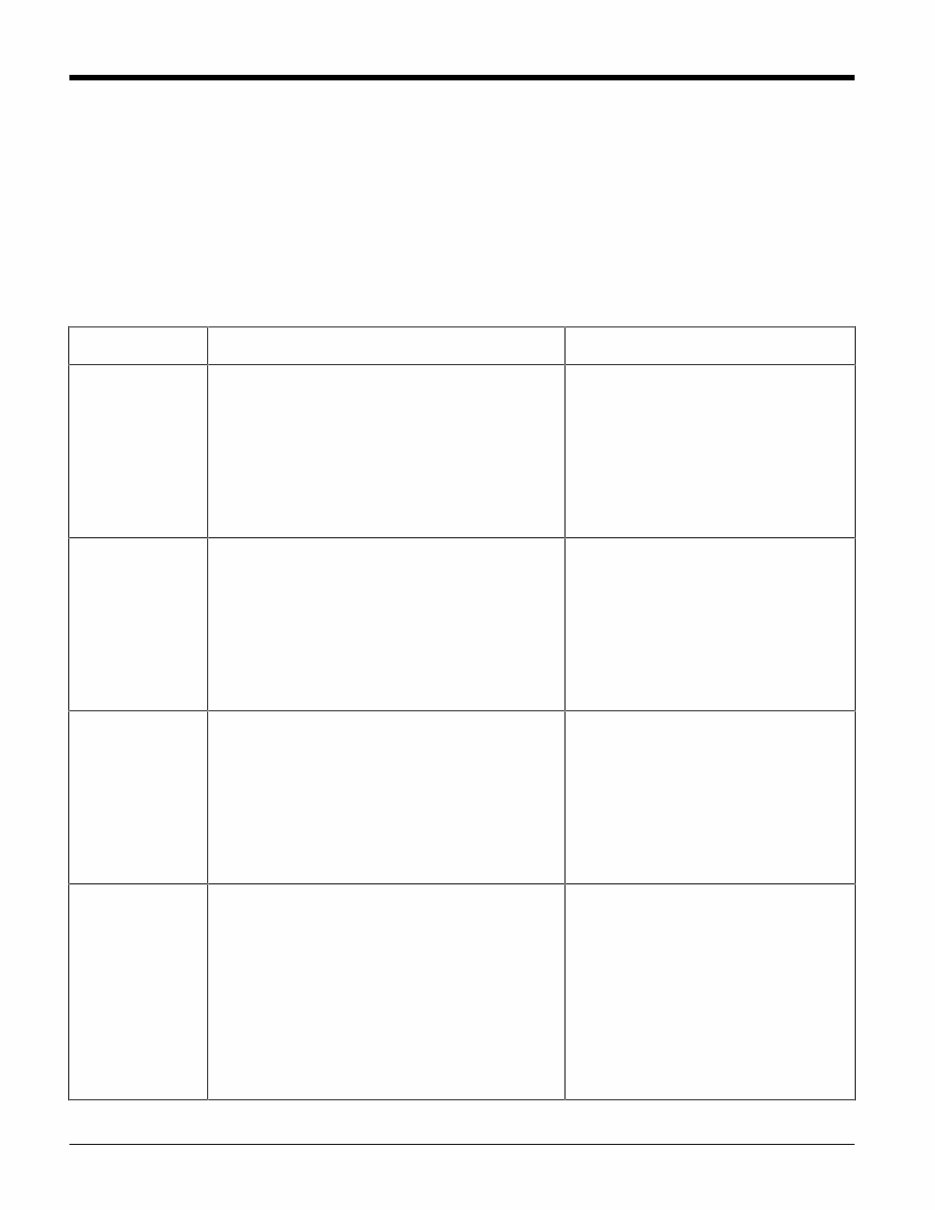

An engine code decal is attached to the engine front

cover. The symbol code on the decal identifies each

engine for determining parts usage.

01-3 Engine Service - General 01-3

DIAGNOSIS

DIAGNOSIS

Inspection

Inspect to determine if any of the following mechanical concerns apply:

• Engine oil leaks.

• Damaged and/or severely worn parts.

• Loose mounting bolts, studs and nuts.

CONDITION POSSIBLE SOURCE ACTION

DIFFICULT

STARTING

• Burnt valve.

• Worn piston.

• Worn piston ring(s).

• Worn cylinder.

• Damaged cylinder head gasket.

• Malfunctioning or damaged fuel system.

• Malfunctioning or damaged ignition system.

• Replace valve.

• Replace piston.

• Replace piston ring(s).

• Service or replace cylinder block.

• Replace cylinder head gasket.

• Refer to section on fuel system.

• Refer to section on ignition system.

POOR IDLING

• Damaged hydraulic valve tappet.

• Damaged hydraulic valve tappet guide.

• Improper valve to valve seat contact.

• Damaged cylinder head gasket.

• Malfunctioning or damaged fuel system.

• Malfunctioning or damaged ignition system.

• Replace hydraulic valve tappet.

• Replace hydraulic valve tappet

guide.

• Replace valve and/or valve seat.

• Replace cylinder head gasket.

• Refer to section on Fuel system.

• Refer to section on ignition system.

ABNORMAL

COMBUSTION

• Damaged hydraulic valve tappet.

• Damaged hydraulic valve tappet bore.

• Burnt or sticking valve.

• Weak or broken valve spring.

• Carbon accumulation in combustion chamber.

• Malfunctioning or damaged fuel system.

• Malfunctioning or damaged ignition system.

• Replace hydraulic valve tappet.

• Replace cylinder block.

• Service or replace valve.

• Replace valve spring.

• Eliminate carbon buildup.

• Refer to section on fuel system.

• Refer to section on ignition system.

EXCESSIVE OIL

CONSUMPTION

• Worn piston ring groove.

• Sticking piston ring(s).

• Worn piston or cylinder.

• Worn valve stem seal.

• Worn valve stem or valve guides.

• Leaking oil.

• Worn piston rings.

• Plugged pcv system.

• Replace piston.

• Service or replace piston ring (s).

• Service or replace piston or cylinder

block.

• Replace valve stem seal.

• Replace valve stem and guide.

• Service oil leak.

• Replace piston rings.

• Service PCV system.

01-4 Engine Service - General 01-4

DIAGNOSIS

CONDITION POSSIBLE SOURCE ACTION

ENGINE NOISE

• Excessive main bearing oil clearance.

• Seized or heat damaged crankshaft main

bearing.

• Excessive crankshaft end play.

• Excessive connecting rod bearing oil

clearance.

• Heat damaged connecting rod bearing.

• Damaged connecting rod bushing.

• Worn cylinder.

• Worn piston or piston pin.

• Damaged piston ring(s).

• Bent connecting rod.

• Malfunctioning hydraulic valve tappet.

• Excessive hydraulic valve tappet clearance.

• Broken valve spring.

• Excessive valve guide clearance.

• Malfunctioning or damaged cooling system.

• Malfunctioning or damaged fuel system.

• Leaking exhaust system.

• Improper drive belt tension.

• Malfunctioning generator bearing.

• Loose riming belt.

• Damaged timing belt tensioner.

• Malfunctioning water pump bearing.

• Adjust clearance or replace

crankshaft main bearing.

• Replace crankshaft main bearing.

• Adjust end play or replace

crankshaft.

• Adjust clearance or replace

connecting rod.

• Replace connecting rod bearing.

• Replace connecting rod bushing.

• Service or replace cylinder block.

• Replace piston or piston pin.

• Replace piston ring(s).

• Replace connecting rod.

• Replace hydraulic valve tappet.

• Adjust clearance or replace

hydraulic valve tappet.

• Replace valve spring.

• Service clearance or replace valve

guide/stem.

• Refer to section on cooling system.

• Refer to section on fuel system.

• Service exhaust leakage.

• Refer to section on accessory

drivebelts.

• Refer to section on charging system.

• Adjust or replace timing belt.

• Replace timing belt tensioner.

• Refer to section on cooling system.

INSUFFICIENT

POWER

• Malfunctioning hydraulic valve tappet.

• Damaged hydraulic valve tappet bore.

• Seized valve stem.

• Weak or broken valve spring.

• Damaged cylinder head gasket.

• Cracked or distorted cylinder head.

• Damaged, worn or sticking piston ring(s).

• Worn or damaged piston.

• Malfunctioning or damaged fuel system.

• Malfunctioning or damaged ignition system.

• Replace hydraulic valve tappet.

• Replace cylinder block.

• Service or replace valve, valve seat

and/or cylinder head.

• Replace valve spring.

• Replace cylinder head gasket.

• Replace cylinder head.

• Service or replace piston ring(s).

• Replace piston.

• Refer to section on fuel system.

• Refer to section on ignition system.

01-5 Engine Service - General 01-5

DIAGNOSIS

PCV System Malfunction

A malfunctioning Positive Crankcase Ventilation

System (closed type) may be indicated by loping or

rough engine idle. Do not attempt to compensate for

this idle condition by disconnecting the crankcase

ventilation system and making an air bypass or idle

speed adjustment. The removal of the crankcase

ventilation system from the engine will adversely

affect fuel economy and engine crankcase

ventilation with resultant shortening of engine

life.

Engine Oil Leak Check

When diagnosing engine oil leaks, it is important that

the source and location of the leak be positively

identified prior to service.

NOTE: Due to their remote location, rear engine

oil leaks may be very difficult to pinpoint. This

area is also very difficult to clean. Make sure to

eliminate all other possibilities before removing

the engine to repair a suspected leak in this area.

There are two methods of diagnosing engine oil leaks.

The following procedure has been found to be very

effective and requires only a minimum of equipment.

Prior to using this procedure, it is important to clean

the cylinder block, cylinder heads, valve covers, oil

pan and flywheel housing areas with a suitable

solvent to remove all traces of oil.

Fluorescent Oil Additive Method

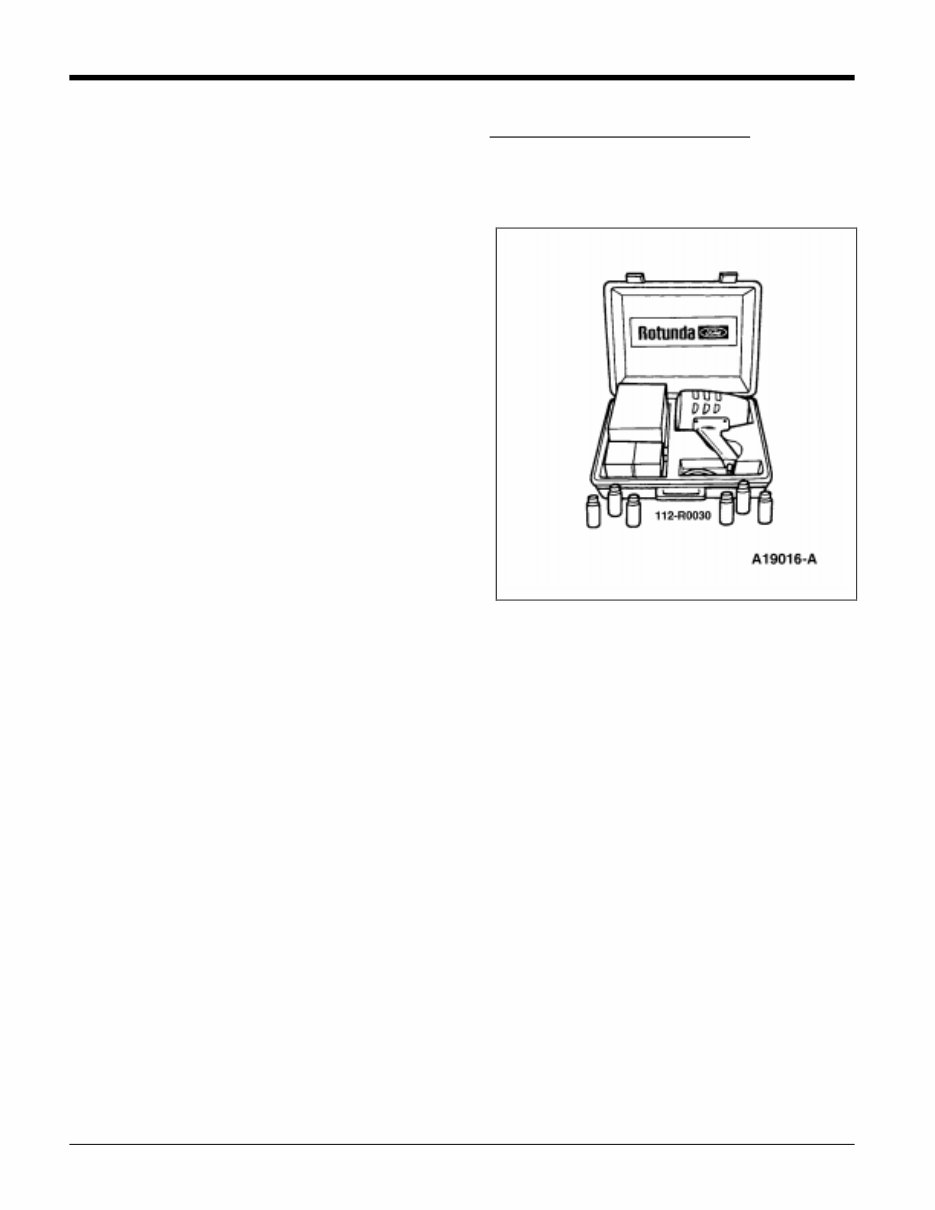

To perform oil leak diagnosis using Rotunda Oil Leak

Detector Kit 112-R0030, or equivalent, perform the

following procedure.

1. Clean engine with a suitable solvent to remove all

traces of oil.

2. Drain engine oil from crankcase and refill with

recommended oil, premixed with Rotunda

Fluorescent Oil Additive 112-R0015, or

equivalent. Use 29.6ml (1 fluid once) of

fluorescent additive. If oil is not premixed,

fluorescent additive must be added to crankcase

first.

3. Run engine for 15 minutes. Stop engine and

inspect all seal and gasket areas for leaks using

Rotunda Oil Leak Detector Y112-R0021 (part of

112-R0030 kit) Lamp or equivalent. A clear bright

yellow or orange area will identify leak. For

extremely small leaks, several hours may be

required for the leak to appear.

4. If necessary, pressurize main oil gallery system to

locate leaks due to improperly sealed, loose or

cocked plugs. If flywheel bolts leak oil, look for

sealer on threads.

5. Service all leaks as required.

01-6 Engine Service - General 01-6

DIAGNOSIS

Pressure Method

As an alternative testing procedure, the crankcase

can be pressurized, not to exceed 27 kPa (4 psi), to

locate oil leaks. The following materials are required

to fabricate the tool to be used:

• Air supply and air hose.

• Air pressure gauge that registers pressure in

increments of one psi.

• Air line shutoff valve.

• Appropriate fittings to attach the above parts to oil

fill, PCV grommet holes and PCV fresh air hose

tube.

• Appropriate plugs to seal any openings leading to

crankcase.

• A solution of liquid detergent and water to be

applied with a suitable type applicator such as a

squirt bottle or brush.

Fabricate the air supply hose to include the air line

shutoff valve and the appropriate adapter to permit

the air to enter the engine through the rocker arm

cover tube. Fabricate the air pressure gauge to a

suitable adapter for installation on the engine at the oil

fill opening.

CAUTION: Use extreme caution when

pressurizing crankcase. Applying air pressure

above specified pressure risks damage to seals,

gaskets and core plugs. Under no circumstances

should pressure be allowed to exceed 27 kPa (4

psi).

1. Open air supply valve until pressure gauge

maintains 20 kPa (3 psi).

2. Inspect sealed and/or gasketed areas for leaks

by applying a solution of liquid detergent and

water over areas for formation of bubbles, which

indicates leakage.

3. Examine the following areas for oil leakage:

• Rocker cover sealant or gaskets

• Intake manifold gaskets/end seals

• Cylinder head gaskets

• Oil bypass filter

• Oil level indicator (dipstick) tube connection

• Oil pressure sensor

• Cup plugs and/or pipe plugs at end of oil

passages

• Oil pan gasket

• Oil pan front and rear end seals

• Oil pan front and rear end seals

• Crankshaft front seal

• Crankshaft rear oil seal

• Oil pump

• Crankshaft rear oil seal

Air leakage in area around a crankshaft rear oil seal

does not necessarily indicate a rear seal leak.

However, if no other cause can be found for oil

leakage, it can be assumed that rear seal is the cause

of the oil leakage:

• Rear main bearing cap parting line.

• Rear main bearing cap and seals.

• Flywheel mounting bolt holes.

• Rear cup plugs and/or pipe plugs at the end of oil

passages.

Oil leaks at crimped seams in sheet metal parts and

cracks in cast or stamped parts can be detected when

pressurizing the crankcase.

Light foaming equally around rocker arm cover bolts

and crankshaft seals is not detrimental and no

corrections are required in such cases.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$35.99

Viewed 57 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$35.99

This workshop service repair manual is for the Ford 2.5L (153 CID) LRG-425 Industrial Engine Service & Repair Manual and includes an operator's manual. The manual covers the 2.5L I-4 cylinder, 4-stroke, spark ignition engine and provides the following detailed technical information:

- Engine service procedures and torque specifications

- Ignition system and fuel pump system details

- Engine diagnosis and troubleshooting guidelines

- Step-by-step instructions for engine removal and installation

- Camshaft, connecting rod, and crankshaft service procedures

- Cylinder block and cylinder head servicing information

- Engine block plug, exhaust manifold, and hydraulic valve tappet/adjuster service details

- Intake manifold, oil pan, piston, and carburetor system maintenance

- Information on starter motor, governor system, cooling system, and generator system

- Lists of special tools and wiring diagrams

This comprehensive manual is available in .PDF format and features detailed exploded views, clear illustrations, and diagrams. It is designed to assist both professional mechanics and DIY enthusiasts with repairs, maintenance, and servicing of the Ford 2.5L (153 CID) LRG-425 Industrial Engine.