VANGUARD 3CYL. Diesel & TURBO-Diesel Engine Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

FORM MS-1055-5/02 2002 BRIGGS & STRATTON DAIHATSU LLC PRINTED IN U.S.A.

REPAIR MANUAL

For 3 Cylinder LiquidĆCooled Diesel Engines

FOREWORD

The information, procedures and specifications provided in this repair manual are current as of the date of

publication and subject to change without notice. Appropriate changes will be included in the next revision of this

manual.

Note: Manufacturing standards may vary from service specifications. Always refer to the service procedures and

specifications in this manual when engine service is required.

GENERAL REPAIR INSTRUCTIONS

Before attempting a B&SD engine overhaul or a tune-up, it is necessary that your shop be equipped with proper tools,

equipment and mechanics who are thoroughly familiar with Briggs & Stratton engine design and construction. With

your shop thus equipped, this book will serve as a guide in performing the various steps necessary to do a complete

and satisfactory job. Use only genuine replacement parts. Always use recommended service tools.

This engine is designed and manufactured using metric dimensions. The English equivalents provided may have been

rounded up or down to the closest numerical interpretation of the metric dimension.

The terms Inspect, Check, Test and Replace are used as follows:

INSPECT Visual inspection look for signs of wear, scoring, cracks, stripped threads, etc.

CHECK Measure by means of plug gauges, micrometer, feeler gauges, scale, etc.

TEST Analyze with proper test equipment.

REPLACE This usually means to take off the old part and reassemble it or replace it with a new one.

Disassembly

As engine is being disassembled, mark parts which are part of an assembly, to prevent interchanging. Arrange parts in

an orderly manner, keeping parts which are an assembly together.

Visually inspect each part as it is removed look for signs of wear, scoring, cracks, stripped threads, etc.

Inspection and Measurement

Carefully check parts that can be reconditioned and/or reused.

Replace any parts that are not within specification.

Clean parts to be reused

Clean or wash disassembled parts.

Assemble

Use a torque wrench to torque bolts and nuts to required specifications.

Replace all gaskets, cotter pins, oil seals and O-rings.

ABBREVIATIONS

Abbreviation Meaning

ASSY Assembly

BDC Bottom Dead Center

DT Diesel Turbocharger

EX Exhaust

ID Inside Diameter

IN Intake

LH Left Hand

MP Multi-purpose

Abbreviation Meaning

OD Outside Diameter

OPT Optional

O/S Oversize

RH Right Hand

SAE Society of Automotive

Engineers

T/C Turbocharger

TDC Top Dead Center

U/S Undersize

Copyright " 2002 by Briggs & Stratton Corporation

All rights reserved. No part of this material may be reproduced or

transmitted, in any form or by any means, electronic or mechanical,

including photocopying, recording or by any information storage

and retrieval system, without permission in writing from Briggs &

Stratton Corporation.

TABLE OF CONTENTS

See Pages II and III for Section Contents

GENERAL INFORMATION Section 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CYLINDER HEAD AND VALVES Section 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TIMING GEARS AND GEAR CASE Section 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FLYWHEEL AND REAR SEAL RETAINER Section 4 . . . . . . . . . . . . . . . . . . . . . . .

CYLINDER BLOCK DISASSEMBLY Section 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CYLINDER BLOCK INSPECTION AND REPAIR Section 6 . . . . . . . . . . . . . . . . . .

CRANKSHAFT, CAMSHAFT AND BEARINGS Section 7 . . . . . . . . . . . . . . . . . . . .

PISTON, RINGS AND CONNECTING ROD

INSPECTION AND ASSEMBLY Section 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CYLINDER BLOCK ASSEMBLY Section 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FUEL SYSTEM AND RELATED COMPONENTS Section 10 . . . . . . . . . . . . . . . . .

ELECTRICAL SYSTEMS Section 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LUBRICATION SYSTEM Section 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COOLING SYSTEM Section 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TOOLS Section 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I

SECTION CONTENTS

IV

1

Section 1

GENERAL INFORMATION

Engine Identification

In The Interest Of Safety

Engine Views

Engine Specifications And Data

Fastener Specifications

Briggs & Stratton Numerical Number System

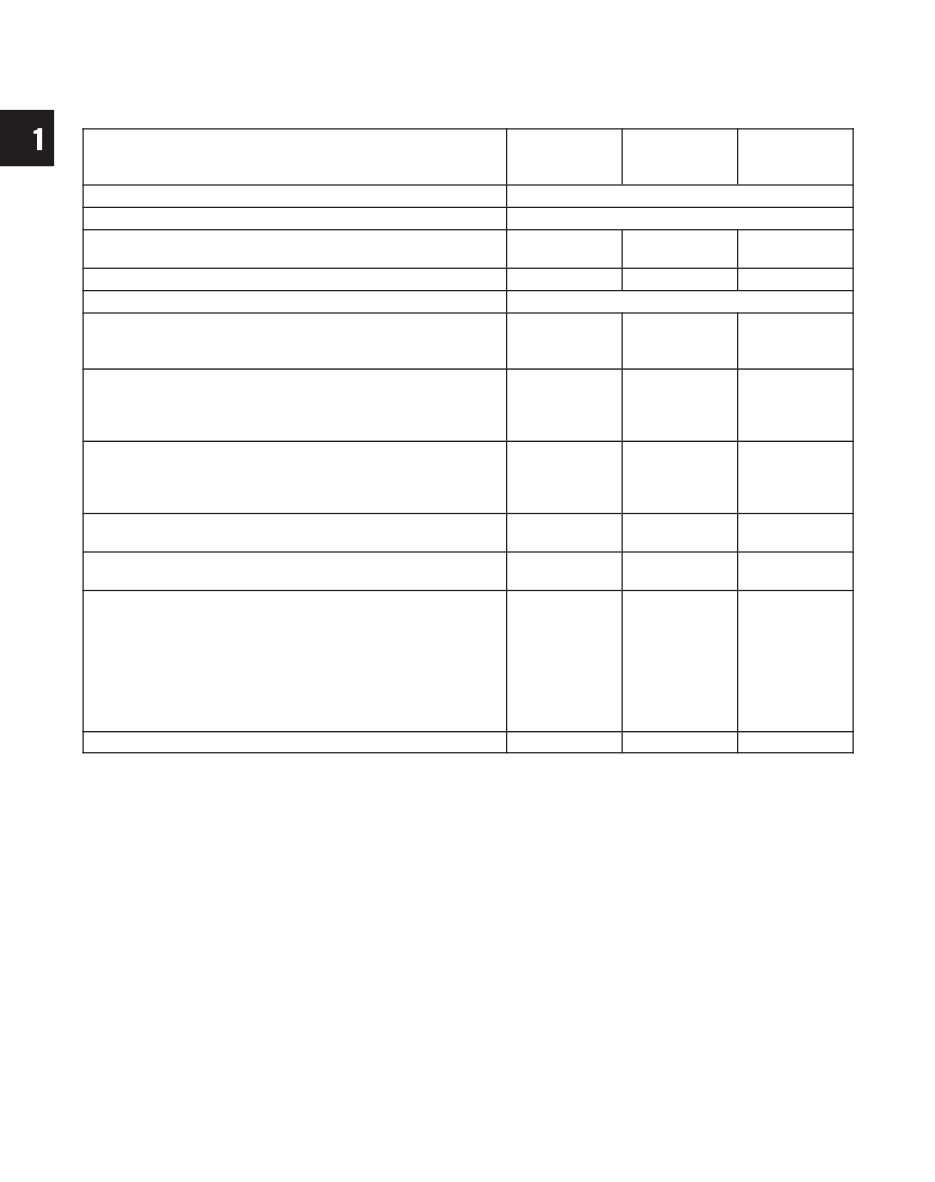

Maintenance Schedule

2

Section 2

CYLINDER HEAD AND VALVES

Remove Cylinder Head

Disassemble Cylinder Head

Inspect And Repair

Cylinder Head

Valve Guides

Valves

Disassemble Rocker Arm Shaft

Assemble Rocker Arm Shaft

Assemble Cylinder Head

Install Cylinder Head

Adjust Valves

3

Section 3

TIMING GEARS AND GEAR CASE

Remove Timing Gear Cover And Gears

Checking Gears

Remove Gear Case

Replace Timing Gear Cover Oil Seal

Assemble Timing Gear Case And Gears

4

Section 4

FLYWHEEL AND REAR SEAL RETAINER

Removing Flywheel And Rear Seal Retainer

Replacing Oil Seal

Installing Rear Seal Retainer And Flywheel

Install Oil Pan

5

Section 5

CYLINDER BLOCK DISASSEMBLY

Engine Stand Fixture

Cylinder Block Disassembly

6

Section 6

CYLINDER BLOCK INSPECTION AND

REPAIR

Checking Cylinder Block

Replacing Camshaft Bearing

Replacing Camshaft Plug

7

Section 7

CRANKSHAFT, CAMSHAFT AND BEARINGS

Checking Crankshaft

Checking Main Bearing Clearances

Checking Connecting Rod Bearing Clearances

Checking Crankshaft End Play

Checking Camshaft

8

Section 8

PISTON, RINGS AND CONNECTING ROD

INSPECTION AND ASSEMBLY

Disassemble Piston And Connecting Rod

Checking Piston And Rings

Checking Piston Pin And Connecting Rod

Assemble Piston And Connecting Rod

Assemble Piston Rings To Piston

9

Section 9

CYLINDER BLOCK ASSEMBLY

Install Crankshaft

Install Pistons And Connecting Rods

General Assembly

Oil Pickup Tube

Rear Seal Retainer And Starter Motor

Flywheel

Install Timing Gear Case, Camshaft And

Gears

Install Oil Pan

Install Alternator

10

Section 10

FUEL SYSTEM AND RELATED

COMPONENTS

General Information

Injector Pump Timing Specifications

Checking Injector Pump Timing

SECTION CONTENTS (contd)

III

Adjusting Injector Pump Timing

Injectors

Remove Injectors

Checking Injectors

Install Injectors

Fuel Filter General

Draining Water Collector

Change Fuel Filter

Fuel Shut-Off Solenoid

Checking Fuel Shut-Off Solenoid

Wiring

Injector Pump Identification

Engine Speed Identification Chart

Adjust Idle Speed

Adjust Top No Load Speed

11

Section 11

ELECTRICAL SYSTEMS

Electrical System Components

Glow Plug System

Glow Plug Specifications

Remove Glow Plugs

Test Equipment

Testing Glow Plug

Preheat Timer And Glow Relay

Testing Preheat Timer

Testing Glow Relay

Keyswitches

Charging Systems

14 Amp Charging System

Test Equipment

Testing Alternator AC Output

Testing Regulator-Rectifier DC

Output

Testing Charge Indicator Bulb And

Wiring

40 Amp Charging System

Test Equipment

Testing Alternator DC Output

Disassemble Alternator

Checking Bearings

Install Ball Bearing

Check Brushes

Check Regulator

Check Rectifier

Assemble Alternator

Starter System

Starter Current Draw Test Installed

Test Equipment

Testing Starter

Starter Current Draw Test No Load

Testing Starter (No Load)

Starter Solenoid

Equipment To Test Solenoid

Testing Solenoid

Remove Solenoid

Check Pinion And Clutch Assembly

Assemble Pinion And Clutch Assembly

Install Solenoid

Install Solenoid Contacts And Plunger

Disassemble Starter Motor

Inspect Armature Commutator

Inspect Brushes

Replace Brushes

Assemble Starter Motor

Wiring Diagrams

40 Amp Wiring Diagram

14 Amp Wiring Diagrams

12

Section 12

LUBRICATION SYSTEM

Description

Change Oil

Change Oil Filter

Check Oil Pressure

Disassemble Gear Case

Remove Oil Pump

Assemble Gear Case

Install Oil Pump

13

Section 13

COOLING SYSTEM

General Information

Checking Cooling System

Pressure Testing Cooling System

Testing Radiator Cap

Changing Coolant

Thermostat

Removing Thermostat

Checking Thermostat

Installing Thermostat

Water Pump

Inspecting Water Pump

Removing Water Pump

Installing Water Pump

SECTION CONTENTS

IV

14

Section 14

TURBOCHARGER

General Information

Turbocharger Lubrication System

Turbocharger Cooling System

Turbocharger Waste Gate

Turbocharger Pressure Control System

Crankcase Bloeby Recirculating System

Checking Waste Gate Actuator

Servicing And Operating Information

Remove Turbocharger

Checking Turbocharger

Install Turbocharger

Installation Of Coolant Inlet Tube

1 MAY 2002

Section 1

General Information

BRIGGS & STRATTON DAIHATSU 3 CYLINDER

LIQUID-COOLED DIESEL ENGINE REPAIR MANUAL (MS-1055)

Section Contents

Page

ENGINE IDENTIFICATION 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IN THE INTEREST OF SAFETY 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE VIEWS 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE SPECIFICATIONS AND DATA 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FASTENER SPECIFICATIONS 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BRIGGS & STRATTON NUMERICAL NUMBER SYSTEM 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE SCHEDULE 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE IDENTIFICATION NUMBERS

The engine model and type number are located on the vale cover, Fig. 1. The serial number is stamped into the right

side of the cylinder block, behind the intake manifold, Fig. 2.

Fig. 1 Engine Model And Type Number

MODEL AND

TYPE NO.

Fig. 2 Engine Serial Number

SERIAL NO.

2

GENERAL INFORMATION

IN THE INTEREST OF SAFETY

This safety alert symbol indicates that this

message involves personal safety. Signal

words danger, warning and caution indicate

hazard degree. Death, personal injury and/OR

property damage may occur unless instruc-

tions are followed carefully.

WARNING: DO NOT

1. DO NOT run engine in an enclosed area. Exhaust

gases contain carbon monoxide, an odorless and

deadly poison.

2. DO NOT place hands or feet near moving or

rotating parts. Keep all guards in place.

3. DO NOT place hands or feet near electric cooling

fan (if equipped). Fan may start suddenly, de-

pending on coolant temperature.

4. DO NOT store, spill, or use diesel fuel near an

open flame, or devices such as a stove, furnace,

or water heater which use a pilot light or devices

which can create a spark.

5. DO NOT refuel indoors where area is not well

ventilated. Outdoor refueling is preferred.

6. DO NOT fill fuel tank while engine is running. Allow

engine to cool for 2 minutes before refueling.

Store fuel in approved, correct color safety

containers.

7. DO NOT remove fuel tank cap while engine is

running.

8. DO NOT operate engine when smell of fuel is

present or other explosive conditions exist.

9. DO NOT operate engine if diesel fuel is spilled.

Move machine away from the spill and avoid

creating any ignition until the spill has been

wiped up.

10. DO NOT smoke when filling fuel tank.

11. DO NOT tamper with maximum speed set screw

or full load set screw of the injector pump which

may increase the governed engine speed.

12. DO NOT tamper with the engine speed selected

by the original equipment manufacturer.

13. DO NOT operate engine with a damaged muffler

or without muffler. Inspect periodically and

replace, if necessary. If engine is equipped with

muffler deflector(s), inspect periodically and

replace, if necessary, with correct deflector(s).

14. DO NOT operate engine with an accumulation of

grass, leaves, dirt or other combustible material in

the muffler area.

15. DO NOT use this engine on any forest covered,

brush covered, or grass covered unimproved land

unless a spark arrester is installed on the muffler.

The arrester must be maintained in effective

working order by the operator. In the State of

California the above is required by law (Section

4442 of the California Public Resources Code).

Other states may have similar laws. Federal laws

apply on federal lands.

16. DO NOT touch hot muffler(s) or cylinder(s)

because contact may cause burns.

17. DO NOT remove the radiator cap while the engine

is hot. To avoid scalding from hot coolant or steam

blowing out of the radiator, use extreme care when

removing the radiator cap. If possible, wait for

engine to cool. If not possible, wrap a thick rag

around cap while removing. To release pressure,

slowly turn cap counter clockwise to the first stop.

When all pressure has been released, press down

on cap and continue turning.

18. DO NOT start or run engine with air cleaner or air

cleaner cover removed.

WARNING: DO

1. ALWAYS DO disconnect the negative wire from

the battery terminal when servicing the engine or

equipment, TO PREVENT ACCIDENTAL

STARTING.

2. ALWAYS DO disconnect fuel shut off solenoid wire

from injection pump before checking compression,

TO PREVENT ACCIDENTAL STARTING.

3. DO wear eye protection when operating or

repairing equipment.

4. DO keep governor parts free of grass and other

debris which can affect engine speed.

5. DO examine muffler(s) periodically to be sure it is

functioning effectively. A worn or leaking

muffler(s) should be repaired or replaced as

necessary.

6. DO check fuel lines and fittings frequently for

cracks or leaks. Replace if necessary.

CAUTION:

DO use clean fresh diesel fuel with a minimum of 40

cetane.

DO NOT use kerosene. The injection pump requires

diesel fuel for lubrication. Damage to the injection

pump and/or engine may result if kerosene is used.

NOTE: Use Original Briggs & Stratton-Daihatsu

Service Replacement Parts when

servicing your engine. Authorized Briggs

& Stratton-Daihatsu Service Centers

carry a stock of such parts. The use of

Briggs & Stratton-Daihatsu parts

preserves the original design of your

engine. Imitation replacement parts may

not fit or function as original Briggs &

Stratton-Daihatsu parts and can expose

the operator to potential personal injury.

Contact any Authorized Briggs &

Stratton-Daihatsu Service Center for

Original Briggs & Stratton-Daihatsu

Replacement Parts.

3

GENERAL INFORMATION

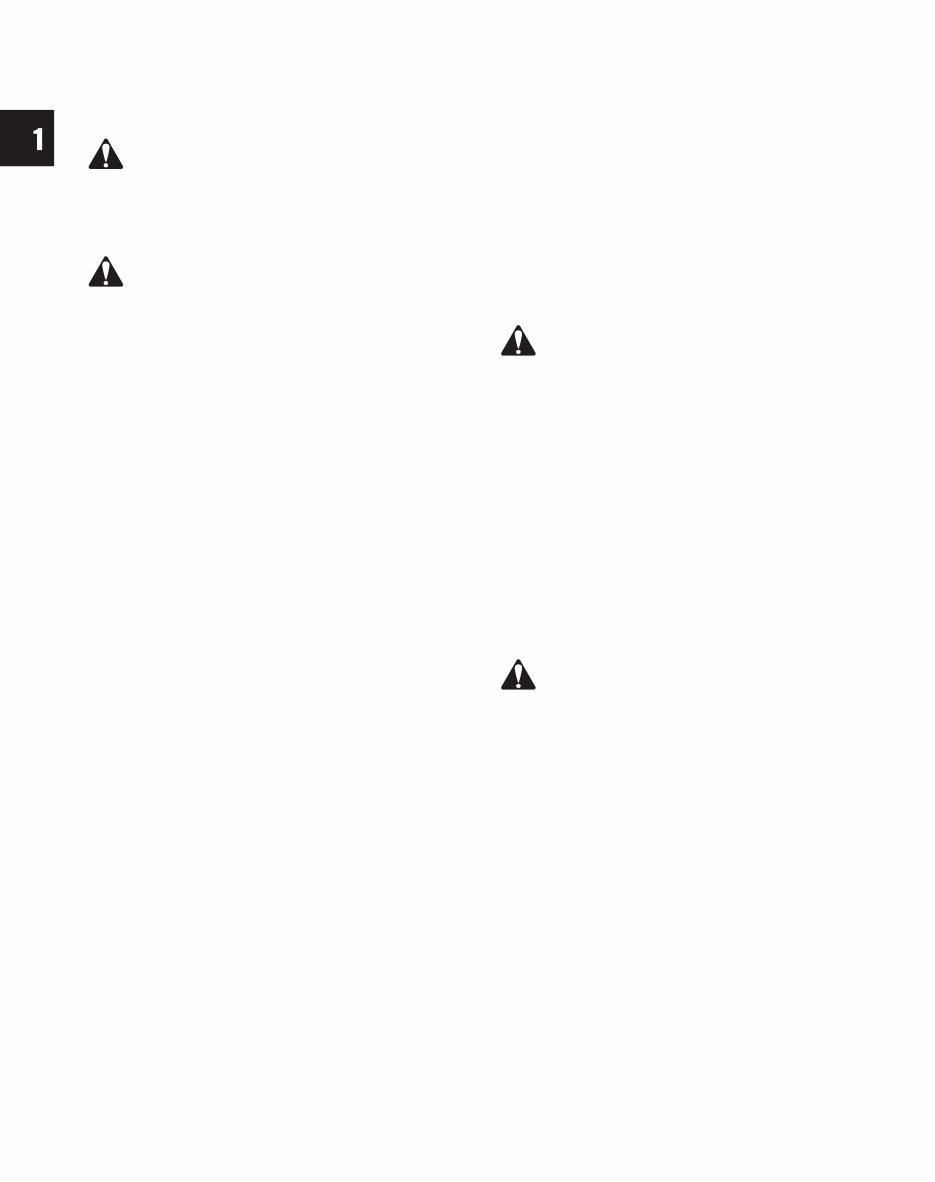

ENGINE VIEWS

1. Thermostat

2. Oil filler cap

3. Electric starter

4. Oil pan

5. Alternator

2

3

5

4

Diesel

1

11

6. Injector nozzle

7. Glow plug

8. Oil drains

9. Oil filter

10. Dipstick

11. Injector pump

12. Engine Date code

xxxxxxxx

13. Engine Model & Type number

xxxxxx xxxx-xx

7

10

13

9

6

8

12

1. Thermostat

2. Oil filler cap

3. Turbocharger

4. Electric starter

5. Alternator

6. Oil pan

Turbo-charged

Diesel

7. Injector nozzle

8. Glow plug

9. Oil drains

10. Oil cooler

(if equipped)

11. Oil filter

12. Dipstick

13. Injector pump

14. Engine Date code

xxxxxxxx

15. Engine Model & Type number

xxxxxx xxxx-xx

4

GENERAL INFORMATION

ENGINE SPECIFICATIONS

Model 432447 522447

582447

@58A447

@588447

Type Diesel, 4-cycle, 3 cylinder, in-line, liquid cooled

Valve mechanism OHV, gear driven

Bore x stroke mm (in)

68 x 64

(2.680 x 2.520)

68 x 78

(2.680 x 3.070)

72 x 78

(2.834 x 3.070)

Piston displacement cc (cu in) 697 (42.5) 850 (52.0) 952 (58.1)

Firing order 1-2-3 (front, center, back)

Compression ratio 25.0:1 24.4:1

24.0:1

@ 24.8:1

Compression pressure (normal)

@

300 RPM Bar

Engine at operating temperature (psi)

glow plugs removed

33.0

(469)

32.0

(455)

34.0

(498)

@ 37

(526)

Compression pressure (minimum)

@

300 RPM Bar

Engine at operating temperature (psi)

glow plugs removed

30.0

(425)

29.0

(412)

30.5

(433)

@ 27

(384)

Gross HP @ 3600 RPM 19.5 23.6

26.5

@ 28.0

Gross Torque @ 2400 RPM 32.5 40.0

44.1

@ 49.2

Dimensions (L x W x H) mm (in)

441.8 x 440.4 x

523.9

(17.4 x 17.34 x

20.6)

434.4 x 442.9 x

548.4

(17.1 x 17.44 x

21.59)

434.4 x 442.9

x 548.4

(17.1 x 17.44 x

21.59)

@ 434.4 x

447.5 x 559.0

(17.1 x 17.62 x

22.01)

Dry weight kg (lbs) 76 (168) 78 (172) 89 (196)

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$37.99

Viewed 56 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$37.99

This workshop repair service manual is designed for the VANGUARD 3CYL. DIESEL & TURBO-DIESEL ENGINE, applicable to various engine models:

- 697 cc 3-CILINDER, 4-CYCLE, IN-LINE, LIQUID-COOLED, OHV, GEAR DRIVEN DIESEL ENGINE for 432447 model

- 850 cc 3-CILINDER, 4-CYCLE, IN-LINE, LIQUID-COOLED, OHV, GEAR DRIVEN DIESEL ENGINE for 522447 model

- 952 cc 3-CILINDER, 4-CYCLE, IN-LINE, LIQUID-COOLED, OHV, GEAR DRIVEN DIESEL ENGINE for 582447/58A447/588447 model

The manual includes detailed information on the following:

- General information

- Cylinder head & valves

- Timing gear & gear case

- Flywheel system

- Seal retainer

- Cylinder block disassembly, inspection, and repair

- Crankshaft/camshaft/bearings

- Piston/rings/connecting rod inspection and assembly

- Fuel system and fuel injector pump

- Electrical system, glow plug system, charging system, and starter system

- Lubrication system and cooling system

- Turbocharger

- Wiring diagram

This comprehensive manual is available in .PDF format and features detailed exploded views, step-by-step written procedures with pictures and diagrams, and is fully printable. It is an essential resource for both professional mechanics and DIY enthusiasts for repairs, maintenance, and servicing of VANGUARD 3CYL. DIESEL & TURBO-DIESEL ENGINES.