Denon AVR X7200W X7200WA Service Manual & Repair Guide

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

START::|sX3k6VQNaf/6VbQg1Aav9Q==|Et47GD/ke3ODnkHXa491WKZgCp4aT5bOv8c/PAauonw=|XOIUVeyoWOE5XcW

MODEL JP E3 E2 EK EA E1 E1C E1K

AVR-X7200W P P P

AVR-

X7200WA

P P P P

INTEGRATED NETWORK AV RECEIVER

S1529V07DM/DG1707

Ver. 7

• Please use this service manual with referring to the operating instructions without fail.

• Some illustrations using in this service manual are slightly different from the actual set.

• For purposes of improvement, specifications and design are subject to change without notice.

Please refer to the

MODIFICATION NOTICE. e

SERVICE MANUAL

e

D&M Holdings Inc.

ABOUT THIS MANUAL .............................................................3

What you can do with this manual ............................................3

Using Adobe Reader (Windows version) ..................................4

SAFETY PRECAUTIONS ..........................................................6

NOTE FOR SCHEMATIC DIAGRAM.........................................7

NOTE FOR PARTS LIST ...........................................................7

TECHNICAL SPECIFICATIONS ................................................9

DIMENSION ...............................................................................9

Precautions During Service...................................................10

Initializing This Unit .................................................................10

Service Jigs .............................................................................10

DISASSEMBLY ........................................................................ 11

1. CX870 ASSY for CX870 model only ..................................14

2. FRONT PANEL ASSY ........................................................14

3. RADIATOR ASSY...............................................................15

4. SMPS ASSY.......................................................................16

5. POWER TRANS ................................................................17

6. BACK PANEL ASSY...........................................................18

SPECIAL MODE ......................................................................19

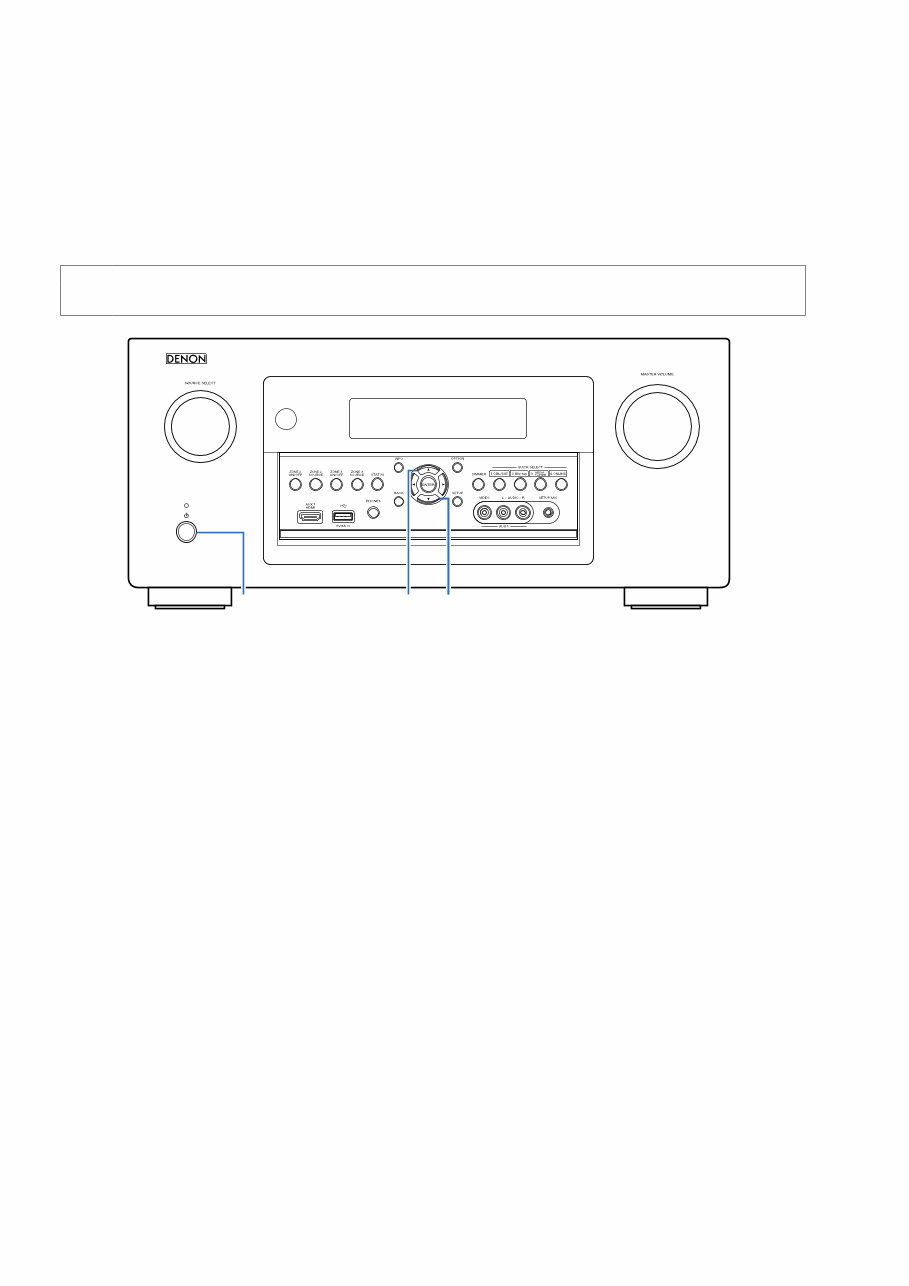

Special Mode Configuration Buttons .......................................19

1. Version Display Mode ........................................................20

2. PANEL / REMOTE LOCK Selection Mode.........................24

3. Selection Modes for Service-related Operations................25

DIAGNOSTIC PATH DIAGRAM.........................................31

4. Remote ID Setup Mode......................................................75

5. Additional Source mode s ...............................................76

6. Protection Pass Mode ........................................................76

7. CX870 / CY920 Reboot Mode............................................77

8. CX870 / CY920 Initialization Mode ....................................77

JIG FOR SERVICING ..............................................................78

Procedure after Replacing the Microprocessor, etc. ..........80

Firmware Update Procedure..................................................80

1. Updating by USB................................................................80

2. Updating by DPMS.............................................................90

ADJUSTMENT .........................................................................97

SURROUND MODES AND PARAMETERS ............................98

TROUBLE SHOOTING ..........................................................101

1. POWER............................................................................101

2. Analog video ....................................................................102

3. HDMI/DVI .........................................................................104

4. AUDIO..............................................................................106

5. Network/Bluetooth/USB ...................................................109

6. SMPS ............................................................................... 115

Audio Check PASS .............................................................. 117

CLOCK FLOW & WAVE FORM IN DIGITAL BLOCK ........... 118

LEVEL DIAGRAM.................................................................. 119

GND DIAGRAM .....................................................................127

POWER DIAGRAM................................................................128

CPU DIAGRAM......................................................................130

PRINTED WIRING BOARDS.................................................131

SCHEMATIC DIAGRAMS (1/37) ...........................................140

SCH01_DIGITAL CONNECT ................................................140

SCH02_DIR ADC ZONEDAC ...............................................141

SCH03_AUDIO PLD .............................................................142

SCH04_DSP1 .......................................................................143

SCH05_DSP2 .......................................................................144

SCH06_DSP3 .......................................................................145

SCH07_DSP4 .......................................................................146

SCH08-1_MAIN CPU_OLD ..................................................147

SCH08-2_MAIN CPU_NEW .................................................148

SCH09_SUB CPU.................................................................149

SCH10_DECODER...............................................................150

SCH11-1_HDMI SW1 AVR-X7200W ONLY ..........................151

SCH11-2_HDMI SW1 AVR-X7200WA ONLY ........................152

SCH12-1_HDMI SW2 AVR-X7200W ONLY ..........................153

SCH12-2_HDMI SW2 AVR-X7200WA ONLY ........................154

SCH13_IP SCALER ..............................................................155

SCH14_IP SCALER DDR .....................................................156

SCH15-1_VIDEO PLD AVR-X7200W ONLY.........................157

SCH15-2_VIDEO PLD AVR-X7200WA ONLY.......................158

SCH16-1_HDMI RX TX AVR-X7200W ONLY .......................159

SCH16-2_HDMI RX TX AVR-X7200WA ONLY .....................160

SCH17-1_HDMI SUPPLY AVR-X7200W ONLY ....................161

SCH17-2_HDMI SUPPLY AVR-X7200WA ONLY ..................162

SCH18-1_NETWOR AVR-X7200W ONLY ............................163

SCH18-2_NETWOR AVR-X7200WA ONLY_OLD.................164

SCH18-3_NETWOR AVR-X7200WA ONLY_NEW................165

SCH19-1_MAIN DAC ............................................................166

SCH19-2_MAIN DAC ............................................................167

SCH20-1_ZONEDAC ADC ...................................................168

SCH20-2_ZONEDAC ADC ...................................................169

SCH21_REAR USB ..............................................................170

SCH22_AUDIO VIDEO CONNECT ......................................171

SCH23_AUDIO VOLUME .....................................................172

SCH24_PREOUT..................................................................173

SCH25_VIDEO SELECTOR .................................................174

SCH26_FRONT JACK ..........................................................175

SCH27_CONNECT ...............................................................176

SCH28_FRONT HDMI USB..................................................177

SCH29_SPEAKER................................................................178

SCH30_REG.........................................................................179

SCH31_FLD ..........................................................................180

SCH32_SMPS ......................................................................181

SCH33_AMP CONNECT ......................................................182

SCH34_232C PHONO..........................................................183

SCH35_POWER AMP...........................................................184

SCH36_CX870 CONNECT AVR-X7200W ONLY..................185

SCH37_BT MODULE AVR-X7200W ONLY ..........................186

EXPLODED VIEW .................................................................187

PACKING VIEW .....................................................................188

SEMICONDUCTORS .............................................................189

1. IC's ...................................................................................189

2. FL DISPLAY ..................................................................... 211

CONTENTS

2

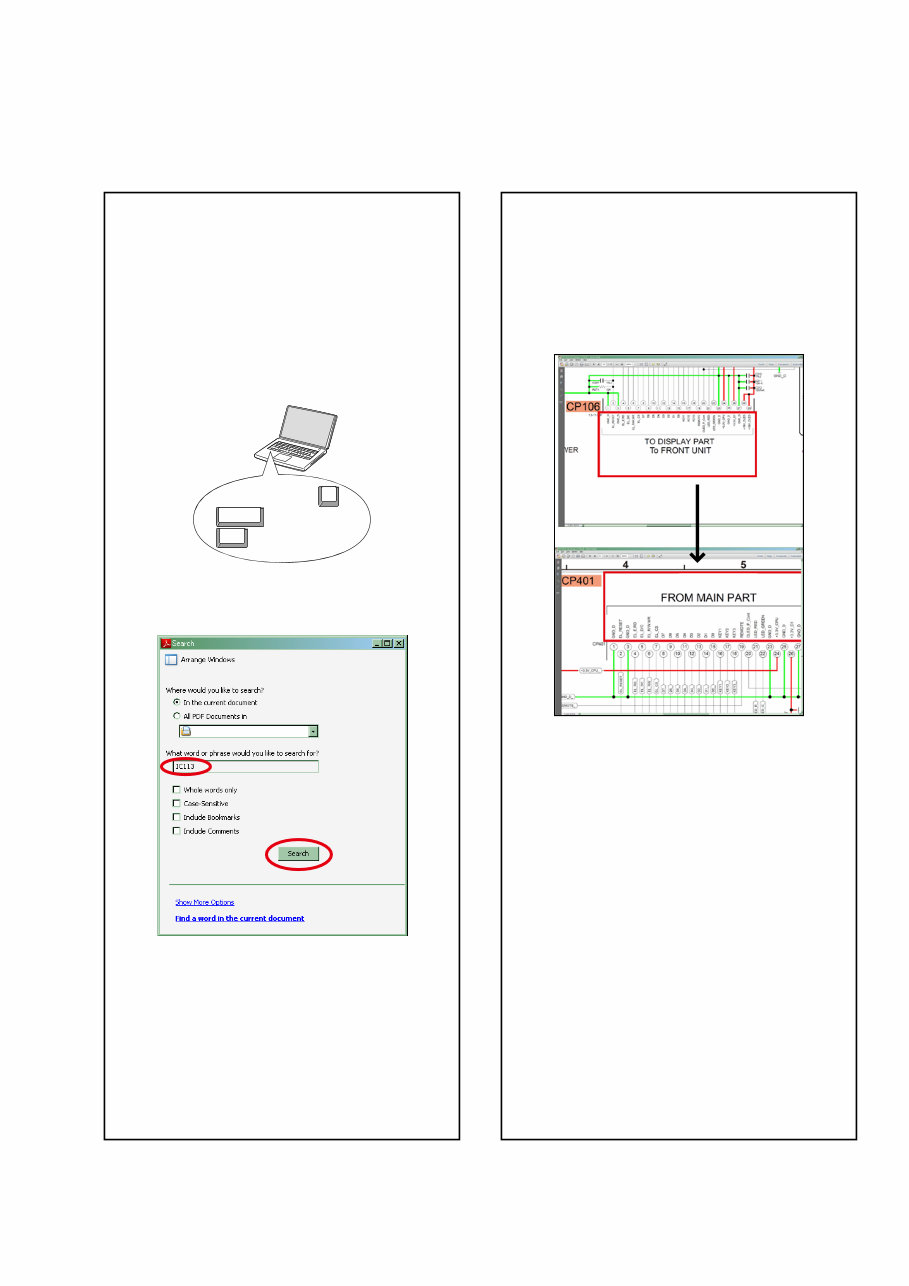

Jump to the target of a schematic

diagram connector

Click the Ref. No. of the target connector in the red

box around a schematic diagram connector.

•The screen jumps to the target connector.

•Page magnification stays the same as before the

jump.

CP401

CP106

v

ABOUT THIS MANUAL

Read the following information before using the service manual.

What you can do with this manual

Search for a Ref. No. (phrase)

(Ctrl+Shift+F)

You can use the search function in Acrobat Reader to

search for a Ref. No. in schematic diagrams, printed

wiring circuit diagrams, block diagrams, and parts

lists.

1.Press Ctrl+Shift+F on the keyboard.

• The Search window appears.

2.Enter the Ref. No. you want to search for in the

Search window, and then click the Search button.

•A list of search results appears.

3.Click an item on the list.

• The screen jumps to the page for that item, and the

search phrase is displayed.

Ctrl

Shift

F

3

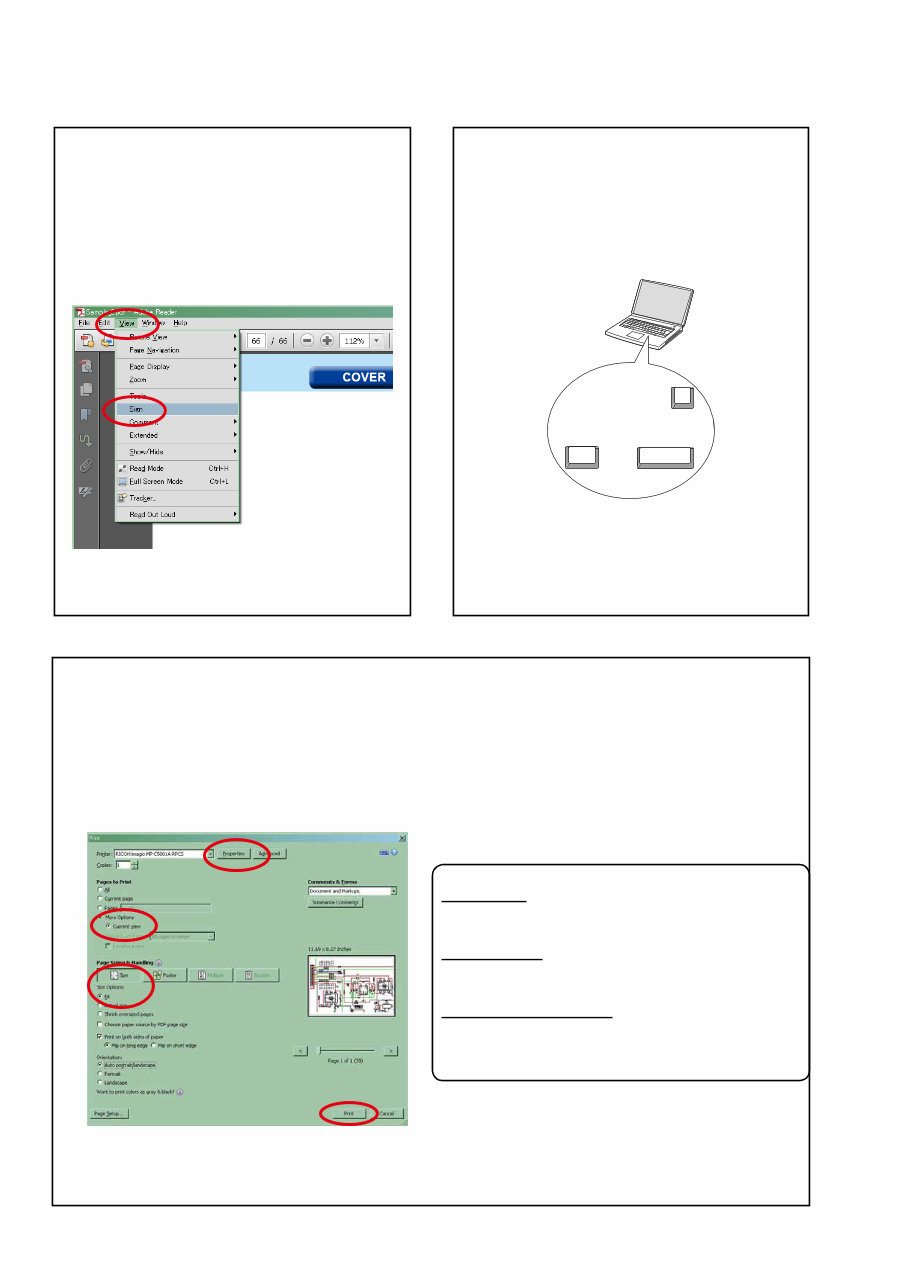

Using Adobe Reader (Windows version)

• Properties

Click this button and check that the printer is set to a

suitable paper size.

• Page to print

Select the following checkbox.

"More Options" : "Current View"

• Page Sizing & Handling

Select the following checkbox.

"Size" / "Size Options" : "Fit"

Add notes to this data (Sign)

The Sign function lets you add notes to the data in

this manual.

Save the file once you have finished adding notes.

[Example using Adobe Reader X]

On the "View" menu, click "Sign".

• The Sign pane appears.

[Example using Adobe Reader 9]

On the "Document" menu, click "Sign".

Magnify schematic / printed circuit

board diagrams - 1

(Ctrl+Space, mouse operation)

Press Ctrl+Space on the keyboard and drag the

mouse to select the area you want to view.

• The selected area is magnified.

• When you want to move the area shown, hold

down Space and drag the mouse.

• When you want to show a full page view, press

Ctrl+0 on the keyboard.

Ctrl Space

0

Print a magnified part of the manual

The Properties dialog box and functions will vary depending on your printer.

1. Drag the mouse to magnify the part you want to print.

2. On the "File" menu, click "Print".

3. Configure the following settings in the Print dialog box.

4. Click the Print button to start printing.

4

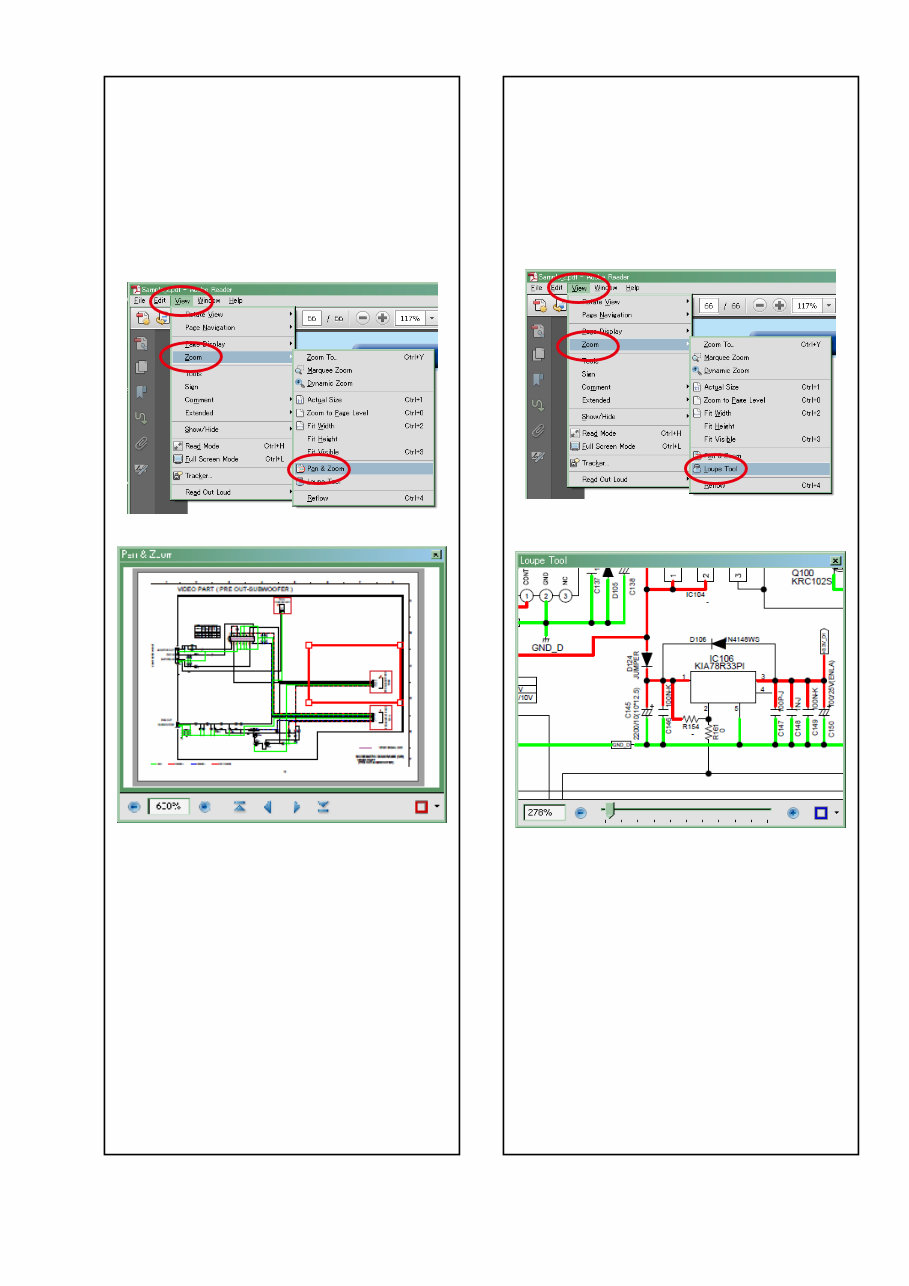

Magnify schematic / printed circuit

board diagrams - 2

(Pan & Zoom function)

The Pan & Zoom function lets you see which part of

a magnified diagram is being shown in a separate

window.

[Example using Adobe Reader X]

On the "View" menu, point to "Zoom", and then click

"Pan & Zoom".

• The Pan & Zoom window appears on the screen.

[Example using Adobe Reader 9]

On the "Tools" menu, point to "Select & Zoom", and

then click "Pan & Zoom Window".

Magnify schematic / printed circuit

board diagrams - 3

(Loupe Tool function)

The Loupe Tool function lets you magnify a specific

part of a diagram in a separate window.

[Example using Adobe Reader X]

On the "View" menu, point to "Zoom", and then click

"Loupe Tool".

• The Loupe Tool window appears on the screen.

[Example using Adobe Reader 9]

On the "Tools" menu, point to "Select & Zoom", and

then click "Loupe Tool Window".

5

SAFETY PRECAUTIONS

The following items should be checked for continued protection of the customer and the service technician.

leakage current check

Before returning the set to the customer, be sure to carry out either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the set is defective.

Be sure to test for leakage current with the AC plug in both polarities, in addition, when the set's power is in each state

(on, off and standby mode), if applicable.

CAUTION

Please heed the following cautions and instructions during servicing and

inspection.

◎ Heed the cautions!

Cautions which are delicate in particular for servicing

are labeled on the cabinets, the parts and the chassis,

etc. Be sure to heed these cautions and the cautions

described in the handling instructions.

◎ Cautions concerning electric shock!

(1) An AC voltage is impressed on this set, so if you

touch internal metal parts when the set is energized,

you may get an electric shock. Avoid getting an

electric shock, by using an isolating transformer

and wearing gloves when servicing while the set is

energized, or by unplugging the power cord when

replacing parts, for example.

(2) There are high voltage parts inside. Handle with

extra care when the set is energized.

◎ Caution concerning disassembly and

assembly!

Through great care is taken when parts were

manufactured from sheet metal, there may be burrs on

the edges of parts. The burrs could cause injury if fingers

are moved across them in some rare cases. Wear gloves

to protect your hands.

◎ Use only designated parts!

The set's parts have specific safety properties (fire

resistance, voltage resistance, etc.). Be sure to use parts

which have the same properties for replacement. The

burrs have the same properties. In particular, for the

important safety parts that are indicated by the z mark

on schematic diagrams and parts lists, be sure to use

the designated parts.

◎ Be sure to mount parts and arrange the wires

as they were originally placed!

For safety seasons, some parts use tapes, tubes or other

insulating materials, and some parts are mounted away

from the surface of printed circuit boards. Care is also

taken with the positions of the wires by arranging them

and using clamps to keep them away from heating and

high voltage parts, so be sure to set everything back as

it was originally placed.

◎ Make a safety check after servicing!

Check that all screws, parts and wires removed or

disconnected when servicing have been put back in their

original positions, check that no serviced parts have

deteriorate the area around. Then make an insulation

check on the external metal connectors and between

the blades of the power plug, and otherwise check that

safety is ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet, disconnect

the antenna, plugs, etc., and on the power. Using a 500V

insulation resistance tester, check that the insulation

resistance value between the inplug and the externally

exposed metal parts (antenna terminal, headphones

terminal, input terminal, etc.) is 1MΩ or greater. If it is

less, the set must be inspected and repaired.

Many of the electric and the structural parts used in the

set have special safety properties. In most cases these

properties are difficult to distinguish by sight, and the use

of replacement parts with higher ratings (rated power

and withstand voltage) does not necessarily guarantee

that safety performance will be preserved. Parts with

safety properties are indicated as shown below on the

wiring diagrams and the parts list in this service manual.

Be sure to replace them with the parts which have the

designated part number.

(1) Schematic diagrams.......Indicated by the z mark.

(2) Parts lists.......Indicated by the z mark.

The use of parts other than the

designated parts could cause electric

shocks, fires or other dangerous

situations.

CAUTION Concerning important

safety parts

6

NOTE FOR SCHEMATIC DIAGRAM

WARNING:

Parts indicated by the z mark have critical characteristics. Use ONLY replacement parts recommended by the manufacturer.

CAUTION:

Before returning the set to the customer, be sure to carry out either (1) a leakage current check or (2) a line to chassis resistance check.

If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the power cord is less than 460 kohms, the

set is defective.

WARNING:

DO NOT return the set to the customer unless the problem is identified and remedied.

NOTICE:

ALL RESISTANCE VALUES IN OHM. k=1,000 OHM / M=1,000,000 OHM

ALL CAPACITANCE VALUESARE EXPRESSED IN MICRO FARAD, UNLESS OTHERWISE INDICATED. P INDICATES MICRO-MICRO

FARAD. EACH VOLTAGE AND CURRENT ARE MEASURED AT NO SIGNAL INPUT CONDITION. CIRCUIT AND PARTS ARE SUBJECT

TO CHANGE WITHOUT PRIOR NOTICE.

NOTE FOR PARTS LIST

1. Parts indicated by "nsp" on this table cannot be supplied.

2. When ordering a part, make a clear distinction between "1" and "I" (i) to avoid mis-supplying.

3. A part ordered without specifying its part number can not be supplied.

4. Part indicated by " ★ " mark is not illustrated in the exploded view.

WARNING: Parts indicated by the z mark have critical characteristics. Use ONLY replacement parts recommended by the manufacturer.

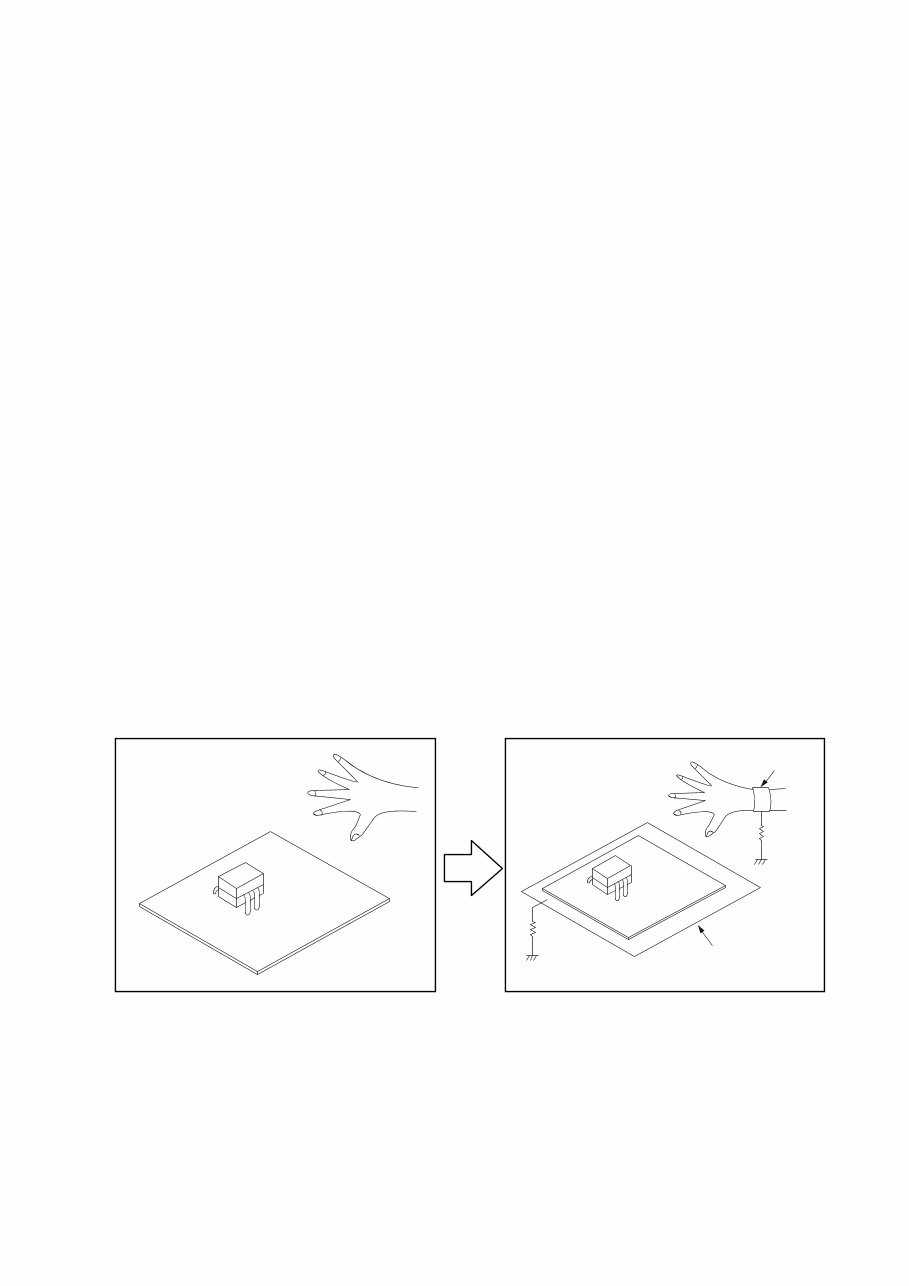

INSTRUCTIONS FOR HANDLING SEMI-CONDUCTORS AND OPTICAL UNIT

Electrostatic breakdown of the semi-conductors or optical pickup may occur due to a potential difference caused by

electrostatic charge during unpacking or repair work.

1. Ground for Human Body

Be sure to wear a grounding band (1 MΩ) that is properly grounded to remove any static electricity that may be

charged on the body.

2. Ground for Workbench

Be sure to place a conductive sheet or copper plate with proper grounding (1 MΩ) on the workbench or other surface,

where the semi-conductors are to be placed. Because the static electricity charge on clothing will not escape through

the body grounding band, be careful to avoid contacting semi-conductors with your clothing

<Incorrect>

CBA

Grounding Band

Conductive Sheet or

Copper Plate

1MΩ

1MΩ

<Correct>

CBA

7

Personal notes:

8

TECHNICAL SPECIFICATIONS

n Audio section

• Power amplifier

Rated output :

Front:

150W+150W (8Ω, 20Hz - 20kHz with 0.05% T.H.D.)

190W+190W (6Ω, 1kHz with 0.7% T.H.D)

Center:

150W (8Ω, 20Hz - 20kHz with 0.05% T.H.D.)

190W (6Ω, 1 kHz with 0.7 % T.H.D.)

Surround:

150W+150W (8Ω, 20 Hz - 20 kHz with 0.05% T.H.D.)

190W+190W (6Ω, 1 kHz with 0.7 % T.H.D.)

Surround back:

150W+150W (8Ω, 20 Hz - 20 kHz with 0.05% T.H.D.)

190W+190W (6Ω, 1 kHz with 0.7 % T.H.D.)

Height1 / Front wide / Height2:

150W+150W (8Ω, 20 Hz - 20 kHz with 0.05% T.H.D.)

190W+190W (6Ω, 1 kHz with 0.7 % T.H.D.)

Rated output:

170 W x 2-channel (8 Ω)

280 W x 2-channel (4 Ω)

Output connectors:4 - 16Ω

n Analog section

Input sensitivity/Input impedance:200 mV/47 kΩ

Frequency response: 10 Hz - 100 kHz — +1, -3 dB(Direct mode)

S/N:102 dB(IHF-A weighted, Direct mode)

Distortion:0.005 % (20 Hz – 20 kHz) (Direct mode)

Rated output:1.2 V

n Digital section

D/A output:Rated output — 2 V (at 0 dB playback)

Total harmonic distortion — 0.008 % (1 kHz, at 0 dB)

S/N ratio — 102 dB

Dynamic range — 100 dB

Digital input:Format — Digital audio interface

n Phono equalizer section

Input sensitivity: 2.5 mV

RIAA deviation: ±1 dB (20 Hz to 20 kHz)

S/N: 74 dB (IHF-A)

Distortion factor: 0.03 % (1 kHz, 3 V)

n Video section

• Standard video connectors

Input/output level and impedance:1 Vp-p, 75 Ω

Frequency response:5 Hz – 10 MHz — 0, –3 dB

• Color component video connector

Input/output level and impedance:Y signal — 1 Vp-p, 75 Ω

PB / CB signal — 0.7 Vp-p, 75 Ω

PR / CR signal — 0.7 Vp-p, 75 Ω

Frequency response:5 Hz - 60 MHz — 0, -3 dB

n Tuner section

Reception frequency range:FM 87.5 MHz - 107.9 MHz (for E3)

FM 87.5 MHz - 108.0 MHz (for E2, E1C)

FM 76.0 MHz - 90.0 MHz (for JP)

AM 530 kHz - 1710 kHz (for E3)

AM 522 kHz - 1611 kHz (for E2, E1C)

AM 522 kHz - 1629 kHz (for JP)

Effective sensitivity: FM 1.5μV (14.8dBf) (for E3)

FM 1.2μV (12.8dBf) (for E2, E1C, JP)

AM 20 μV (for E3)

AM 18 μV (for E2, E1C, JP)

50 dB sensitivity: MONO ― 2.8 μV (20.2 dBf) (for E2, E1C, JP)

S/N ratio (IHF-A): MONO ― 70 dB (for E3)

MONO ― 78 dB (for E2, E1C, JP)

STEREO ― 68 dB (for E3)

STEREO ― 67 dB (for E2, E1C, JP)

HD ― FM 85dB AM 85dB (for E3)

Distortion (1 kHz): MONO ― 0.1 % (for E3)

MONO ― 0.7 % (1 kHz) (for E2, E1C, JP)

SRETEO ― 0.2 % (for E3)

SRETEO ― 1.0 % (1 kHz) (for E2, E1C, JP)

HD ― FM 0.02% AM 0.02% (for E3)

n Wireless LAN section

Network type (wireless LAN standard): Conforming to Wi-Fi®z1

Security: WEP 64 bit, WEP 128 bit

WPA/WPA2-PSK (AES)

WPA/WPA2-PSK (TKIP)

Radio frequency: 2.4 GHz

No. of channels: 1 - 11 ch (for E3)

1 - 13 ch (for E2, E1C, JP)

z1 The Wi-Fi® CERTIFIED Logo and the Wi-Fi CERTIFIED On-Product

Logo are registered trademarks of the Wi-Fi Alliance.

n Bluetooth section

Communications system:Bluetooth Version 2.1 + EDR

(Enhanced Data Rate)

Transmission power:Maximum 2.5 mW (Class 2)

Maximum communication range:Approx. 32.8 ft/10 m in line of sight

Frequency band:2.4 GHz band

Modulation scheme:FHSS (Frequency-Hopping Spread Spectrum)

Supported profiles:A2DP (Advanced Audio Distribution Profile) 1.2

AVRCP (Audio Video Remote Control Profile) 1.4

Corresponding codec:SBC, AAC

Transmission range (A2DP):20 Hz - 20,000 Hz

n General

Power supply:(for E3) : AC 120 V, 60 Hz

(for E2) : AC 230 V, 50 Hz / 60Hz

(for E1C) : AC 220 V, 50 Hz

(for JP) : AC 100 V, 50 Hz / 60Hz

Power consumption:780W

Power consumption in standby mode:0.1W

Power consumption in CEC standby mode:0.5W

Power consumption in network standby mode :4.5W

(Adapted to NEW DIGITAL PCB products) :2.7W

For purposes of improvement, specifications and design are subject to

change without notice.

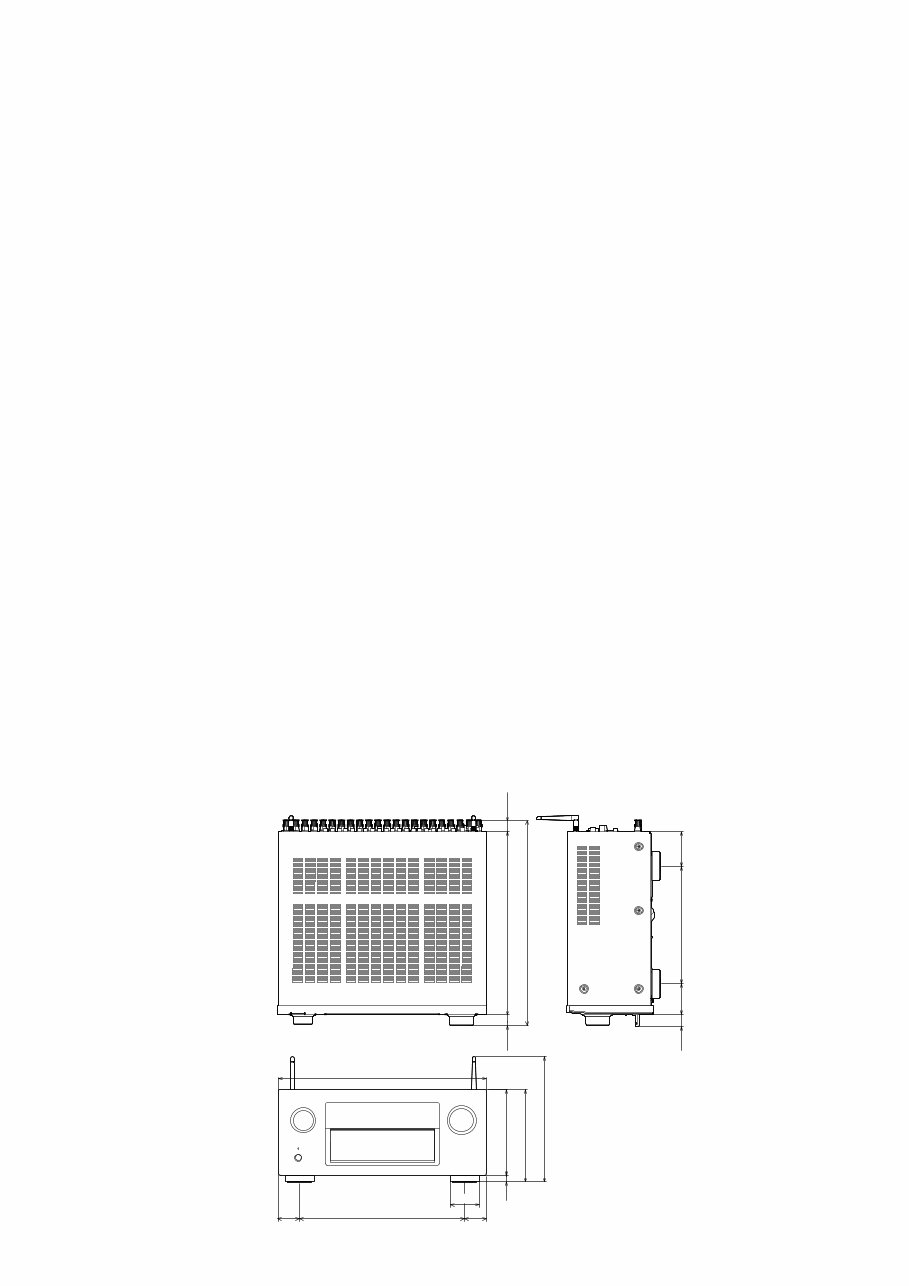

DIMENSION

Unit:in. (mm)

Weight:31 lb 1 oz (14.1 kg)

434

16 180

196

259

344

60

45 45

245

65 73

25

383

427

22 22

h

9

PRECAUTIONS DURING SERVICE

Initializing This Unit

Initialize this unit if you have replaced the microcomputer, one of the parts around the microcomputer, or the digital PCB.

1. Press the power button to turn off the power.

2. Hold down buttons "CURSOR d" and "CURSOR f" at the same time and press the power button to turn on the power.

3. Release the buttons after confirming that the display flashes in intervals of approximately 1 second.

* The unit is initialized.

NOTE: • If the status in step 3 does not occur, start again from step 1.

• Initializing the device restores settings configured by the user to the factory settings. Take note of your settings beforehand

and reconfigure them after initialization.

Service Jigs

The following jigs (extension cable kit) are used when repairing the PCBs.

Order the jigs from your dealer if necessary.

8U- 110084S : EXTENSION UNIT KIT : 2 Set

(See 78 page)

X CURSOR d CURSOR f

10

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$36.99

$48.99

Viewed 25 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$36.99

$48.99

This Denon AVR X7200W X7200WA Integrated Network Audio/Video Receiver service and repair manual is an essential resource for both professional mechanics and DIY enthusiasts. It contains comprehensive technical information required for servicing and repairing the receiver.

- Specifications

- Adjustments

- Special Modes

- Disassembly Instructions

- Semiconductors

- Troubleshooting

- Clock Flow & Wave Forms

- Surround Modes and Parameters

- Firmware Update Procedures

- Block Diagrams

- Level Diagram

- Printed Wiring Boards

- CPU Diagram

- GND Diagram

- Wiring Diagrams

- Power Diagram

- Schematic Diagrams

- Exploded Views

- Parts List Catalog

This official advanced service manual is available in high-resolution format and provides instant access after payment, allowing for quick initiation of repairs. The manual is in English and consists of 245 pages.