Service Manual COMMODORE 1701/1702 MONITOR

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

SERVICE MANUAL

MODEL 1701/1702 MONITOR

Preliminary

APRIL 1985 PN-314004-01

Commodore Business Machines, Inc.

1200 Wilson Drive, West Chester, Pennsylvania 19380 U.S.A.

Commodore makes no expressed or implied war-

ranties with regard to the information contained

herein. The information is made available solely on

an as is basis, and the entire risk as to quality and

accuracy is with the user. Commodore shall not be

liable for any consequential or incidental damages

in connection with the use of the information con-

tained herein. The listing of any available replace-

ment part herein does not constitute in any case

a recommendation, warranty or guaranty as to

quality or suitability of such replacement part.

Reproduction or use without expressed permission,

of editorial or pictorial content, in any matter is

prohibited.

This manual contains copyrighted and proprietary information. No part

of this publication may be reproduced, stored in a retrieval system, or

transmitted in any form or by any means, electronic, mechanical,

photocopying, recording or otherwise, without the prior written permis-

sion of Commodore Electronics Limited.

Copyright © 1985 by Commodore Electronics Limited.

All rights reserved.

CONTENTS

Title Page

SPECIFICATIONS

SAFETY PRECAUTIONS ......................................................................................... 2

ADJUSTMENTS

PURITY ...................................................................................................... 4

CONVERGENCE ... ........................ .............. .............. ........................ .... ........ 5

WHITE BALANCE ........................................................................................ 5

B1 VOLTAGE, FOCUS, VERT. & HOR. ADJ. ................................................... 6

SUB TINT, SUB CONTRAST, COLOR SYNC, 3.58 MHz TRAP ........................... 7

BLOCK DIAGRAM

CIRCUIT NOTES

8

VIDEO CIRCUIT ....... ............ ... ................... ........ ................... ................ .... ... 9

AUDIO CIRCUIT ............ ......... .......... ........................ .... ....... .... ... ................. 10

COLOR DEMODULATION CIRCUIT ................................................................ 11

CHROMA OUTPUT CIRCUIT ................................................... ........ .... ....... ... 12

CONTROL CIRCUIT .......................................................................... ............ 13

H. OSC., V. OSC. & V. OUT CIRCUIT ................ ...................... ...................... 14

HORIZONTAL OUTPUT CIRCUIT ................................................................... 15

POWER CiRCUiT ........................................................................................ , 16

TROUBLESHOOTING GUIDE

NO RASTER, NO SOUND (81 NORMAL) .............. .......... .......... .............. ........ 17

NO RASTER, NO SOUND (81 ABNORMAL) ...... ........................ .............. ........ 18

NO RASTER, NORMAL SOUND .............................................. ' ............. , ........ 19

NO SOUND, NORMAL PICTURE ................................................. , .................. 19

SINGLE HORIZONTAL LINE, NORMAL SOUND ....... .............. ........................... 20

IMPROPER HORIZONTAL OR VERTICAL SYNC ...... ........ .......... ....................... 22

1701 PARTS LIST ........ ......................... ..... ............. .......................... ... ......... ........ 23

1701 BOARD LAYOUT ................................... ............................ .......... ........... ...... 30

1701 SCHEMATIC NOTES ..................................................................................... 31

1701 SCHEMATIC ................................................................................................ 31

iii

.-----~-~--~------

CONTENTS (Continued)

Title Page

TROUBLESHOOTING GUIDE - 1702 32

DEAD SET, B+ ABNORMAL ......................................................................... 33

NO RASTER, SOUND NORMAL, HIGH VOLTAGE NORMAL .............................. 34

NO RASTER, NO SOUND, B+ NORMAL ........................................................ 35

NO CHROMA, SOUND NORMAL, BLACK & WHITE TRACKING ......................... 36

NO VIDEO, SOUND NORMAL, RASTER NORMAL ...................... ...................... 37

NO SOUND, VIDEO NORMAL ....................................................................... 38

NO VERTICAL SWEEP .................................................................................. 38

CANNOT SET BLACK & WHITE TRACKING .................................................... 39

1702 MODEL IDENTIFICATION ............................................................................... 40

1702 PARTS LIST ................................................................................................. 41

1702 BOARD LAYOUT .......................................................................................... 48

1 702 SCHEMATIC NOTES ..................................................................................... 49

1702 SCHEMATIC ................................................................................................ 49

1 702T BOARD LAYOUT ........................................................................................ 50

1702T UNIQUE PARTS .......................................................................................... 51

1702T SCHEMATIC .............................................................................................. 51

iv

GENERAL DESCRIPTION

C1701/C1702 COLOR MONITORS

PRODUCT SPECIFICATION

The C1701 and C1702 are quality, high resolution color monitors, designed to maximize the video

capabilities of your Commodore Computer. They give you a superior color picture that enhances your

computing experience and are completely compatible with all Commodore equipment.

SCREEN SIZE

13 Inch (screen measured diagonally). NTSC color standard

DISPLAY

40 Columns x 25 lines

RESOLUTION

1000 Characters per screen

CONTROLS

Color, tint, brightness, contrast, volume, vertical hold and horizontal hold

AUDIO

Built-in audio amplifier and speaker

INPUTS

Chrominance, luminance, composite video and audio

OTHER FEATURES

Video cassette recorder compatible (1 V p-p, 75 Ohms)

COMPUTERS

Commodore 64, VIC 20, Plus/4 and C16

POWER REQUIREMENTS

120 Volts, 60 Hz, 0.85 Amps

POWER CONSUMPTION

87 Watts

All specifications subject to change without notice.

1

SAFETY PRECAUTIONS

1 . This product contains special designed circuits and components that were designed for safety

purposes.

For continued protection, changes should not be made to the original design unless authorized

in writing by the manufacturer. Replacement parts must be identical to those used in the original

circuits. Service should be performed by qualified personnel only.

2. Alterations to the design or circuitry of this receiver should not be made. Any design alterations

or additions will void the manufactuer's warranty and will further relieve the manufacturer of

responsibility for personal injury or property damage resulting therefrom.

3. Many electrical and mechanical parts in MONITOR sets have special safety-related characteristics.

These characteristics are often not evident from visual inspection nor can the protection afforded

by them necessarily be obtained by using replacement components rated for higher voltage, watt-

age, etc. Replacement parts which have these special safety characteristics are identified in the

parts list of this service manual. Electrical components having such features are identified by

shading on the schematics and by (*) on the parts list in this service manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended

replacement part shown in the parts list may create shock, fire, or other hazards.

4. If any repair has been made to the chassis, it is recommended the the B1 setting be checked

or adjusted (See ADJUSTMENT OF B1 VOLTAGE).

5. The high voltage applied to the picture tube must conform with that specified in this service manual.

Excessive high voltage can cause an increase in X-Ray emission, arcing and possible component

damage, therefore operation under excessive high voltage conditions should be kept to a minimum,

or should be prevented. If severe arcing occurs, remove the AC power immediately and deter-

mine the cause by visual inspection (incorrect installation, cracked or melted high voltage harness,

poor soldering, etc.). To maintain the proper minimum level of soft X-Ray emission, components

in the high voltage circuitry including the picture tube, must be the exact replacements or alter-

natives approved by the manufacturer of the complete product.

6. Do not check high voltage by drawing an arc. Use a high voltage meter or a high voltage probe

with a VTVM. Discharge the picture tube before attempting meter connection by connecting a

clip lead to the ground frame and connecting the other end of the lead through a 1 OkQ 2W resistor

to the anode button.

7. When service is required, observe the original lead dress. Extra precaution should be given to

assure correct lead dress in the high voltage circuit area. Where a short circuit has occurred,

those components that indicate evidence of overheating should be replaced. Always use the

manufacturer's replacement components.

2

SAFETY PRECAUTIONS (Continued)

8. ISOLATION CHECK (SAFETY FOR ELECTRICAL SHOCK HAZARD)

After re-assembling the product, always perfrom an isolation check on the exposed metal parts

of the cabinet, screwheads, cable jacks, controls shafts, etc., to be sure the product is safe to

operate without danger of electrical shock.

(A) DIELECTRIC STRENGTH TEST

The isolation between the AC primary circuit and all metal parts exposed to the user, par-

ticularly any exposed metal part having a return path to the chassis should withstand a voltage

of 1,1 OOV AC (r.m.s.) for a period of one second.

This method of test requires test equipment not generally found in the service trade. *

(8) LEAKAGE CURRENT CHECK

*

Plug the AC line cord directly into the AC outlet (do not use a line isolation transformer dur-

ing this check). Using a "Leakage Current Tester", measure the leakage current from each

exposed metal part of the cabinet, particularly any exposed metal part having a return path

to the chassis, to a known good earth ground (water pipe, etc.). Any leakage current must

not exceed 0.5mA.

ALTERNATE CHECK METHOD

Plug the AC line cord directly into the AC output (do not use a line isolation transformer

during this check). Use an AC voltmeter having 1,000 ohms per volt or more sensitivity in

the following manner. Connect a 15000 10W resistor paralleled by a 0.15/LF AC-type

capacitor between an exposed metal part and a known good earth ground (water pipe, etc.).

Measure the AC voltage across the resistor with the AC voltmeter.

Move the resistor connection to each exposed metal part, particularly any exposed metal

part having a return path to the chassis, and measure the AC voltage across the resistor.

Now, reverse the plug in the AC outlet and repeat each measurement. Any voltage measured

must not exceed 0.35V AC (r.m.s). This corresponds to 0.5mA AC (r.m.s.).

CAUTION:

When troubleshooting, with power applied, use an isolation transformer and confirm that

the CRT earth wire is connected to the CRT socket board and the chassis.

3

ADJUSTMENTS - PURITY, CONVERGENCE

AND WHITE BALANCE

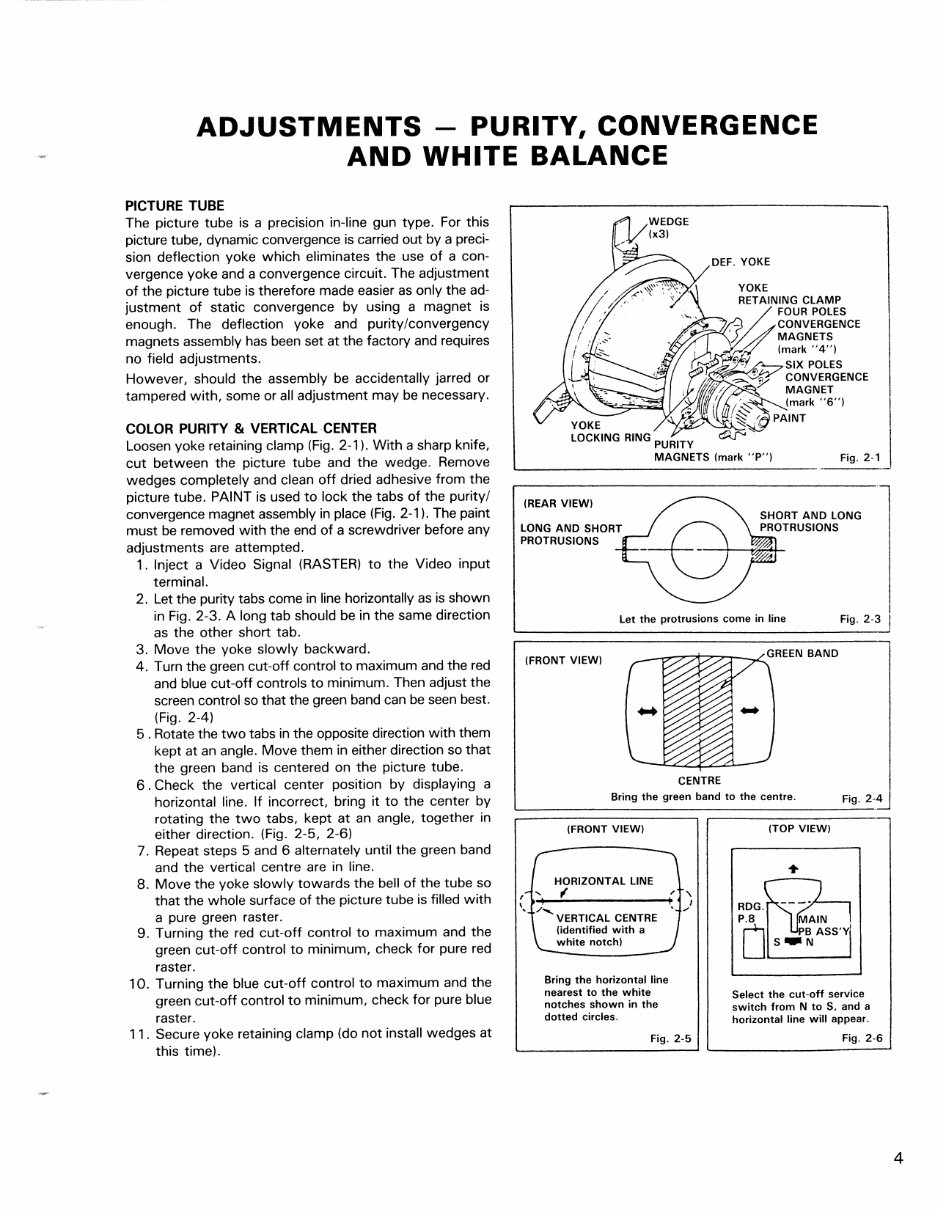

PICTURE TUBE

The picture tube is a precision in-line gun type. For this

picture tube, dynamic convergence is carried out by a preci-

sion deflection yoke which eliminates the use of a con-

vergence yoke and a convergence circuit. The adjustment

of the picture tube is therefore made easier as only the ad-

justment of static convergence by using a magnet is

enough. The deflection yoke and purity/convergency

magnets assembly has been set at the factory and requires

no field adjustments.

However, should the assembly be accidentally jarred or

tampered with, some or all adjustment may be necessary.

COLOR PURITY & VERTICAL CENTER

Loosen yoke retaining clamp (Fig. 2-1). With a sharp knife,

cut between the picture tube and the wedge. Remove

wedges completely and clean off dried adhesive from the

picture tube. PAINT is used to lock the tabs of the purity/

convergence magnet assembly in place (Fig. 2-1). The paint

must be removed with the end of a screwdriver before any

adjustments are attempted.

1. Inject a Video Signal (RASTER) to the Video input

terminal.

2. Let the purity tabs come in line horizontally as is shown

in Fig. 2-3. A long tab should be in the same direction

as the other short tab.

3. Move the yoke slowly backward.

4. Turn the green cut-off control to maximum and the red

and blue cut-off controls to minimum. Then adjust the

screen control so that the green band can be seen best.

(Fig. 2-4)

5 . Rotate the two tabs in the opposite direction with them

kept at an angle. Move them in either direction so that

the green band is centered on the picture tube.

6 . Check the vertical center position by displaying a

horizontal line. If incorrect, bring it to the center by

rotating the two tabs, kept at an angle, together in

either direction. (Fig. 2-5, 2-6)

7. Repeat steps 5 and 6 alternately until the green band

and the vertical centre are in line.

8. Move the yoke slowly towards the bell of the tube so

that the whole surface of the picture tube is filled with

a pure green raster.

9. Turning the red cut-off control to maximum and the

green cut-off control to minimum, check for pure red

raster.

10. Turning the blue cut-off control to maximum and the

green cut-off control to minimum, check for pure blue

raster.

11. Secure yoke retaining clamp (do not install wedges at

this time).

YOKE

LOCKING RING PURITY

MAGNETS (mark "P") Fig. 2-1

(REAR VIEW)

LONG AND SHORT

PROTRUSIONS

Let the protrusions come in line

Fi g .2- 3 J

(FRONT VIEW)

_-o--7"7t7::,.,-_.L GREEN BAN D

CENTRE

Bring the green band to the centre.

Fig. 2-4

(FRONT VIEW)

HORIZONTAL LINE

(~~--'------------~

(identified with a

white notch)

Bring the horizontal line

nearest to the white

notches shown in the

dotted circles.

Fig. 2-5

(TOP VIEW)

RDG.

IJL-___ --I

Select the cut-off service

switch from N to S, and a

horizontal line will appear.

Fig. 2-6

4

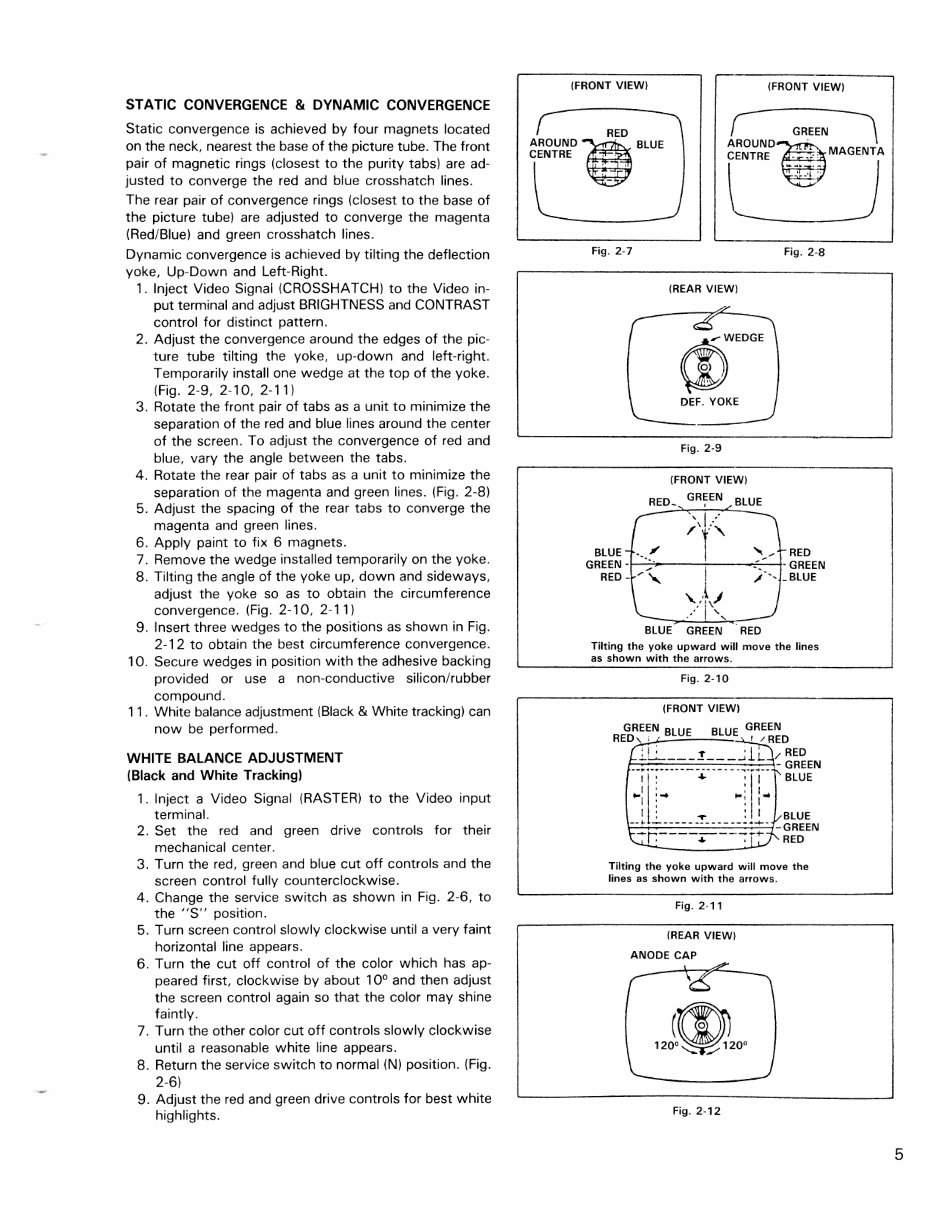

STATIC CONVERGENCE & DYNAMIC CONVERGENCE

Static convergence is achieved by four magnets located

on the neck, nearest the base of the picture tube. The front

pair of magnetic rings (closest to the purity tabs) are ad-

justed to converge the red and blue crosshatch lines.

The rear pair of convergence rings (closest to the base of

the picture tube) are adjusted to converge the magenta

(Red/Blue) and green crosshatch lines.

Dynamic convergence is achieved by tilting the deflection

yoke, Up-Down and Left-Right.

1. Inject Video Signal (CROSSHATCH) to the Video in-

put terminal and adjust BRIGHTNESS and CONTRAST

control for distinct pattern.

2. Adjust the convergence around the edges of the pic-

ture tube tilting the yoke, up-down and left-right.

Temporarily install one wedge at the top of the yoke.

(Fig. 2-9, 2-10, 2-11)

3. Rotate the front pair of tabs as a unit to minimize the

separation of the red and blue lines around the center

of the screen. To adjust the convergence of red and

blue, vary the angle between the tabs.

4. Rotate the rear pair of tabs as a unit to minimize the

separation of the magenta and green lines. (Fig. 2-8)

5. Adjust the spacing of the rear tabs to converge the

magenta and green lines.

6. Apply paint to fix 6 magnets.

7. Remove the wedge installed temporarily on the yoke.

8. Tilting the angle of the yoke up, down and sideways,

adjust the yoke so as to obtain the circumference

convergence. (Fig. 2-10, 2-11)

9. Insert three wedges to the positions as shown in Fig.

2-12 to obtain the best circumference convergence.

10. Secure wedges in position with the adhesive backing

provided or use a non-conductive siliconlrubber

compound.

11. White balance adjustment (Black & White tracking) can

now be performed.

WHITE BALANCE ADJUSTMENT

(Black and White Tracking)

1. Inject a Video Signal (RASTER) to the Video input

terminal.

2. Set the red and green drive controls for their

mechanical center.

3. Turn the red, green and blue cut off controls and the

screen control fully counterclockwise.

4. Change the service switch as shown in Fig. 2-6, to

the "S" position.

5. Turn screen control slowly clockwise until a very faint

horizontal line appears.

6. Turn the cut off control of the color which has ap-

peared first, clockwise by about 10

0

and then adjust

the screen control again so that the color may shine

faintly.

7. Turn the other color cut off controls slowly clockwise

until a reasonable white line appears.

8. Return the service switch to normal (N) position. (Fig.

2-6)

9. Adjust the red and green drive controls for best white

highlights.

(FRONT VIEW) (FRONT VIEW)

RED

AROUND~. BLUE

CENTRE '

, ,

~

1ROUND-~ G~.EEN \

CENTRE __ :': MAGENTA

I

-•.. - I

' .... , "

"------

Fig. 2·7 Fig. 2-8

BLUE

GREEN -

RED -

-

(REAR VIEW)

W

,..WEDGE

0)

!

"

DEF. YOKE

Fig. 2-9

(FRONT VIEW)

RED.

GREEN

BLUE ,

, I "

"

/'f" ,,~,

.. ......

-

/~ I

"

./-',

'\.,\j

/1 ' . "-

BLUE GREEN RED

RED

- GREEN

_BLUE

Tilting the yoke upward will move the lines

as shown with the arrows.

Fig. 2-10

(FRONT VIEW)

GREEN BLUE BLUE GREEN

RED, ; , ! /RED

; I ; l' ' 1 ' RED

__ ::::-_:_-=--=~=-:.:_:~ __ :_ -::: GREEN

I I : + : I' BLUE

..,Ii:'" .,.' I ..

I • ' I

--t l.- ____ = _____ Jl. -~~~~N

~r.----~--'-:- +- RED

Tilting the yoke upward will move the

lines as shown with the arrows.

Fig. 2-11

(REAR VIEW)

ANODE CAP

Fig, 2-12

5

NOTE: 1702 locations in ( ).

B1 VOLTAGE - Inject a video signal

1701 (110V)

Regulate VR, R109, for B1 adjustment so that Dc voltage between TP-91 and earth is 110 volts.

1702 (125V.)

Confirm that the voltage at TP-94 and IC901 pin 4 is 125 volts.

NOTE: Meter should be periodically calibrated at 20K ohms/volt.

FOCUS

Adjust the FOCUS control for best overall definition and picture detail at normal brightness and contrast.

VERTICAL POSITION

Adjust the V. center VR R428 (R429) to the optimum vertical picture position.

VERTICAL HEIGHT AND LINEARITY

1 . Display a pattern which allows easy confirmation of symmetry (such as a circle or crosshatch).

2. Reduce the vertical size with the V. HEIGHT VA.

3. Adjust the vertical linearity with the V. LIN. VA.

4. Readjust the vertical height, so that the picture extends to normal size.

HORIZONTAL WIDTH

Adjust H. WIDTH control coil L503 (L522) by turning it with a hexagonal adjusting bar only if RIGHT

and LEFT sides of picture can't be seen.

HORIZONTAL OSCILLATOR

1. Set the H. FREQ. VR to the mechanical center position.

2. Connect a jumper clip between TP-33A and TP-33B.

3. While rotating the H. FREQ. VR, R504, keep the picture stationary or slowly moving.

4. Remove the jumper wire.

5. Make sure that the set maintains horizontal sync, when signals are switched.

6

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$30.99

Viewed 52 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$30.99

Looking to repair your COMMODORE 1701/1702 MONITOR? Save on mechanic fees with our comprehensive repair manual, suitable for professional mechanics and DIY enthusiasts alike. This manual provides detailed specifications, safety precautions, adjustments, block diagrams, circuit notes, troubleshooting guides, and more, spanning 100 pages. Available in English, the manual is compatible with both Windows and Mac operating systems. With printable pages, you can conveniently bring the manual to your home, office, or repair shop. It's packed with diagrams and pictures, making it easy to understand and follow. Skip the wait for CD ROMs – order now and get instant access.