Continental engine overhaul service manual IO-520 IO520

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Publication X30039

©

2011 CONTINENTAL MOTORS, INC. AUG 2011

IO-520

CONTINENTAL

®

AIRCRAFT ENGINE

OVERHAUL

MANUAL

TECHNICAL CONTENT ACCEPTED BY THE FAA

A IO-520 Series Engine Overhaul Manual

31 August 2011

Supersedure Notice

This manual revision replaces the front cover and list of effective pages for Publication Part No. X30039, dated

September 1977. Previous editions are obsolete upon release of this manual.

Effective Changes for this Manual

0 .......... September 1977

1 ............ 31 August 2011

List of Effective Pages

Document Title: IO-520 Series Engine Overhaul Manual

Publication Number: X30039 Initial Publication Date: September 1977

Page Change Page Change Page Change Page Change

Cover ............................ 1

A ................................... 1

i thru v .......................... 0

1-1 thru 1-10................. 0

2-1 thru 2-10................. 0

3-1 thru 3-2................... 0

4-1 thru 4-30................. 0

5-1 thru 5-12................. 0

6-1 thru 6-30................. 0

7-1 thru 7-8................... 0

8-1 thru 8-20................. 0

9-1 thru 9-8................... 0

10-1 thru 10-2............... 0

Published and printed in the U.S.A. by Continental Motors, Inc.

Available exclusively from the publisher: P.O. Box 90, Mobile, AL 36601

Copyright © 2011 Continental Motors, Inc. All rights reserved. This material may not be reprinted, republished, broadcast, or otherwise

altered without the publisher's written permission. This manual is provided without express, statutory, or implied warranties. The publisher will

not be held liable for any damages caused by or alleged to be caused by use, misuse, abuse, or misinterpretation of the contents. Content is

subject to change without notice. Other products and companies mentioned herein may be trademarks of the respective owners.

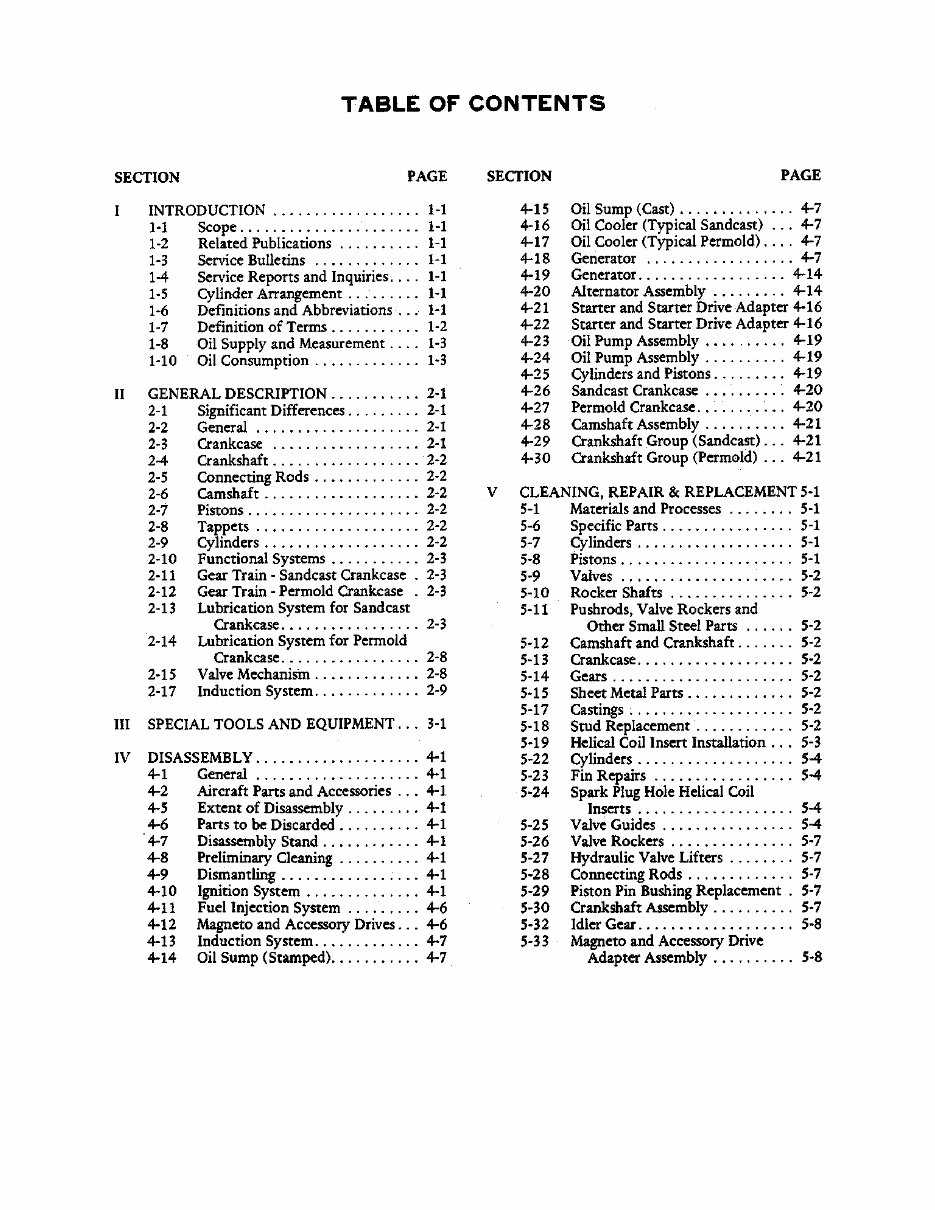

i

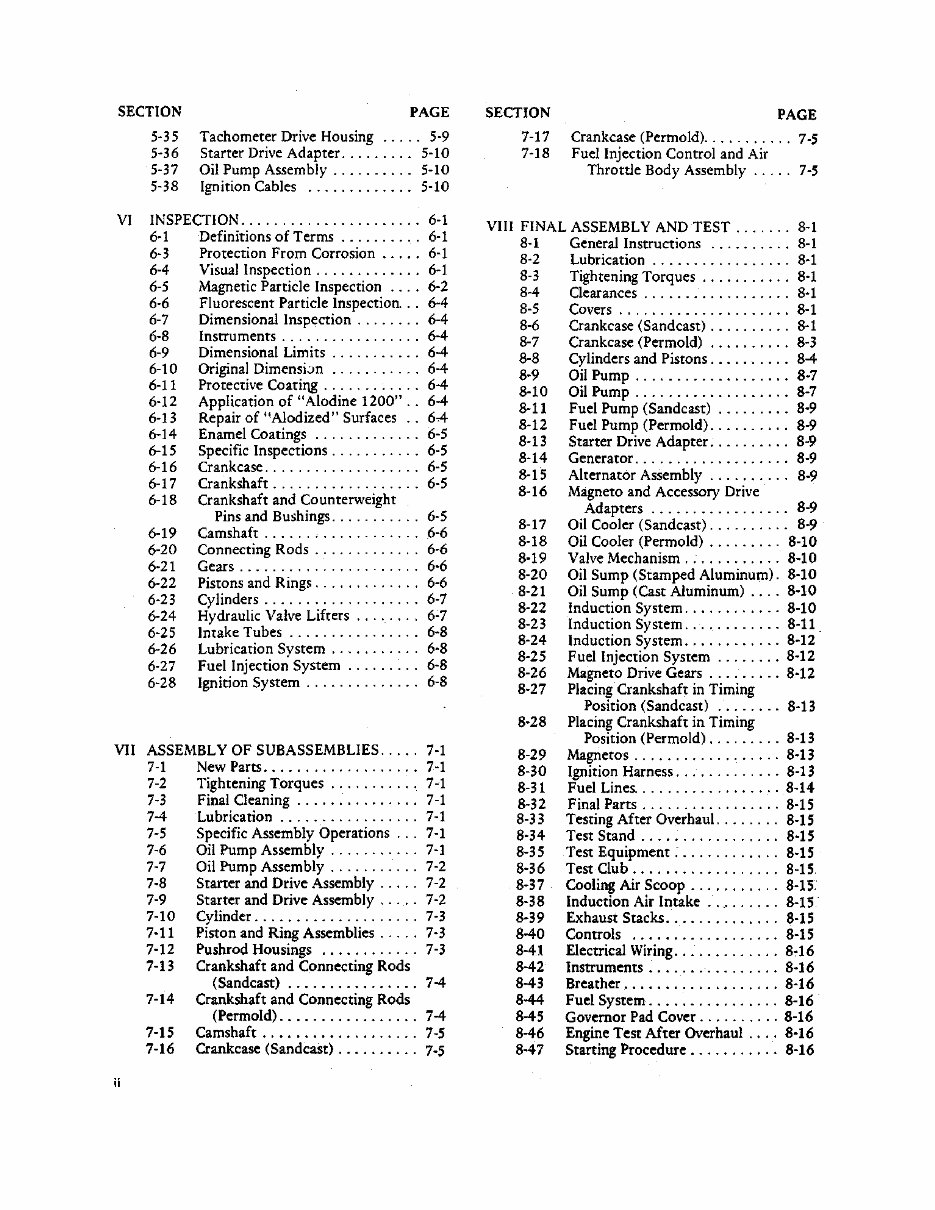

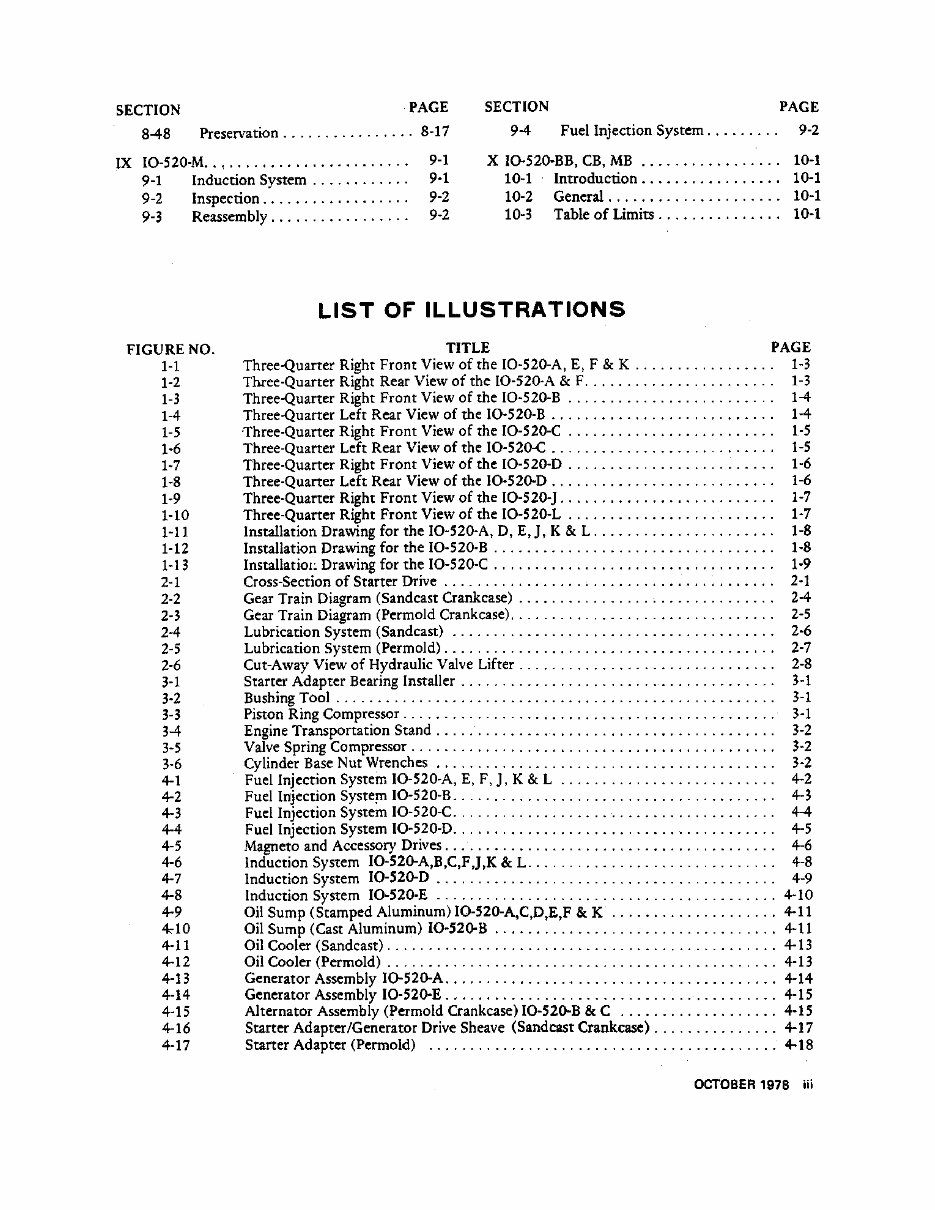

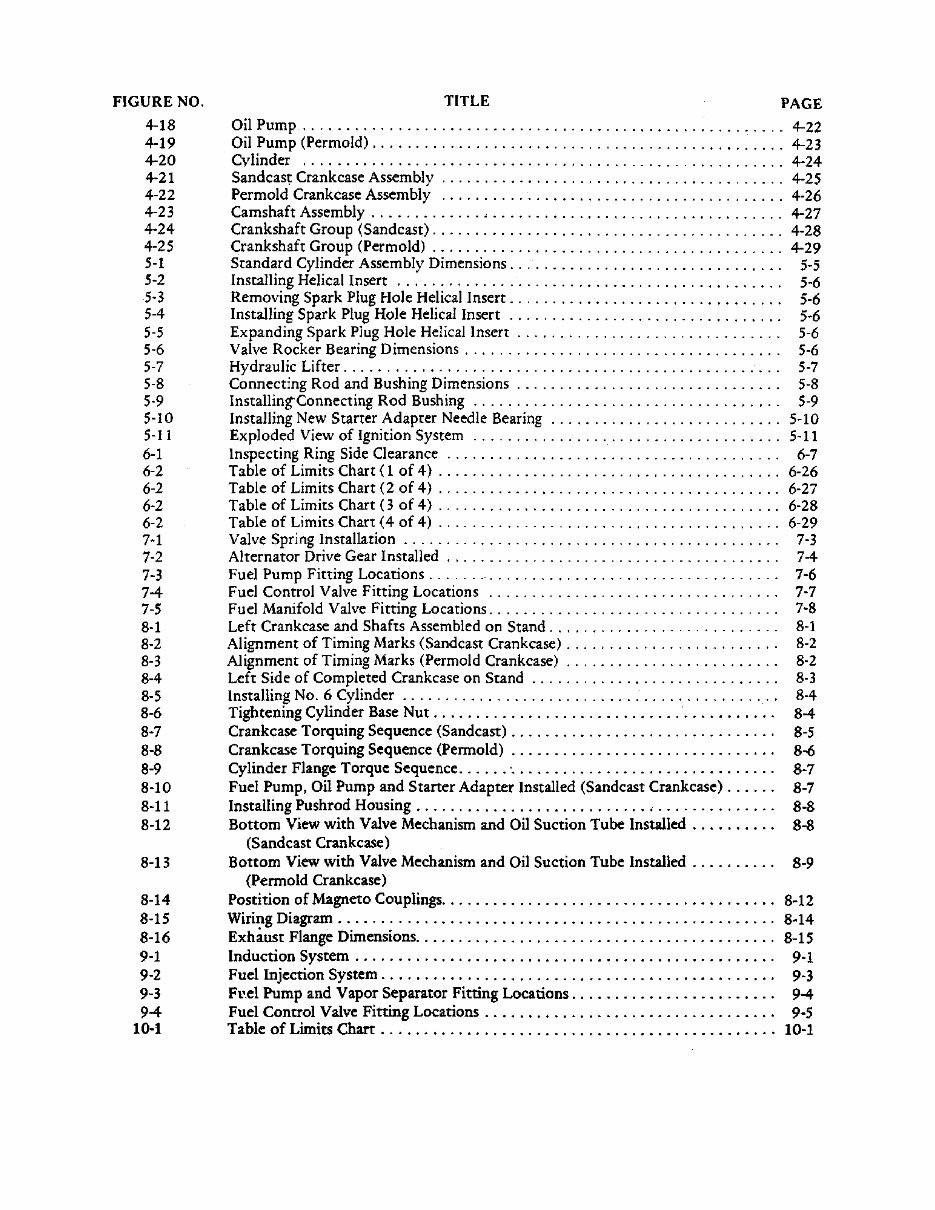

iv October 1978

October 1978 v

Intentionally Left Blank

MAY 1980 1-1

SECTION I

INTRODUCTION

1-1. SCOPE. This publication comprises

Overhaul Instructions for the IO-520 Series Aircraft

Engines.

1-2. RELATED PUBLICATIONS. Detail part

numbers and service assemblies for these engine

models are contained in Parts Catalog X-30040A.

Operating instructions are contained in Operator's

Handbook X-30041.

a. Service instructions for Slick Magneto Model

No. 662 may be obtained from Slick Electro Inc.,

Rockford, Illinois 61100.

b. Service instructions for Bendix Magneto

Model S6RN-201, S6RN-205, S6RN-1201 and

S6RN-1205 may be obtained from Bendix

Corporation, Electrical Components Division,

Sidney, New York 13830.

c. Service instructions for Delco-Remy Starters,

Generators or Alternators may be obtained from

Delco-Remy Division, General Motors Corporation,

Anderson, Indiana 96011.

1-3. SERVICE BULLETINS. Important

changes and product improvements are covered by

factory service bulletins available for study at all

Approved Distributors. These Bulletins are also

available to owners, operators or maintenance

personnel on an annual subscription basis.

1-4. SERVICE REPORTS AND INQUIRIES.

It is the policy of Teledyne Continental Motors to

handle all reports of service difficulty and requests

for information through Approved Distributors.

Request for further copies of this or any other

Teledyne Continental Aircraft Engine Service

Publication should be made through these facilities.

There is an Approved Distributor at every major

airport.

1-5. CYLINDER ARRANGEMENT. Cylinders

are numbered starting from the rear, with odd

numbers on the right and even numbers on the left.

1-6. DEFINITIONS AND ABBREVIATIONS

Term . Explanation

A.B.C. After Bottom Center

Approx. Approximately

A.T.C. After Top Center

Bar. Barometric

B.B.C. Before Bottom Center

B.H.P. Brake horsepower

B. T.C. Before Top Center

F.A.A. Federal Aviation Administration

C.A.R. Civil Air Regulations

c.f.m. Cubic feet per minute

C.G. Center of Gravity

Dia. Diameter

° Degrees of Angle

°F. Degrees Farenheit

Fig. Figure (Illustration)

Front Propeller End

ft. foot or feet

G.P .M. Gallons per minute

H2O Water

Hg. Mercury

I.D. Inside Diameter

in. (") Inches

Hex. Hexagon

hr. Hour

Left Side Side on which Nos. 2, 4 and

6 cylinders are located

Lbs. Pounds

Lockwire Soft steel wire used to safety

connections, etc.

Man. Manifold or manometer

Max. Maximum

Min. Minimum

30' thirty minutes of angle

(60' equal one degree)

N.P.T. National pipe thread

(tapered)

1-2

Term . Explanation

N.C. National Coarse (thread)

N.F. National Fine (thread)

O.D. Outside Diameter

Press. Pressure

p.s.i. Pounds per square inch

Rear Accessory end of engine

Right Side Side on which Nos. 1, 3 and

5 cylinders are located

R.P.M. Revolution per minute

Std. Standard

T.D.C. Top dead center

Temp. Temperature

Torque Force x lever arm (125 ft.-lbs.

force applied one ft. from bolt

center or 62-1/2 lbs. applied

2 ft. from center)

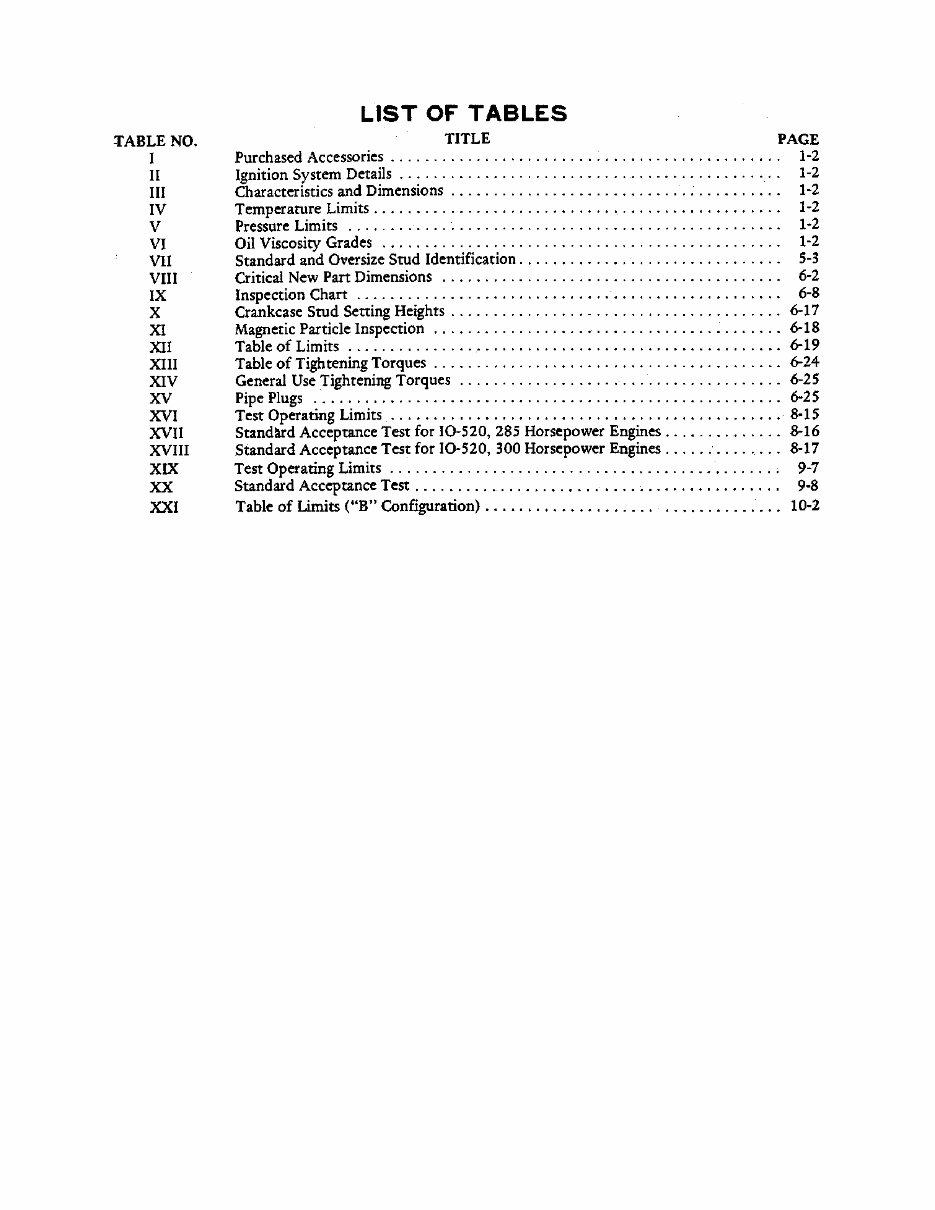

TABLE I. PURCHASED ACCESSORIES

ACCESSORY QTY

Magneto ....................................................................... 2

Starter .......................................................................... 1

Alternator ..................................................................... 1

Generator ..................................................................... 1

Oil Cooler ..................................................................... 1

Fuel Pump.................................................................... 1

Spark Plugs................................................................ 12

TABLE II. IGNITION SYSTEM DETAILS

FEATURE VALUE

Left Magneto Fires ............................... Lower No. 1-3-5

And Upper No. 2-4-6 plugs

Right Magneto Fires ............................. Upper No. 1-3-5

And Lower No. 2-4-6 plugs

Firing order (cylinder numbers) .................... 1-6-3-2-5-4

Permissible RPM spread when

Switched from “Both” to either

“Left” or “Right” magneto ............................................ 50

1-7. DEFINITION OF TERMS. Front, rear, left

and right, as used in this manual, refer to the engine

as viewed by the mechanic in a normal position,

facing the accessory end.

TABLE III.

CHARACTERISTICS AND DIMENSIONS

DIMENSION VALUE

Piston stokes per cylinder ............................................ 4

Number of cylinders ..................................................... 6

Cylinder bore (inches) ............................................. 5.25

Piston stroke (inches) ............................................. 4.00

TABLE IV. TEMPERATURE LIMITS

INDICATED CONDITION MIN. MAX.

Oil temperature at takeoff 75°F --

Oil temperature in flight -- 240°F.

Cylinder head temperature

(bayonet thermocouple)* -- 460°F.

Magneto temperature

(at coil hold-down screw) -- 170°F.

* Installed in tapped hole in bottom of cylinder head.

TABLE V. PRESSURE LIMITS

INDICATION MIN. MAX.

Oil pressure (idling) 10 psi --

Oil pressure (in flight) 30 psi 60 psi

Oil pressure (with cold oil) -- 100 psi

TABLE VI. VISCOSITY OIL GRADES

OIL OPERATING OIL

TEMPERATURE GRADE

Below 40°F. 30 OR 10W-30

Above 40°F. 50

Ambient air temperature is the controlling factor on all

engines having oil temperature control valves installed.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$35.99

Viewed 19 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$35.99

An overhaul manual for the IO-520 series aircraft engines, X30039, is available. This manual, current as of 2012, contains 133 pages in print. It is a valuable resource for both professional mechanics and DIY enthusiasts involved in the maintenance and repair of these aircraft engines.