System description

Electronic monitoring system EMS 2

© 0702 Page 55

EMS 2

1 Foreword

This system description provides an overview of the design and the operation of the electronic monitoring

system (EMS 2).

In addition, the functions which the EMS 2 contains, and the manner in which problems in the engine and in

the EMS 2 can be detected, are explained.

© 0702 Page 57

EMS 2

Important notes

2 Important notes

In the event of critical conditions, the EMS 2 may independently shut the engine off, either

with or without prior warning depending on the configuration, or may merely provide a

warning. The user must be informed of this and must be familiarised with limp-home mode.

! The following states can be recognised with the diagnostic lamp

! The illumination of the maintenance/service lamp demands that the engine be maintained by the

DEUTZ Service department.

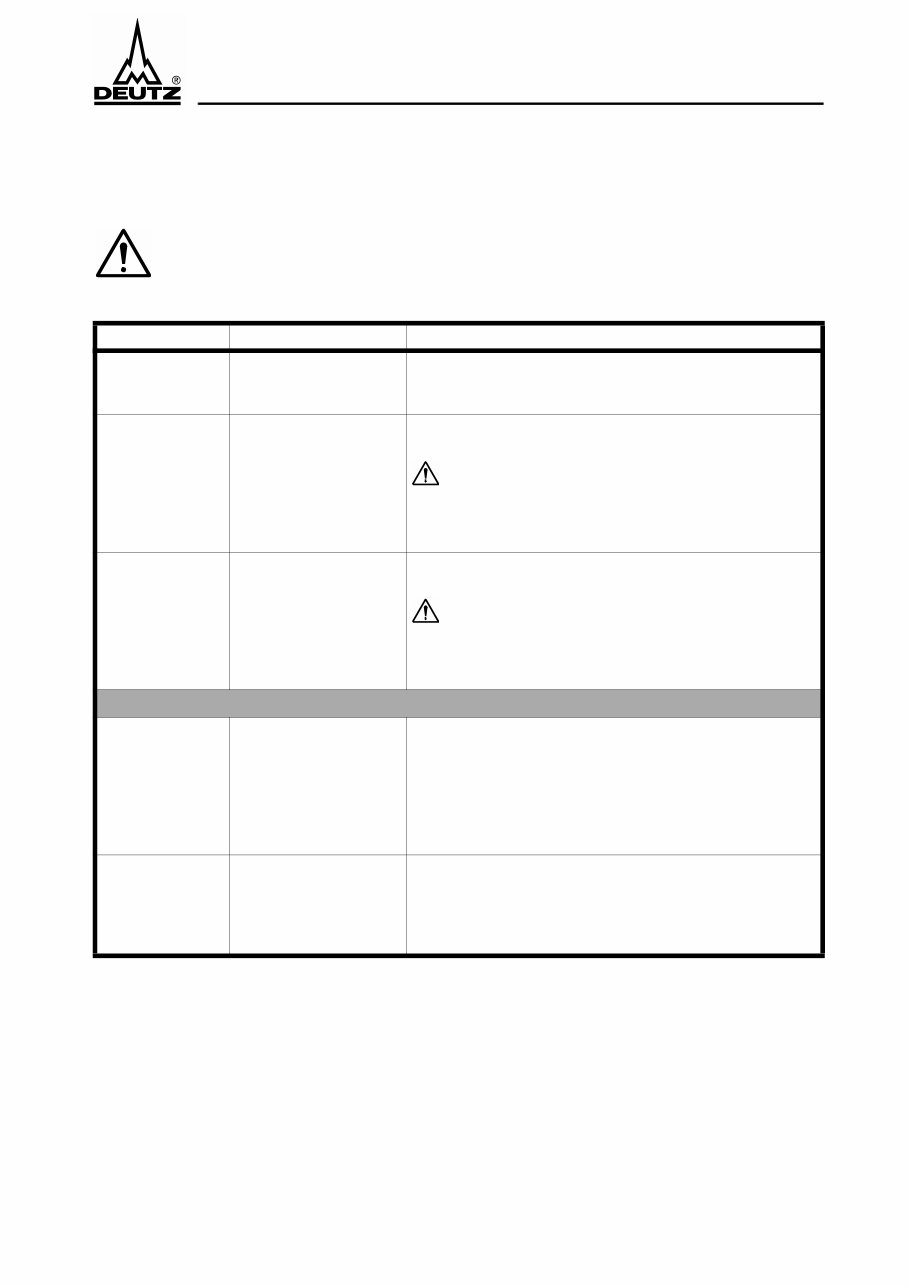

Display State Indicates

Diagnostic lamp

illuminates for 2 s

from ignition on.

Lamp test System is ready for operation.

Diagnostic lamp

continuously

illuminated.

Warning

regarding exceeded limit

values and system faults.

A reduction in power is only possible in combination with

an engine governor, e.g. EMR and MVS.

The reduction in power can be temporarily bridged with

the limp-home mode button . (Depression of the

button is confirmed with slow flashing, see *).

After the engine has been shut-off, fault code enquiry is

possible (see **).

Diagnostic lamp

flashes rapidly

(approx. 1 Hz).

Emergency engine

shut-off if shut-off limits

are exceeded or not

achieved.

Attention: In a few seconds, the engine will be

automatically shut-off for the purpose of protection.

T he reduction in power can be temporarily bridged with

the limp-home mode button . (Depression of the

button is confirmed with slow flashing, see *).

After the engine has been shut-off, fault code enquiry is

possible (see **).

* Diagnostic lamp

flashes slowly

(approx. 0.5 Hz).

The limp-home mode

button has been

actuated in order to

bridge the reduction in

power or engine shut-off.

Bridging is stored in the

control unit.

Attention : Following actuation of the l imp-home mode

button , the engine continues to run without protection for

a short time, and may become damaged ! For this reason,

only actuate the button in the event of an emergenc y

( e.g. if life is otherwise placed at risk )!

** Fault code

enquiry

The diagnostic lamp ser-

ves to display a fault

code (a sequence of

short and long flashing

impulses).

In the event of engine standstill , an enquiry regarding the

fault code may be made with the limp-home mode button/

diagnostic button, see Chapter 8.4.

Page 58 © 0702

EMS 2

Important notes

© 0702 Page 59

EMS 2

System description

3 System description

3.1 Use of the EMS 2

The EMS 2 is a monitoring system for the 1013, 1015 engine model series. It can be used on its own and

also in combination with the MVS (solenoid valve system) or the EMR (electronic engine governor).

The EMS 2 provides functions for engine protection, for indicating maintenance requirements and for

diagnostic purposes. With the aid of the data recorder function, an overview of the manner of operation,

capacity utilisation and possible causes of engine failure may be obtained. In addition, data exchange with

other electronic control units (e.g. EMR, MVS) is possible via the CAN interface.

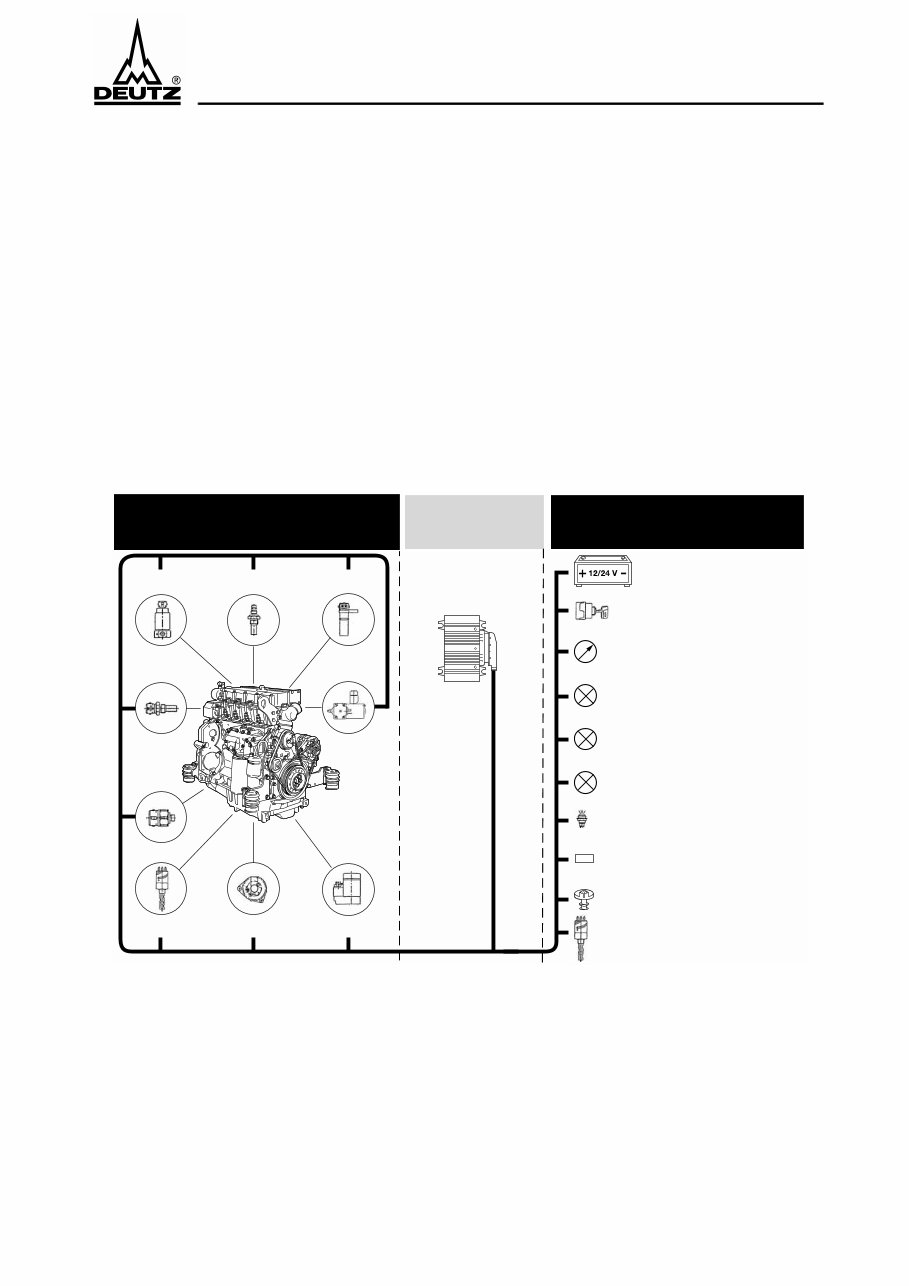

3.2 System overview

3.2.1 EMS 2 alone

EMS

Control unit

Vehicle-side/

System-side facility

Engine-side facility

Energy supply

Glow-start switch

Multi-functional display

Configurable outputs

(e.g. indicator lamps)

Maintenance/service

Diagnostic lamp

Flame system

solenoid valve

Flame system

temperature sensor

Engine speed

Oil level switch Alternator Starter

Coolant

temperature sensor

Engine shut-off

lifting magnet

Oil pressure

sensor

Diagnostic button/

limp-home button

Diagnostic interfaces

• S, L line (ISO 9141)

• CAN bus (SAE J1939)

• SAE J1708 / J1587

Air filter differential

pressure sensor

Coolant level switch

© 0702

Page 60 © 0702

EMS 2

System description

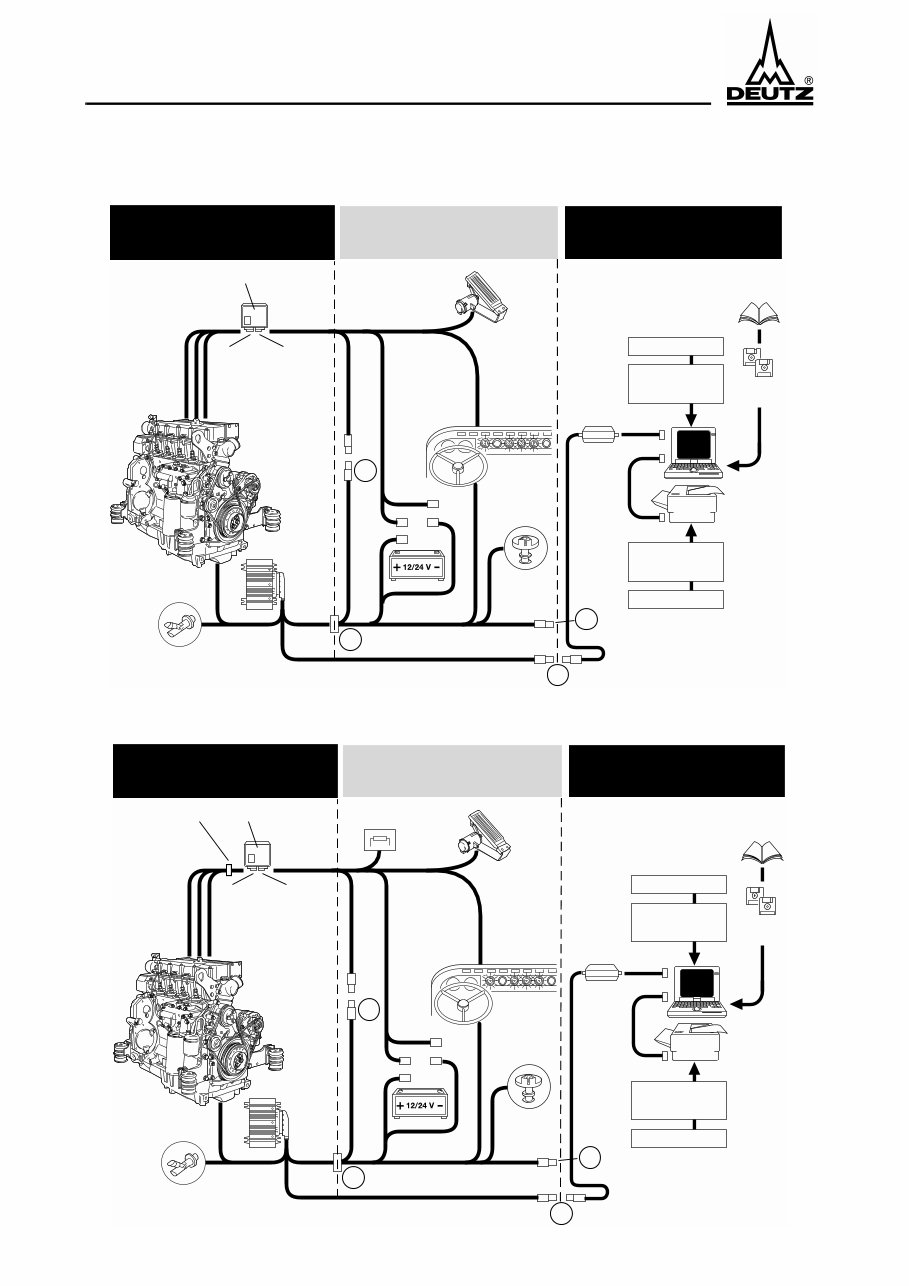

3.2.2 EMS 2 in combination with MVS

3.2.3 EMS 2 in combination with EMR

Vehicle-side installation Service

Interface

Software

disc

User level

depending on

authorization

Power supply

or

battery

Accelerator pedal

Interface

SAE J1708/

J1587

Diagnostic plug

Part No.: 0419 9615

Central

plug

Diagnostic lamp (MVS)

Diagnostic button (MVS)

Indicator lamp (EMS)

Maintenance/service (EMS)

Diagnostic lamp (EMS)

Diagnostic button/limp-home button (EMS)

Operating manual

110 / 220 V~

110 / 220 V~

Power supply

or

battery

Printer

Engine

plug

Vehicle

plug

MVS

Engine

wiring

harness

DEUTZ scope of delivery

EMS 2

X23

Coolant

level sensor

Air filter

differential

pressure switch

CAN

X22

X25

X26

© 0702

Vehicle-side installation Service

Interface

Software

disc

User level

depending on

authorization

Power supply

or

battery

Terminating

resistor (CAN)

Accelerator

pedal

Interface

SAE J1708/

J1587

Diagnostic plug

Part No.: 0419 9615

Central

plug

X23

Coolant

level sensor

Air filter

differential

pressure switch

CAN

Operating manual

110 / 220 V~

110 / 220 V~

Power supply

or

battery

Printer

Engine

plug

Vehicle

plug

EMR

Engine

wiring

harness

Transfer plug

DEUTZ scope of delivery

EMS 2

Fault lamp (EMR)

Indicator lamp (EMS)

Maintenance/service (EMS)

Diagnostic lamp (EMS)

Diagnostic button/limp-home button (EMS)

X22

X25

X26

© 0702

© 0702 Page 61

EMS 2

System functions

4 System functions

1

4.1 Introduction

The EMS 2 serves to electronically monitor the engine. Its functions include:

Engine protection functions

● Warning the operator if limit values are exceeded or not achieved.

● Reduction in engine power.

● Emergency engine shut-off if operating data exceed or do not achieve the shut-off limits.

Indication of maintenance requirements

in order to remind the operator and to reduce the consumption of operating media. The maintenance

intervals can be obtained from the DEUTZ engine operating instructions, Chapter 5.1.

● in the event of excessive air filter differential pressure.

● if the number of operating hours leads to the achievement of the next maintenance requirements.

● if the load population reaches a maintenance limit.

● if calculation of the engine operating statuses (temperatures, speed, etc.) results in the oil change limit's

being exceeded.

Data exchange

with other systems via the CAN interface, e.g. with the solenoid valve system (MVS):

● Transmission of the output reduction signal if limit values are exceeded.

● Engine shut-off via the CAN interface sets, e.g. the fuel injection quantity to zero.

● The integration of measurement data and fault messages via the CAN interface extends the input signals

of the EMS 2 for executing engine protection functions and system diagnosis (see above).

● Transfer of the EMS 2 measurement data to other systems.

Diagnosis of the entire system

● System self-diagnosis, i.e. of the control unit, the sensors and the actuators.

● Display of engine operating data and self-diagnosis data on a PC (ISO9141 / RS232).

● Forwarding of the engine operating data to the SAE-J1708/1587 interface for diagnostic and display

systems.

● Actuation of a telltale and output of a flashing code for fault identification.

Data recorder

Determination of the manner of operation, capacity utilisation and causes of engine failure.

● Recording the most important measurement variable signals.

● Determination of the load population.

● Storage of exceeded maintenance intervals.

● Documentation of hours of engine operation.

Engine operation display

● Output of a signal (telltale or relay) as soon as the speed exceeds 400 rpm.

1)

Not all functions are available in all applications.

Page 62 © 0702

EMS 2

System functions

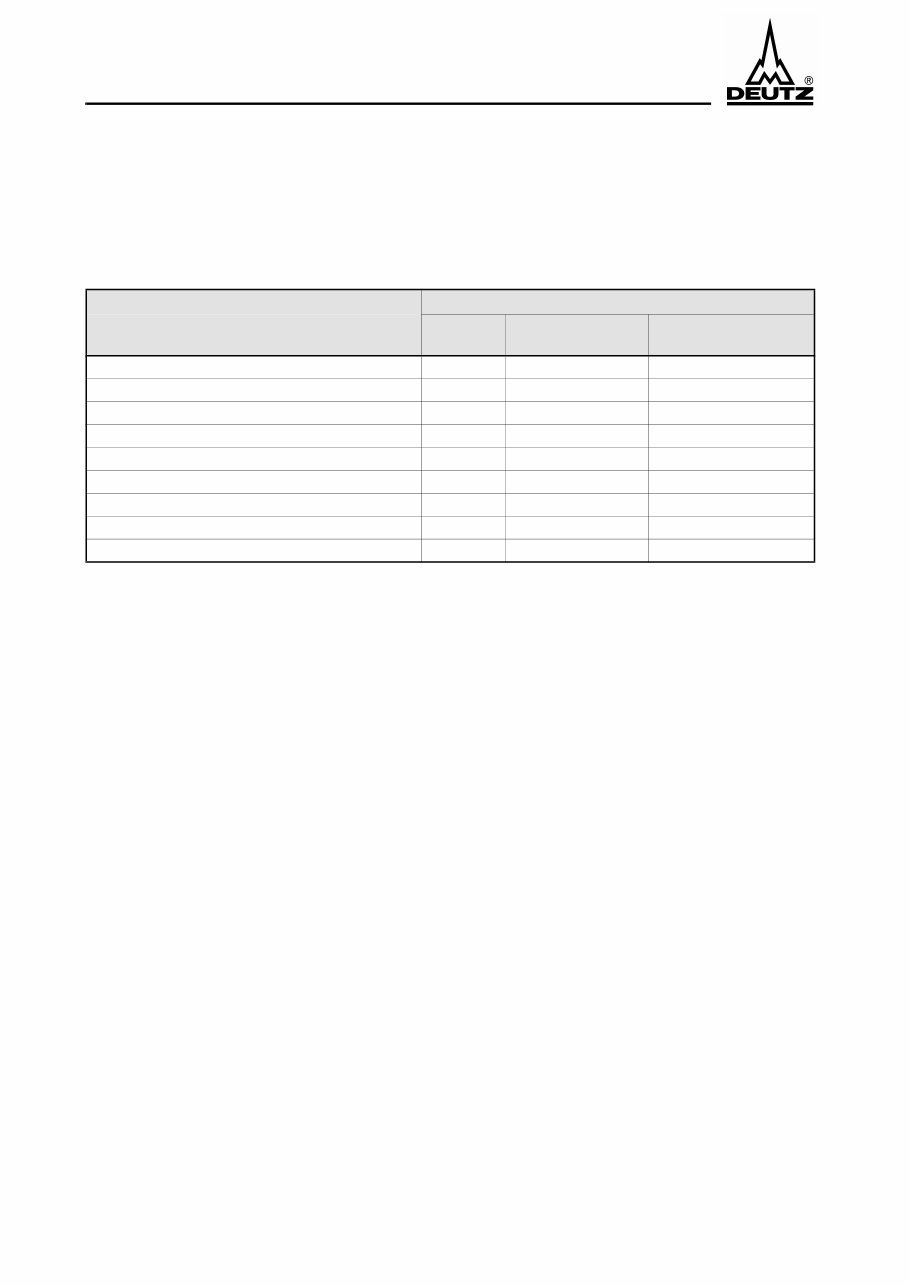

4.2 Engine protection functions

4.2.1 General

The following table contains an overview of the measurement variables which can be monitored, together

with the relevant, possible engine protection functions.

● If the measurement variable lies within the warning range , the diagnostic lamp is continuously illumi-

nated. As a result of a command via the CAN interface to the EMR or MVS, the power is reduced . If the

measurement variable exceeds/does not achieve the recovery threshold, the lamp is extinguished again.

● A reduction in power is only possible in combination with EMR and MVS.

● If the measurement lies within the shut-off range , emergency engine shut-off is carried out following

the expiry of a waiting period. The diagnostic lamp flashes rapidly (frequency approx. 1 Hz). Shut-off is

effected either

- via a shut-off solenoid or

- via the CAN interface on other electronic control units (EMR, MVS)

● Limit values which are exceeded or not achieved are documented in the fault memory .

● The fault message is output if the diagnostic button is actuated during engine standstill

- as a flashing code via the diagnostic lamp.

- with a notebook connected via the ISO9141 interface with the SERDIA diagnostic programme.

- via the ISO J1708/1587 interface according to standard.

● Starting prevention can be recognised via the rapid flashing of the diagnostic lamp (1Hz) in the event of

engine standstill. If the EMS 2 has shut the engine off on the basis of the engine monitoring functions,

restarting is prevented. The same applies if monitoring is carried out during standstill, and engine star-

ting is blocked due e.g. a low coolant level.

● The engine can be restarted by switching the ignition off/on (terminal 15).

● Outputs may also be used to initialise lamps or relays if limit values are exceeded or not achieved, see

Chapter entitled Outputs 5.2.

Monitorable measurement variable

Possible engine protection function

1

1

The configuration is programmed in the factory.

Warning Power reduction Emergency engine

shut-off

Speed x x

Oil temperature x x x

Coolant temperature x x x

Cylinder temperature 1 x x x

Cylinder temperature 2 x x x

Oil pressure x x x

Coolant leveld x x x

Oil level x x x

Reserve signal T1 x x x

You're Reading a Preview

What's Included?

Lifetime Access

Access PDF Contents & Bookmarks

Print one or all pages of your manual