Case 450 Crawler Backhoe Loader Tractor OEM Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Case 450

Crawler Backhoe

Loader Tractor

Service Maintenance

Manual

v 7.0

http://BestManuals.net

Best.Manuals@yahoo.com

© 2009, 2010 BestManuals/UserFriendlyCDs

TABLE OF CONTENTS

SERIES/SECTION SECTION NO .

10 SERIES . GENERAL

General Engine Specifications ..................................... 11

Detailed Sp*ificatiws ......................................... 12

Maintenance and Lubrication ................................... -1050

Torque Chart ............................................... 1051

20 SERIES . ENGINE

Cylinder Head and Valves ....................................... 22

Engine Block Assemblies ........................................ 23

Engine Removal. Installation. Stall Tests ............................ 2050

Air Cleaner ................................................ 2051

30 SEMES- FUELSYSTEM

Fuel System and Filters ........................................ 31

.......................... Eoosa Master Model DB Fuel Injection Pump 32

..................................... Roosa Master Fuel Injectors 33

Throttle Linkage Adjustments. Fuel Lines ........................... 3052

40 SERIES . HYDRAULICS

................. Hydraulic Diagrams. Trouble Shooting. Pressure Checks

4011

EquipmentPump ............................................ 4013

................................. Loader and Dozer Control Valves 4021

Commercial-Shearing Backhoe Control Valves ........................ 4022

............................... Miscellaneous Valves and Couplings 4028

D26726 and D45399 Diversion Valves

D39297 4-111-1 Bucket Relief Valve

D43 550 Anti-Rollback Check Valve

D46850 Relief Valve

Backhoe "Quick Disc~nnect~~ Couplings

Pull Behind "Quick Disconnectw Couplings

......................................... Boom Lockout System 4041

.......................................... Hydraulic Cylinders 4057

50 SERIES . TRACK

....................................

Track and Suspension System 5010

................

Torquing Procedure for Sprocket Mounting Bolts

5010. Supp't 1

60 SEMES . POWER TRAIN

................................... Transmission and Final Drives 64

Trouble Shooting the ~ransmission/Converter Hydraulic

.................................... System with a Flowmeter 6012

~ransmission/~onverter Hydraulic System Diagram.

Transmission Removal. Transmission Controls .................... -6013

............................................ Torque Converter 6016

.............................................. Charging Pump 6017

............................................ Declutch Lockout 6019

................................................ Drive Shafts 6022

J I Case TENNEco

ATenneco Company 0

Burl . Form 9-72332 May 1973 PRINTED IN U.S.A.

70 SERIES - BRAKES

Master Cylinders, Parking Brakes , Adjustments •.. •• .•.•... •••• .... •.. 7010

NOTIE: Also refer to Brakes in Section 64.

80 SERIES - ELECTRICAL SYSTE M

\Vlrlng DIagrams ... .. ... ..... .. ••••• ... . .. • •.. . ... .. .•••.. .. 80 11

Trouble Shooting .............. .•.•.. ..•. ..... • •• • .... •• •• .... 8012

Ign ition System .. .... .. ....... . ••••• ....... ••• ... .... ••• .... 8013

Batteries .............. ...... .• ••... . .. . .•• ..... .... •• .... 8014

Starter and Starter Solenoid . ......... ••... ... ..•. .. . ...... • . .... 8015

Generator a nd Voltage Regulator .. .. .. .. ••• ...... ••• ....... ••• .... 8017

90 SERIES - MOUNTED EQUIPMEN T

Loader ........ ... ............. •• • ....... ...• ... ..... •. ... 9011

Dozers .. .... .. ... ...... .. . .. ... .• ••••. .. . .• •• ..... ••• .... 9013

Models 9 and 19 Gearmatic Winches ...... ••• ........ •• ... .. .. •.. .. 9014

Ripper .. .. . .. .... . ... .... ...... •••• .. ... . .••. ...... • •. .. . 9015

Rollover Protection Structure . ....... • .•• . •• ..•.. . .•••• .... . •.. .. 9019

Models 26 a nd 26C Backhoe .. ... . .. .. .. .. •• . ..... ••• ••... ..•.. .. 9022

Model 32 Backhoe . . ... .......... . ..• •• .. .... ..••.. .. .. .. • .... 9023

Model 33 Backhoe .. . ... ..... .. .. .... .. • ..... .. . ••... . ..• .... 9024

Seat and T ank Assembly ..... .. . .. ..... •• ........ •• ... .. ..• .... 9025

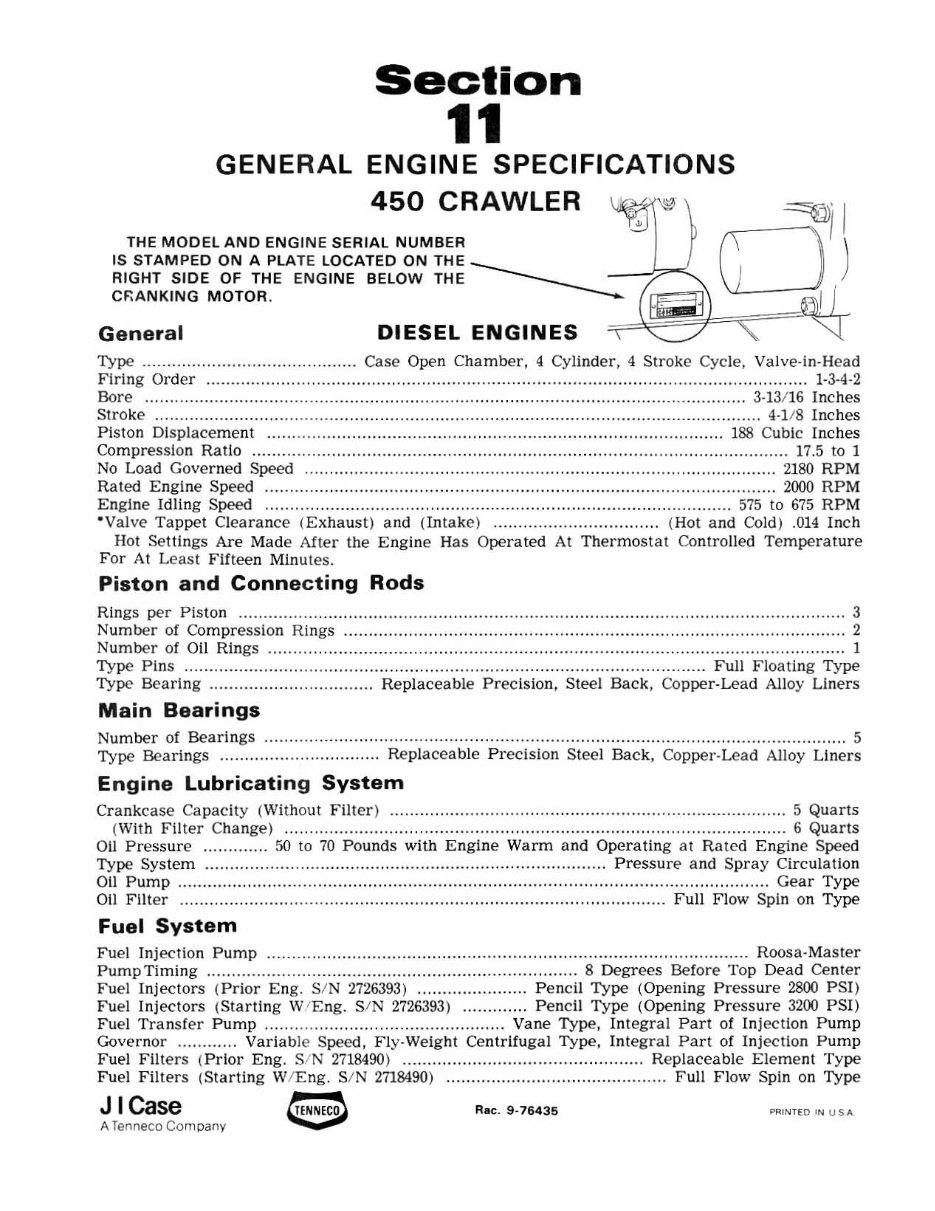

Section

11

GENERAL ENGINE SPECIFICATIONS

450 CRAWLER ~. I

THE MODEl AND ENGINE SERIAL NUMBER 0

1

)

IS STAMPED ON A PLATE LOCATED ON THE _______ _

RIGHT SIDE OF THE EN GINE BELOW THE _____ - -'l-'

C~A NKING MOTOR . =~[{;~H~?JI=",==, ~I J

Ge neral DIESEL ENGINES "i .~

Type .... .. .. ........................ ..... .... Case Open Chamber, 4 Cylinder, 4 Stroke Cycle, Valv e- in-Hea d

Firing Order ............................................................ .. ....... ................................................... 1- 3-4-2

Bore .... ................................. ................. ................. .. ....... ............... ................ .. ....... 3· 13/ 16 Inches

Stroke ................................................................................. .................... .. .................. 4·]/8 Inches

P iston Displacement .............. .. ......................... ................................ .................. 1 88 Cubic Inches

Compres sion Ratio ........... ........................ ................ ............ ........... ................................. 17.5 to 1

No Load Governed Speed .......... ................ ......................... ..................... .. .................. .. 2180 RPM

Rated Engine Speed ...................................................................................................... 2000 RPM

Engine Idling Speed ....... .. ......................... ........ ...................... ......... .................... 575 to 675 RPM

· Valve Tappet Clearance (E xhaus t) and (Intake) ................................. (Hot and COld ) . 014 I nch

Hot Settings Are Made After the Engine Has Operated At Thermosta t Controlled Temperature

For At Least Fifteen Minutes.

Piston and Connecting Rods

Rings per Piston ..................... .. ... ......................................................... ........................... ...... ..... 3

Number of Compression Rings ............................... .......... ......................... ........................ .......... 2

Number of Oil Rings .......... ...................................................................... ................................ .. . 1

Type Pins .......................... ..................... ................................. .............. .......... Full Floating Type

Type Bearing .................. ............... Re placeable Precis ion, Steel Bac k, Co pper· Lead Alloy Liners

Main Bearings

Number of Bearings .......................... ................ .......... .............. ............. ..................................... 5

Type Bearings ................................ Replaceable Preci sion Steel Back , Copper·Lead Alloy Liners

En gine Lubricatin g System

Crankcase Ca pacity (Without Filt er) ......... ................... ................ .......... ......................... 5 Quarts

(With Filt er Change) ...... .. ................. .. .. ................................................................. ...... 6 Quarts

011 Pressure ............. 50 to 70 Pounds wi th Engine Warm and Operating at Rated Engine Speed

Type System ........................................................... . ....... . .. .......... Pressu re a nd Spray Circul ation

011 Pump ........................ .. .................................. ...................... ..... ............................... Gear Type

Oil Filter ................................................................... .............................. Full Flow Spin on T ype

Fuel System

Fuel Injection Pump ............................................................................................... Roosa·Mas ter

Pump Timing ........................................ .. ................................ 8 Degrees Before Top Dead Cenler

Fuel Injectors ( Prior Eng. SIN 2726393) " .................... Pencil Type (Opening Press ure 2800 PSI )

Fuel Inj ectors (St arti ng Wi Eng. SIN 2726393 ) ............. Pen c il Type (Opening Pressure 3200 PSI)

Fuel Tra ns fer Pump .. .... .. ............ ........... ................. Vane Type, In tegra l Part of Injection Pu mp

Governor ............ Variab le Speed, Fly·Welght Cen tr if ugal Type, In tegral Part of Inj ection Pu mp

Fuel Filters (Pr ior Eng . SIN 2718490) ................................. .. ............. Replaceable Eleme nt Type

F uel Fil ters (Starti ng W/ Eng . SIN 2718490) ........................................ Fu ll Flow Spin on Type

J I Case e Rae. 9 · 764 35 PRI~TEO I~ USA

A Ten neco Co mp any

Section

12

DETAILED SPECIFICATION S

e

ser nendly

TABLE OF CONTENTS

ENGINE BLOCK "" .. .. . ........ ... ... .. ............ .. ...... .......... .. . ........ ....... .. ...... .. ........ ...... .. .... ............... 2

CYLINDER HEAD AND VALVES 7

COOLING SYSTEM . ... .. . ... 10

ENGINE OIL FILTER .. 11

AIR CLE ANER ............ .. ... .... ............. .......... ........ ...... , ....... ............... .. ........ , ..... ...... ,...... 11

FUE L SYSTEl\'[ .. .. ... .................. .. ..... ................ ...... ........ .. ' ........... ... ........ , .......... , ..... . ..... 12

BHAKES .. ... .. .... .. . ........ . .... . ... . ... ... .. .... .. '" 14

PO\VER TRAIN ... ... ...... ..... ..... .. ................. ....... .. .............. ....... " .' ....... .. ... . ... .... ....... ....... 15

STEERING .................... ..

.. ... .... ... .. .......... . 16

GE NERAL TORQUE TABLE ...... ........... ... ....... . ........ ...... ................ . .. ...... . . .... ........ ...... 17

SPECIAL TORQ UES .. .......... .... .. ........... .......................... ... .. .......... . .. 17

Rd". F orm 9 ·807 31

12-2

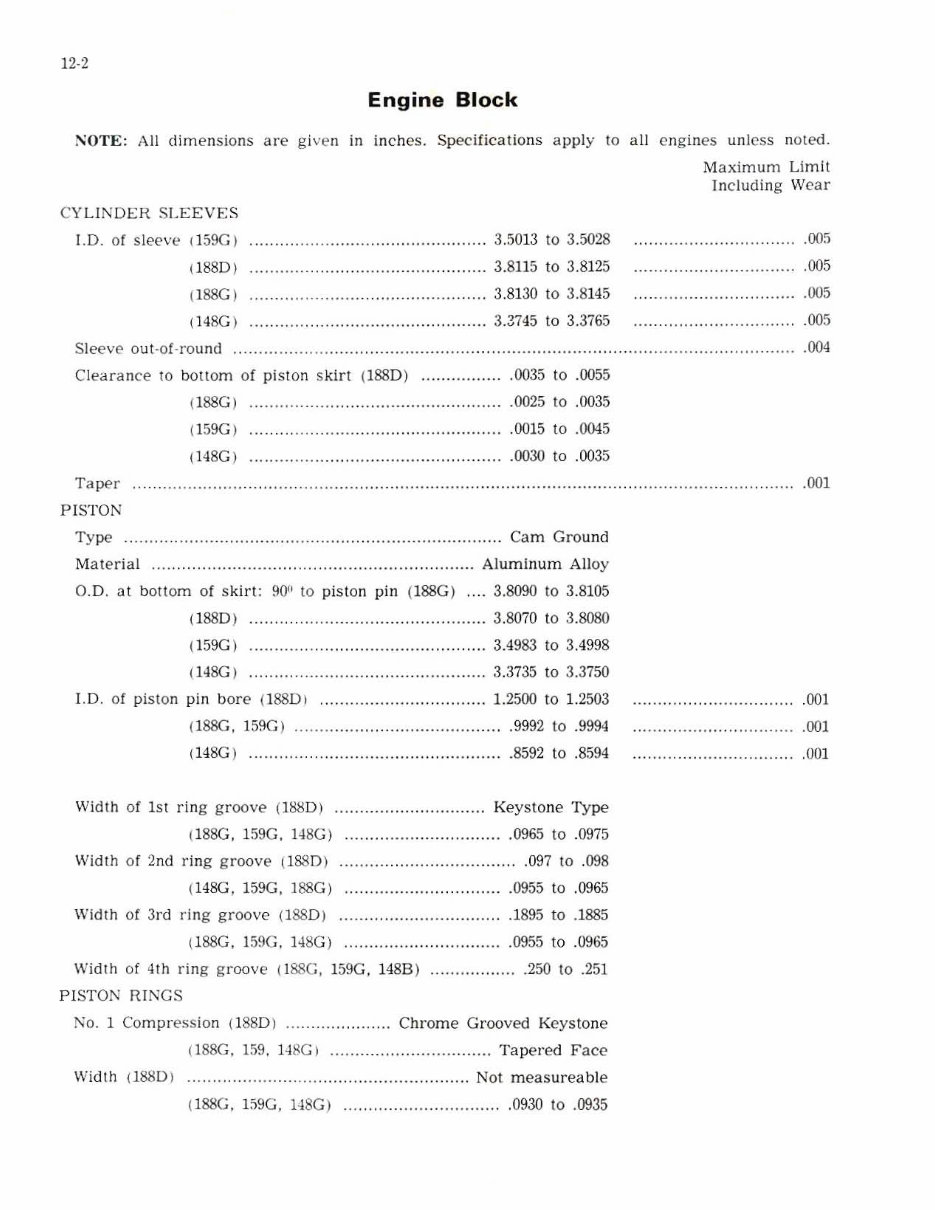

Engine Block

NOTE: All dimensions are given in inche s. Specifications apply to all engines unless noted.

C YLINDER S LEEVES

J.D. of sleeve (159C )

(1880 I

(l88C1

(l48G I

......... ........ . ............. .. ..... .. 3.5013 to 3.5028

...... .. ................. ......... .. .. ....... 3.8115 to 3.8125

.. .. ............ ... ............ ......... 3.81 30 to 3.8145

.... ................. .. .. .. ......... 3.3745 to 3.3765

Maximum Lim it

ln cluding Wear

.005

Sleeve out -o f· round ......... .... ... ... . .. ..... .. ......... .. ..... ....... .................... ................. ........ ...... .. .... .

.005

.005

.005

.004

Cleara nce to botlom of pi ston s kirt (188D) ................ . 0035 to .0055

(l88GI .. ... ... ...... . ................................... 0025 to .0035

(159C )

(!48GI

.0015 to .0045

.0030 to .0035

Tape r

PI STON

.. . .... ........ ....... ............. ....... ... .. ................ ......................... .. .. ..... . 001

Type ... ......................................... .. .......... .. .............. .. Cam Groun d

Mate ria l . .. ... ... ............ . .......... . ................... ........... Al um inum Alloy

G.D. at b ottom of s kirt : 90!! to piston pin (l88G ) . .. . 3.8090 to 3.8105

(1 88 01 . .. ......... .. .. ....................... 3.8070 to 3.8080

(!59G I ....... ... ........ ........ . ............ . ...... 3.4983 to 3. 499 8

(H SG I ......... ..... ......... ........... ............. 3.3735 to 3.3750

l. D. of piston pin b ore (18801 ................................. 1. 2500 to 1. 2503

(188C . 15SGI ... ..... .. ...... .. ....................... 9992 to .9994

(148G I . . ......... . ...................................... 859 2 to .8594

Wi dt h of 1st ring groove (lS!:!D) ..... ... _ .... . ................ Key stone Type

(18SG . 159G. " 8GI ................................ 0965 to .0975

Width of 2nd ring gr oove ll88D) ........... .. ....................... 09 7 to .098

( 148G , l 59G , J88G) . .. ......... .. .... .. .... ...... 0955 to .0965

Widt h of 3rd ring groov e (188 0) ................... . ............. 1895 to .1885

(l 88G. 159G, 148G) ..................... ........... 0955 to .0965

Width of 4th ring groove (l 88G, 159G. 148B ) ......... . .. . ..... 250 to .251

PI STON RINGS

No .1 Comp r ess ion (188D) ............ .. .. Ch rome Grooved Key sto ne

(l 88G. 1 59 . 1 -l 8G) ..... ................ ........... Tapered F ace

Width (188D ) ............ ... .. ....... .. ............. . ........ .. ..... Not meas ureable

(l88G. !S9G. "8G ) .... ..................... . 0930 to .0935

.OO!

.001

.U01

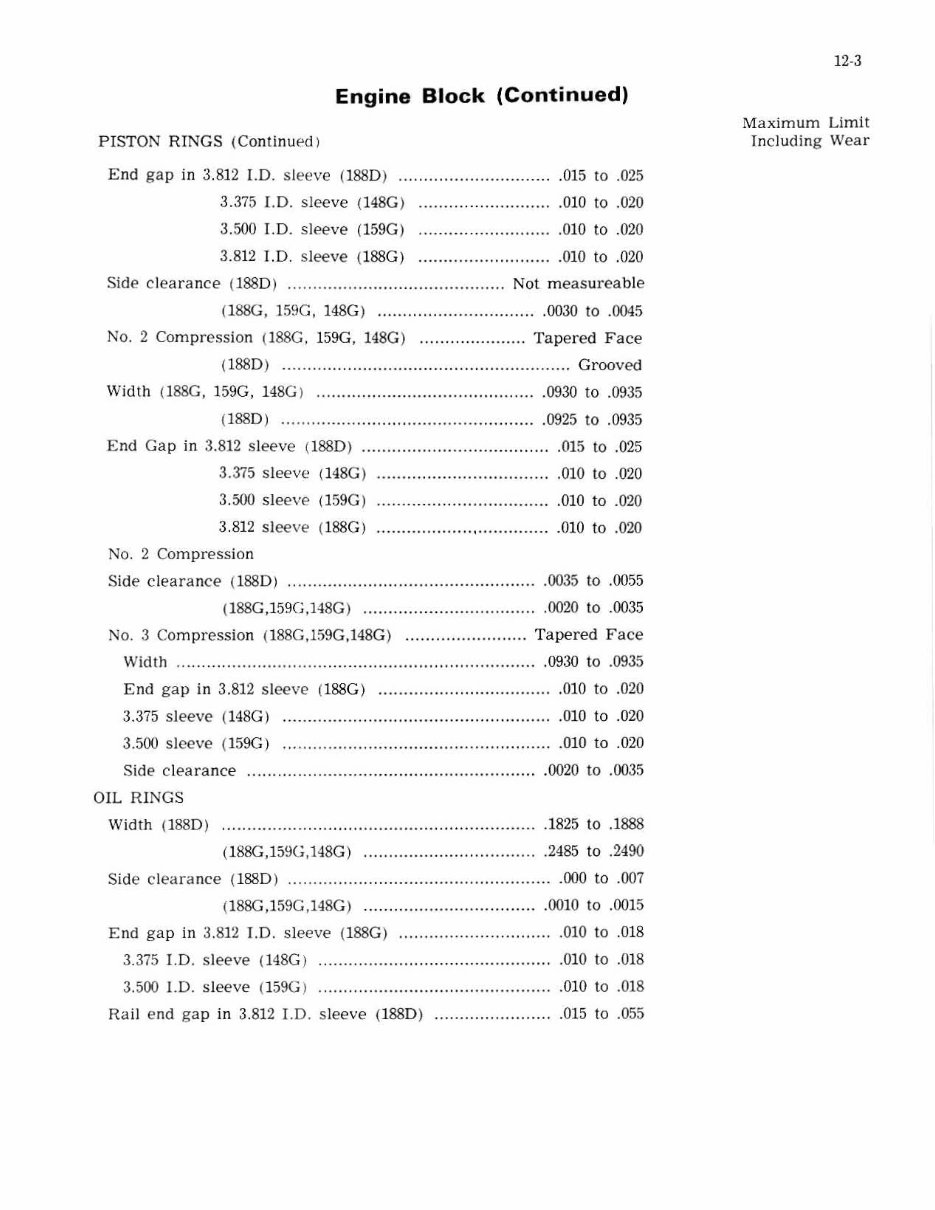

Engine Block (Continued)

P ISTON RINGS (Continued)

End gap in 3. 812 LD. slee ve (1 880) ... .. ....... ............ ... ... 015 to .025

3.375 I.D. sleeve ( H8G )

3.500 J.D. sl eeve (159G)

3.812 T. D. sleeve (ISSG)

.010 to .020

.010 to .020

.010 to .020

Side clearance (1880) ....................... . ............. ...... Not meas ureab Je

(188G. 159G. H SG ) ................................ 0030 to .0045

No.2 Compr ession (l88G, 159G , 148G) ............. __ ...... T apered Face

(188D) .... . .................................................... Grooved

Width (188G . 159G. 148G ) .. ....... .. .. ............................ ... 0930 to .0935

( l88D ) ..... .............................................. 0925 to .0935

End Gap in 3.812 sleeve (l88D) ........................ .............. 015 to .025

3.315 s l eeve (H8G ) ........ ...... . .................... 010 to .020

3.500 s l eeve (159G )

3 .812 slee ve (l88G)

No. 2 Compression

Side clearance (1880 )

.010 to .020

................... , ............... 010 to .020

.0035 to .0055

(I88G.159G.14SG) ................................... 0020 to .0035

No.3 Compression (188G.l59G.148G ) ........................ T ape r ed Face

\Vidth .......... ...... ............. .. . ...... . ................................. 0930 to .0935

End gap in 3.812 s l eeve (l88G ) ................................... 010 to .020

3.375 sleeve (14SG) ...................................................... 010 to .020

3.500 sleeve ( 159G) .... . ................................................. 010 to .020

Si de c learance ....................... . ...... . .......................... 0020 to .0035

OIL RINGS

\Vidt.h (l88D) .......... ...... ........ .... ........... .... . ........ . .......... 1825 to .1888

(188G,159G.148G) .. . ............ . ........... ........ 2485 to .2490

Side cleara nce (l 88D ) ... ..... ............................................. 000 to .007

(188G.159G .148G) ...... ............................. 0010 to .0015

End gap in 3.812 J.D. sleeve ( l88G ) ................. ... .. ......... 010 to .018

3.375 I.D. s leeve (H8G ) .010 to .018

3.500 1.0. sleeve (159G ) ..... .............. . ........................... 01 0 to .018

Rail e nd gap in 3.812 J.D. s leeve (188D) ........................ 015 to .055

12·3

Maximum Limit

Including Wear

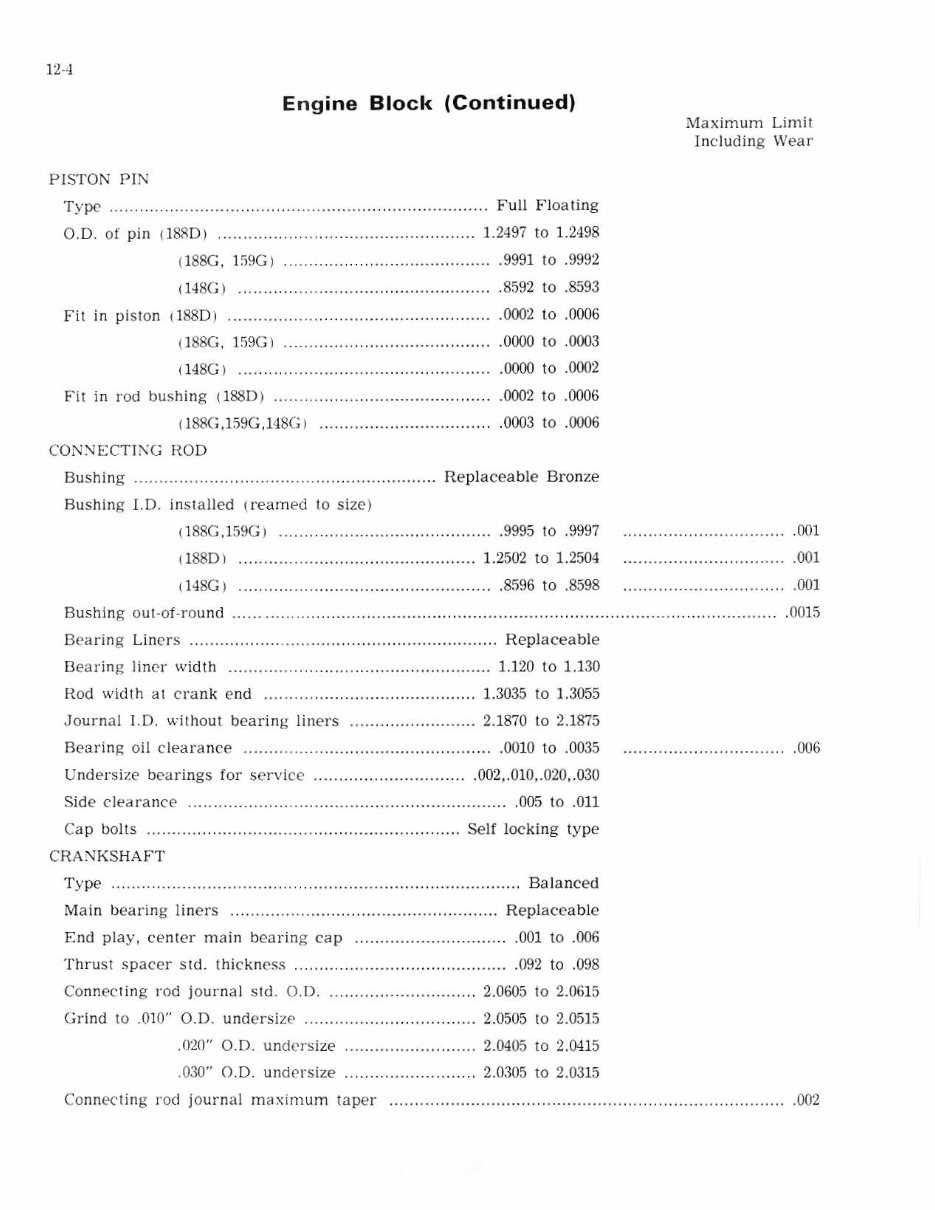

],·4

Engine Block (Continued)

PISTON P]N

Type ......................... ...... ................. .... ......... ... ........ Fu ll F loating

0.0. of pin (lAAD) ............... ..... . ............................ 1.2497 to 1.2498

1l88G , 109G ) .. . ..... .. . ,.,,"""""" ,999] to .9992

1148G ) ... "" . .... ". ,,"""""""" .8092 10 .8593

Fit in pi ston (188D )

(lS8G, 159G )

1l48G ) ""

F it in rod bu shing (1880 ) ................... ...... .. .

(188G.159G,148G ) .. . ............. . ......... .

CON:-.JECTTi\C HOD

,0002 to ,000 6

.0 000 to .0003

. 0000 to .(01)2

.0002 to .0006

.0003 to ,0006

Bushing ............ ......... ........... . . ......... .. Replaceable Bronze

Bushing I.D . inst a lled {reamed to size)

( 188G,159G) . ...... .. . ......... ... .. ..... .. ........... 9995 to .999 7

1 188D ) .. ..... .......... ... ................... 1. 2502 to 1.2504

1l48G ) ................. .. ....................... 8596 to .8598

Bushing out·ot-round ............... ...... ................. .......... ..... .. ....... ........ .. ......... .

Bearin g Liners ....... .......... .. .... ....... .......... ................... Repla ce able

B earing line r width ............. .. . ............................. 1.] 20 to 1.130

Rod width at cra nk cnd ...... . . " " , .......... " " .. . ... 1.3035 to 1.3055

Journal J.D. without bearin g liners .... .. .. ......... ........ 2.1870 to 2.1875

Bearing oil c leara nce ... .... ...... .................................... 0010 to .0035

Under size bcarings for serv ice ....... ..... ............... .. .002,. 010,.020, .030

Side clearance .................. . .. .............. .......................... 0 05 to .011

Cap bolts .... ... ... .. .. .................... ...... ........... ......... Self locking type

CRA:"J I{ SHA FT

Type ........... .......................... .......... .. ...... ............ ........ ..... Balanced

Main bearin g liners ..... .. ........ ........................... .... ....... Replacea ble

End play, center main bearing cap .... ..... .......... .

Thrust space r s td. thickness

.001 to .006

,092 to ,098

ConneCT in g rod journal std. 0. 0 . .................... ........ . 2.0605 to 2.0615

Grind to .010" 0.0 . undersize .. .... .... . .. ... .. ...... 2.0505 to 2.0515

.020" 0. 0. undersize

.030" 0. 0. un de rsize

2.0405 to 2.0415

2. 030 5 to 2.0315

Maximum Limit

ln c ludin g Wear

.00]

.001

... " ..... . " ,001

.. ............ ,0010

.006

Co nnecting ro cl journal m aximu m taper ........ .. ..... .......... ............... ..................... ... .... ... .... . ,002

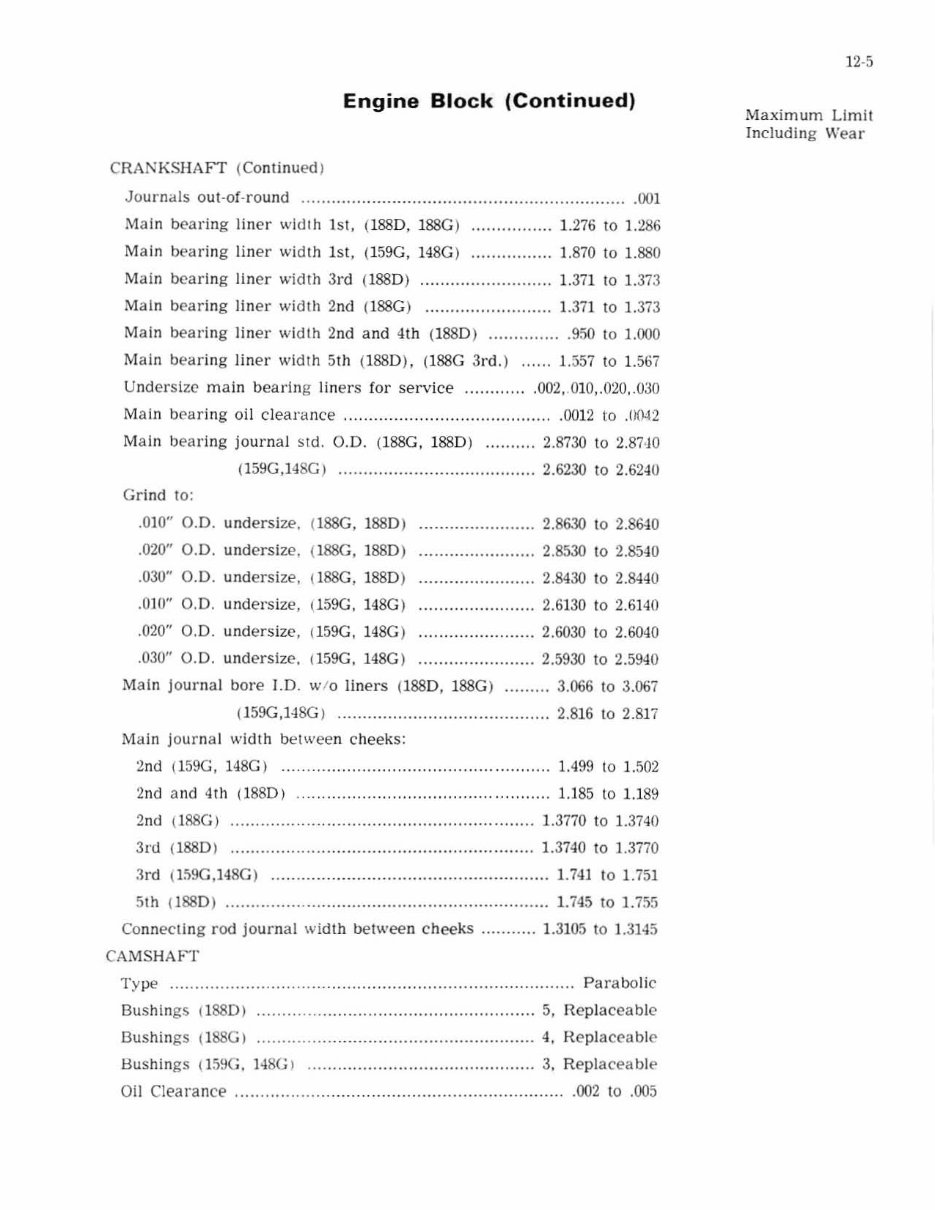

Engine Block (Continued)

CRAN KSHAFT (ContinuedJ

Journal s out-oC-round .............. .................... __ .. __ ........................ . (Xn

Main bearing liner wid th 1st, (I 88D , 188G) .............. __ 1.276 to 1.286

Main bearing liner width 1st, ( 159G, 148G) ............. __ . 1.870 to 1.880

Main bear in g lin er width 3rd (1880) .......................... 1.3il to 1. 373

Main bearing liner width 2nd (l 88G) ......................... 1.371 to 1.373

Main bearing liner width 2nd a nd 4th (1880) .... _____ ..... . 950 to 1.000

Main bearing liner width 5th (1880), (l 88C 3rd.l ...... 1.557 to 1.567

U nd ersize ma in bearing liners for service ............ . 002, .010,.020 .. 030

Main bearing o il clearance ......................................... . 0012 to .0042

Mai n bearing journal S Id. 0 .0 . (lSSG, 1880) .......... 2.8730 to 2.87 · jO

(159G ,148G ) ......... .............................. 2.6230 10 2.6240

Grind to:

.010" 0.0. undersi ze..

.020" 0.0. undersize,

.030" 0.0. und ersi ze ,

.010" 0.0. undersize,

.020" 0.0. und er size,

.030" 0.0. undersize,

(I88G, 1880 )

(I88G, 1880)

!l88G, 1880)

(l59G, 148G)

1159G, 148G)

(159G. 148G)

.. ..................... 2.8630 to 2.8&10

....................... 2.8530 10 2.8540

....................... 2.8430 10 2.8440

......... .............. 2.6130 10 2.6140

. ......... ............. 2.6030 10 2.6040

....................... 2.5930 to 2.59<1 0

Main journal bore 1.0 . w/o liners (1880, 188G) ......... 3.066 10 3.067

(159G,148G) ............................ . ............ 2.816 1 02.817

Main journal width between c heeks:

2nd (159G, 148G) ................................................. 1.499 10 1.502

2nd and 4Th (lB8D) .. .............. ................... ..... ... U85 10 U 89

2nd (188G) ....... . ................................... 1.3770 to 1.3740

3rd (1880) ....... .................................................... 1.3740 to ].3770

3rd (159G,148G) ....................................................... 1.741 to 1.751

5th (1880) ............... . .............. ..... ............................. 1.745 101.755

Connecting rod journal wid th bel wee n cheeks ........... 1. 3105 to 1. 3145

CAMSHM -r

Type ................................................................................ Parabolic

Bushings (I 88D) ............. .......................................... 5, Replaceable

Bushings (1SSG) ...... .... ........ ..................................... 4, Replaceable

Bushings (l59G . 148G ) .. ................ ........................... 3, Repla cea bl e

Oil Clearance ................................................................. . 002 to .005

12·5

Ma ximum Limit

Including Wear

12-6

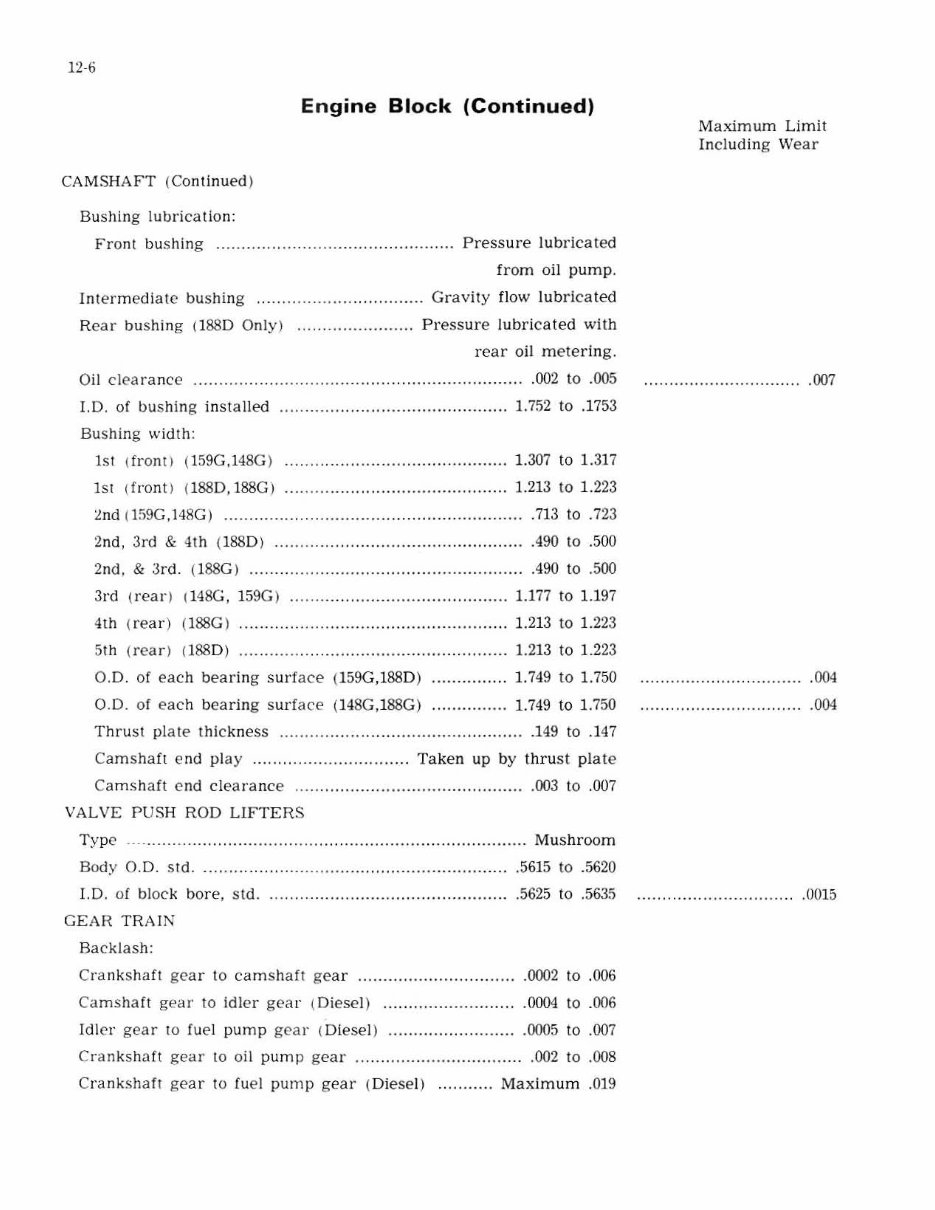

En gine Block (Continued)

CAMSHAFT (Con tinued )

Bushing lubricat ion:

Front bushing ............... .. ..... .. ........ ............. . Pres s ure lubricated

fr om oil pump .

I ntermediate bushing ............ .. . .................. Gravity flow lubr ica ted

Rear bushing (1880 Only) ....................... Press ure l ubricated with

rear oil metering.

Oi l clearance ....... ........ .. .. ...... ..... ....... ....... ..................... 002 to .005

LD. of bushing installed ... . .. ....... ..... ............... ........... 1.752 to .1753

Bushing width:

lSI (fronO (159G,148G ) 1 .307 to 1. 317

lSI ( front) (1880, 188G) .......... ... ................. ............. 1.213 to 1.223

~nd (1 59G, 148G ) .. ......... ....... . ............... ........ ... ........ .... . 713 to .723

2nd, 3rd & 4th (1 88 0) .... .. .. ........... . ........... ............ .. . .490 to .500

2nd, & 3r d. ( l88G) ........... ......................................... .490 to .500

3rd (rear) 1 148G, 159G) ............. ...... ........................ 1.177 to 1.197

4th (re ar ) (188G ) ............. .. .................................. ... . 1.213 to 1.223

5th (re ar ) (188 0) ..... .. . .... ............................... . ......... 1.213 to 1. 223

0.0 . of each bearing surface (159G,188D)

0.0. of e ach bearing surfac e ( 148G ,188G)

1. 749 to 1.750

1.749 to 1.750

Thrust plale thic kne ss ... ... ................................ ........ ... 149 to .147

Cam s haft end play .. ............ . ................ Ta ke n up by thrust pla te

Camshaft cnd clearance ..... ............ ....... ................. .. ... 003 to .007

VALVE PUS H ROD LIFTER S

Type' .... ............. .. ...... ...... .......... ......... .... ..... .. ........ Mushroom

Body 0.0 . std .... . .. .... .. ........ ..... ................................. .

1.0. of block bore, std.

GEAR TRAIN

Backlash:

.5615 to .5620

.5625 to .56.15

Cranksh<'lfl g ear to camshaft ge ar ...... .. ............... .... ..... 0002 to .006

Camshaft gear to Idler gear ( Diesel) ................. . ......... 0004 to .006

Idler gear to fuel pump ge ar (Diesel) .......................... 0005 to .007

Crankshaft gear to oil pump gea r .. ......... ........... ........ .. .002 to .008

Crank s haft g ear to fuel pump gear (Di esel) ... ........ Maximum .0 ]9

Maximum Limit

Including Wear

...... ...................... . ... 007

.004

.004

.......................... ..... . 0015

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$32.99

Viewed 81 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$32.99

- The Case 450 Crawler Backhoe Loader Tractor Service & Repair Manual is an essential resource for professionals and enthusiasts working on this specific heavy machinery model.

- This official manual comprehensively covers maintenance, diagnostics, repair, and rebuilding, including hydraulic, electrical, engine, and transmission systems.

- It features high-quality diagrams, illustrations, and step-by-step instructions to ensure accurate repairs and troubleshooting.

- Designed for mechanics and operators, it provides manufacturer-approved methods and specifications for effective complex repairs and routine maintenance, preserving the machine's lifespan and reliability.

- Format: PDF

- Language: English

- Compatibility: Compatible with various electronic devices, including PC, Mac, Android, and Apple devices.

- Requirements: Adobe Reader (free)