JCB Robot 190, 190HF, 1110, 1110HF, 190T, 190THF, 1110T, 1110THF Skid Steer Loader Service Repair Workshop Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Service

Manual

ROBOT

190, 1110

PUBLISHED BY THE

TECHNICAL PUBLICATIONS DEPARTMENT

OF JCB SERVICE; ©

WATERLOO PARK, UTTOXETER,

STAFFORDSHIRE, ST14 5PA, ENGLAND

Tel. ROCESTER (01889) 590312

PRINTED IN ENGLAND

Publication No. 9803/8530 issue 8

Copyright © 2004 JCB SERVICE

All rights reserved. No part of this publication may be reproduced, stored in

a retrieval system, or transmitted in any form or by any other means, elec-

tronic, mechanical, photocopying or otherwise, without prior permission

from JCB SERVICE.

General Information 1

Care & Safety 2

Routine Maintenance 3

Attachments A

Body & Framework B

Electrics C

Controls D

Hydraulics E

Transmission F

Brakes G

Tracks J

Engine K

R

Introduction

This publication is designed for the benefit of JCB Distributor Service Engineers who are receiving, or have received, training by

JCB Technical Training Department.

These personnel should have a sound knowledge of workshop practice, safety procedures, and general techniques associated

with the maintenance and repair of hydraulic earthmoving equipment.

Renewal of oil seals, gaskets, etc., and any component showing obvious signs of wear or damage is expected as a matter of

course. It is expected that components will be cleaned and lubricated where appropriate, and that any opened hose or pipe

connections will be blanked to prevent excessive loss of hydraulic fluid and ingress of dirt. Finally, please remember above all

else SAFETY MUST COME FIRST!

The manual is compiled in sections, the first three are numbered and contain information as follows:

1 = General Information - includes torque settings and service tools.

2 = Care & Safety - includes warnings and cautions pertinent to aspects of workshop procedures etc.

3 = Routine Maintenance - includes service schedules and recommended lubricants for all the machine.

The remaining sections are alphabetically coded and deal with Dismantling, Overhaul etc. of specific components, for example:

A = Attachments

B = Body & Framework ...etc.

The page numbering in each alphabetically coded section is not continuous. This allows for the insertion of new items in later

issues of the manual.

Section contents, technical data, circuit descriptions, operation descriptions, etc. are inserted at the beginning of each

alphabetically coded section.

All sections are listed on the front cover; tabbed divider cards align directly with individual sections on the front cover for rapid

reference.

Where a torque setting is given as a single figure it may be varied by plus or minus 3%. Torque figures indicated are for dry

threads, hence for lubricated threads may be reduced by one third.

'Left Hand' and 'Right Hand' are as viewed from the rear of the machine facing forwards.

9803/8530 Issue 1

i

Contents Page No.

Identifying your Machine 1 - 1

Torque Settings

- Unsealed Hoses and Adapters 2 - 1

- ‘O’ Ring Face Seal System 2 - 3

- ‘Torque Stop’ Hose System 2 - 4

Service Tools

- Numerical List 3 - 1

- Body and Framework 4 - 1

- Electrics 5 - 1

- Hydraulics 6 - 1

Sealing and Retaining Compounds 8 - 1

Section 1 General Information

9803/8530

Section 1

i

Issue 2*

*

1 - 1

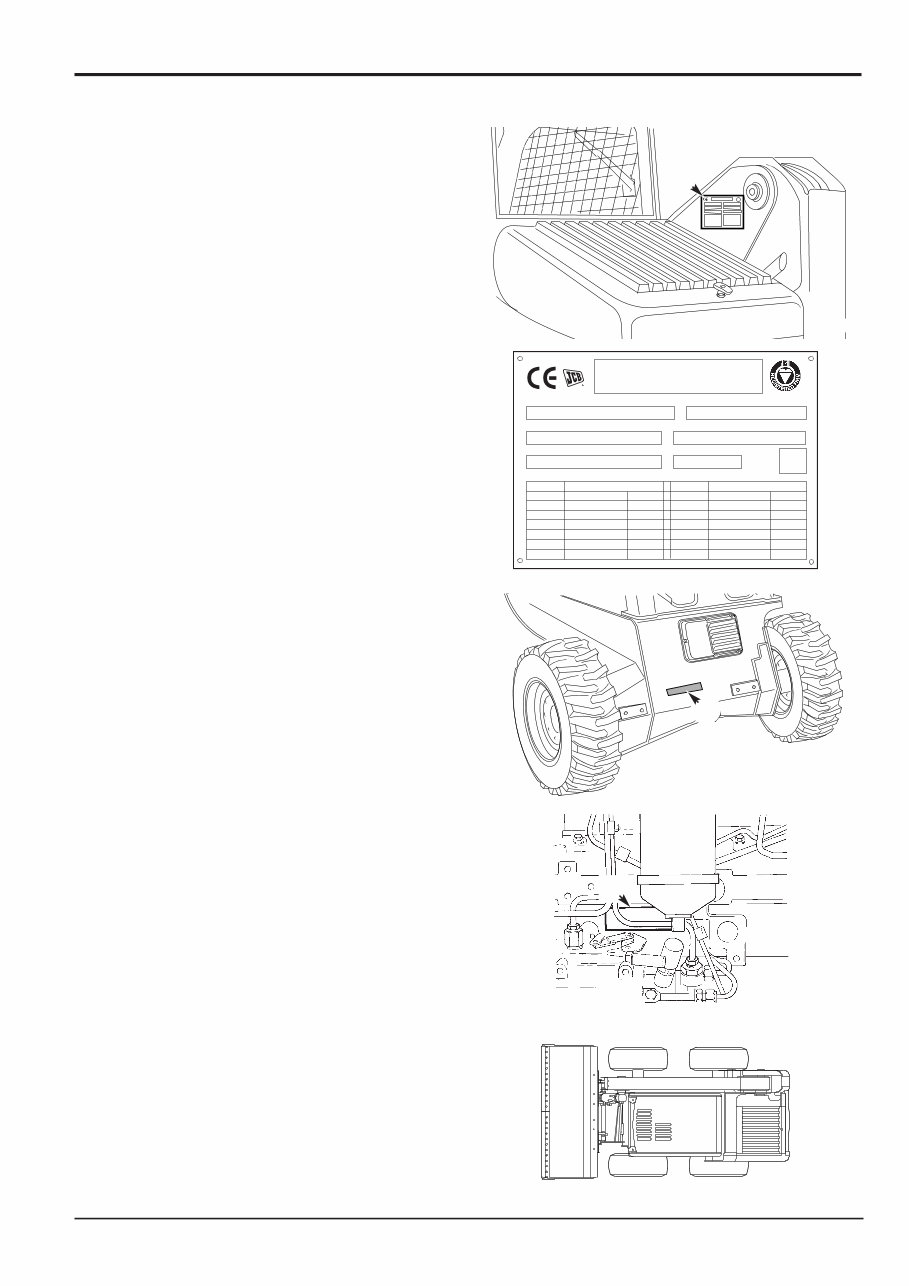

Machine Identification Plate

The machine identification plate A is located as shown. It is

stamped with the serial numbers of the major individual

units.

Typical Vehicle Identification Number (VIN)

SLP 190 S B V E 888001

World Manufacturer Identification

Machine Model

Machine Type (S = Standard, H = High-flow)

Build Type (A = Canopy, B = Cab)

Year of Manufacture:

W = 1998 2 = 2002

X = 1999 3 = 2003

Y = 2000 4 = 2004

1 = 2001 5 = 2005

Manufacturer Location (E = England)

Product Identification Number (PIN)

Unit Identification

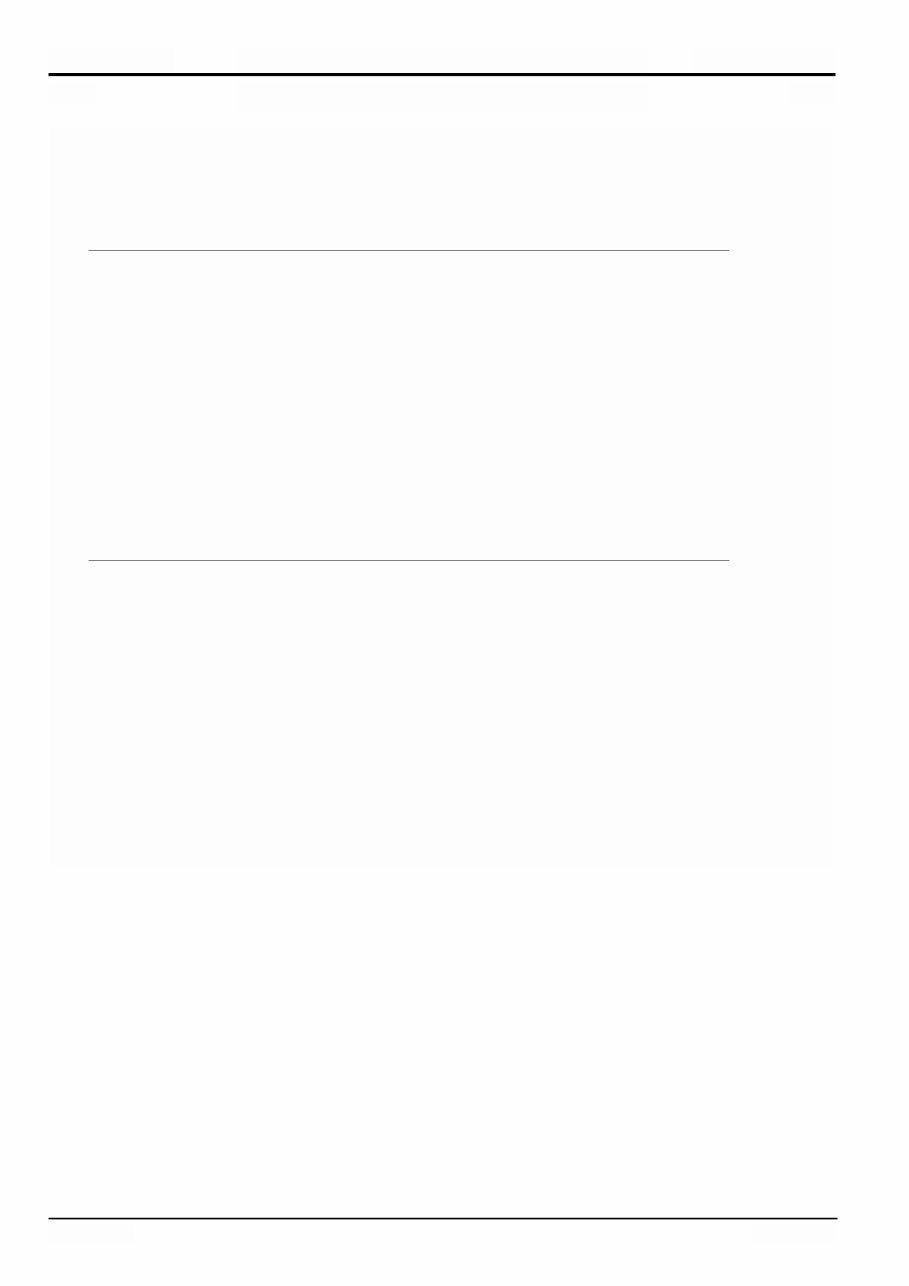

The chassis serial number is stamped on the front face of

the chassis as shown at B.

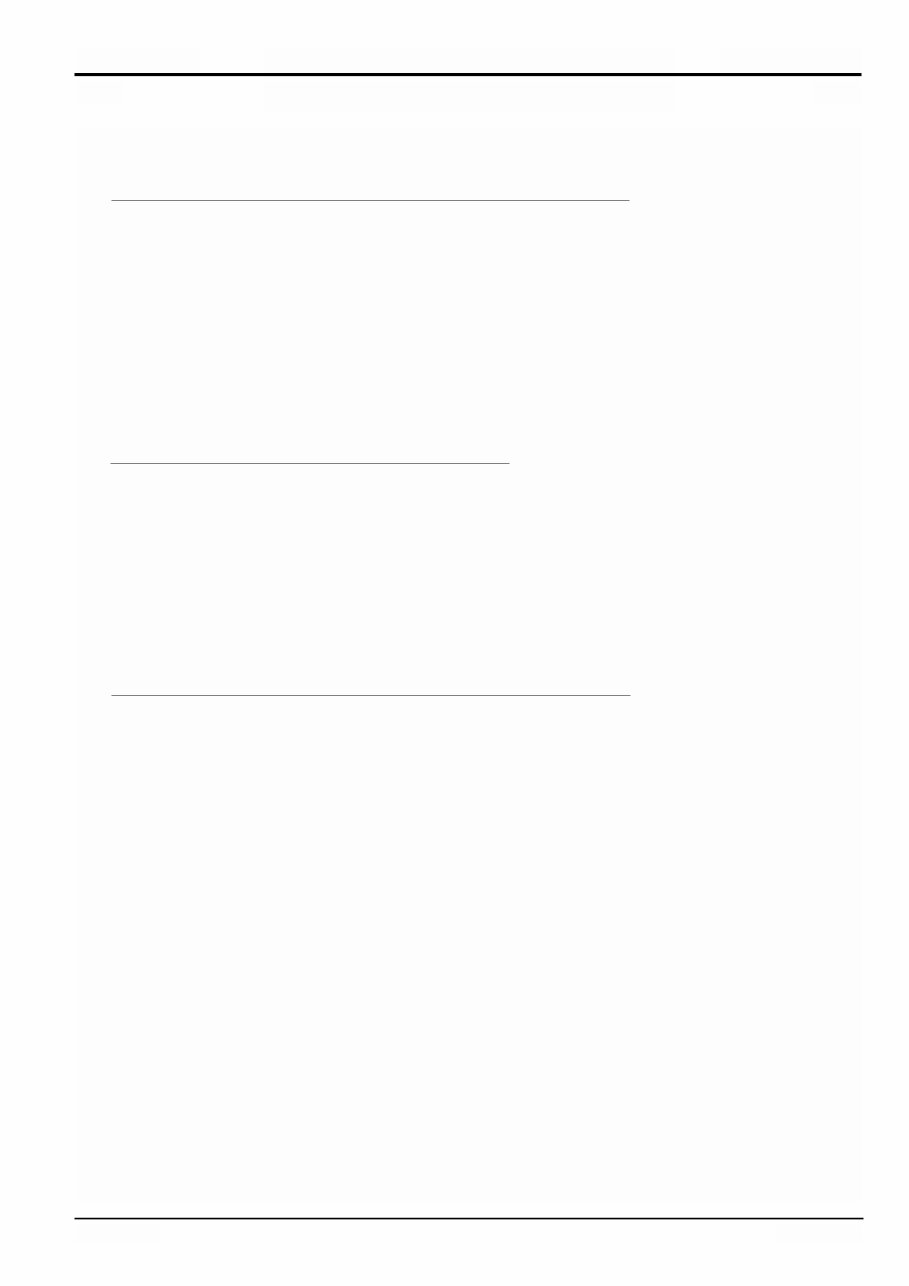

The engine serial number is stamped on a label C on the

side of the cylinder block.

If any of the major units are replaced with new ones, the

relevant serial number on the Machine Identification Plate

will be superseded. Either stamp the plate with the new

number or stamp out the old number.

Typical Engine Identification Number

AR 50262 U 500405 P

A B C D E

A Engine Type

AR = 4 cylinder naturally aspirated - low emission

AK = 4 cylinder turbo - low emission

RE = 4 cylinder naturally aspirated - low emission stage 2

RG = 4 cylinder turbo - low emission stage 2

Where the service procedure differ between the engine

types, the text and/or illustration will specify.

B Build Number

C Country of Origin

D Engine Sequence Number

E Year of Manufacture

Left Side, Right Side

In this manual, 'left' X and 'right' Y mean your left and right

when you are seated correctly in the machine.

Section 1 General Information

9803/8530

Section 1

1 - 1

Issue 4

Identifying your Machine

1 2 3 4 5 6 7

1

2

3

4

5

6

7

378270

B

378260

A

S181760

C

378210

Y

X

CONSTRUCTOR MADE IN UK

JCB COMPACT PRODUCTS LIMITED

HAREWOOD ESTATE, LEEK ROAD,

CHEADLE, STOKE ON TRENT,

UNITED KINGDOM ST10 2JU

Vehicle Identification No. Product Identification No.

ENGINE SERIAL No. WEIGHT

PUMP SERIAL No. YEAR OF MANUFACTURE

MODEL 80/1269/EEC MODEL 80/1269/EEC

POWER KW R.P.M. POWER KW R.P.M.

160

170

170 HF

35.7

37.3

37.3

2600

2800

2800

817/19702

1CX HF 1CX

190

190 HF

1110

1110 HF

37.3 2800 2800

59.7

59.7

68.6

68.6

2200

2200

2200

2200 35.7 2600 160 HF

2800

37.3

180 44.7 2800 180 HF 44.7

2 - 1

Section 1 General Information

9803/8530

Section 1

2 - 1

Issue 1

Torque Settings

Use only where no torque setting is specified in the text. Values are for dry threads and may be within three per cent of the

figures stated. For lubricated threads the values should be REDUCED by one third.

UNF Grade 'S' Bolts

Bolt Size Hexagon (A/F) Torque Settings

in (mm) in Nm kgf m lbf ft

1

/4 (6.3)

7

/16 14 1.4 10

5

/16 (7.9)

1

/2 28 2.8 20

3

/8 (9.5)

9

/16 49 5.0 36

7

/16 (11.1)

5

/8 78 8.0 58

1

/2 (12.7)

3

/4 117 12.0 87

9

/16 (14.3)

13

/16 170 17.3 125

5

/8 (15.9)

15

/16 238 24.3 175

3

/4 (19.0) 1

1

/8 407 41.5 300

7

/8 (22.2) 1

5

/16 650 66.3 480

1 (25.4) 1

1

/2 970 99.0 715

1

1

/4 (31.7) 1

7

/8 1940 198.0 1430

1

1

/2 (38.1) 2

1

/4 3390 345.0 2500

Metric Grade 8.8 Bolts

Bolt Size Hexagon (A/F) Torque Settings

in (mm) in Nm kgf m lbf ft

M5 (5) 8 7 0.7 5

M6 (6) 10 12 1.2 9

M8 (8) 13 28 3.0 21

M10 (10) 17 56 5.7 42

M12 (12) 19 98 10 72

M16 (16) 24 244 25 180

M20 (20) 30 476 48 352

M24 (24) 36 822 84 607

M30 (30) 46 1633 166 1205

M36 (36) 55 2854 291 2105

Note: All bolts used on JCB machines are high tensile and must not be replaced by bolts of a lesser tensile specification.

2 - 2

BSP Adapters with Bonded Washers.

Adapter Size Spanner size Torque Settings

in mm Nm kgf m lbf ft

1

/8 11 20 2.0 15

1

/4 19 34 3.5 25

3

/8 22 75 7.6 55

1

/2 27 102 10.4 75

5

/8 30 122 12.4 90

3

/4 32 183 18.7 135

1 38 203 20.7 150

1

1

/4 305 31.1 225

1

1

/2 305 31.1 225

SAE Adapters with ‘O’ rings.

Adapter Size Torque Settings

in Nm kgf m lbf ft

7

/16 20 2.0 15

9

/16 35 3.6 26

3

/4 81 8.3 60

7

/8 108 11.0 80

1

1

/16 183 18.7 135

1

5

/16 298 30.4 220

1

5

/8 380 38.8 280

Hydraulic Coned BSP Hoses.

Hose Size Spanner size Torque Settings

in mm Nm kgf m lbf ft

1

/8 14 14 1.4 10

1

/4 19 27 2.7 20

3

/8 22 40 4.0 29

1

/2 27 55 5.6 40

5

/8 30 65 6.6 48

3

/4 32 95 9.7 70

1 38 120 12.2 88

1

1

/4 189 19.3 139

1

1

/2 244 24.9 180

Section 1 General Information

9803/8530

Section 1

2 - 2

Issue 1

Torque Settings

2 - 3

‘O’ Ring Face Seal System

Adaptors screwed into valve blocks

Adaptors screwed into valve blocks, etc. seal onto an 'O' ring which is compressed into a 45

o

seat machined in the face of the

tapped port.

Common Spanner Size (A/F) Tightening Torque

Adaptor Size mm in. Nm lbf ft

1/4” BSP 19 0.75 18 13

3/8” BSP 22 0.875 31 23

1/2” BSP 27 1 49 36

5/8” BSP 30 60 44

3/4” BSP 32 1.25 81 60

1” BSP 38 1.5 129 95

1 1/4” BSP 206 152

SAE SAE Port Common Spanner Size (A/F) Tightening Torque

Tube Size Thread Size mm in. Nm lbf ft

4 7/16 - 20 15.9 0.625 20 - 28 16.5 - 18.5

6 9/16 - 18 19.1 0.750 46 - 54 34 - 40

8 3/4 - 16 22.2 0.875 95 - 105 69 - 77

10 7/8 - 14 27.0 1.063 130 - 140 96 - 104

12 1.1/16 - 12 31.8 1.250 190 - 210 141 - 155

16 1.5/16 - 12 38.1 1.500 290 - 310 216 - 230

20 1.5/8 - 12 47.6 1.875 280 - 380 210 - 280

Hoses Screwed onto Adaptors

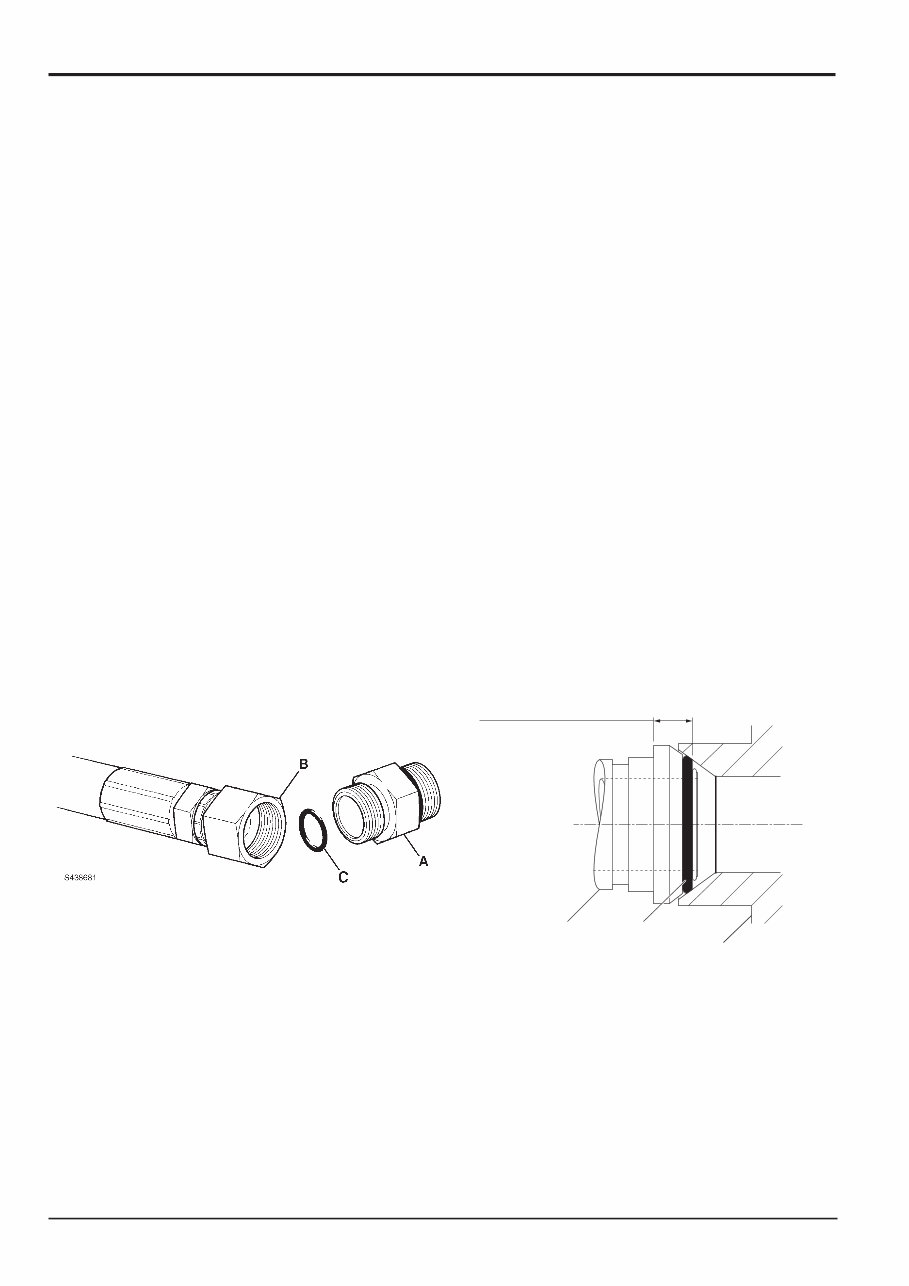

Hoses B screwed onto adaptors A etc. seal onto an 'O' ring C which is compressed into a 45

o

seat machined in the face of the

adaptor port.

Common Spanner Size (A/F) Tightening Torque

Hose Size mm in. Nm lbf ft

1/8” BSP 14 14 10

1/4” BSP 19 0.75 24 18

3/8” BSP 22 0.875 33 24

1/2” BSP 27 1 44 33

5/8” BSP 30 58 43

3/4” BSP 32 1.25 84 62

1” BSP 38 1.5 115 85

1 1/4” BSP 189 140

1 1/2” BSP 244 180

Section 1 General Information

9803/8530

Section 1

2 - 3

Issue 1

Torque Settings

B

A

C

A438691

Dimension will vary depending

on torque applied.

2 - 4

'Torque Stop' Hose System

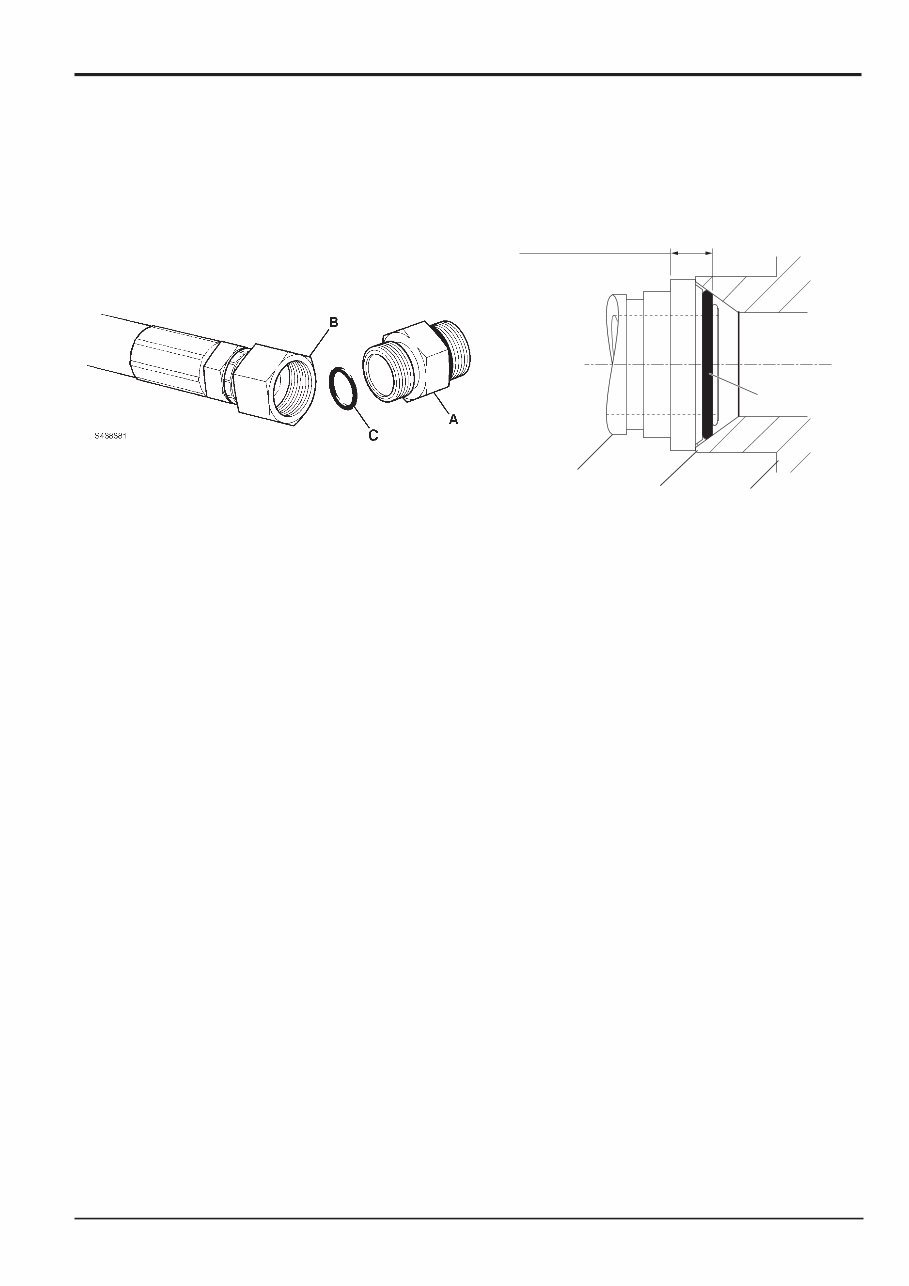

'Torque Stop' Hoses B screwed onto adaptors A etc. seal onto an 'O' ring C which is compressed into a 45

o

seat machined in

the face of the adaptor port. To prevent the ‘O’ ring being damaged as a result of over tightening, 'Torque Stop' Hoses have an

additional shoulder, which acts as a physical stop.

Common Spanner Size (A/F) Tightening Torque

Hose Size mm in. Nm lbf ft

1/8” BSP 14 14 10

1/4” BSP 19 0.75 27 20

3/8” BSP 22 0.875 40 30

1/2” BSP 27 1 55 40

5/8” BSP 30 65 48

3/4” BSP 32 1.25 95 70

1” BSP 38 1.5 120 89

1 1/4” BSP 189 140

1 1/2” BSP 244 180

Section 1 General Information

9803/8530

Section 1

2 - 4

Issue 1

Torque Settings

A438701 D

B

A

C

Minimum dimension fixed

by shoulder D.

3 - 1

Numerical List

Page No.

1406/0011 Bonded Washer 6 - 2

1406/0018 Bonded Washer 6 - 2

1406/0021 Bonded Washer 6 - 1/6 - 2

1406/0029 Bonded Washer 6 - 2

1604/0003 Adapter 6 - 2

1604/0004 Adapter 6 - 2

1604/0006 Adapter 6 - 1/6 - 2

1606/0003 Adapter 6 - 2

1606/0004 Adapter 6 - 2

1606/0007 Adapter 6 - 2

1606/0008 Adapter 6 - 2

1606/0009 Adapter 6 - 2

1612/0006 Adapter 6 - 1

331/22966 Pump Drive Alignment Tool 6 - 4

4101/0251 Threadlocker and Sealer 8 - 1

4101/0451 Threadlocker 8 - 1

4101/0552 Threadlocker and Sealer (High Strength) 8 - 1

4101/0651 Retainer (High Strength) 8 - 1

4102/0551 High Strength Threadlocker 8 - 1

4102/1201 Multi-Gasket 8 - 1

4104/0251 Activator (Aerosol) 8 - 1

4104/0253 Activator (Bottle) 8 - 1

4104/1310 Hand Cleaner 4 - 1

4104/1557 JCB Cleaner/Degreaser 8 - 1

816/00189 Blanking Cap 6 - 2

816/00190 Blanking Cap 6 - 2

816/00193 Blanking Cap 6 - 2

816/00196 Blanking Cap 6 - 2

816/00197 Blanking Cap 6 - 2

816/00294 Blanking Cap 6 - 2

816/15118 Pressure Test Adapter 6 - 1

816/20008 Adapter 5 - 2

816/50043 'T' Adapter 6 - 3

816/55038 Pressure Test 'T' Adapter 6 - 1

816/55040 Pressure Test 'T' Adapter 6 - 1

816/60096 'T' Adapter 6 - 3

826/01099 Rivet Nut 4 - 3

826/01101 Rivet Nut 4 - 3

826/01102 Rivet Nut 4 - 3

826/01103 Rivet Nut 4 - 3

826/01104 Rivet Nut 4 - 3

826/01105 Rivet Nut 4 - 3

892/00047 'T' Adapter 6 - 3

892/00048 'T' Adapter 6 - 3

892/00055 Blanking Plug 6 - 2

892/00056 Blanking Plug 6 - 2

892/00057 Blanking Plug 6 - 2

892/00059 Blanking Plug 6 - 2

892/00060 Blanking Plug 6 - 2

892/00074 Female Connector 6 - 3

892/00075 Female Connector 6 - 3

892/00077 Female Connector 6 - 3

892/00137 Hose 6 - 2

892/00223 Hand Pump 6 - 2

892/00253 Pressure Test Kit 6 - 1

892/00255 Pressure Test Adapter 6 - 1

892/00256 Pressure Test Adapter 6 - 1

892/00257 Pressure Test Adapter 6 - 1

Page No.

892/00258 Pressure Test Adapter 6 - 1

892/00259 Pressure Test Adapter 6 - 1

892/00260 Pressure Test Adapter 6 - 1

892/00261 Pressure Test Adapter 6 - 1

892/00262 Pressure Test 'T' Adapter 6 - 1/6 - 2

892/00263 Pressure Test 'T' Adapter 6 - 1

892/00264 Pressure Test 'T' Adapter 6 - 1

892/00265 Pressure Test 'T' Adapter 6 - 1

892/00268 Flow Monitoring Unit 6 - 1

892/00269 Sensor Head 6 - 1

892/00270 Load Valve 6 - 1

892/00271 Adapter 6 - 1

892/00272 Adapter 6 - 1

892/00274 Adapter 6 - 2

892/00275 Adapter 6 - 1

892/00276 Adapter 6 - 1

892/00277 Adapter 6 - 1

892/00278 Gauge 6 - 2

892/00279 Gauge 6 - 2

892/00281 AVO Meter 5 - 1

892/00282 Shunt 5 - 1

892/00283 Tool Kit Case 5 - 1

892/00284 Tachometer 5 - 1

892/00285 Hydraulic Oil Temperature Probe 5 - 1

892/00286 Surface Temperature Probe 5 - 1

892/00706 Test Probe 6 - 2

892/00842 Glass Lifter 4 - 1

892/00843 Folding Stand 4 - 1

892/00844 Long Knife 4 - 2

892/00845 Cartridge Gun 4 - 1

892/00846 Glass Extractor (Handles) 4 - 2

892/00847 Nylon Spatula 4 - 3

892/00848 Wire Starter 4 - 2

892/00849 Braided Cutting Wire 4 - 2

892/00858 Pump Support Bracket 6 - 2

926/15500 Rubber Spacer Blocks 4 - 3

992/09300 Spanner 6 - 3

992/09400 Spanner 6 - 3

992/09500 Spanner 6 - 3

992/09600 Spanner 6 - 3

992/09700 Spanner 6 - 3

992/12300 12V Mobile Oven 4 - 1

992/12400 Static Oven - 2 Cartridge 4 - 1

992/12600 Static Oven - 6 Cartridge 4 - 1

992/12800 Cut-Out Knife 4 - 2

992/12801 "L" Blades 4 - 2

993/55700 Direct Glazing Kit 5 - 1

993/68100 Slide Hammer 6 - 3

The following parts are replacement items for kits and would

normally be included in the kit numbers quoted above.

Replacement items for kit no. 892/00253

892/00201 Replacement Gauge 6 - 1

892/00202 Replacement Gauge 6 - 1

892/00203 Replacement Gauge 6 - 1

892/00254 Replacement Hose 6 - 1

Section 1 General Information

9803/8530

Section 1

3 - 1

Issue 2*

Service Tools

*

4 - 1

Section B - Body and Framework

Section 1 General Information

9803/8530

Section 1

4 - 1

Issue 1

Service Tools

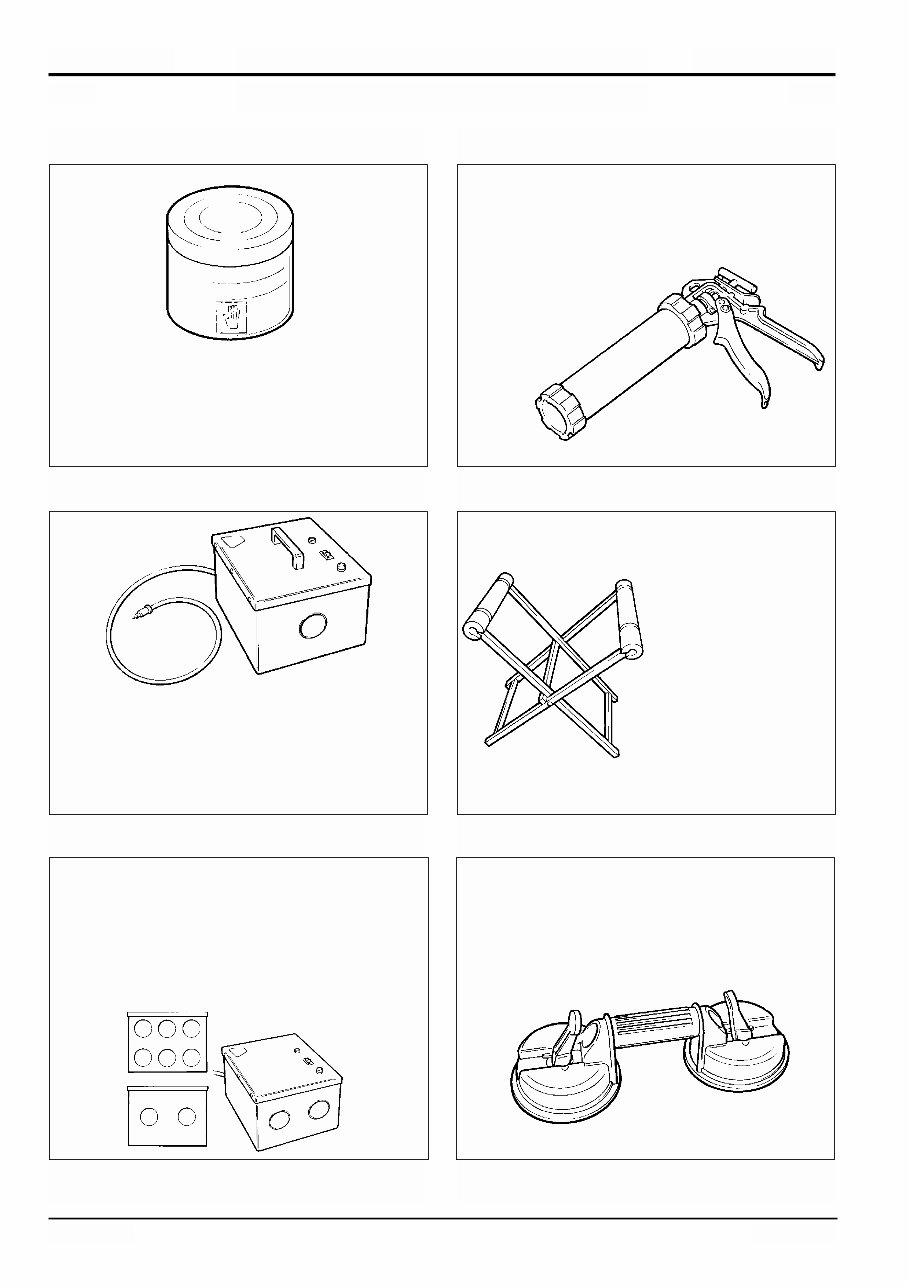

Cartridge Gun - hand operated - essential for the

application of sealants, polyurethane materials etc.

JCB part number - 892/00845

S186240

Hand Cleaner - special blend for the removal of

polyurethane adhesives.

JCB part number - 4104/1310

(454g; 1 lb tub)

S186270

S186250

12V Mobile Oven - 1 cartridge capacity - required to

pre-heat adhesive prior to use. It is fitted with a male

plug (703/23201) which fits into a female socket

(715/04300).

JCB part number - 992/12300

Folding Stand for

Holding Glass -

essential for preparing

new glass prior to

installation.

JCB part number -

892/00843

S186280

S186300

240V Static Oven - available with 2 or 6 cartridge

capacity - required to pre-heat adhesive prior to use.

No plug supplied. Note: 110V models available upon

request - contact JCB Technical Service.

JCB part number:

992/12400 - 2 Cartridge x 240V

992/12600 - 6 Cartridge x 240V

Glass Lifter - minimum 2 off - essential for glass

installation, 2 required to handle large panes of glass.

Ensure suction cups are protected from damage

during storage.

JCB part number - 892/00842

S186260

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 97 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

These manuals cover the following machine models and serial numbers:

- Robot 190, 190HF / 1291500 to 1294999

- Robot 1110, 1110HF / 1291500 to 1294999

- Robot 190T, 190THF / 1407000 to 1409999

- Robot 1110T, 1110THF / 1407000 to 1409999

These manuals are valuable resources for both professional technicians and first-time owners or DIY enthusiasts. They provide comprehensive information necessary to perform procedures correctly, from routine maintenance to preventive care. By following the guidelines in this service manual, users can save time and money by preventing premature failure and unnecessary repairs.

Manual Contents:

- General Information

- Care and Safety

- Routine Maintenance

- Attachments

- Body and Framework

- Electrics

- Controls

- Hydraulics

- Transmission

- Brakes

- Tracks

- Engine

File Format: PDF

Compatibility: All Versions of Windows & Mac

Language: English

Requirements: Adobe Reader & Win