Wisconsin Motors Continental TM20 TM27 Gasoline & LPG Engines TM Series Full Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

CONTINENTAL

GASOLINE/LPG

ENGINES

OPERATORS

GUIDE &

R EPAIR

M ANUAL

WISCONSIN

MOTORS, LLC

2020 Fletcher Creek Drive, Memphis, Tennessee 38133

www.wisconsinmotors.com

(800) 932-2858

2006 All Rights Reserved

Wisconsin Motors, LLC

T

M

S

E

R

I

E

S

Good operation and a planned maintenance program as outlined in this manual are vital in ob-

taining maximum engine performance and long engine life. The instructions on the following pages

have been written with this in mind, to give the operator a better understanding of the various problems

which may a rise, and the manner in which these problems can best be solved or avoided.

The operator is cautioned against the use of any parts, other than genuine Wisconsin Motors,

LLC parts, for replacement or repair. These parts have been engineered and tested for their particular

job, and the use of any other parts may result in unsatisfactory performance and short enginel ife.

Wisconsin Motors, LLC distributors and dealers, because of their close factory relations, can

render the best and most efficient service.

THE LIFE OF YOUR ENGINE DEPENDS ON THE CARE IT RECEIVES

The MODEL, SPECIFICATION and SERIAL NUMBER of your engine must be given when order-

ing parts. The MODEL and SPECIFICATION number are on the nameplate. The SERIAL NUMBER

is stamped either on the crankcase or the engine’s identification tag.

Copy the MODEL, SPECIFICATION and SERIAL NUMBER in the spaces provided below so that

it will be available when ordering parts.

MODEL SPECIFICATION

SERIAL NUMBER

To insure prompt and accurate service, the following information must also be given:

1. State EXACTLY the quantity of each part and part number.

2. State definitely whether parts are to be shipped by express, freight or parcel post.

3. State the exact mailing address.

IMPORTANT

READTHESE INSTRUCTIONSCAREFULLY

All points of operation and maintenance have been covered as carefully as possible, but if further

information is required, send inquiries to the factory for prompt attention.

When writing to the factory, ALWAYS GIVE THEMODEL, SPECIFICATION AND SERIAL

NUMBER of the enginereferred to.

Startin_a and O_Deratin_a New En~aines

Carefulbreaking-inof a new engine will greatly increase its life andresult in trouble-free

operation. A factory test is not sufficient to establish the polished bearing surfaces, which are so

necessary to the proper performance and long life of an engine.These canonly be obtained by

runninga new engine carefully and underreduced loads for a short time.

¯ Be sure the engine is filled to the proper level with a good quality engine oil.

¯ For proper procedures to follow when breaking-in a new engine, see’Testing Rebuilt Engine’.

The various bearing surfaces in a new engine have not been glazed, as they will be with continued

operation, and it is in this period of "running in" that specialcare must be exercised, otherwise

the highly desired glaze will neverbe obtained. A new bearing surface that has oncebeen

damaged by carelessness will be ruined forever.

Proper repair is important to the safe and reliable operation of an engine. This Service Manual outlines

basic recommended procedures, some of which require special tools, devices or work methods.

Improper repair procedures can be dangerous and could result in injury or death.

READ AND UNDERSTAND ALL SAFETY PRECAUTIONS AND

WARNINGS BEFORE PERFORMING REPAIRS ON THIS ENGINE

Warning labels have also been put on the engines to provide instructions and identify specific hazards which

if not heeded could cause bodily injury or death to you or other persons. These labels identify hazards which

may not be apparent to a trained mechanic. There are many potential hazards for an untrained mechanic and

there is no way to label the engine against all such hazards. These warnings in the Service Manual and on the

engine are identified by this symbol:

Operations that may result only in engine damage are identified in the Service Manual by the word

CAUTION.

Wisconsin Motors, LLC cannot anticipate every possible circumstance that might involve a potential hazard.

The warnings in this manual are therefore not all inclusive. If a procedure, tool, device or work method not

specifically recommended by Wisconsin Motors, LLC is used, you must satisfy yourself that it is safe for you

and others. You should also ensure that the engine will not be damaged or made unsafe by the procedures

you choose.

IMPORTANT SAFETY NOTICE

IMPORTATNT the information, specifications and illustrations in this book are on the basis of

information available at the time it was written. The specifications, torques, pressures of operation,

measurements adjustments, illustrations and other items can change at any time. These changes can

effect the service given to the product. Get the complete and most current information before you start

any job. Continental Distributors/Dealers have the most current information which is available. For a

list of current Distributors/Dealers, refer to directory LIT1017 or www.wiscosninmotors.com.

WARNING

!

1

WARNING

!

Most sub-systems used in conjunction with Wisconsin Motors, LLC industrial engines including, but not lim-

ited to, radiators, hoses, fans fuel tanks, fuel lines or other fuel systems components, hydraulic pumps and

generators, are not supplied by Wisconsin Motors, LLC, but are provided by the manufacturer of the end item

in which the eingine is used.

Some of the dangers assoicatied with servicing such items are generally mentioned in this manual; however, the

appropriate handbooks and safety instructions procided by the manufactureer of the end item should always be

consulted prior to undertaking any work on sub-systems attached to the engine, to avoid any hazards inherent

to these sub-systems.

Read and observe all individual safety warnings as you use this manual to operate, service or repair your

engine.

Always exercise caution whenever working with an engine or any associated system.

Injuries may be caused by lack of care when working with, or near, moving parts, hot parts, pressurized systems,

electrical equipment, or fuel systems.

Always wear eye and hearing protection when working on or near engines.

Improper attire such as loose clothing, ties, rings, soft shoes or bare feet could be hazardous and should be

avoided when servicing engines.

Use or service of the engine (including the use of modified parts or materials) not in accordance with

manufacturer’s specifications could damage your engine or cause personal injury.

Starting fluids or aids such as ether or gasoline must not be used in a diesel engine air intake system. The use of

these fluids will cause severe internal engine damage and/or bodily injury.

Some equipment and materials used in the overhaul or maintenance of an engine such as machine tools,

electrical equipment, compressed air, solvents, diesel, gasoline or other fuels may be dangerous and can

cause injury. Always observe safety precautions associated with these items.

WARNING

!

WARNING

!

WARNING

!

2

CONTENTS

CONTINENTAL INDUSTRIAL ENGINES

SECTION 1

General Information ................................................................... Page 5

SECTION 2

Operating Instructions ................................................................

Page 7

SECTION 3

Lubrication ............................................................................... Page 13

SECTION 4

Cooling System ........................................................................

Page 15

SECTION 5

Fuel Systems ............................................................................. Page 21

SECTION 6

Governors ................................................................................. Page 25

SECTION 7

Ignition Systems .......................................................................

Page 29

SECTION 8

Preventive Maintenance ...........................................................

Page 39

SECTION 9

Engine Repair and Overhaul ....................................................

Page 47

SECTION 10

Trouble Shooting ......................................................................

Page 67

SECTION 11

Torque Specifications ...............................................................

Page 71

INDEX ...........................................................................................

Page 75

MADE IN USA

WISCONSIN MOTORS, LLC

MEMPHIS TENNESSEE

TME27 08500 1001

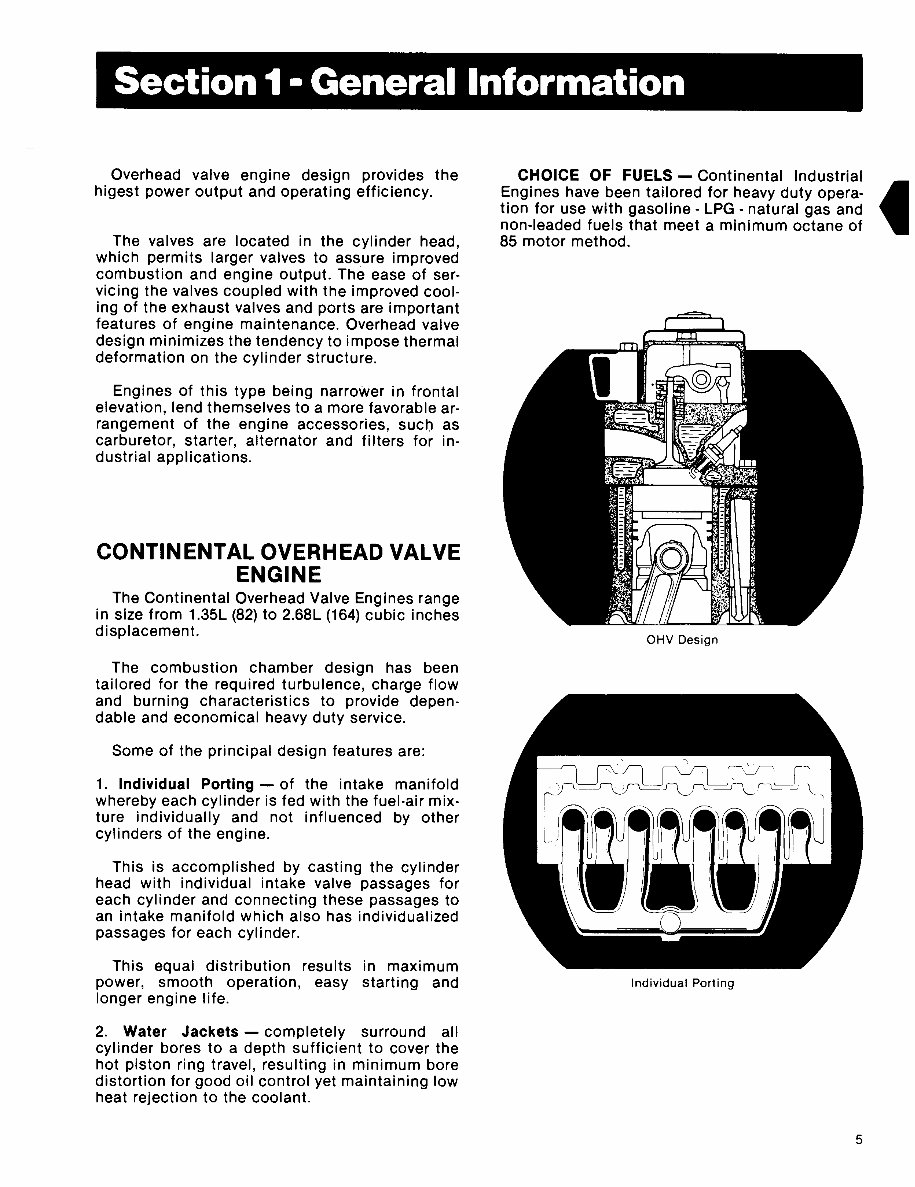

Section I - General Information

Overhead valve engine design provides the

higest power output and operating efficiency.

The valves are located in the cylinder head,

which permits larger valves to assure improved

combustion and engine output. The ease of ser-

vicing the valves coupled with the improved cool-

ing of the exhaust valves and ports are important

features of engine maintenance. Overhead valve

design minimizes the tendency to impose thermal

deformation on the cylinder structure.

Engines of this type being narrower in frontal

elevation, lend themselves to a more favorable ar-

rangement of the engine accessories, such as

carburetor, starter, alternator and filters for in-

dustrial applications.

CONTINENTAL OVERHEAD VALVE

ENGINE

The Continental Overhead Valve Engines range

in size from 1.35L (82) to 2.68L (164) cubic inches

displacement.

The combustion chamber design has been

tailored for the required turbulence, charge flow

and burning characteristics to provide depen-

dable and economical heavy duty service.

Some of the principal design features are:

1. Individual Porting- of the intake manifold

wherebyeach cylinder is fed with the fuel-air mix-

ture individually and not influenced by other

cylinders of the engine.

This is accomplished by casting the cylinder

head with individual intake valve passages for

each cylinder and connecting these passages to

an intake manifold which also has individualized

passages for each cylinder.

This equal distribution results in maximum

power, smooth operation, easy starting and

longer engine life.

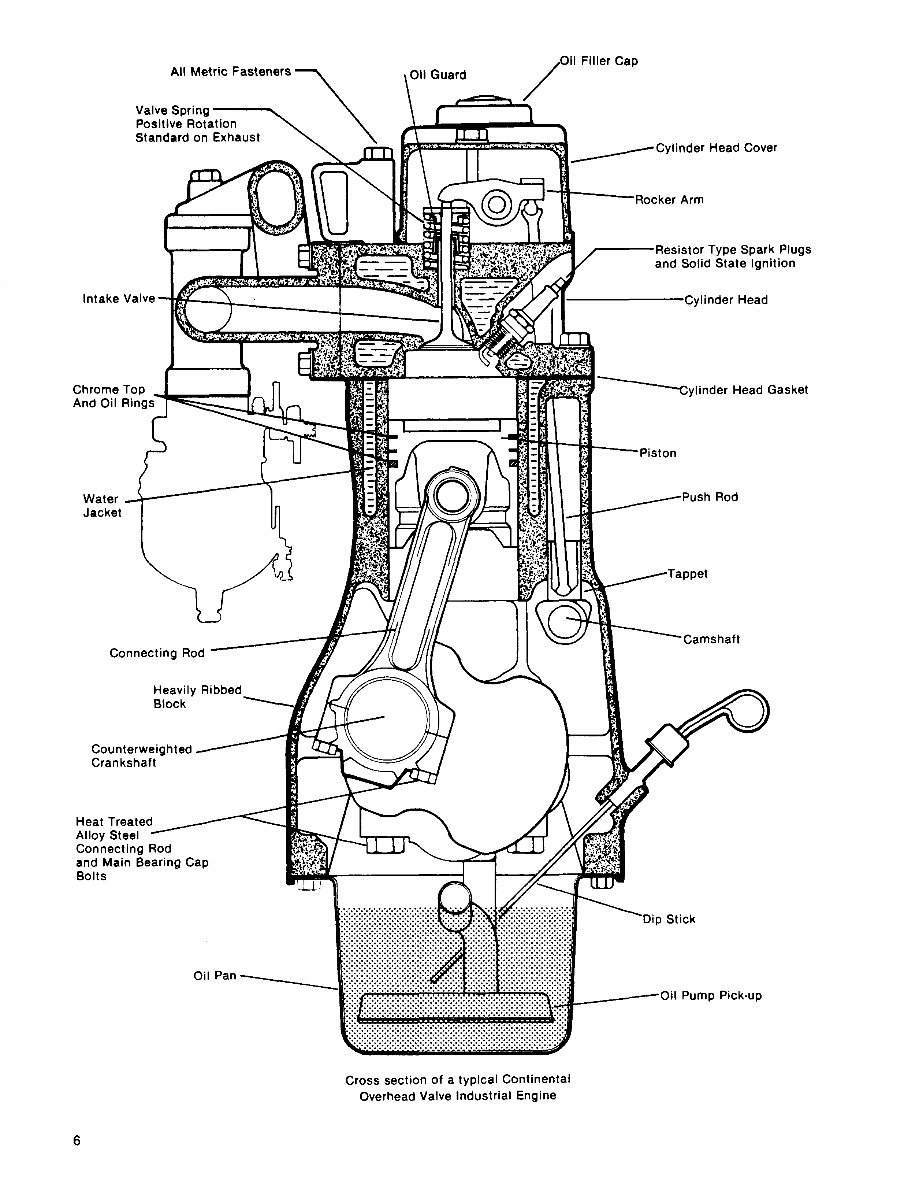

2. Water Jackets-- completely surround all

cylinder bores to a depth sufficient to cover the

hot piston ring travel, resulting in minimum bore

distortion for good oil control yet maintaining low

heat rejection to the coolant.

CHOICE OF FUELS--Continental Industrial

Engines have been tailored for heavy duty opera-

tion for use with gasoline- LPG - natural gas and

non-leaded fuels that meet a minimum octane of

85 motor method.

OHV Design

Individual Porting

All Metric Fasteners "~

Valve Spring

Positive Rotation

Standard on Exhaust

Intake Valve

Oil Guard

Filler Cap

~Cylinder Head Cover

~Rocker Arm

Resistor Type Spark Plugs

and Solid State Ignition

.Cylinder Head

Chrome Top

And Oil Rin

"~’~’-"~ylinder Head Gasket

Water

Jacket

Rod

Connecting Rod

Heavily Ribbed

Block

~pet

3amshaft

Counterweighted

Crankshaft

Heat Treated

Alloy Steel

Connecting Rod

and Main Bearing Cap

Bolts

Oil Pan

!:i:!:i:i:!:i:i

Stick

PumpPick-up

Cross section of a typical Continental

Overhead Valve Industrial Engine

Section 2 - Operating Instructions

The person operating the engine naturally

assumesresponsibility for its care while it is

being operated. This is a very important respon-

sibility since the care and attention given the

engine goes a long way in determining how long a

period it will operate satisfactorily before having

to be shut down for repairs.

The operating and preventive maintenance in-

structions for the Overhead Valve type engines

are simple and should be followed without devia-

tion.

The entire aim in setting forth these instruc-

tions is to give you a benefit of the knowledge and

experience gained over a long period of collabora-

tion between Engineering Research and Field Ser-

vice.

PREPARATION OF A NEW ENGINE

FOR OPERATION

/ WARNING

Before placing a new engine in operation, it

must be thoroughly inspected for external

damage and particular attention paid to the

following items:

1. Inspect Engine Hold Down Bolts -- To make

certain that they are firmly set.

2. Close water drain cock -- on the side of the

block. (In some cases, this may be a pipe plug.)

Fill radiator and water jacket with coolant (see

Cooling System section 4).

Radiator Coolant Inlet

5. Electrical Connections -- Check storage

battery terminals and all electrical connections.

Check each spark plug wire for tightness.

Stop engine before checking battery terminals or elec-

trical connections. Do not hold ignition wires with bare

hands since shocks or other injuries can result. Sparks

or flames near a battery could cause an explosion or

fire. Battery acid can cause corrosive burns. Always

wear eye protection. Use of jumper cables or battery

charging should be done only as directed by manufac-

turers safety instructions.

Read and observe safety warnings on pages 1 and 2.

Electrical Connections

STARTING THE ENGINE

/ WARNING

Water Drain Cock

3. Fill Crankcase with oil -- Use the oil recom-

mended for the ambient temperature (see chart on

page 14).

4. EngineAccessories -- see that all points re-

quiring lubrication are properly lubricated.

Bodily injury or death may result to individuals during

operation of an engine within any enclosure not ade-

quately or properly ventilated. Engineoperation in any

enclosure requires adequate and proper ventilation to

avoid asphyxiation or other interruption of normal

breathing, to supply sufficient air to cool the engine,

provide air to mix with fuel and to carry awayheated air

from the building.

Read and observe safety warnings on pages 1 and 2.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

Viewed 78 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

This is a comprehensive factory service repair workshop manual for Wisconsin Motors Continental TM20 TM27 Gasoline & LPG Engines TM Series. It is available for instant access on your computer, tablet, or smartphone without any extra fees or expiry dates.

Designed for professional mechanics and DIY enthusiasts, this manual covers all repair, servicing, and troubleshooting procedures with detailed photos, diagrams, step-by-step instructions, and highly detailed exploded diagrams and pictures.

- Printing: You have the flexibility to print out a single page or the entire manual as per your requirement.

- Multi-Device Usage: This manual can be used on multiple computers without any limitations.

- Full Version: This is the full manual without any trial periods or limitations, and it can be used for life.

- Compatibility: It is fully compatible with all Windows and MAC computers.

Thank you for considering this manual. Click the button to access it now.