Continental A50 A65 A75 A80 Operator Manual Owner Manuals*

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Continental

A50

A65

A75

ABO

Engines

Combined Manual

Operator's, Maintenance, Overhaul

&

Parts Manuals

http://www.ioffer.com/selling/userfriendlycds

http://stores.ebay.com/UserFriendlyCDs

This Page is Blank

1u.pa.-co.1

http://www.ioffer.com/selling/userfriendlycds

http://stores.ebay.com/UserFriendlyCDs

ii

CONTINENTAL A 50, A 6 5 , A 7 5 , A80 ENGINES

INTRODUCTION

THIS book is a combined Operator's Manual, Maintenance and

Overhaul Manual and Illustrated Parts and Price List for the

Continental A50, A65, A 75, and A80 series 8 and 9 engines.

This manual is intended for use by operators and mechanics

as a guide and reference book in the operation and servicing of

these engines.

The book is divided into five main groups: Operating and

Maintenance Instructions, Overhaul Instructions, Table of Limits,

the Illustrated Parts List, and Accessories.

It is suggested that a careful study be made of this manual.

A strict adherence to the instructions outlined herein will assure

a fine operating record. However, if any point is not entirely

clear, do not hesitate to contact the nearest Authorized Conti-

nental Service Station or the factory Service Department.

In the event of failure of any engine part, notify the nearest

Authorized Continental Service Station at once, giving the engine

serial number, and full particulars. Do not attempt any repairs

without factory permission if any adjustment is expected.

CONTINENTAL MOTORS CORPORATION

Muskegon, Michigan

iii

CONTINENTAL A 50, A 6 5 , A 7 5 , A80

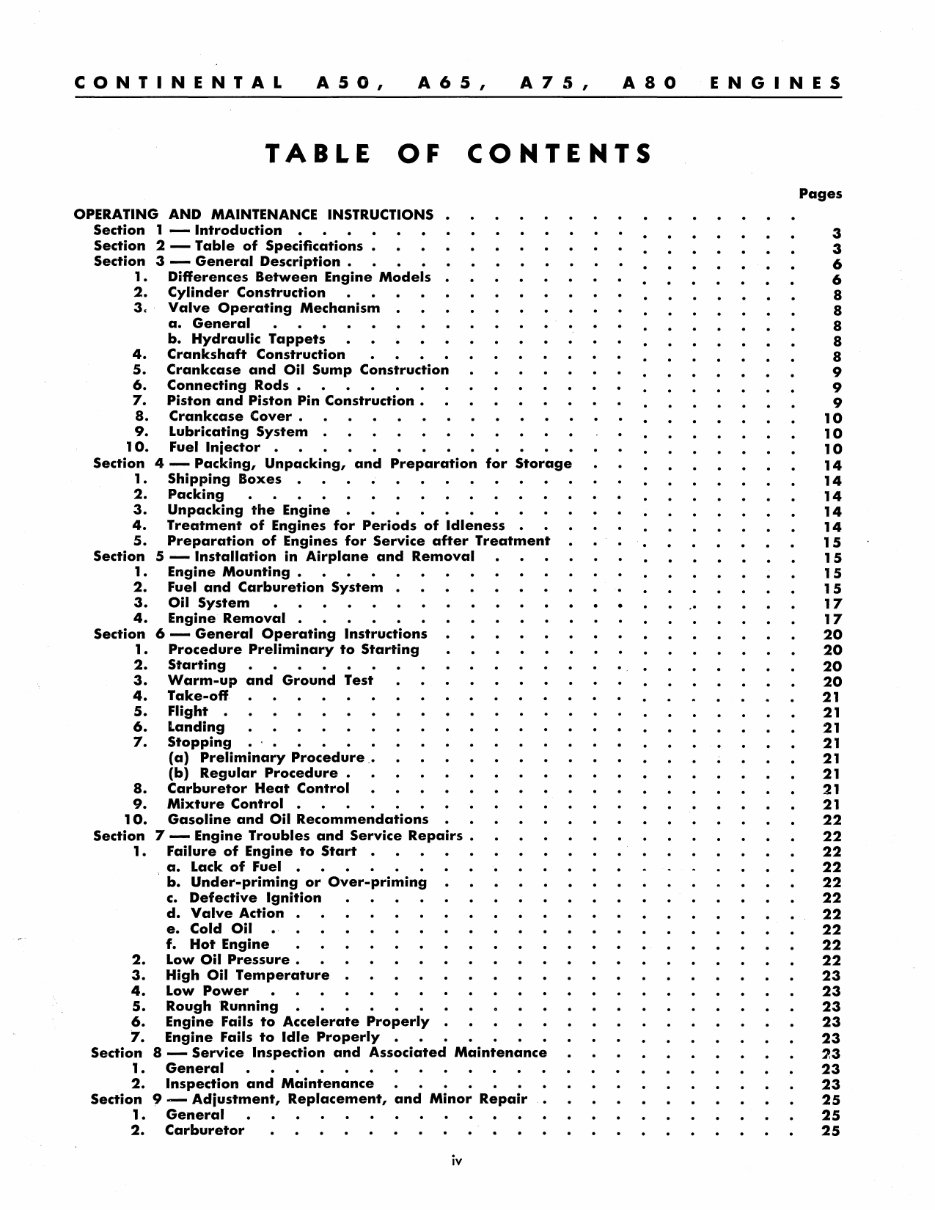

TABLE OF CONTENTS

OPERATING AND MAINTENANCE INSTRUCTIONS •

Section 1 - Introduction

Section 2 - Table of Specifications •

Section 3 - General Description •

1 • Differences Between Engine Models •

2. Cylinder Construction

3, Valve Operating Mechanism •

4.

5.

6.

7.

8.

9.

10.

a. General

b. Hydraulic Tappets

Crankshaft Construction

Crankcase and Oil Sump Construction

Connecting Rods •

Piston and Piston Pin Construction •

Crankcase Cover •

Lubricating System •

Fuel Injector •

Section

1.

2.

3.

4.

5.

4 - Packing, Unpacking, and Preparation for Storage

Shipping Boxes •

Packing

Unpacking the Engine •

Treatment of Engines for Periods of Idleness •

Preparation of Engines for Service after Treatment

Section

1.

2.

3.

4.

Section

1.

2.

3.

4.

5.

6.

7.

5 - Installation in Airplane and Removal

Engine Mounting •

Fuel and Carburetion System •

Oil System

Engine Removal .

6 - General Operating Instructions

Procedure Preliminary to Starting

Starting

Warm-up and Ground Test

Take-off

Flight •

Landing

Stopping

(a) Preliminary Procedure.

(b) Regular Procedure.

Carburetor Heat Control

Mixture Control •

8.

9.

10. Gasoline and Oil Recommendations

Section 7 - Engine Troubles and Service Repairs •

1 • Failure of Engine to Start •

, a. Lack of Fuel •

b. Under-priming or Over-priming

c. Defective Ignition

d. Valve Action •

e. Cold Oil

f. Hot Engine

2. Low Oil Pressure •

3. High Oil Temperature •

4. Low Power

5. Rough Running

6. Engine Fails to Accelerate Properly •

'7. Engine Fails to Idle Properly •

'.

Section 8 - Service Inspection and Associated Maintenance

1. General

2. Inspection and Maintenance

Sect'ion 9 - Adjustment, Replacement, and Minor Repair •

1. General

2. Carburetor

iv

..

ENGINES

Pages

3

3

6

6

8

8

8

8

8

9

9

9

10

10

10

14

14

14

14

14

15

15

15

15

17

17

20

20

20

20

21

21

21

21

21

21

21

21

22

22

22

22

22

22

22

22

22

22

23

23

23

23

23

23

23

23

25

25

25

CONTINENTAL A 50, A 6 5 , A 7 5 ,

TABLE Of CONTENTS - Continued

3. Magnetos.

4. Magneto Installation and Timing to the Engine

5. Ignition Wiring •

6. Removal of Parts

7. General Inspection •

8. Reassembly

a. General

b. Valves.

c. Valve Springs.

d. Piston Pins, Pistons, and Cylinders

e. Rocker Arms and Push Rods

f. Rocker Box Cover

g. Spark Plugs •

h. Adjustment of Valve Tappet Clearance

OVERHAUL INSTRUCTIONS •

Section

1.

2.

3.

4.

5.

Section

1.

2.

Section

1.

2.

10 - Disassembly, Cleaning and Inspection

General

Preliminary Operations •

Disassembly •

a. Oil Sump and Suction Tube •

b. Intake Pipes and Manifold •

c. Rocker Box Covers •

d. Push Rods and Rocker Arms

e. Cylinder and Pistons

f. Crankcase

g. Crankcase Cover Assembly (Series 8)

h. Crankcase Cover Assembly (Series 9)

Cleaning

a. General

b. Cleaning of Engine Parts

Inspection •

a. General

b. Inspection of Engine Parts

(1) Crankcase

(2) Cylinders

(3) Valve Mechanism

(4) Oil Sump.

(5) Crankshaft and Connecting Rods

(6) Pistons and Piston Pins

(7) Crankcase Cover

(8) Camshaft

(9) Gears

11 - Repair and Replacement

General •

Repair and Replacement of Engine Parts

a. Crankcase

b. Cylinders •

c. Valve Mechanism

d. Crankshaft and Connecting Rods

e. Pistons and Piston Pins •

f. Crankcase Cover Assembly

g. Camshaft and Hydraulic Tappets

h. Gear •

i. Intake Pipes, Connections and Clamps

j. Push Rod Housing Flanges, Connections and Clamps

k. Ignition System •

12 - Reassembly, Final Assembly, Timing and Testing

General • •

Reassembly of Major Sub-Assemblies

a. Cylinder and Valve Assembly Procedure

b. Connecting R~d to Crankshaft •

v

A80 ENGINES

Pages

26

26

26

27

27

27

27

27

27

27

28

28

28

28

29

29

29

.29

29

29

29

29

29

29

30

31

31

31

31

31

32

32

32

32

32

32

33

33

33

33

33

33

34

34

35

35

35

35

36

36

36

36

36

36

36

37

37

37

37

37

37

CONTINENTAL A 50, A 6 5 , A 7 5 ,

TABLE Of CONTENTS - Continued

c. Pistons and -Piston Pins • •

d. Crankcase Cover Assembly (Series 8)

e. Crankcase Cover Assembly (Series 9)

f. Intake Pipes and Hose Connections •

3. Final Assembly Procedure •

a. Preliminary

b. Installing Crankshaft and Connection Rods •

c. Assembly of Crankcases and Component Parts •

d. Installing Gears and Crankcase Cover •

e. Installing Oil Sump and Oil Suction Tube •

f. Installing Hydraulic Units and Push Rod Housing Flanges.

g. Installing Cylinders. •

h. Installing Air Intake System •

i. Installing Ignition System •

j. Installing Radio Shielded Ignition Wires

k. Testing Engine After Overhaul •

TABLE OF LIMITS

ILLUSTRATED PARTS LIST •

Section 13 - Introduction •

Section 14 - Group Assembly Parts List

Section 1 5 - Numerical Parts List

Section 16 - Oversize and Undersize Parts

ACCESSORIES. •

Section 1 7 - Stromberg NA-S3A 1 Carburetor

Service Instructions

Service Parts List •

Section 1 8 - Bendix-Scintilla Magneto

Service Instructions ' •

Service Parts List •

Section 1 9 - Wilcox Rich Hydraulic Lifters

Service Instructions

, .

vi

.,

A80 ENGINES

Pages

37

37

38

38

38

38

39

40

41

42

42

42

43

44

45

45

49

51

51

53

78

89

91

91

94

96

96

98

102

102

CONTINENTAL

INDEX

Figure

No.

A 5 0,

FOR

Title

A 6 5 , A 7 5 , A80

ILLUSTRATIONS

ENGINES

Page

No.

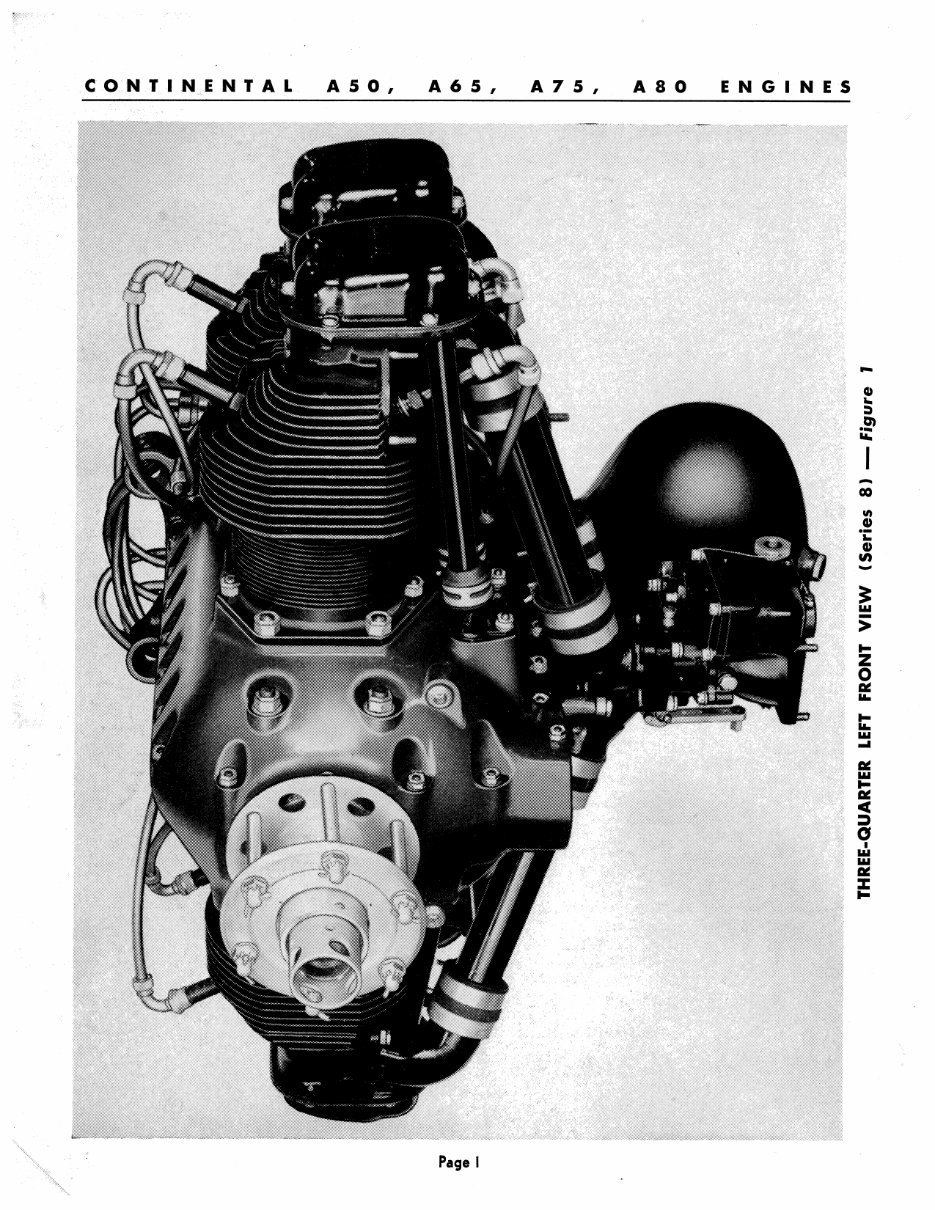

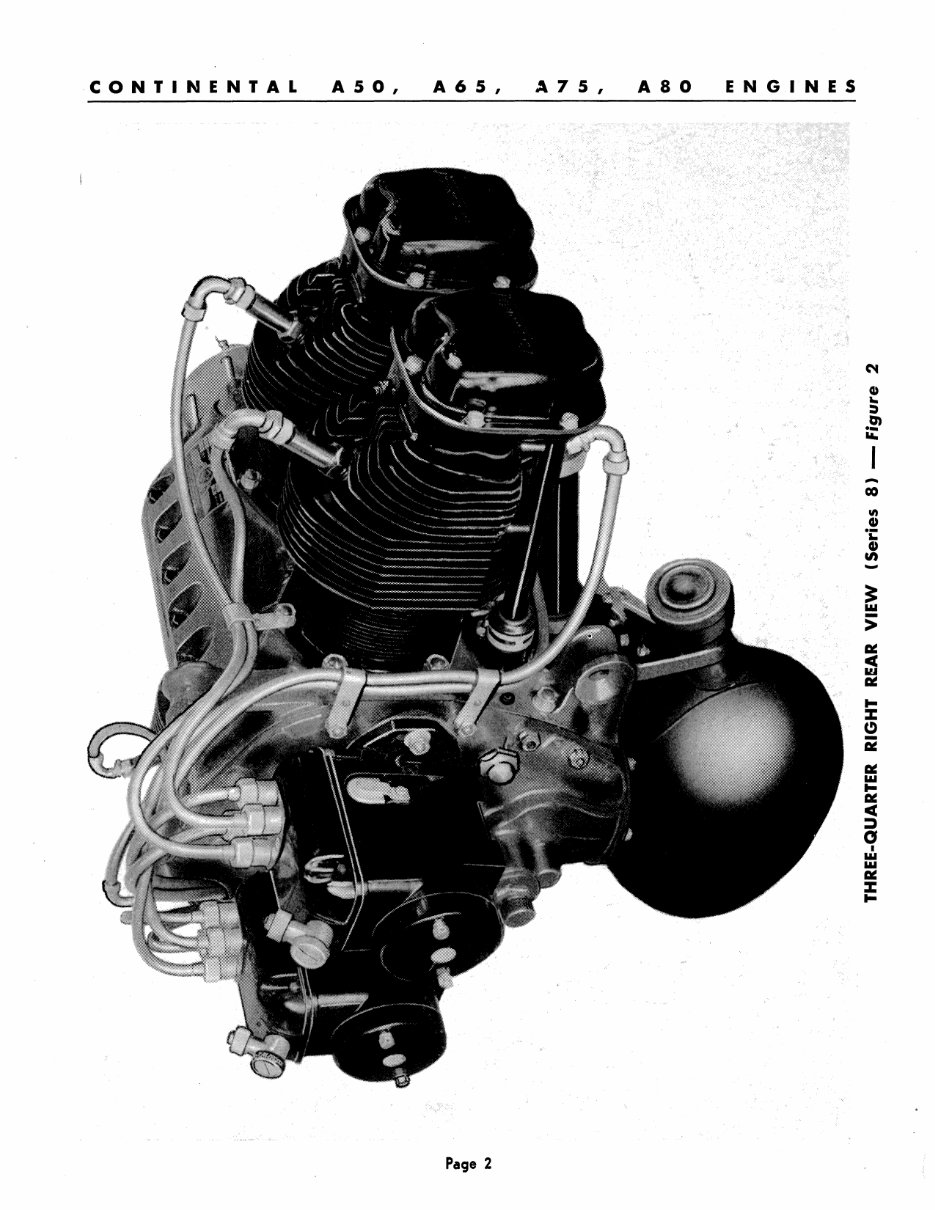

1 Three-Quarter Left Front View (Series 8) ................................... 1

2 Three-Quarter Right Rear View (Series 8) .................................. 2

3 Performance and Fuel Consumption Curves for A50, A65, A75, A80 Engines .. 5

4 Left Side View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 7

5 Right Side View.............................................................. 7

6 Section Through Hydraulic Tappet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 8

7 Fuel Injector Engine .......................................................... 11

8 Cutaway View Showing Gear Train .......................................... 13

9 Hoisting Engine with Crankshaft Lifting Eye ................................ 14

10 Hoisting Engine with Lifting Sling ........................................... 16

11 Typical Installation Diagram ................................................. 17

12 Installation Drawing .......................................................... 18

12a Installation Drawing .......................................................... 19

13 Ignition Wiring Diagram ..................................................... 26

14 Compressing· Valve Springs for Installation and Removal of Locks ........... 30

15 Removal of Hydraulic Unit from Cam Follower Body ......................... 30

16 Assembling and Removing Connecting Rods .................................. 31

17 Stud Identification ............................................................ 34

18 Assembling Rocker Shaft Bushings ........................................... 35

19 Installing Cam Follower Body into Crankcase ................................ 38

20 Installing -Crankshaft Bearings into Crankcase .............................. 39

21 Installing and Removing Crankshaft and Connecting Rods ................... 39

22 Installation of Crankcase 1-3 over Crankcase 2-4 ........................... .40

23 Installation of Gears in 'Crankcase ........................................... 41

24 Installation of Crankcase Cover to Crankcase .............. , ................. 41

25 Installation of Cylinder on Crankcase ........................................ 43

23 Determining Firing Position ................................................. 44

27 Lubrication Chart - Cross-sectional View .............................. , ..... 46

28 Lubrication Chart - Longitudinal View ...................................... 47

29 Lubrication Chart - Rear View ......................... : ................... 48

30 Crankcase - Illustrated Parts ·List ........................................... 52

31 Crankshaft, Connecting Rods and Pistons - Illustrated Parts List ............ 55

32 Cylinder and Valves - Illustrated Parts List ................................. 57

33 Rear Crankcase Cover and Gear Train - Illustrated Parts List .............. 59

34 Oil Sump and Suction Tube - Illustrated Parts List ......................... 62

35 Ignition System - Unshielded - Illustrated Parts List ....................... 64

36 Ignition System - Radio Shielded - Illustrated Parts List ................... 66

37 Carburetor, Carburetor Air Intake and Filter System - Illustrated Parts List. 68

38 Camshaft, Push Rods, Valve Tappets and Propeller Hub - Illustrated

Parts List .................................................................. 70

39 Fuel Injector Equipment - Illustrated Parts List ............................ 72

40 Fuel Pump and Oil Cooler Equipment - Illustrated Parts List ................ 75

41 Showing Magneto Timing Markers ............................................ 96

42 Timing Magneto ............................................................. 96

43 Breaker Mechanism .......................................................... 97

44 Magneto Illustrated Parts ................................................... 100

vii

A.5 0 I A 6 5, A 7 5 , A80 ENG I N ES

Page I

-

- co

;

0i:

G)

tn

-

!

>

Ii-

Z

o

~

...

t:

III

...

CONTINENTAL A 50, A 6 5 , .l 7 5 , A80 ENGINES

....

Page 2

CONTINE.NTAL A 50, A 6 5 , A'Z 5 , A80 ENGINES

OPERATING AND MAINTENANCE

INSTRUCTIONS

Section 1

INTRODUCTION

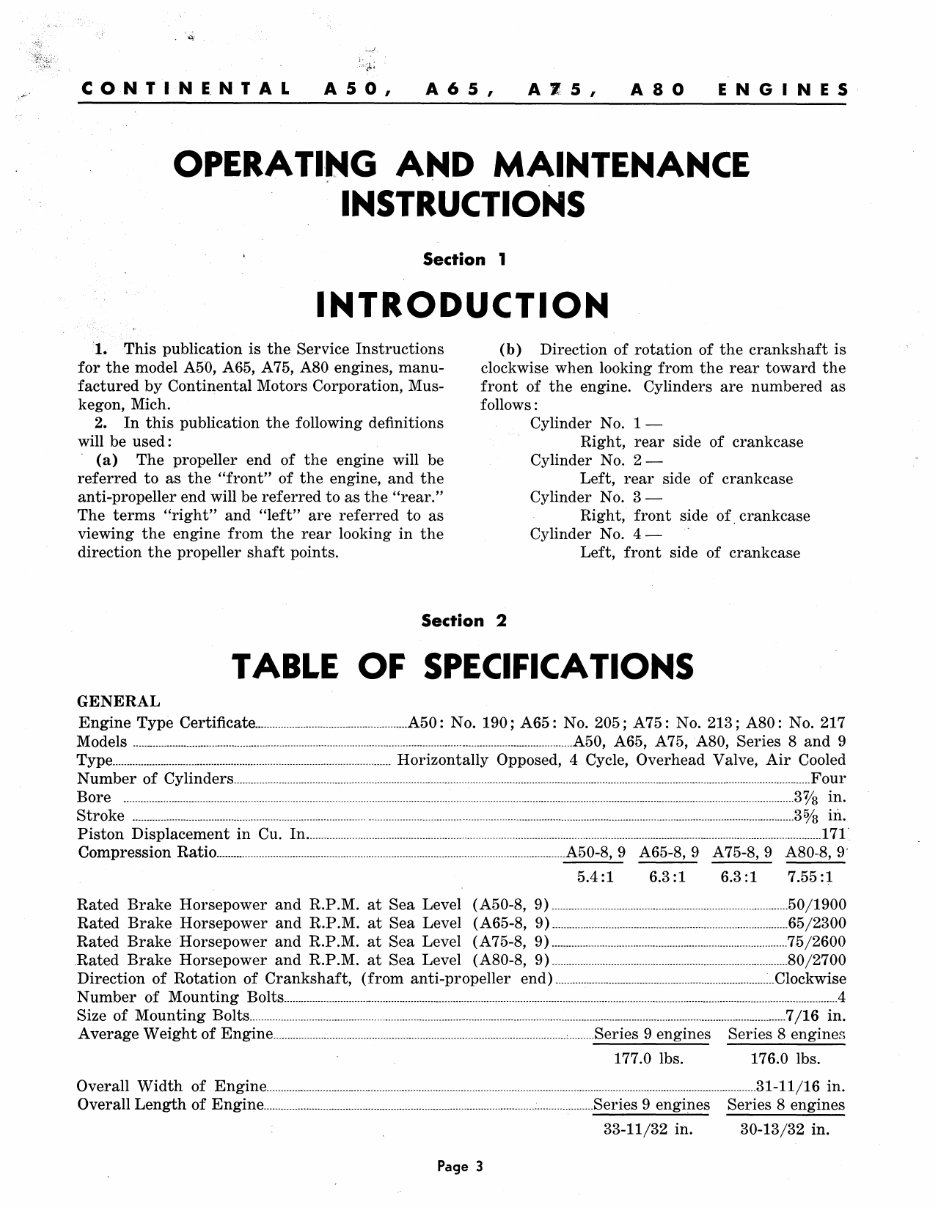

1. This publication is the Service Instructions

for the model A50, A65, A 75, A80 engines, manu-

factured by Continental Motors Corporation, Mus-

kegon, Mich.

2. In this publication the following definitions

will be used:

(a) The propeller end of the engine will be

referred to as the "front" of the engine, and the

anti-propeller end will be referred to as the "rear."

The terms "right" and "left" are referred to as

viewing the engine from the rear looking in the

direction the propeller shaft points.

(b) Direction of rotation of the crankshaft is

clockwise when looking from the rear toward the

front of the engine. Cylinders are numbered as

follows:

Cylinder No. 1-

Right, rear side of crankcase

Cylinder No. 2-

Left, rear side of crankcase

Cylinder No. 3-

Right, front side of crankcase

Cylinder No. 4-

Left, front side of crankcase

Section 2

TABLE OF SPECIFICATIONS

GENERAL

Engine Type Certificate ..... _________ . __ . ________________________________ . __ A50 : No. 190; A65 : No. 205; A 75 : No. 213; A80 : No. 217

Models . __ ._. __ . ___ ............... ___ ...... ______ ... _ .. ______ . _______ ... ________ . _______ . _____ ........... __ . __ ._ .......... _._ .. ___ .A50, A65, A 75, A80, Series 8 and 9

Type ....................... _ .. ___ ..... _ .... __ .......... _______________________ . ______________ ...... Horizontally Opposed, 4 Cycle, Overhead Valve, Air Cooled

Number of Cylinders __ .. ____________ .. ______ ... ___ .___________ _ ______________ . ____ ....... _. ________ ............. _._ ........ __ . _______ ....... _. ___ . ___ ........ __________________ .. ____ ...... Four

Bore .. ____ ..... _ .. ___ .. ___ ... ___________ . __ . ______________________________________________ . _____________ .. ________ _ ____ . _________ .. ___ ... _. _____ . ________ .... __ . ___ ....... _. _____ . _____ . _________________ .. __________ ...... 3 0/8 in.

Stroke .. _._ .. _____ . ____ .. _____ ........... _. ______ . __________ .______ _ ___________________ .... ___ . __________ ... _ .... __________ ....... _. _____ .. _. __ .... _____ . __ . _____________ . ___ ._----...... 30/8 in.

Piston Displacement in Cu. In .... _______ _________ ......... _. ___ . ___ .___ _ ____________ .... ____. _____ .. __________ . ____ .. _____ ....... ___ ... ___ ._. ____ ... ____ . _____ ... __ ... _________ 171·

Compression Ratio .......... _____ ... _____ ..... _____ ... ___ . __ . __ . ___ .. ____ .. ___ .. __ ._. __ ..... ___ ...... __ . ______ ._ .. _____ .. ___ . ____ A50-8, 9 A65-8,9 A75-8,9 A80-8,9'

5.4 :1 6.3:1 6.3:1 7.55:1

Rated Brake Horsepower and R.P.M. at Sea Level (A50-8, 9) ______ ... _ .. _. __ . __ ... _ .... _. __ .. _ .... _. __ .___. ____ . _____ 50/1900

Rated Brake Horsepower and R.P .M. at Sea Level (A65-8, 9) ... __________________ ... _____ . ________ . _________ ..... _. ___________ . _________________ 65 /2300

Rated Brake Horsepower and R.P.M. at Sea Level (A75-8, 9) ............ ________ .. _ ... ____ . _____ ............... __ ... ___ ........ _____ ..... _______ 75/2600

Rated Brake Horsepower and R.P .M. at Sea Level (A80-8, 9) . ___________ . __ . __ .. ______ ..... _________________ ....... _________________ . __________ .80 /2700

Direction of Rotation of Crankshaft, (from anti-propeller end) __ .. ________ .. ____ ......... __ .... _ ... _____ .. _. ______ .... _ .......... __ ......... Clockwise

Number of Mounting Bolts ....... ___________ ........ ___ .. _ .. _ ............. _ ...... _____ ... _ .. _ ... _ .. ______ .... _ .. ____ .. ____________ ... ______________ . ___________ .. _ ...... ___ . ___________ . _________________ ._. ____ ... __ 4

Size of Mounting Bolts________ _ ________________________________ .. _________ . ___ .... ______________________ . _____ ... __ . ______________ . ___ . ___________ ........ ____ . ____ ..... __ . __ ._.7 /16 in.

Average Weight of Engine ___ ... ____________ . ________ . ___________ ._. __ . ___ . ___ ........ _._____. ___________ .. _______Series 9 engines Series 8 engines

177.0 lbs. 176.0 lbs.

Overall Width of Engine __ .... _____ .. __ . __ .. ____ . ___________ . _______ .. __ ..... _. ___________ .. _______________ . ______ ._....... ______ . _______ ................ __ .. _______ .. _. __ . _____ 31-11 /16 in.

Overall Length of Engine .... _. ______ .... ______ ........ _____ .. _ ....... __ .. ______ .. _ .. ____________________ ..... ____ ..... _______ ._. __ Series 9 engines Series 8 engines

33-11/32 in. 30-13/32 in.

Page 3

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 17 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

This is the Operators Handbook for the Continental Aircraft Engines:

- A50 series 5, 6, 7, 8 & 9

- A65 series 1, 3, 6, 7, 8 & 9

- A75 series 3, 6, 8 & 9

- A80 series 3, 6, 8 & 9

This handbook contains necessary information for operating, servicing, and overhauling the A50, A65, A75 & A80 engines. It is our suggestion that you study this entire manual closely. A strict adherence to the instructions outlined herein will assure you a fine operating record.

This manual is clear and written in a way so that just about anybody can follow it.

This manual is SEARCHABLE... Just type in what you are looking for & that Page will come up.

Why pay big bucks to have someone else print it for you?

Print what you need when you need it!

Save a tree, buy digitally!