Caterpillar 3208 Marine Engine Maintenance Intervals

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

SAFETY.CAT.COM

3208

MARINE ENGINE

Maintenance Intervals

Excerpted from Operation & Maintenance Manual (SEBU6090-03-01)

© 2007 Caterpillar

All Rights Reserved

56

Maintenance Section

Maintenance Interval Schedule

i00917973

Maintenance Interval Schedule

SMCS Code: 1000; 7500

Note: Ensure that the Safety Information, warnings,

and instructions are read and understood before

operation or maintenance procedures are performed.

Before each consecutive interval is performed, all

of the maintenance requirements from the previous

interval must also be performed.

Note: For engines that are equipped with

AIRSEP® engine air cleaners, the turbocharger

should be inspected every 1000 service hours.

When Required

Belt - Inspect/Adjust/Replace ................................ 59

Battery - Recycle .................................................. 61

Battery or Battery Cable - Disconnect .................. 62

Engine Oil Level Gauge - Calibrate ...................... 78

Fuel System - Prime ............................................. 87

Daily

Cooling System Coolant Level - Check ................ 66

Engine Air Cleaner Service Indicator - Inspect ..... 75

Engine Oil Level - Check ...................................... 77

Fuel System Water Separator - Drain ................... 90

Marine Transmission Oil Level - Check ................ 95

Walk-Around Inspection ...................................... 102

Every 1900 L (500 US gal) of Fuel or 50

Service Hours

Aftercooler Drain Plug - Inspect ............................ 57

Engine Air Cleaner Element (Foam) -

Clean/Replace .................................................... 71

Zinc Rods - Inspect/Replace ............................... 104

Initial 9000 L (2400 US gal) of Fuel or 250

Service Hours or 1 Year

Engine Valve Lash - Inspect/Adjust ...................... 84

Every 9000 L (2400 US gal) of Fuel or 250

Service Hours or Yearly

Auxiliary Water Pump - Inspect ............................. 59

Belt - Inspect/Adjust/Replace ................................ 59

Battery Electrolyte Level - Check .......................... 61

Cooling System Supplemental Coolant Additive

(SCA) - Test/Add ................................................. 67

Engine Air Cleaner Element - Clean/Replace ....... 72

Engine Crankcase Breather - Clean ..................... 76

Engine Oil Sample - Obtain .................................. 81

Engine Oil and Filter - Change ............................. 82

Engine Protective Devices - Check ...................... 83

Exhaust Restrictor - Inspect/Adjust ....................... 84

Fuel System Primary Filter/Water Separator Element

- Replace ............................................................. 88

Fuel System Secondary Filter - Replace .............. 89

Fuel Tank Water and Sediment - Drain ................. 91

Hoses and Clamps - Inspect/Replace .................. 93

Magnetic Pickups - Clean/Inspect ........................ 94

Oil Fumes Filter - Replace .................................... 95

Sea Water Strainer - Clean/Inspect .................... 100

Every 36 000 L (9000 US gal) of Fuel or 1000

Service Hours or 2 Years

Aftercooler Core - Clean/Test ............................... 57

Cooling System Coolant (DEAC) - Change .......... 62

Cooling System Water Temperature Regulator -

Replace ............................................................... 69

Engine - Clean ...................................................... 71

Governor Housing - Drain ..................................... 92

Marine Transmission Oil Cooler - Clean/Inspect .. 94

PCV Valve - Inspect .............................................. 99

Every 72 000 L (19 000 US gal) of Fuel or

2000 Service Hours

Alternator - Inspect ............................................... 58

Crankshaft Vibration Damper - Inspect ................. 70

Engine Mounts - Inspect ....................................... 77

Engine Valve Lash - Inspect/Adjust ...................... 84

Fuel Injection Nozzles - Test/Exchange ................ 86

Fuel Ratio Control - Inspect/Adjust ....................... 87

Heat Exchanger - Inspect ..................................... 92

Starting Motor - Inspect ...................................... 101

Turbocharger - Inspect ........................................ 101

Every 108 000 L (28 500 US gal) of Fuel or

3000 Service Hours or 2 Years

Cooling System Coolant Extender (ELC) - Add .... 66

Water Pump - Inspect ......................................... 103

Every 114 000 L (30 000 US gal) of Fuel

Overhaul Considerations ...................................... 96

Every 216 000 L (57 000 US gal) of Fuel or

6000 Service Hours or 4 Years

Cooling System Coolant (ELC) - Change ............. 64

57

Maintenance Section

Aftercooler Drain Plug - Inspect

i00913406

Aftercooler Drain Plug -

Inspect

SMCS Code: 1063-040

g00466348

Illustration 15

Typical location of aftercooler drain

Inspect the plug for the aftercooler drain (if equipped).

Ensure that the plug is one of the following plugs:

•

101-3713 Tethered Plug

•

9x-8406 Plug (stainless steel)

NOTICE

A failed aftercooler drain plug can cause the engine

compartment to fill with sea water. Any plugs used

in the aftercooler drain port, other than those recom-

mended above, may corrode. Use only those recom-

mended plugs.

i00744980

Aftercooler Core - Clean/Test

SMCS Code: 1064-070; 1064-081

1. Remove the core. Refer to the Service Manual

for the procedure.

2. Turn the aftercooler core upside-down in order

to remove debris.

NOTICE

Do not use a high concentration of caustic cleaner to

clean the core. A high concentration of caustic cleaner

can attack the internal metals of the core and cause

leakage. Only use the recommended concentration of

cleaner.

3. Back flush the core with cleaner.

Caterpillar recommends the use of Hydrosolv

liquid cleaner. Table 23 lists Hydrosolv liquid

cleaners that are available from your Caterpillar

dealer.

Table 23

Hydrosolv Liquid Cleaners

(1)

Description Container

1U-8812 Hydrosolv 4165 4 L (1 US gal)

1U-5490 Hydrosolv 4165 19 L (5 US gal)

8T-7570 Hydrosolv 4165 208 L (55 US gal)

1U-8804 Hydrosolv 100 4 L (1 US gal)

1U-5492 Hydrosolv 100 19 L (5 US gal)

8T-7571 Hydrosolv 100 208 L (55 US gal)

(1)

Use a two to five percent concentration of the cleaner at

temperatures up to 93°C (200°F). Refer to Application

Guide, NEHS0526 or consult your Caterpillar dealer for more

information.

4. Steam clean the core in order to remove any

residue. Flush the fins of the aftercooler core.

Remove any other trapped debris.

5. Wash the core with hot, soapy water. Rinse the

core thoroughly with clean water.

58

Maintenance Section

Alternator - Inspect

Personal injury can result from air pressure.

Personal injury can result without following prop-

er procedure. When using pressure air, wear a pro-

tective face shield and protective clothing.

Maximum air pressure at the nozzle must be less

than 205 kPa (30 psi) for cleaning purposes.

6. Dry the core with compressed air. Direct the air in

the reverse direction of the normal flow.

7. Inspect the core in order to ensure cleanliness.

Pressure test the core. Many shops that service

radiators are equipped to perform pressure tests.

If necessary, repair the core.

8. Install the core. Refer to the Service Manual for

the procedure.

For more information on cleaning the core, consult

your Caterpillar dealer.

i00997205

Alternator - Inspect

SMCS Code: 1405-040

Note: This engine is equipped with an alternator

circuit breaker. Note the location of the alternator

circuit breaker for your particular application. If the

alternator circuit breaker trips, you will need to reset

the breaker in order for the charging system to

operate. Refer to the information that is provided by

the OEM for more information.

Caterpillar recommends a scheduled inspection

of the alternator. Inspect the alternator for loose

connections and proper battery charging. Inspect the

ammeter (if equipped) during engine operation in

order to ensure proper battery performance and/or

proper performance of the electrical system. Make

repairs, as required. Refer to the Service Manual.

Check the alternator and the battery charger for

proper operation. If the batteries are properly

charged, the ammeter reading should be very near

zero. All batteries should be kept charged. The

batteries should be kept warm because temperature

affects the cranking power. If the battery is too cold,

the battery will not crank the engine. The battery will

not crank the engine, even if the engine is warm.

When the engine is not run for long periods of time

or if the engine is run for short periods, the batteries

may not fully charge. A battery with a low charge will

freeze more easily than a battery with a full charge.

59

Maintenance Section

Auxiliary Water Pump - Inspect

i00911249

Auxiliary Water Pump - Inspect

SMCS Code: 1371-040

Impellers and seals require periodic inspection.

Impellers have a service life that is limited. The

service life depends on the engine operating

conditions.

Inspect the components more frequently when the

pump is exposed to debris, sand, or other abrasive

materials. Inspect the components if the pump is

operating at a differential pressure of more than

103 kPa (15 psi).

Check the following components for wear or damage:

•

Bearings

•

Cam

•

Impeller

•

Seals

•

Wear plate

If wear or damage is found, replace the components

which are worn or damaged. Use the proper repair

kit for the pump. Refer to the Disassembly and

Assembly for more information on servicing the

auxiliary water pump.

i00912007

Belt - Inspect/Adjust/Replace

SMCS Code: 1357-039

Inspection

Belt tension should be checked initially between

the first 20 to 40 hours of engine operation.

After the initial check, the belt tension should be

checked at Every 250 Service Hours or Three

Months.

To maximize the engine performance, inspect the

belts for wear and for cracking. Replace belts that are

worn or damaged.

For applications that require multiple drive belts,

replace the belts in matched sets. Replacing only

one belt of a matched set will cause the new belt to

carry more load because the older belt is stretched.

The additional load on the new belt could cause the

new belt to break.

If the belts are too loose, vibration causes

unnecessary wear on the belts and pulleys. Loose

belts may slip enough to cause overheating.

If the belts are too tight, unnecessary stresses are

placed on the pulley bearings and on the belts. This

may shorten the service life of the components.

Remove the belt guard. Inspect the condition and

adjustment of the alternator belts and accessory

drive belts (if equipped).

If the belts do not require replacement or adjustment,

install the belt guard. If the belts require adjustment

or replacement, perform the following procedure to

adjust the belt tension.

60

Maintenance Section

Belt - Inspect/Adjust/Replace

Adjustment

Alternator Belt

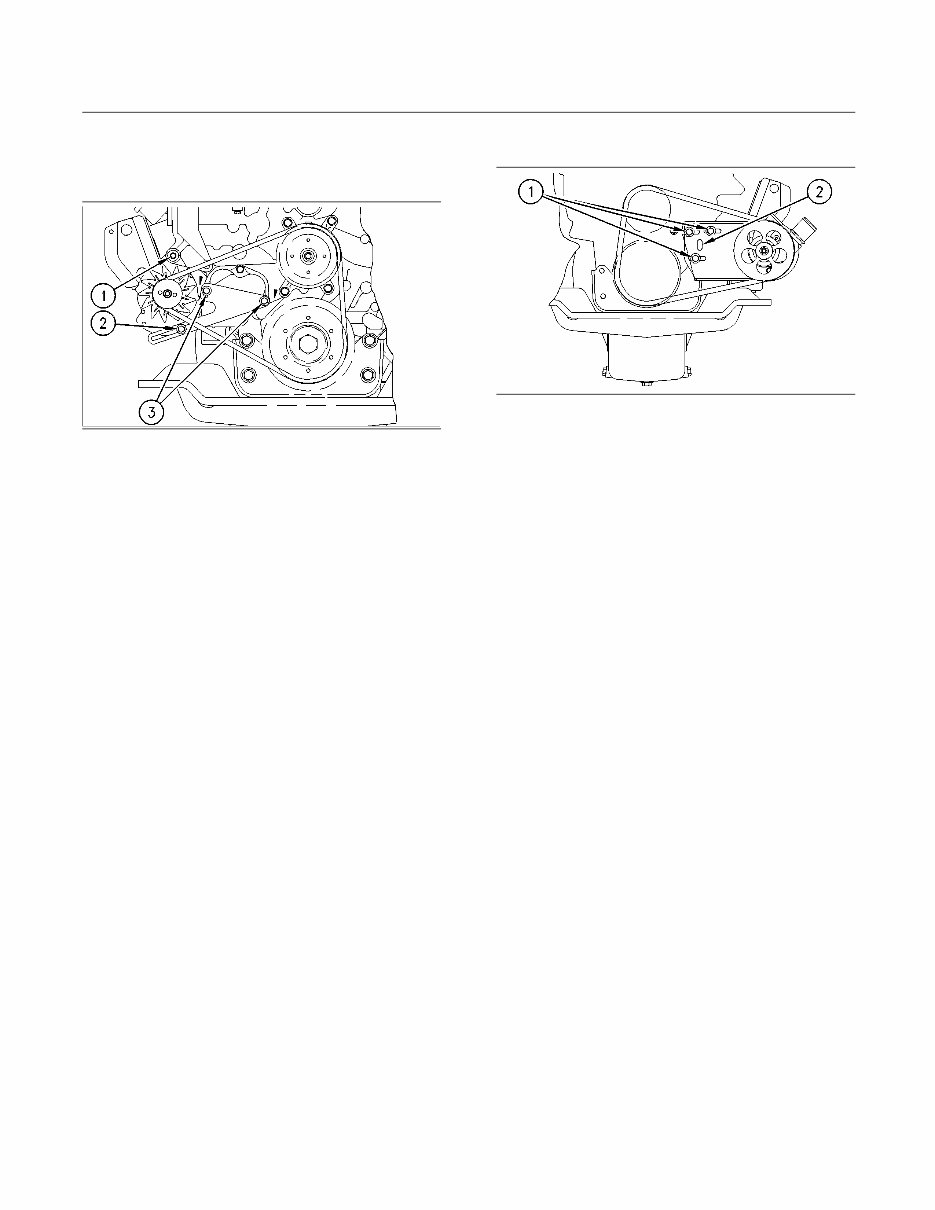

g00465617

Illustration 16

Typical illustration

(1) Mounting bolt

(2) Adjustment bolt

(3) Bracket bolts

1. Slightly loosen mounting bolt (1) and adjusting

bolt (2).

2. Move the alternator in order to adjust the belt

tension. If the alternator will not adjust, it may be

necessary to slightly loosen bracket bolts (3).

Refer to the Specifications, “Belt Tension Chart”

topic.

3. Tighten adjusting bolt (2) and mounting bolt (1).

Tighten bracket bolts (3) if the bracket bolts

were loosened. Refer to the Operation and

Maintenance Manual, “Torque Specifications”

topic (Maintenance Section).

4. Install the belt guard.

If new belts are installed, check the belt tension again

after 30 minutes of engine operation at the rated rpm.

Auxiliary Water Pump Belt

g00465541

Illustration 17

Typical illustration

(1) Mounting bolts

(2) Slotted hole

1. Slightly loosen mounting bolts (1).

2. Adjust the belt tension with a pry bar in slotted

hole (2). Refer to the Specifications, “Belt Tension

Chart” topic.

3. Tighten mounting bolts (2). Refer to the Operation

and Maintenance Manual, “Torque Specifications”

topic (Maintenance Section).

4. Install the belt guard.

If new belts are installed, check the belt tension again

after 30 minutes of engine operation at the rated rpm.

61

Maintenance Section

Battery - Recycle

i00037658

Battery - Recycle

SMCS Code: 1401-561

1. Always recycle a battery. Never discard a battery.

2. Always return used batteries to one of the

following locations.

•

A battery supplier

•

An authorized battery collection facility

•

Recycling facility

i00914454

Battery Electrolyte Level -

Check

SMCS Code: 1401-081

When the engine is not run for long periods of time or

when the engine is run for short periods, the batteries

may not fully recharge. Ensure a full charge in order

to help prevent the battery from freezing. If batteries

are properly charged, ammeter reading should be

very near zero.

All lead-acid batteries contain sulfuric acid which

can burn the skin and clothing. Always wear a face

shield and protective clothing when working on or

near batteries.

1. Remove the filler caps. Maintain the electrolyte

level to the “FULL” mark on the battery.

If the addition of water is necessary, use distilled

water. If distilled water is not available use clean

water that is low in minerals. Do not use artificially

softened water.

2. Check the condition of the electrolyte with the

1U-7298 Coolant/Battery Tester (°C) or the

1U-7297 Coolant/Battery Tester (°F).

3. Keep the batteries clean.

Clean the battery case with one of the following

cleaning solutions:

•

A mixture of 0.1 L (.12 qt) of baking soda and

1 L (1 qt) of clean water

•

A mixture of 0.1 L (.12 qt) of ammonia and 1 L

(1 qt) of clean water

Thoroughly rinse the battery case with clean water.

Use a fine grade of sandpaper to clean the

terminals and the cable clamps. Clean the items

until the surfaces are bright or shiny. DO NOT

remove material excessively. Excessive removal

of material can cause the clamps to not fit properly.

Coat the clamps and the terminals with 5N-5561

Lubrication Compound, petroleum jelly or MPGM

grease.

62

Maintenance Section

Battery or Battery Cable - Disconnect

i00095575

Battery or Battery Cable -

Disconnect

SMCS Code: 1402-029

1. Turn the start switch to the OFF position. Turn the

ignition switch (if equipped) to the OFF position

and remove the key and all electrical loads.

2. Disconnect the negative battery terminal at the

battery that goes to the start switch. Ensure that

the cable cannot contact the terminal. When four

12 volt batteries are involved, the negative side of

two batteries must be disconnected.

3. Tape the leads in order to help prevent accidental

starting.

4. Proceed with necessary system repairs. Reverse

the steps in order to reconnect all of the cables.

i00906400

Cooling System Coolant

(DEAC) - Change

SMCS Code: 1350-070; 1395-044

Clean the cooling system and flush the cooling

system before the recommended maintenance

interval if the following conditions exist:

•

The engine overheats frequently.

•

Foaming is observed.

•

The oil has entered the cooling system and the

coolant is contaminated.

•

The fuel has entered the cooling system and the

coolant is contaminated.

NOTICE

Use of commercially available cooling system clean-

ers may cause damage to cooling system compo-

nents. Use only cooling system cleaners that are ap-

proved for Caterpillar engines.

Note: Inspect the water pump and the water

temperature regulator after the cooling system has

been drained. This is a good opportunity to replace

the water pump, the water temperature regulator and

the hoses, if necessary.

Drain

Pressurized System: Hot coolant can cause seri-

ous burns. To open the cooling system filler cap,

stop the engine and wait until the cooling system

components are cool. Loosen the cooling system

pressure cap slowly in order to relieve the pres-

sure.

1. Stop the engine and allow the engine to cool.

Loosen the cooling system filler cap slowly in

order to relieve any pressure. Remove the cooling

system filler cap.

2. Open the cooling system drain valve (if equipped).

If the cooling system is not equipped with a drain

valve, remove one of the drain plugs.

Allow the coolant to drain.

63

Maintenance Section

Cooling System Coolant (DEAC) - Change

NOTICE

Dispose of used engine coolant properly or recycle.

Various methods have been proposed to reclaim used

coolant for reuse in engine cooling systems. The full

distillation procedure is the only method acceptable by

Caterpillar to reclaim the used coolant.

For information regarding the disposal and the

recycling of used coolant, consult your Caterpillar

dealer or consult Caterpillar Service Technology

Group:

Outside Illinois: 1-800-542-TOOL

Inside Illinois: 1-800-541-TOOL

Canada: 1-800-523-TOOL

Flush

1. Flush the cooling system with clean water in order

to remove any debris.

2. Close the drain valve (if equipped). Clean the

drain plugs. Install the drain plugs. Refer to the

Operation and Maintenance Manual, “Torque

Specifications” topic (Maintenance Section) for

more information on the proper torques.

NOTICE

Fill the cooling system no faster than 19 L (5 US gal)

per minute to avoid air locks.

3. Fill the cooling system with a mixture of clean

water and Caterpillar Fast Acting Cooling System

Cleaner. Add .5 L (1 pint) of cleaner per 15 L

(4 US gal) of the cooling system capacity. Install

the cooling system filler cap.

4. Start and run the engine at low idle for a minimum

of 30 minutes. The coolant temperature should be

at least 82 °C (180 °F).

NOTICE

Improper or incomplete rinsing of the cooling system

can result in damage to copper and other metal com-

ponents.

To avoid damage to the cooling system, make sure

to completely flush the cooling system with clear wa-

ter. Continue to flush the system until all signs of the

cleaning agent are gone.

5. Stop the engine and allow the engine to cool.

Loosen the cooling system filler cap slowly

in order to relieve any pressure. Remove the

cooling system filler cap. Open the drain valve

(if equipped) or remove the cooling system

drain plugs. Allow the water to drain. Flush the

cooling system with clean water. Close the drain

valve (if equipped). Clean the drain plugs. Install

the drain plugs. Refer to the Operation and

Maintenance Manual, “Torque Specifications”

topic (Maintenance Section) for more information

on the proper torques.

Cooling Systems with Heavy

Deposits or Plugging

Note: For the following procedure to be effective,

there must be some active flow through the cooling

system components.

1. Flush the cooling system with clean water in order

to remove any debris.

2. Close the drain valve (if equipped). Clean the

drain plugs. Install the drain plugs. Refer to the

Operation and Maintenance Manual, “Torque

Specifications” topic (Maintenance Section) for

more information on the proper torques.

NOTICE

Fill the cooling system no faster than 19 L (5 US gal)

per minute to avoid air locks.

3. Fill the cooling system with a mixture of clean

water and Caterpillar Fast Acting Cooling System

Cleaner. Add .5 L (1 pint) of cleaner per 3.8 to 7.6 L

(1 to 2 US gal) of the cooling system capacity.

Install the cooling system filler cap.

4. Start and run the engine at low idle for a minimum

of 90 minutes. The coolant temperature should be

at least 82 °C (180 °F).

NOTICE

Improper or incomplete rinsing of the cooling system

can result in damage to copper and other metal com-

ponents.

To avoid damage to the cooling system, make sure

to completely flush the cooling system with clear wa-

ter. Continue to flush the system until all signs of the

cleaning agent are gone.

64

Maintenance Section

Cooling System Coolant (ELC) - Change

5. Stop the engine and allow the engine to cool.

Loosen the cooling system filler cap slowly

in order to relieve any pressure. Remove the

cooling system filler cap. Open the drain valve

(if equipped) or remove the cooling system

drain plugs. Allow the water to drain. Flush the

cooling system with clean water. Close the drain

valve (if equipped). Clean the drain plugs. Install

the drain plugs. Refer to the Operation and

Maintenance Manual, “Torque Specifications”

topic (Maintenance Section) for more information

on the proper torques.

Fill

NOTICE

Fill the cooling system no faster than 19 L (5 US gal)

per minute to avoid air locks.

1. Fill the cooling system with coolant/antifreeze.

Refer to the Operation and Maintenance

Manual, “Cooling System Specifications” topic

(Maintenance Section) for more information on

cooling system specifications. Do not install the

cooling system filler cap.

2. Start and run the engine at low idle. Increase the

engine rpm to 1500 rpm. Run the engine at high

idle for one minute in order to purge the air from

the cavities of the engine block. Stop the engine.

3. Check the coolant level. Maintain the coolant level

within 13 mm (.5 inch) below the bottom of the

pipe for filling. Maintain the coolant level within

13 mm (.5 inch) to the proper level on the sight

glass (if equipped).

4. Clean the cooling system filler cap. Inspect the

gasket that is on the cooling system filler cap. If

the gasket that is on the cooling system filler cap

is damaged, discard the old cooling system filler

cap and install a new cooling system filler cap.

If the gasket that is on the cooling system filler

cap is not damaged, perform a pressure test. A

9S-8140 Pressurizing Pump is used to perform

the pressure test. The correct pressure for the

cooling system filler cap is stamped on the face of

the cooling system filler cap. If the cooling system

filler cap does not retain the correct pressure,

install a new cooling system filler cap.

5. Start the engine. Inspect the cooling system for

leaks and for proper operating temperature.

i00906586

Cooling System Coolant (ELC)

- Change

SMCS Code: 1350-070; 1395-044

Clean the cooling system and flush the cooling

system before the recommended maintenance

interval if the following conditions exist:

•

The engine overheats frequently.

•

Foaming is observed.

•

The oil has entered the cooling system and the

coolant is contaminated.

•

The fuel has entered the cooling system and the

coolant is contaminated.

Note: When the cooling system is cleaned, only

clean water is needed when the ELC is drained and

replaced.

Note: Inspect the water pump and the water

temperature regulator after the cooling system has

been drained. This is a good opportunity to replace

the water pump, the water temperature regulator and

the hoses, if necessary.

Drain

Pressurized System: Hot coolant can cause seri-

ous burns. To open the cooling system filler cap,

stop the engine and wait until the cooling system

components are cool. Loosen the cooling system

pressure cap slowly in order to relieve the pres-

sure.

1. Stop the engine and allow the engine to cool.

Loosen the cooling system filler cap slowly in

order to relieve any pressure. Remove the cooling

system filler cap.

2. Open the cooling system drain valve (if equipped).

If the cooling system is not equipped with a drain

valve, remove the cooling system drain plugs.

Allow the coolant to drain.

NOTICE

Dispose of used engine coolant properly or recycle.

Various methods have been proposed to reclaim used

coolant for reuse in engine cooling systems. The full

distillation procedure is the only method acceptable by

Caterpillar to reclaim the used coolant.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 98 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Get your hands on the comprehensive Maintenance Intervals manual for the 2007 Marine Engine. This manual is an invaluable resource for both professional mechanics and DIY enthusiasts. It provides detailed guidance on maintenance schedules, including crucial intervals for servicing various components. Whether you're looking to ensure optimal performance or extend the lifespan of your marine engine, this manual equips you with the necessary information to keep your engine running smoothly.