MTD REAR Engine RIDERS Lawn TractorS Service Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

MTD SERVICE LLC Product Training and Education Department

For Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

TABLE OF CONTENTS

WORK SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 1

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 2

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Batteries And Charging Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

ELECTRICAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 3

Safety Interlock Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Safety Interlock Systems - Changes for 1991 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Electric Start System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Recoil Start System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Safety Interlock Systems Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Troubleshooting Safety Interlock Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Evaluating Electric Clutches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-56

BELTS AND DRIVE SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 4

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Proper Storage of Belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Causes of V-Belt Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

V-Belt Problems with Rotary Tillers, Self-Propelled Mowers and Riding Mowers . . . . . . . . . . . . . . . . . . . . 4-4

Belt Wear Due to Normal Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Pulley Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Idlers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Maintenance Of Variable Speed Pulleys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Four Wheel Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Disassembly Of Four Wheel Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Brake Adjustment for 600 and 700 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

HYDROSTATIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 5

TRANSAXLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 6

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Transaxle Changes For 1990, 1991, 1992 and 1997 Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Disassembly/Assembly of Transaxle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Hydrostatic Transaxle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Integrated Hydrostatic Transaxle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

LAWN TRACTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 7

300 and 400 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Rear Engine Riding Mowers 500 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Transmatic LT 600A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Hydrostatic Drive 700 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-35

YARD BUG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 8

Deck Leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Brake Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Blade Brake/PTO Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Speed Control Pedal Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Steering Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Removal and Installation of Deck Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

Removal and Installation of Mowing Deck Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

Removal and Replacement of the Drive Belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

Transmission Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

Transmission Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

Transmission Reassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-23

2

3

4

5

6

1

7

8

For Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

AUTO DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 9

Leveling the Cutting Deck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Deck Belt Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

Cutting Deck Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

Brake Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Autodrive Pedal Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Drive Belt Removal and Reinstallation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Transmission Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

Transmission Disassembly and Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

Deck Belt Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-14

Hydrostatic Transmission Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-16

Steering Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-20

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-21

Autodrive/Autocruise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-30

MTD Z SERIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 10

Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Neutral/Steering Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Removal of ZTT Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-8

Transmission Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-13

ZERO TURN TRACTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Section 11

624 Zero Turn Tractor - The Revolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

46" Cutting Deck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

Cutting Deck Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

Lower Deck Belt Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-3

Servicing the IZT Drive Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-3

Servicing the IZT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-7

Adjustments to the IZT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-9

Parking Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-10

Under Dash Service Points1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-11

Dash Panel Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-12

Front Axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-16

ATTACHMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 12

Cutting Decks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-3

Improvements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-22

Grass Collectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-37

Front Bumper. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-39

Trapac . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-39

42" Dozer Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-40

GLOSSARY

9

10

11

12

Glossary

For Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

1-1

1

1. To prevent accidental starting, always pull the

high tension wire(s) off the spark plug(s) before

servicing and/or adjusting the machine.

2. To prevent injury, do not allow children or

bystanders around the machine while it is

being adjusted and/or serviced.

3. Do not wear rings, wrist watches or loose fitting

clothing when working on machinery; they

could catch on moving parts causing serious

injury. Wear sturdy, rough-soled work shoes.

Never adjust and/or service a machine in bare

feet, sandals or sneakers.

4. Always wear safety glasses when using a

hammer, chisel or other tools that may cause

chips to fly.

5. Be sure to reinstall safety devices, guards or

shields after adjusting and/or servicing the

machine.

6. When operating a power washer to clean a

machine before servicing, be careful at all

times to avoid injury. Maintain proper footing

and balance at all times. Never direct the spray

at people or animals, as high pressure spray

can cause serious injury.

7. If a portable heater is used to heat the service

area, the following precautions must be

observed

a. Do not use portable heaters in presence of

volatile materials such as gasoline or paint,

as fire or explosion may result.

b. To avoid being burned, do not touch the

heater during operation.

c. Portable heaters consume oxygen and

combustion fumes can be hazardous.

Heater should be used only in a well-venti-

lated area. Keep a window or door partially

open to provide ventilation.

d. Keep the heater at least four feet from

combustible materials.

e. Never use gasoline as fuel.

8. Handle gasoline with care—it is highly flamma-

ble.

a. Use approved gasoline container.

b. Never remove the fuel tank cap or fill the

fuel tank when the engine is running, is hot

or indoors. Also, do not smoke when working

around flammable fuel.

c. Avoid fires—be sure container or funnel

does not touch the battery. Do not overfill

the fuel tank. Wipe up spilled gasoline.

d. Replace fuel tank cap securely.

9. Never use trouble lights or electric powered

tools that have cut and/or damaged cords or

plugs. Be sure all electric tools are properly

grounded.

10. Never run an engine in a confined area such

as a garage or storage building any longer

than is necessary for immediate moving of the

machine out of or into the area. EXHAUST

GASES ARE TOXIC. OPENING DOORS AND

WINDOWS MAY NOT PROVIDE ADEQUATE

VENTILATION.

11. After servicing, be sure all tools, parts or ser-

vicing equipment are removed from the

machine.

12. Electrical storage batteries give off highly

inflammable hydrogen gas when charging and

continue to do so for some time after receiving

a steady charge. Do not under any circum-

stances allow an electric spark or an open

flame near the battery. Always disconnect a

battery cable before working on the electrical

system.

WORK SAFELY—FOLLOW THESE RULES

This symbol is used to call your attention to instructions concerning

your personal safety. Be sure to observe and follow these instructions.

For Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

1-2

13. Hydraulic fluid escaping under pressure can

have enough force to penetrate the skin.

Hydraulic fluid may also infect a minor cut or

opening in the skin. If injured by escaping fluid,

see a doctor at once. Serious infection or reac-

tion can result if medical treatment is not given

immediately. Do not attempt to repair or tighten

hoses that are under pressure, when the boom

is raised or with the tractor engine running.

Cycle all hydraulic control valves to relieve all

pressure before disconnecting the lines or per-

forming other work on the hydraulic system.

Make sure all connections are tight and hoses

and lines are in good condition before applying

pressure to the system. To locate a leak under

pressure, use a small piece of cardboard or

wood. Never use hands.

14 When using an acetylene torch, always wear

welding goggles and gloves. Keep a charged

fire extinguisher within reach. Do not weld or

heat areas near fuel tanks or fuel lines and uti-

lize proper shielding around hydraulic lines.

15. Always use safety stands in conjunction with

hydraulic jacks or hoists. Do not rely on the

jack or hoist to carry the load; it could fail.

Always use a safety bar to block hydraulic cyl-

inders.

16. When splitting tractors or disassembling

machines, be sure to use safety stands and

adequate supports to prevent tipping or roll-

over.

17. Use a safety catch on all hoist hooks. Do not

take a chance, the load could slip off the hook.

18. Use pullers to remove bearings, bushings,

gears, cylinder sleeves, etc. when applicable.

Use hammers, punches and chisels only when

absolutely necessary. Then, be sure to wear

safety glasses.

19. Be careful when using compressed air to dry

parts. Use approved air blow guns, do not

exceed 30 psi, wear safety glasses or goggles

and use proper shielding to protect everyone in

the work area.

20. Petroleum based solvents, often used for

cleaning parts, are flammable. Use care to

avoid fire or explosion when using these sol-

vents.

IMPORTANT : The above is only a partial list of

safe work rules. In addition, always refer to the

Operator’s Manual for the specific machine for

additional safe work rules regarding the

machine operation.

For Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

2-1

2

2-1. SAFETY PRECAUTIONS.

2-1.1 Refer to the Safety Summary on page 1-1, and

observe all WARNINGS and CAUTIONS when

servicing equipment covered in this manual.

2-2. GENERAL.

2-2.1 This service manual covers lawn mowers, rid-

ing equipment, snowthrowers, chore perform-

ers, rotary tillers and accessories through

model year 1998.

2-2.2 More detailed instructions can be found in

each of the individual model service manuals.

2-3. REFERENCE DATA.

2-3.1 Serial Number Location. Serial number plate is

located behind the seat on the rear fender. See

Figure 2-1.

NOTE

LEFT and RIGHT indicate the left and right

side when facing forward in the driver’s seat or

behind the piece of equipment.

2-4. NUMBERING SYSTEM.

2-4.1 Due to the many different models, types of

equipment and parts, it is very important to

understand the MTD numbering system and

how it is used. The following pages, Figures

and Tables will explain the system and what

each number and digit means.

NOTE

IMPORTANT: When ordering replacement

parts, it is necessary to use both the model

number and the date code.

2-4.2 Due to the many different colors of rims and

different tire tread designs on riding mowers,

orders for replacement tires and wheel assem-

blies must specify both color and tire brand.

These can be identified by using the appropri-

ate 900 series number after the part number.

NOTE

If you are entering an order electronically, the

tire identification number can be entered where

the paint code number is entered for a painted

part.

2-5. CUSTOMER NUMBERS.

2-5.1 In addition to customers who purchase tractors

and equipment marked with the MTD brand

and name logos, there are customers who

order tractors and equipment marked with their

own brand name and/or logos. Basic units are

the same except for color and decoration.

2-6. GENERAL.

2-6.1 The main storage or electrical power in our

electric start lawn mowers, riders and tractors

is the battery. With proper setup and mainte-

GENERAL INFORMATION AND SAFETY PRECAUTIONS

For Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

2-2

nance the battery will last for years. However,

in some remote cases even with proper main-

tenance a battery can lose power. This is

unavoidable and should be handled as per

warranty guidelines.

2-6.2 A chemical reaction between the battery’s

electrolyte and plates, or electrodes, will sup-

ply electrical energy to an external circuit.

When the battery is being used, or discharg-

ing, the positive plate (lead dioxide) and the

negative plate (sponge lead) are both changed

to lead sulphate. At the same time, part of the

electrolyte (diluted sulfuric acid) is changed to

water. This conversion of diluted sulfuric acid

to water reduces the specific gravity of the

electrolyte. By measuring this specific gravity,

a direct measure of how far the discharge pro-

cess has progressed can be made.

2-7. BATTERIES AND CHARGING RATES.

2-7.1 There are basically 5 different batteries used.

In this section we will show the battery number,

the replacement number, cause of replace-

ment, size, cold cranking amps and amp hours

at a given rate.

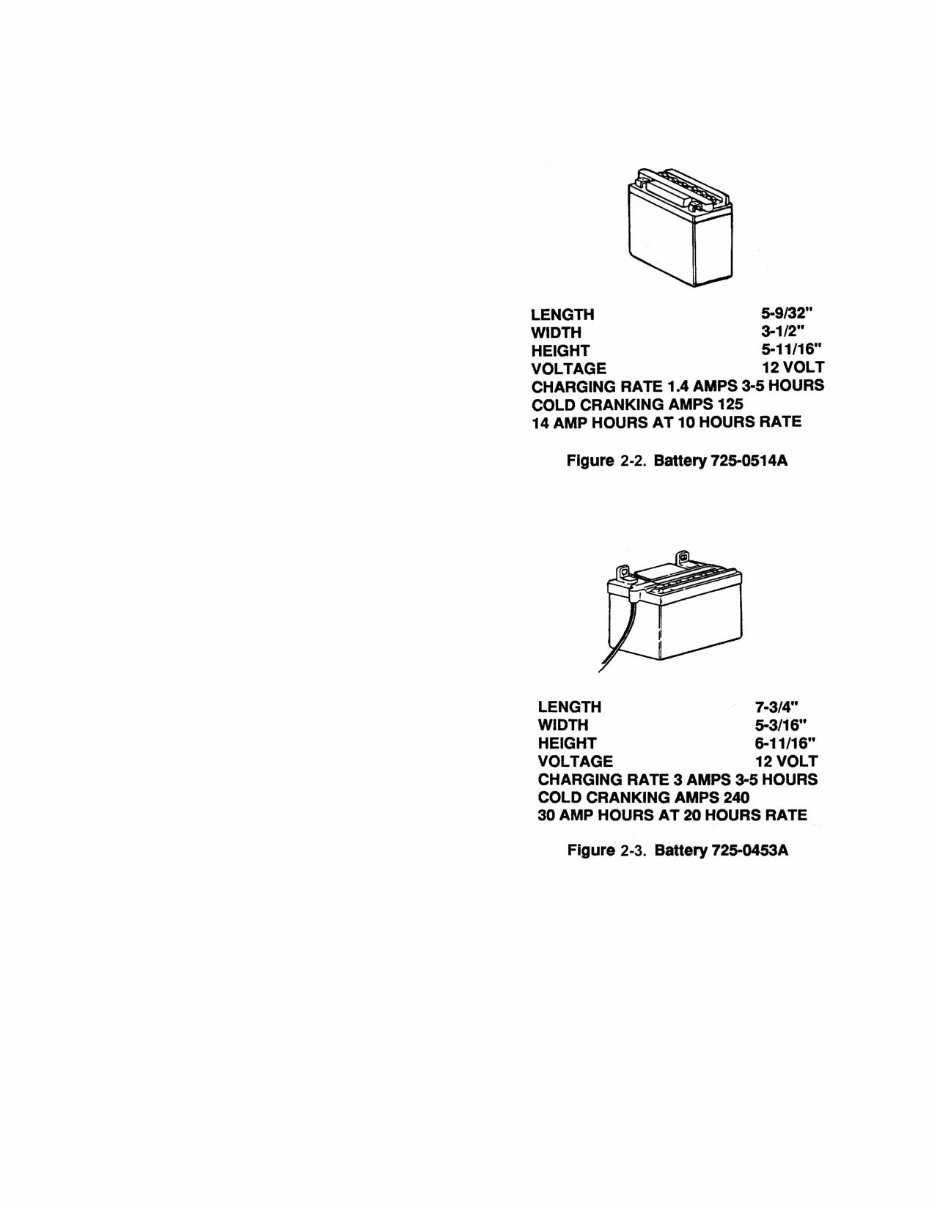

1. Battery 725-0514A (Figure 2-2) is replaced by

725-1633. These batteries are used on riders

and are the same size with the same cold

cranking amps. The number was changed due

to shipping regulations which would not allow

acid packs to be shipped with batteries. Acid

packs can be obtained by ordering part num-

ber 725-1637; however, we suggest dealer

obtain acid locally. Battery caps, part number

725-0691, can also be ordered separately.

2. Battery 725-0453A (Figure 2-3) is shipped with

no acid. Acid can be obtained by ordering part

number 725-1637, but it is suggested acid be

purchased locally. Battery caps can also be

purchased separately by ordering part number

725-0690. Battery 725-0453A was used on

1989 and prior 700 and 800 series tractors.

This battery is currently used in the 900 series

tractor.

3. Battery 725-1105 which was supplied in 1987

is no longer available. Use kit number 753-

0459 as a replacement. The kit includes a bat-

tery, cover and adapting clip. The larger termi-

nal end goes on the negative side of the

battery. The adapting clip also goes on the

negative side. The electric start unit uses a 7

amp fuse system

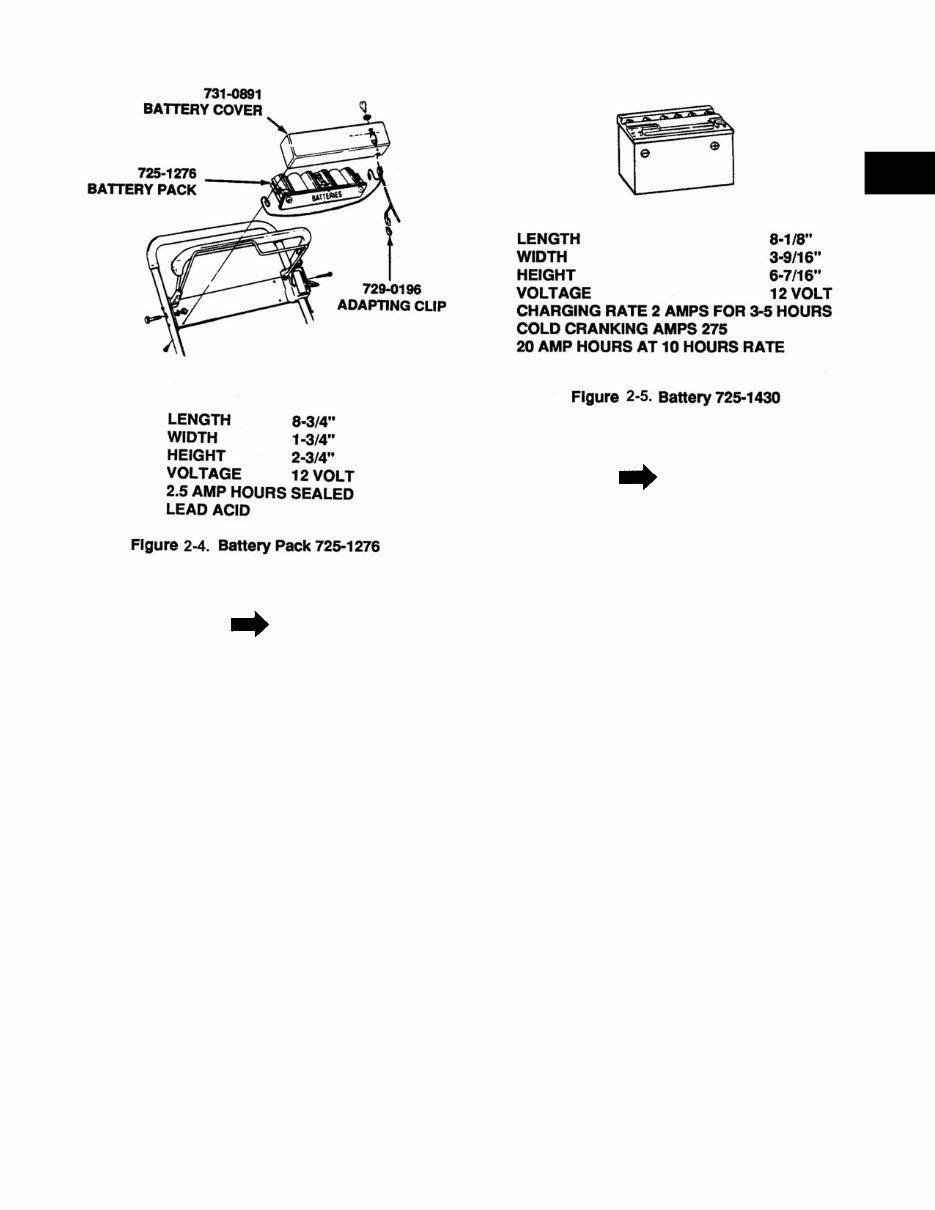

4. Battery pack 725-1276 (Figure 2-4) is installed

in electric lawn mowers.

BATTERIES AND CHARGING SYSTEMS

For Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

2-3

2

NOTE

During shipment, the hot wire can vibrate off

the battery and the unit will not start. Take the

battery cover off, hook up the wire and charge

the battery.

5. Battery 725-1430 (Figure 2-5) is replaced by

725-1635. These batteries are the same size

with the same cold cranking amp. The number

was changed due to shipping regulations

which do not allow acid packs to be shipped

with batteries. Acid packs can be obtained by

ordering part number 725-1637; however, we

suggest dealers obtain acid locally.

NOTE

Batteries 725-1430 only contain a special

chemical sulfate stop that has been added to

reduce sulfate crystal deposits (which eventu-

ally prevent the battery from accepting a

charge). Sulfate stop is a white powder chemi-

cal that may be visible before the battery is

activated, but dissolved once electrolyte is

added. After charging the battery (with sulfate

stop added), the specific gravity of electrolyte

rises to 1.280 or above. On a 5 ball hydrome-

ter, it is acceptable to see the fifth ball float. If

the battery contains sulfate stop and has not

been in use for a long period of time, extended

recharging time is required.

For Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

2-4

2-7.2 BATTERIES SECTION 1996-1998

#725-0453 E

Battery Type U1-11L

Dry 380 CCA Cold Cranking Amps @ Zero Degrees

Group No. U1L

Voltage 12V

Size Top 5.18 x 7.7

Number of plates 66

Height 6.12 to top of post 7.16

Weight wet 20.6 lbs.

Electrolyte capacity 72 oz.

Previously this battery was 240 CCA and it has been

upgraded to 380 CCA which gives added cranking

power in cold weather. It is shipped dry and it is sug-

gested that the acid should be purchased locally. The

acid pack number as shown is #725-1670 but acid is

considered to be hazardous material, therefore when

shipped, charges will be excessive due to special han-

dling.

Battery #725-1704

Note! New Warning symbols

Battery Type U-1

Wet 125 CCA Cold Cranking Amps

All batteries are date coded

Replaced by #725-1707 C DRY 275 CCA Cold

Cranking Amps

Size 5.18 x 7.7

Height 6.12 with Post 7.29

Voltage 12 volts

The #725-1704 is a wet battery meaning that it is

shipped in the rider and it is hooked up with the positive

terminal connected and the negative terminal has a

plastic cover over it to protect from shorting out. The

purpose of this is to assist stores with fast product turn-

over and in this manner the unit is ready to operate in

the least amount of set-up time.

Battery #725-1705C

WET 150 CCA Cold Cranking Amps.

Battery Type U-1

All batteries are date coded

Replaced by #725-1707C DRY 275 CCA Cold

Cranking Amps.

Voltage 12V

The #725-1705C is a wet battery and it is the same as

stated above. If a failure occurs in warranty the #725-

1707C will be shipped.

Battery #725-1706

WET 270 CCA Cold Cranking Amps.

Battery Type U-1

Negative terminal covered with a plastic cover and

shipped with the positive cable connected.

Replaced by #725-1707C DRY 275 CCA Cold

Cranking Amp.

All batteries are date coded

Battery is non-serviceable

Voltage 12V

The #725-1706 is a wet battery and is shipped in the

tractor and is ready to go by just removing the plastic

cover on the negative terminal and connecting the neg-

ative cable to the negative terminal.

Battery #725-1707C

DRY 275 CCA Cold Cranking Amps.

Battery Type U-1 Flat Top

Size 5.19 x 7.72

Height 6.12 Including Post 7.30

Voltage 12V

Manifold Vented

Specifications for ’97-’98 will be the same except all will

be flat top style. The knobs will be flush with the top of

the battery.

YUASA - EXIDE makes the DRY, add acid type batter-

ies EAST PENN makes the WET non-serviceable type

battery.

WET batteries are anticipated to be used in 50% of

our production for fast moving product customers, all

batteries can not be shipped wet because they would

have a shorter shelf life than a dry battery.

For ’97-’98 little changes are anticipated. Dependability

over all styles will remain the same. Replacement bat-

teries will continue to be shipped without acid, and acid

must be obtained locally due to acid being a hazardous

material, therefore requires special handling when

shipped.

New for ’98 season batteries will be similar in size but

top will be flat with nothing sticking up except the posts.

Fill caps will be flush with the top of the battery.

For Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

2-5

2

Batteries must be properly maintained if you

want long-life, this remark is repeated over and

over.

1. Check the electrolyte and add only water.

2. Keep clean, excessive acid build up around

the terminals and top of battery will cause a

discharge and drain the battery.

3. Check cables and clamps and battery case for

obvious reasons of leakage as this could

cause damage to the painted surfaces, the

battery compartments and to the pulleys and

transmission.

4. Make sure of the routing of the vent tubes and

that it is not pinched and left to drip on pulleys,

etc.

5. Replace caps firmly, if one or two gets lost,

replace them as soon as possible, often they

can be obtained from old batteries.

6. Maintain a fully charged battery with a reading

by hydrometer showing 1.265.

2-7.3 Recently, a man well experienced in automo-

biles and lawn and garden equipment was

charging a battery in his automobile in the

garage for a long period of time and decided to

check on how it was progressing. He walked

into a partially dark garage, not thinking, and

leaned over the battery and flipped on this cig-

arette lighter. Well, you can guess what hap-

pened next. The electrolyte gas exploded,

which is hydrogen and oxygen. He was very

lucky to have glasses on as the top of the bat-

tery hit him in the face. He quickly remembered

to turn the hose on his face and wash off the

acid which was starting to burn and no damage

was done, but he was left quite shaken and

thankful that things worse didn’t take place.

Think about it. His glasses were broken and

bent tight to his eyes which helped protect his

eyes, which proves it is a good practice to

wear glasses when working with batteries.

2-8. BATTERY STARTING CIRCUITS.

2-8.1 Battery starting circuits consists of the following:

•Battery as a source of energy

•Starter solenoid switch to transfer high starting

current from battery to starter (starter relay)

•Key start switch or other switch to energize

the starter solenoid

•Starter. A series wound, low resistance, high

current draw direct current motor.

NOTE

Sometimes the circuit breaker kicks out and

will not allow the unit to crank. Check the diode

wires to see if they are crossed. Reverse the

diode wires if crossed.

2-9. BATTERY CHARGING SYSTEM.

2-9.1 There are four types of charging systems typi-

cally used on lawn and garden equipment.

•Single circuit—3 amp system with one diode

•Dual circuit—3 amp AC system that runs the

lights and a 3 amp DC circuit to charge battery

•Tri-circuit—5 amp two diode system

•Regulated 16 amp system

MTD mainly uses the dual circuit and regulated

systems.

2-9.2 Regulated systems are installed on units with

electric clutches. These are Briggs and Strat-

ton engines with a voltage regulator. Some of

the early units had an 8 amp circuit breaker in

the unit. This is a 16 amp unit and needs a 20

amp circuit breaker (part number 725-1382).

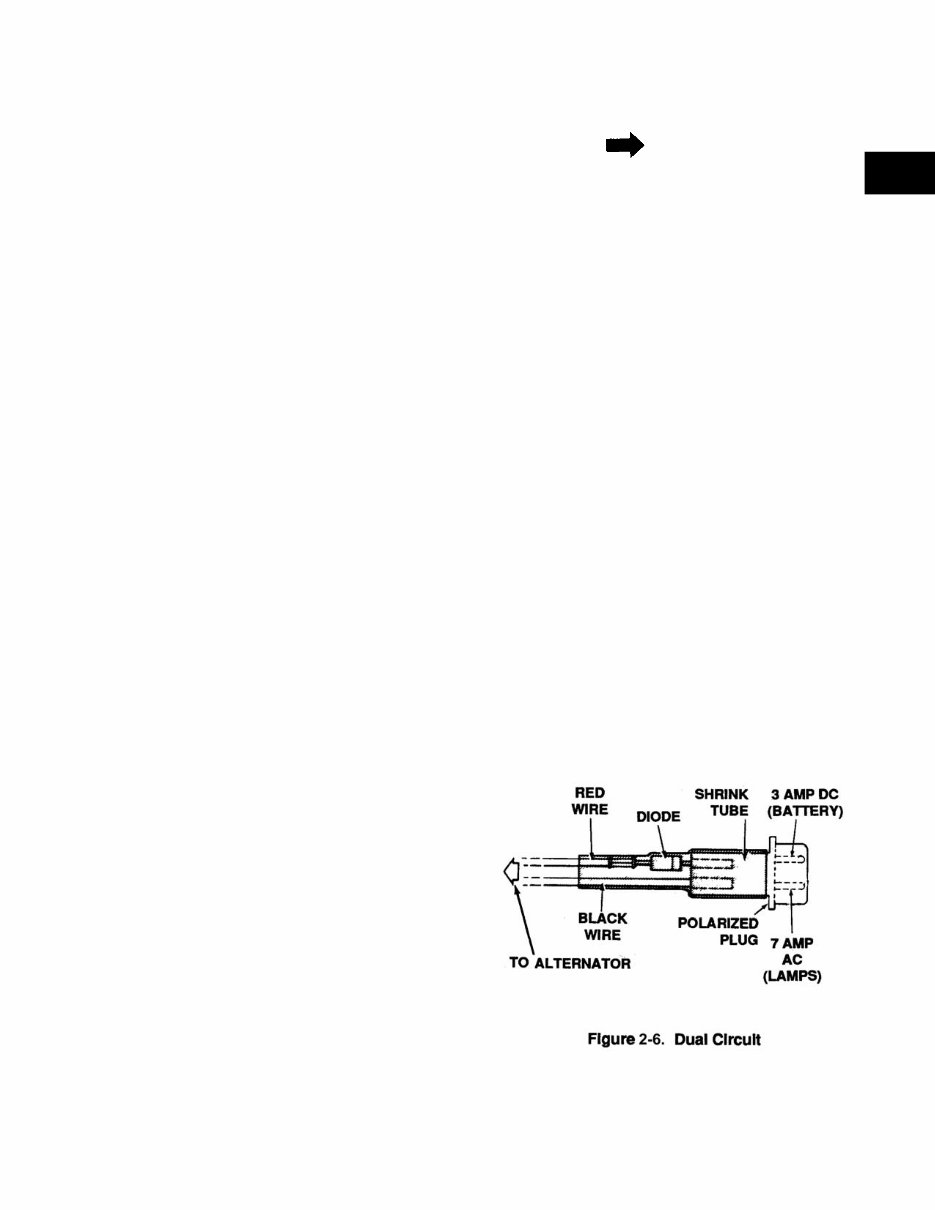

2-9.3 Dual Circuit (Engine Alternator) (Figure 2-6).

1. The charging system is an alternator located

under the flywheel. A half wave rectification

(single diode) is unregulated and rated at 3

amps at 3600 RPM.

For Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$52.99

Viewed 89 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$52.99

MTD REAR ENGINE RIDERS & LAWN TRACTORS SERVICE WORKSHOP REPAIR SHOP MANUAL

- GENERAL INFORMATION

- Safety Precautions

- Batteries And Charging Systems

- ELECTRICAL

- Safety Interlock Systems

- Safety Interlock Systems - Changes for 1991

- Electric Start System

- Recoil Start System

- Safety Interlock Systems Wiring Diagrams

- Troubleshooting Safety Interlock Systems

- Evaluating Electric Clutches

- BELTS AND DRIVE SYSTEM

- General

- Proper Storage of Belts

- Causes of V-Belt Problems

- V-Belt Problems with Rotary Tillers, Self-Propelled Mowers and Riding Mowers

- Belt Wear Due to Normal Life

- Pulley Alignment

- Idlers

- Maintenance Of Variable Speed Pulleys

- Four Wheel Steering

- Disassembly Of Four Wheel Steering

- Brake Adjustment for 600 and 700 Series

- HYDROSTATIC

- TRANSAXLES

- General

- Transaxle Changes For 1990, 1991, 1992 and 1997 Models

- Disassembly/Assembly of Transaxle

- Hydrostatic Transaxle

- Integrated Hydrostatic Transaxle

- TRANSAXLES

- LAWN TRACTORS

- 300 and 400 Series

- Rear Engine Riding Mowers 500 Series

- Transmatic LT 600A

- Hydrostatic Drive 700 Series

- YARD BUG

- Deck Leveling

- Brake Adjustment

- Blade Brake/PTO Adjustment

- Speed Control Pedal Adjustment

- Steering Adjustment

- Removal and Installation of Deck Belt

- Removal and Installation of Mowing Deck Assembly

- Removal and Replacement of the Drive Belts

- Transmission Removal and Installation

- Transmission Disassembly

- Transmission Reassembly

- Electrical

- AUTO DRIVE

- Leveling the Cutting Deck

- Deck Belt Removal and Installation

- Cutting Deck Removal

- Brake Adjustments

- Autodrive Pedal Adjustment

- Drive Belt Removal and Reinstallation

- Transmission Removal and Installation

- Transmission Disassembly and Reassembly

- Deck Belt Removal

- Hydrostatic Transmission Removal

- Steering Adjustments

- Electrical

- Autodrive/Autocruise

- MTD Z SERIES

- Transmission

- Neutral/Steering Adjustment

- Removal of ZTT Transmission

- Transmission Disassembly

- ZERO TURN TRACTORS

- 624 Zero Turn Tractor - The Revolution

- 46" Cutting Deck

- Cutting Deck Removal

- Lower Deck Belt Removal

- Servicing the IZT Drive Belt

- Servicing the IZT

- Adjustments to the IZT

- Parking Brake

- Under Dash Service Points1

- Dash Panel Removal

- Front Axle

- ATTACHMENTS

- Cutting Decks

- Improvements

- Grass Collectors

- Front Bumper

- Trapac

- 42" Dozer Blade