DETROIT DIESEL

V-71 Service Manual

Sections 1-3

D __ e_T_R_o_•_T_~-!-~-0-~-~- . o-~---- ~

3400 Outer Drive. West I Detroit. Michigan 48239-4001

Telephone. 313-592-5000

Telex 4320091 I TWX: 810-221-1649

Fax· 313-592-7288

6SE193 69090 De t ro it Diesel Corporation Lltho In USA

FOREWORD

Thi manual contains in truction on the overhaul, maintenance

and oper at ion of the ba ic V- 71 Detroit D ie el En gi ne .

Fu ll bene fi t of the long life and dependability built into the e engine

can be realized thro ugh proper operation and maintenance. Of equal

importance i the u e of proper procedure during engine overhaul.

Pe onnel responsible for engine operation and maintenance hould

tudy the ection of the manual pertaining to their particular dutie .

imilarly, before beginning a repair or overhaul job , the erviceman

hould read the manual carefully to familiarize him elf with the part or

uba embli of the engine with which he ' ill be concerned.

The information, pecification and illu trarion in thi. publication

are ba ed on the information in effect at the time of approval for printing.

Thi publication i revi ed and reprinted periodically. It i recommended

that u er contact an authorized Detroit Di el Corporation ervi e

Outlet for information on the latest revi ion . he right i r erved to

make changes at any time without obligation.

TNEWCAMP MANUALS

CAUTION

To reduce the chance of per onal injury and/or property damage,

the following inst.ructions must be carefully observed .

Proper ervice and repair are important to the safety of the service

tecbnician and the safe, reliable operation of the engine. If part

replacement is necessary, the part mu t be replaced with one of the ame

part number or with an equivalent part. Do not u ea replacement part

of lesser quality.

The ervice procedures recommended by Detroit Diesel

Corporation and described in this service manual are effective method

of performing ervice and repair. Some of these procedures require the

use of tools specially designed for the purpose.

Accordingly, anyone who intends to use a replacement part,

service procedure or tool, which is not recommended by Detroit Diesel

Corporation, must first determine that neither his safety nor the safe

operation of the engine will be jeopardized by the replacement part,

service procedure or tool selected.

It i important to note that thi manual contain ariou

"Caution " and " otices' that mu t be carefully observed in order to

reduce the ri k of personal injury during ervice or repair or the

po sibility that improper service or repair may damage the engine or

render it unsafe. It is also important to understand that the e

'Caution " and "Notices" are not exhau tive, because it is impos ible

for Detroit Diesel Corporation to warn of all the possible hazardou

consequences that might result from failure to follow these instruction .

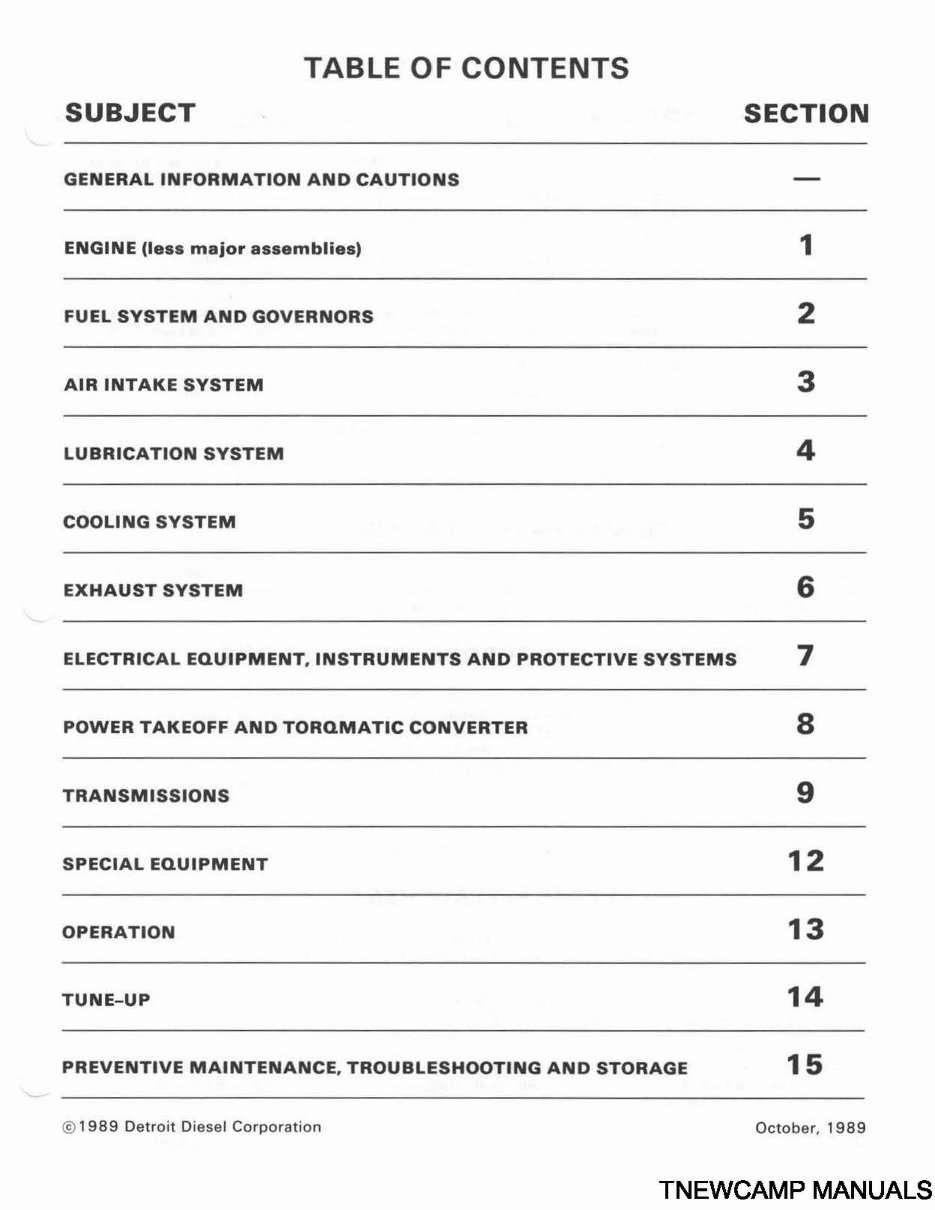

TABLE OF CONTENTS

SUBJECT SECTION

GENERAL INFORMATION AND CAUTIONS

ENGINE (less major assemblies) 1

FUEL SYSTEM AND GOVERNORS 2

AIR INTAKE SYSTEM 3

LUBRICATION SYSTEM 4

COOLING SYSTEM 5

EXHAUST SYSTEM 6

ELECTRICAL EQUIPMENT, INSTRUMENTS AND PROTECTIVE SYSTEMS 7

POWER TAKEOFF AND TORQMATIC CONVERTER 8

TRANSMISSIONS 9

SPECIAL EQUIPMENT 1 2

OPERATION 13

TUNE-UP 14

PREVENTIVE MAINTENANCE, TROUBLESHOOTING AND STORAGE 1 5

© 1989 Detroit Diesel Corporation October , 1989

TNEWCAMP MANUALS

General Information DETROIT DIESEL V-71

SCOPE AND USE OF THE MANUAL

Thi manual covers the basic V-71 Diesel Engine built by the Detroit Diesel Corporation. Complete instruction on

operation, adju tment (tune-up), preventive maintenance and lubrication, and repair (in.eluding complete overhaul) are

covered. The manual was written primarily for persons ervicing and overhauling the engine and, in addition, contain all of the

instruction es ential to the operators and u er . Basic maintenance and overhaul. procedures are common co all V -7 1 engines

and therefore, apply to all V- 71 model .

The manual is divided into numbered ections. The first ection covers the engine (le major as. emblie ). The following

ections cover a complete system such a the fuel system, lubrication sy tern or air system. Each ection is divided into

ubsections which contain complete maintenance and operating instruction for a pecitic . uba sembly on the engine. For

example, Section l, which cover the basic engine, contain ubsection I. I pertaining to the cylinder block, sub ection 1.2

covering the cylinder head, etc. The subject and ections are listed in the Table of Content on the preceding page. Page are

numbered consecutively, tarting with a new Page I at the beginning of each ubsection. The illustration are also numbered

consecutively, beginning with a new Fig. 1 at the start of each subsection.

Information regarding a general subject, such as the lubrication sy tern, can best be located by using the Table of

Contents. Opposite each ubject in the Table of Contents i a section number which regi ter \ itha tab printed on the fir t page

of each section throughout the manual. Information on a specific subassembly or acces ory can then be found by con ulting the

list of contents on the first page of the section. For example the cylinder liner is part of the basic engine. Therefore, it will be

found in Section 1. Looking down the list of contents on the first page of Section 1, the cylinder liner is found to bejn ubsection

1.6.3. An Alphabetical Index at the back of the manual has been provided a an additional aid for locating information.

SERVICE PARTS AVAILABILITY

Genuine Detroit Diesel service parts are available from authorized Detroit Die el distributor and ervice dealers

throughout the world. A complete list of all distributor and dealers i available in the Worldwide Di tributor and Dealer

Directory 6SE280. This publication can be ordered from any authorized di tributor.

CLEARANCES AND TORQUE SPECIFICATIONS

Clearance of new part and ~ ear limit on used part are listed in tabular form at the end of each e tion throughout the

manual. It hould be pecifically noted that the ' New Part ·" clearance apply only when all new part are used at the point

where lhe various specification apply. This al o applies to reference within the text of the manual. The column entitled

''Limits" Ii t the amount of wear or increa e in clearance which can be tolerated in u ed engine parts and till a ure

·atisfactory performance. It hould be emphasized that the figures given as "Limits' must be quaJjfied by the judgment of

personnel respon ible for in , tailing new part . These wear limits are in geoeraJ, Ii ted only for the parts more rrequently

replaced in engine overhaul work. For additional information, refer 10 the paragraph entitled Jn pection under General

Procedures in this ection.

Bolt, nut and stud torque pecification are al ·o Ii ted in tabular form at the end of each ection.

•PARTS REPLACEMENT

Before in talling a new or u ed part, check it thoroughly to make . ure il i the proper part for the job. The quality of the

replacement part must be equivalent to the quality of the original Detroit Die el component being replaced and mu t meet

DOC specification for new or reusable part .

Part mu t al o be clean and not phy icaJly damaged or defective. For example, bolt and bolt hole thread must not be

damaged or di . torted. Gasketing must have all holes completely punched through with no re idual gasket material left clinging

to the top or bottom. Flatne. and fit pecification in the service manual must be tri tly adhered to.

CAUTION: Failure to inspect parts thoroughly before installation, failure to install the proper

parts, or failure to install parts properly can result in component or engine malfunction and/or

damage and may also result in personal injury.

Page 4 October, 1989 © Detroit Diesel Corporation

--

DETROIT DIESEL V-71 General Information

PRINCIPLES OF OPERATION

The die el engine is an internal combustion power

unit, in which the heat of fuel i converted into work in the

cylinder of the engine.

In the diesel engine, air alone is compressed in the

cylinder; then, after the air has been compressed, a charge of

fuel is sprayed into the cylinder and ignition is accomplished

by the heat of compression.

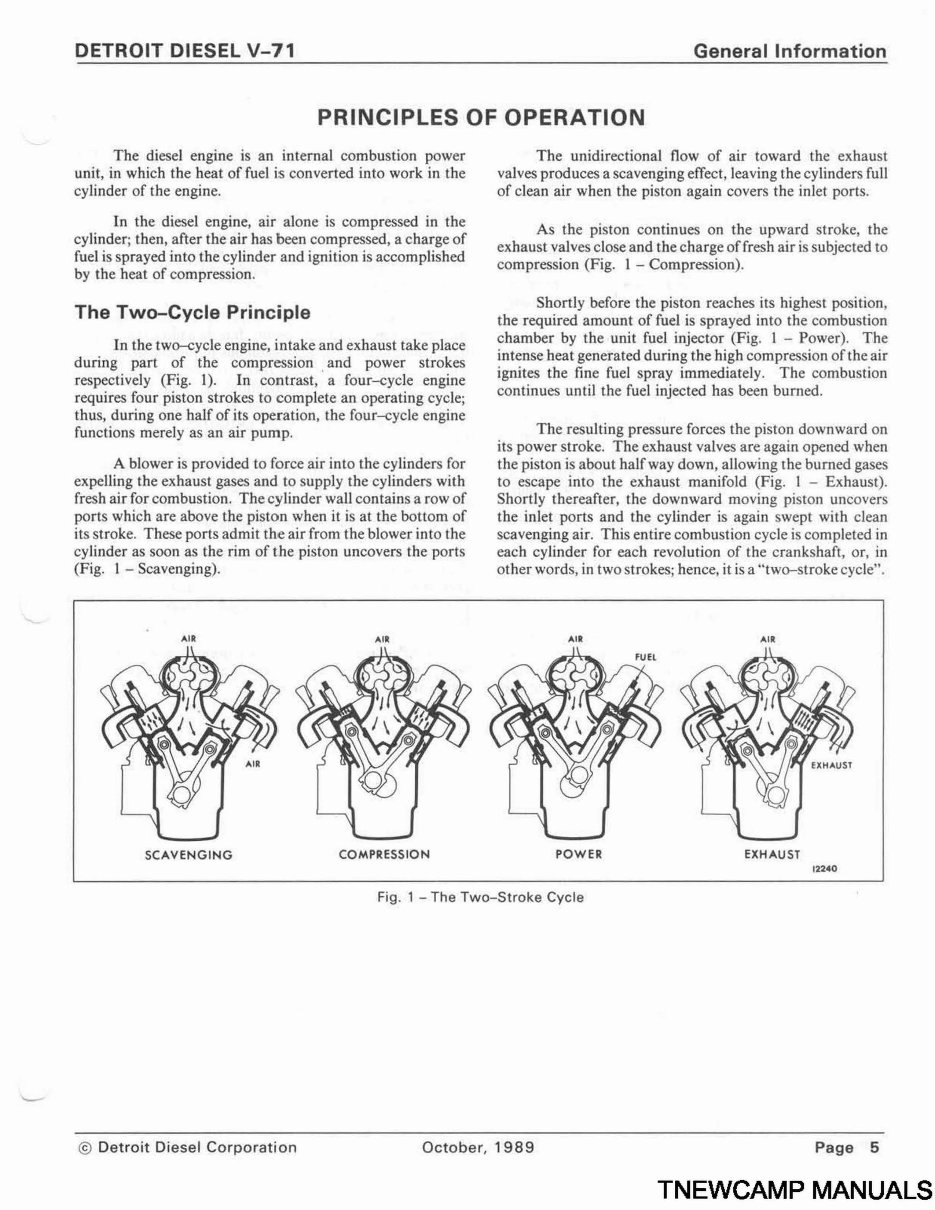

The Two-Cycle Principle

In the two-cycle engine, intake and exhau t take place

during part of the compres ion . and power strokes

re pectively (Fig. 1). In contrast, a four-cycle engine

require four piston strokes to complete an operating cycle;

thus, during one half of its operation, the four-cycle engine

functions merely as an air pump.

A blower is provided to force air into the cylinder for

expelling the exhaust gases and to upply the cylinders with

fresh air for combustion. The cylinder wall contains a row of

ports which are above the piston when it i at the bottom of

it troke. These ports admit the air from the blower into the

cylinder as soon a the rim of the piston uncover the ports

(Fig. I - Scavenging).

AIR AIR

SCAVENGING COMPRESSION

The unidirectional flow of air toward the exhaust

valves produces a scavenging effect, leaving the cylinders full

of clean air when the piston again covers the inlet ports.

A the piston continue on the upward stroke, the

exhaust valve close and the charge of fresh air i subjected to

compression (Fig. l - Compre sion).

Shortly before the piston reaches its highest po ition,

the required amount of fuel is prayed into the combu tion

chamber by the unit fuel injector (Fig. I - Power). The

inten e heat generated during the high compres ion of the air

ignite the fine fuel pray immediately. The combu tion

continues until the fuel injected has been burned.

The re ulting pressure forces the piston downward on

its power stroke. The exhau t valve are again opened when

the pi ton is about halfway down, allowing rhe burned gases

to e cape into the exhau t manifold (Fig. I - Exhaust).

Shortly thereafter, the downward moving pi ton uncover

the inlet ports and the cylinder i again wept with clean

cavenging air. Thi entire combu tion cycle i completed in

each cylinder for each revolution of the crank haft, or, in

other words, in two strokes; hence, it is a "two- troke cycle".

AIR AIR

POWER EXHAUST

1 2240

Fig. 1 - The Two-Stroke Cycle

© Detroit Diesel Corporation October, 1989 Page 5

TNEWCAMP MANUALS

General Information DETROIT DIESEL V-71

GENERAL DESCRIPTION

The two-cycle diesel engines covered in this manual

are produced in 6 8, 12 and 16 cylinder models having the

a.me bore and stroke and many of the major working parts

uch as injectors pistons, connecting rods, cylinder liner

and other part that are interchangeable.

AU cylinder blocks are ymmetrical in design thu

permitting oil cooler or starter installation on the same ide

or on opposite ides of the engine, depending upon the

installation requirements. The engines are built with

right-band or left-hand crankshaft rotation. For example

the crankshaft in an RC engine, viewed from the flywheel

end will rotate counterclockwise the oil cooler will be

mounted on the right-hand ·ide of the engine and the starter

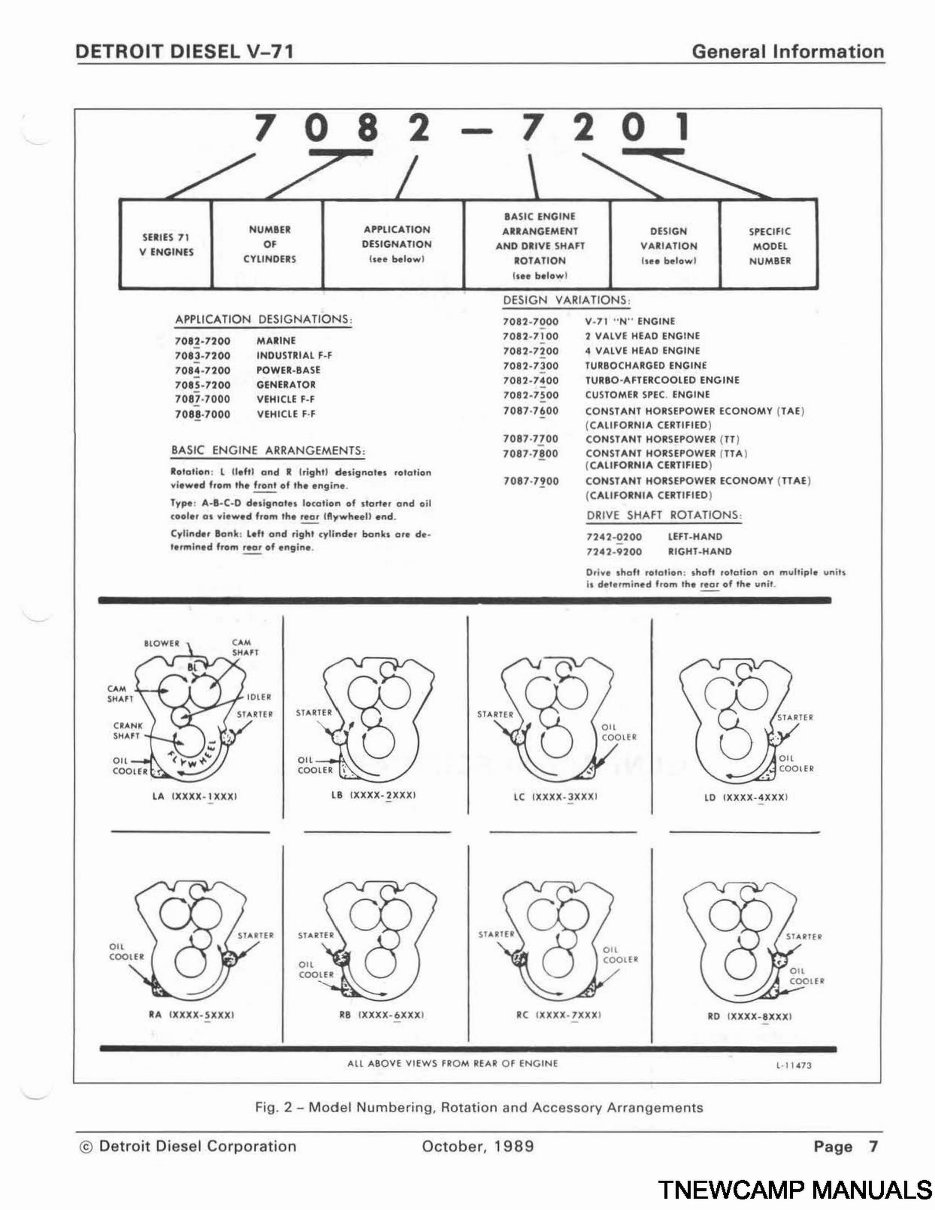

will be on the left-hand ide (Fig. 2).

The meaning of each digit in the model numbering

ystem is hown in Fig. 2. The letter Lor R indicates left or

right-band engine rotation as viewed from the front of the

engine. The letter A, B, C or D designate the location of the

tarter and oil cooler as viewed from the rear of the engine.

Each engine is equipped with oil coolers, lubricating

oil filters fuel oil strainer, fuel oil filter, air cleaner or

ilencer, governor, heat exchanger and raw water pump or

fan and radiator, and tarting motor.

Full pres ure lubrication is upplied to all main,

connecting rod and cam haft bearings, and to other moving

part within the engine. A gear-type pump draw oil from

the oil pan through an intake creen, through the oil filter,

and then to the oil cooler. From the oil cooler, the oil flow

through pas age that connect with the oil galleries in the

cylinder block and cylinder head for distribution to the

bearing , rocker arm mechanism and other functional parts.

Coolant is circulated through the engine by a

centrifugaJ- type water pump. Heat i removed from tbe

coolant, which circulat in a clo ed y tern, by the radiator

or heat exchanger. Control of the engine temperature is

accompli hed by thermo tats which regulate the flow of the

coolant within the cooling system.

Fuel i drawn from the supply tank through the fuel

strainer by a gear-type fuel pump . It i then forced through a

ftlter and into the fuel inlet manifold in the cylinder heads

and to the injector . Excess fuel i returned to the upply

tank through the fuel outlet manifold and connecting lines.

Since the fuel is con tantly circulating through the injectors

it erv to cool the injector and also carries off any air in the

fuel y tern.

Air for cavenging and combustion is supplied by a

blower which pump air into the engine cylinder via the air

box and cylinder liner port . AU air entering the blower first

passes through an air cleaner or ilencer.

Engine starting i provided by a either a hydraulic pt

electric tarting sy ·tern. The electric starting motor is

energized by a storage battery. A battery-charging

generator, with a suitable voltage regulator erves to keep the

battery charged.

Engine speed i regulated by a mechanical or hydraulic

type engine governor, depending upon the engine

application.

Page 6 October, 1989 © Detroit Diesel Corporation

DETROIT DIESEL V-71

SEllES 71

V ENGINES

7

NUMBER

OF

CYLINDERS

0 8 2

APPLICATION

DESIGNATION

( see below l

APPLICATION DESIGNATIONS :

7081-7200 MAllNE

7083-7200 INDUSTRIAL F-F

7084 - 7200 POWER-BASE

7085-7200 GENERATOR

7087-1000 VEHICLE F·F

708_!·7000 VEHICLE H

BASIC ENGINE ARRANGEMENTS :

lololion : L Cleftl and R lrightl designatH rotation

viewed from th1t front of the engine

Type: A-B·C-D designate• location of starter and oil

cooler 01 viewed from the ~ CllywhHll end .

Cyllnd r Bonk: left ond right cylinder bonlts ore de ·

termlned from ~ of engine .

LA IXXXX-1 XXXI LB lXXXX· 2XXXI

IA l XXXX -S XXX I RB I XXXX - 6XXX I

-

General Information

7 2 0 1

BASIC ENGINE

AHANGEMENT

AND DllVE SHAFT

IOTATION

ltH below l

DESIGN

VARIATION

hub lowl

SPECIFIC

MODEL

NUMBER

DESIGN VARIATIONS :

7082 - 7000

7082 - 7100

7082 - 7200

7082-7300

7082 - 7400

7082-7500

7087 - 7600

7087 · 7100

7087 · 7!00

7087 · 7!00

V -7 1 " N " ENGINE

2 VALVE HEAD ENGINE

4 VALVE HEAD ENGINE

TURBOCHARGED ENGINE

TURBO·AFTERCOOLED ENGINE

CUSTOMER SPEC . ENGINE

CONSTANT HORSEPOWER ECONOMY (TAE)

(CALIFORNIA CERTIFIED)

CONSTANT HORSEPOWER ( TT }

CONSTANT HORSEPOWER f TTA )

(CALIFORNIA CERTIFIED)

CONSTANT HORSEPOWER ECONOMY (TTAE )

(CALIFORNIA CERTIFIED)

DRIVE SHAFT ROTATIONS :

7242 - 0200

7242-9200

LEFT-HAND

RIGHT-HAND

Dtive shaft rolatlon ; thoft rotation on multiple units

b det ermi ned fr om rhe reor of rhe unit.

lC IXXXX - 3XXX I lD lXXXX·4XXXl

RC lXXXX· 7XXX I RD I XXXX-8XXX I

All ABOVE VIEWS FROM REAR Of ENGINE

l ·l 1 •73

Fig. 2 - Model Numbering, Rotation and Accessory Arrangements

© Detroit Diesel Corporation October, 1989 Page 7

TNEWCAMP MANUALS

Genera I Information

6V

FRONT

0

0)

~

lot

z

z

0

<

o(

CV

CID

CID

I-

I- :t:

II..

~

w

@

....

©

Ci

( )

FIRING

ORDER

RH-1L - 3R - 3L-2R-2L-1 R

LH-1 l -1 R-2L-2R-3L-3R

c

8V

FRONT

0

Q)

0

0

@

@

©

©

FIRING

ORDER

)

RH -1 l- 3R-3L - 4R . 4L . 2R - 2L -1 R

LH -1 L-1 R-2l-2R -4l-4R-3l - 3R

~

z

<

CID

....

II..

w

_,

c

12V

FRONT

0

0

0

0

0

0

0

©

©

@

©

©

FIRING

ORDER

)

RH- ll - 5l - 3R-4R - 3l .4L

- 2R - 6R - 2L . 6L-1 R .5R

LH.1 l- 5R -1 R- 6L - 2L - 6R-

2R- AL . JL • .4R -3R-5l

DETROIT DIESEL V-71

:lot

z

<

<ID

....

....

w

_,

(

16V

FRONT

CD

CD

0

0

@

0

©

©

©

©

©

©

0

0

©

®

FIRING

ORDER

)

RH - 1L - 2R - 8L - 6R - 2L - 4R - 6L - 5R

. 4L . 3R . 5L . 7R -3L-1 R. 7l . 8R

11750

LH .1 L- SR - ll -1 R- 3l - 7R - 5L - 3R

. 4l - 5 R- 6l - 4R - 2L - 6R - 8l - 2R

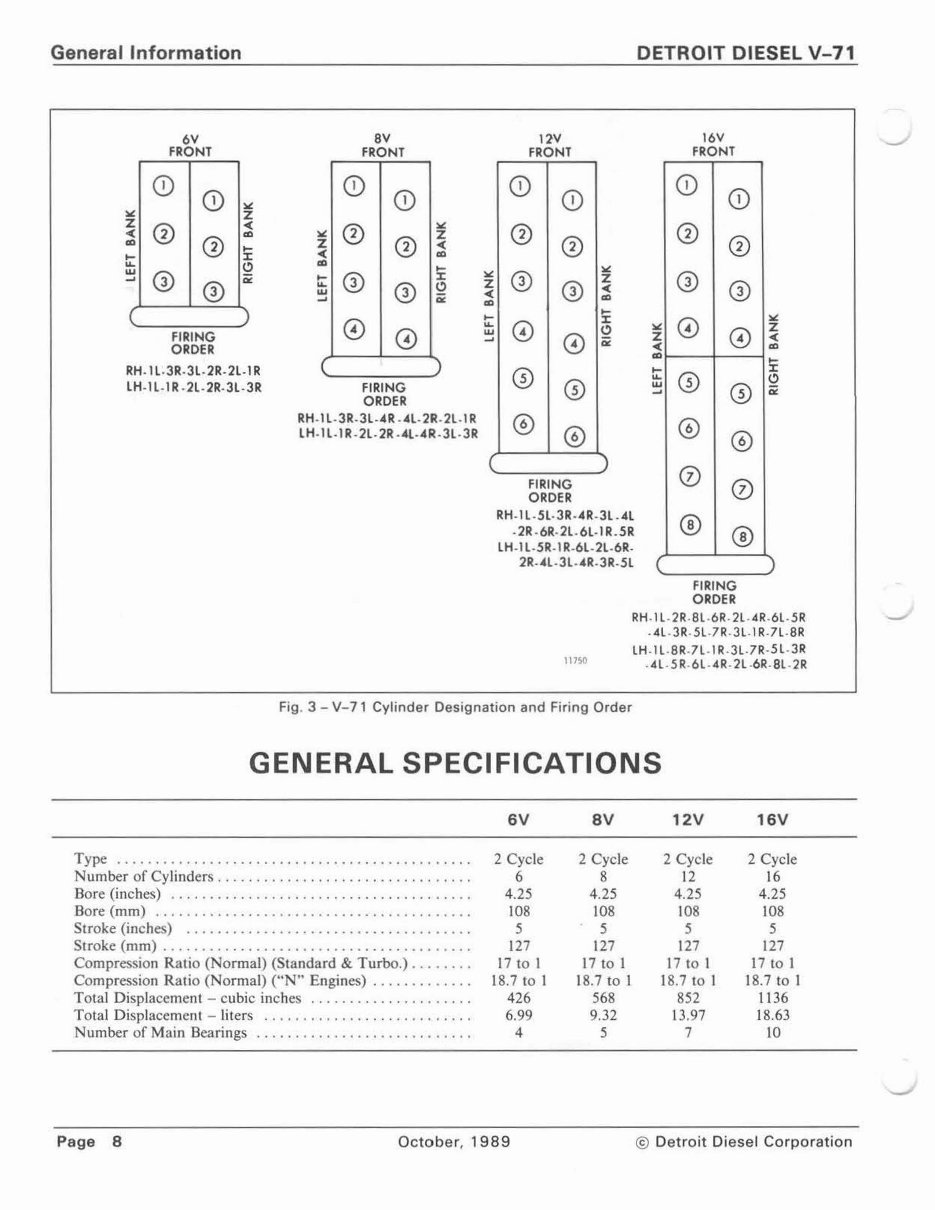

Fig. 3 - V-71 Cylinder Designation and Firing Order

GENERAL SPECIFICATIONS

Type ................. ... ............ . .. .. ..... . .. .

Number of Cylinders , .. . .. ... .... .... .. . .. .. ...... .. .

Bore (inches) .. . ..... . .......... . ..... . ............ .

Bore ( mm) ........... . ................ . ........... .

troke (inch ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Str oke ( mm ) .......... . ................ . .. . ........ .

Compr es ion Ratio Normal) (Standard & Turbo.) ....... .

Compression Ratio (Normal) ("N " Engine ) ...... . ..... .

Total Displacement - cubic inche ....... . .. . ......... .

Total Displacement - liter . .. . .. . ...... .. .... .. .. . . . .

Number of Main Bearings . . ............ . ............ .

6V

2 Cycle

6

4.25

108

5

127

17 to I

18.7 to l

426

6.99

4

Page 8 October, 1989

SV

2 Cycle

8

4. 25

108

5

127

17 to I

18 .7 to 1

568

9. 32

5

12V

2 Cycle

12

4.25

108

5

127

17 to I

18.7 to l

852

13 .97

7

16V

2 Cycle

16

4.25

108

5

127

17 to 1

18 .7 to I

1136

18 .63

10

© Detroit Diesel Corporation

DETROIT DIESEL V-71 General Information

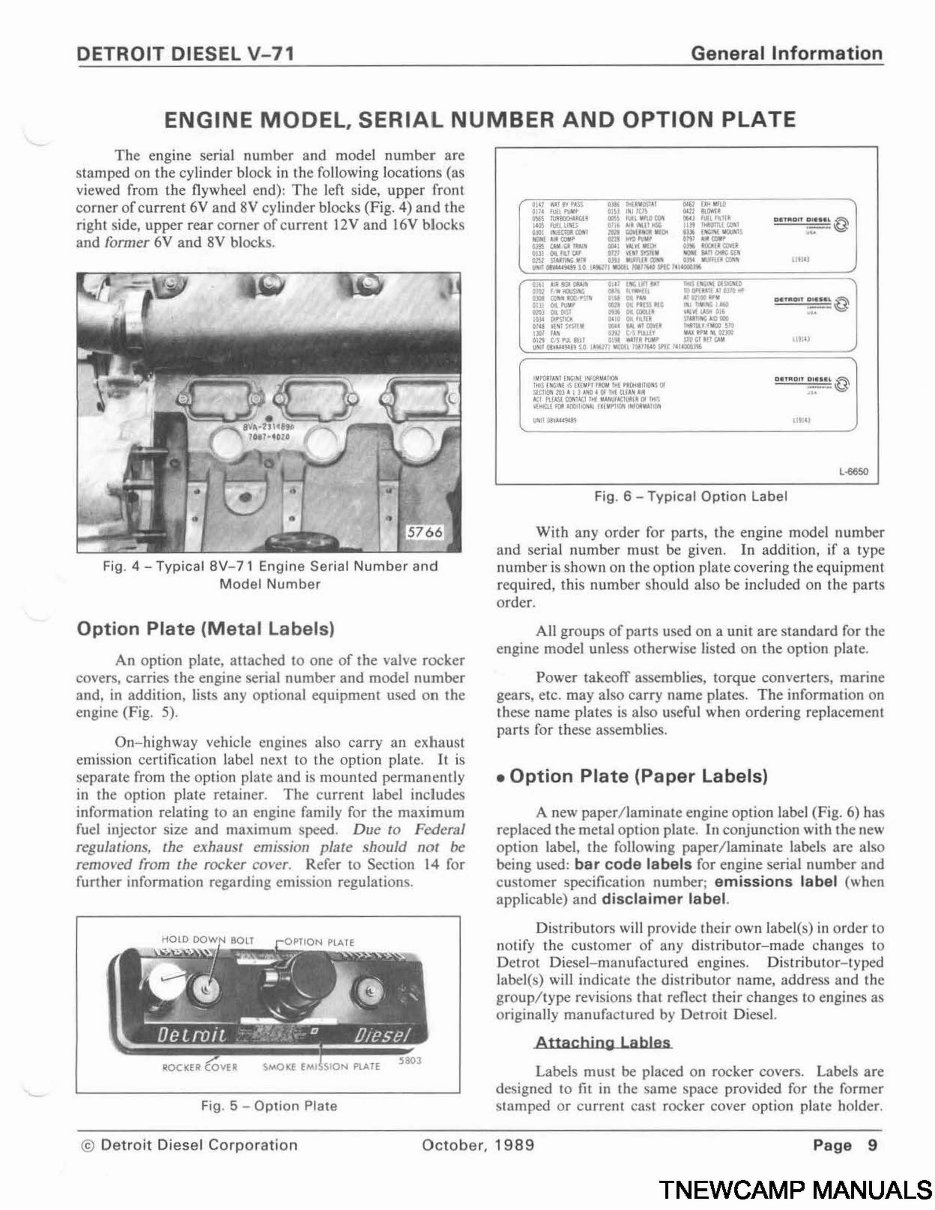

ENGINE MODEL, SERIAL NUMBER AND OPTION PLATE

The engine erial number and model number arc

tamped on the cylinder block in the following location (a

viewed from Lhe flywheel end): The left side, upper front

corner of current 6V and 8V cylinder block (Fig. 4) and the

right ide, upper rear comer of current I 2V and l 6V block

and former 6V and 8V block .

Fig. 4 - Typical BV-71 Engine Serial Number and

Model Number

Option Plate (Metal Labels)

An option plate, atta hed LO one of the val e rocker

c ver , carrie the engine erial number and model number

and, in addition, lj any optional equipment u ed on the

engine (Fig. 5).

On-highway vehicle engine also carry an exhau t

emi sion certification label next to the option plate. It i

eparate from the option plat and i mounted permanently

in the option plate retainer. The current label in lude

information relating to an engine family for the maximum

fuel injector ize and ma imum peed. Due to Federal

regulation , c.he exhau t cmi ion plate hould not be

removed from c.he rocker er . Refer to Section 14 for

further information regarding cmi i n regulation .

Fig. 5 - Option Plate

ltltJ

OOTOOfT 0tU4• j ~

. \g

•n:u

ae"'o tr ;;'"'@

L-6650

Fig. 6 - Typical Option Label

With any order for part , the engine model number

and erial number mu t be given. In addition if a type

number is shown on the option plate covering the equipment

required this number h uld al o be included on the parts

order .

AU group of part u ed on a unic are tandard for the

engine model unles otherwi e Ii ted on the option plate.

Power takeoff embli , torque con erter , marine

gear , etc. ma al o carry name plates. The information on

the e name plate i al o u eful when ordering repla ement

part for the e a embli .

•Option Plate (Paper Labels)

A new paper/ laminate engine option label (Fig. 6) has

replaced the metal option plate. In conjunction with the ne~

ption label the folio' ing paper/laminate label are al o

being u ed: bar code labels for engine erial number and

cu tomer pecification number; emissions label c~ hen

applicable) and disclaimer label.

Di tributor ' ill provide their own label(·) in order to

notify the cu ·tomer f any di tributor-made change lo

Detroc Diesel- manufa tured engines. Di tributor- lyped

label( ) will indicate the di tributor name, addre and the

group/type re i ion that reflect their changes to engine a

originally manufactured b Detroit Diesel.

Attaching Lables

Label mu t be pla ed on rocker cover . Label are

de igned to fit in the ame pace provided for the former

tamped or current ca. t rocker cover option plate holder.

© Detroit Diesel Corporation October, 1989 Page 9

TNEWCAMP MANUALS

You're Reading a Preview

What's Included?

Lifetime Access

Access PDF Contents & Bookmarks

Print one or all pages of your manual

Add to Cart

$41.99

$54.99