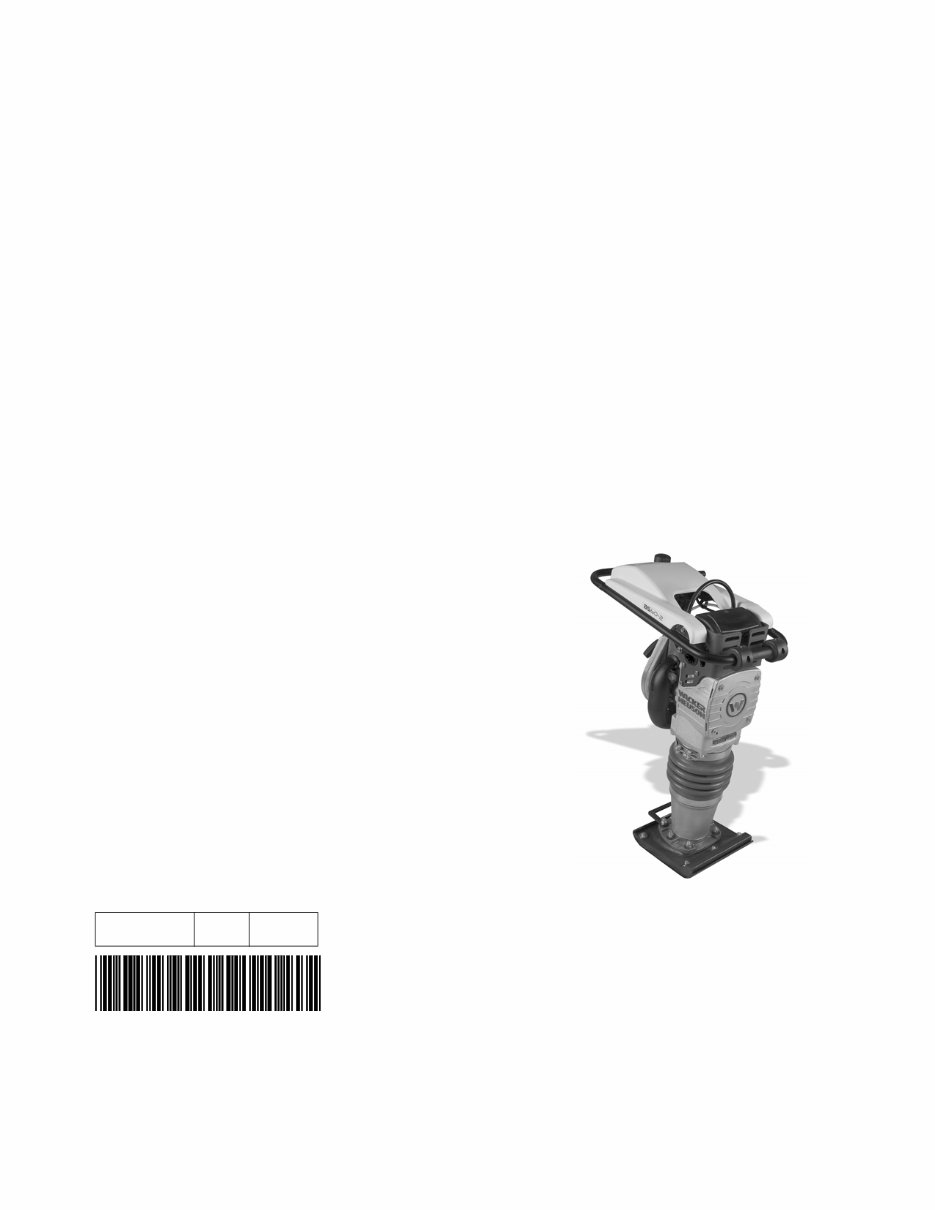

Wacker BS50,BS60,BS70,BS500,BS600, Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

0114549en 010 0510

0 1 1 4 5 4 9 E N

Repair Manual

Rammer

BS 50 / BS 60 / BS 70

BS 500 / BS 600 / BS 700

BS 65 / BS 650

DS 70 / DS 720

Copyright

notice

© Copyright 2010 by Wacker Neuson Corporation.

All rights, including copying and distribution rights, are reserved.

This publication may be photocopied by the original purchaser of the machine. Any

other type of reproduction is prohibited without express written permission from

Wacker Neuson Corporation.

Any type of reproduction or distribution not authorized by Wacker Neuson Corporation

represents an infringement of valid copyrights. Violators will be prosecuted.

Trademarks All trademarks referenced in this manual are the property of their respective owners.

Manufacturer Wacker Neuson Corporation

N92W15000 Anthony Avenue

Menomonee Falls, WI 53051 U.S.A.

Tel: (262) 255-0500 · Fax: (262) 255-0550 · Tel: (800) 770-0957

www.wackerneuson.com

Foreword

wc_tx001543gb.fm 3

Foreword

Machines covered in this manual.

Machine

documentation

Keep a copy of the Operator’s Manual with the machine at all times.

Use the separate Parts Book supplied with the machine to order replacement

parts.

If you are missing any of these documents, please contact Wacker Neuson

Corporation to order a replacement or visit www.wackerneuson.com.

When ordering parts or requesting service information, be prepared to provide

the machine model number, item number, revision number, and serial number.

BS 50-4 0009386, 0009415, 0620108, 0620071, 0620077, 0620078

BS 50-2 0009380, 0009382, 0009384, 0009410, 0009411, 0009413, 0620025,

0620048, 0620609, 0620610, 0620733, 0620609, 0620610, 0620733

BS 50-2i 0009332, 0009338, 0009383, 0009412, 0009414, 0009416, 0009473,

0620026, 0620611

BS 500 0007550, 0008048, 0008049, 0008204, 0009074, 0009075

BS 500-4 0009329

BS 500-oi 0009165, 0009343

BS 500S 0009211

BS 60-4 0009340, 0009422, 0620000, 0620051, 0620109, 0620110, 0620072,

0620073, 0620074, 0620483, 0620563, 0620812, 0620813, 0620816,

0620819, 0620820

BS 60-2 0009388, 0009391, 0009417, 0009418, 0009421, 0620612

BS 60-2i 0009339, 0009393, 0009419, 0009420, 0620613, 0620614

BS 600 0007551, 0008205, 0008207, 0009076, 0009077, 0009307

BS 600-4 0009331

BS 600-oi 0009166, 0009262

BS 600S 0009212

BS 70-2 0009397, 0009399, 0009424, 0009425, 0009427

BS 70-2i 0009341, 0009401, 0009426, 0009428

BS 700 0007552, 0008051, 0008052, 0008206, 0009078, 0009079, 0009308

BS 700-oi 0009167, 0009328

BS 65-V 0009396, 0009423

BS 650 0008209

DS 70 0009342, 0009402, 0009403, 0620049, 0620050, 0620052, 0620053,

0620054

Foreword

4 wc_tx001543gb.fm

Expectations

for

information in

this manual

This manual provides information and procedures to safely operate and main-

tain the above Wacker Neuson model(s). For your own safety and to reduce the

risk of injury, carefully read, understand, and observe all instructions described

in this manual.

Wacker Neuson Corporation expressly reserves the right to make technical

modifications, even without notice, which improve the performance or safety

standards of its machines.

The information contained in this manual is based on machines manufactured

up until the time of publication. Wacker Neuson Corporation reserves the right

to change any portion of this information without notice.

CALIFORNIA

Proposition

65 Warning

Engine exhaust, some of its constituents, and certain vehicle components, contain

or emit chemicals known to the State of California to cause cancer and birth

defects or other reproductive harm.

Laws

pertaining to

spark

arresters

NOTICE: State Health Safety Codes and Public Resources Codes specify that in

certain locations spark arresters be used on internal combustion engines that use

hydrocarbon fuels. A spark arrester is a device designed to prevent accidental dis-

charge of sparks or flames from the engine exhaust. Spark arresters are qualified

and rated by the United States Forest Service for this purpose. In order to comply

with local laws regarding spark arresters, consult the engine distributor or the local

Health and Safety Administrator.

Manufacturer’s

approval

This manual contains references to approved parts, attachments, and modifica-

tions. The following definitions apply:

Approved parts or attachments are those either manufactured or provided by

Wacker Neuson.

Approved modifications are those performed by an authorized Wacker Neu-

son service center according to written instructions published by Wacker Neu-

son.

Unapproved parts, attachments, and modifications are those that do not

meet the approved criteria.

Unapproved parts, attachments, or modifications may have the following conse-

quences:

Serious injury hazards to the operator and persons in the work area

Permanent damage to the machine which will not be covered under warranty

Contact your Wacker Neuson dealer immediately if you have questions about

approved or unapproved parts, attachments, or modifications.

wc_br0114549en_010TOC.fm 5

Table of Contents Rammer Repair

Foreword 3

1 Safety Information 9

1.1 Signal Words Found in this Manual ...................................................... 9

1.2 Machine Description and Intended Use ............................................. 10

1.3 Operating Safety ................................................................................ 11

1.4 Operator Safety while using Internal Combustion Engines ................ 13

1.5 Service Safety .................................................................................... 14

2 Tools 17

2.1 Recommended Special Tools ............................................................ 17

2.2 Recommended Repair Tools .............................................................. 18

3 Maintenance Schedules 19

3.1 Periodic Maintenance Schedule (BS 50/60/70-2, BS 65) ................... 19

3.2 Periodic Maintenance Schedule (BS 500/600/700/650) ..................... 20

3.3 Periodic Maintenance Schedule (BS 50/60/70-2i) .............................. 21

3.4 Periodic Maintenance Schedule (BS 500/600/700-oi) ........................ 22

3.5 Periodic Maintenance Schedule (DS 70) ........................................... 23

3.6 Periodic Maintenance Schedule (DS 720) ......................................... 24

4 Engine and Upper Machine Components 25

4.1 Removing the Silencing Cover ........................................................... 25

4.2 Replacing the Throttle Control (2010 and later 2-stroke models) ....... 26

4.3 Replacing the Throttle Control (2010 4-stroke models) ...................... 28

4.4 Throttle Control (pre-2010 models) .................................................... 31

4.5 Replacing the Stop Switch (2010 and later 2-stroke models) ............ 32

4.6 Replacing the Stop Switch (2010 and later 4-stroke models) ............ 35

4.7 Replacing the Guide Handle (2010 and later 2-stroke models) ......... 37

4.8 Replacing the Guide Handle (2010 and later 4-stroke models) ......... 40

4.9 Replacing the Guide Handle (pre-2010 models) ................................ 44

4.10 Shock Mounts ..................................................................................... 45

6 wc_br0114549en_010TOC.fm

Table of Contents Rammmer Repair

4.11 Tillotson Carburetor (BS 500/600/700/650 only) ................................. 46

4.12 Fuel Lines (BS 50/60/70-2, BS 65) ...................................................... 48

4.13 Fuel Tank (BS Models) ........................................................................ 49

4.14 Fuel Tank (DS Models) ....................................................................... 50

4.15 Fuel Tank Cap ..................................................................................... 52

4.16 Muffler (pre-2009 BS Models) ............................................................. 54

4.17 Engine Cooling Fins ............................................................................ 55

4.18 Muffler (DS Models) ............................................................................ 56

4.19 Replacing the Carburetor (WM 80 engines) ........................................ 58

4.20 Replacing the WM 80 Engine (2010 and later models) ....................... 62

4.21 Replacing the WM 80 Engine (pre-2010 models) ............................... 64

4.22 Replacing the Carburetor (WM 100 Engines) ..................................... 66

4.23 Replacing the WM 100 Engine ............................................................ 70

4.24 Removing the WM 90 Engine .............................................................. 74

4.25 Engine (DS Models) ............................................................................ 76

4.26 Clutch (2- and 4-stroke models) .......................................................... 78

4.27 Clutch (DS 720 only) ........................................................................... 80

4.28 Clutch (DS 70 only) ............................................................................. 82

5 Ramming System 84

5.1 Bellows ................................................................................................ 84

5.2 Replacing the Ramming Shoe ............................................................. 87

5.3 Spring System Cover Removal and Installation .................................. 90

5.4 Spring System ..................................................................................... 96

5.5 Inspecting the Spring System .............................................................. 98

5.6 Protective Pipe .................................................................................... 99

5.7 Ramming System Lubrication (BS 500/600/700/650, DS 720) ......... 100

5.8 Ramming System Lubrication (BS 50/60/70, BS 65, DS 70) ............ 102

6 Crankcase 104

6.1 Crank Gear and Connecting Rod ...................................................... 104

6.2 Crank Gear, Connecting Rod, and Adjuster Assembly (BS 650/65 only) 106

6.3 Clutch Drum ...................................................................................... 110

wc_br0114549en_010TOC.fm 7

Table of Contents Rammer Repair

7 Oil Injection (if equipped) 112

7.1 Testing the Float Switch (2010 and later models) ............................ 112

7.2 Replacing the Float Switch (2010 and later models) ........................ 114

7.3 Float Switch Testing and Replacement (pre-2010 models) ............. 116

7.4 Oil Line Check Valve ........................................................................ 118

7.5 Oil Pump / Cartridge Assembly ........................................................ 120

8 Low Oil Shutdown (if equipped) 123

8.1 Testing the Low Oil Unit ................................................................... 123

9 Troubleshooting 124

9.1 Engine Hard to Start ......................................................................... 124

9.2 Engine Does Not Start ...................................................................... 125

9.3 Engine Does Not Accelerate or Runs Poorly ................................... 125

9.4 Engine Overheats ............................................................................. 126

9.5 Rammer Does Not Tamp ................................................................. 126

9.6 Rammer Jumps Erratically ............................................................... 127

10 Technical Data 128

10.1 BS 50-2 ............................................................................................ 128

10.2 BS 50-4 ............................................................................................ 129

10.3 BS 500 .............................................................................................. 130

10.4 BS 500S ........................................................................................... 131

10.5 BS 50-2i ............................................................................................ 132

10.6 BS 500-oi .......................................................................................... 133

10.7 BS 60/70-2 ....................................................................................... 134

10.8 BS 60-4 ............................................................................................ 135

10.9 BS 600/700 ....................................................................................... 136

10.10 BS 600S ........................................................................................... 137

10.11 BS 60/70-2i ....................................................................................... 138

10.12 BS 600/700-oi ................................................................................... 139

10.13 BS 600/700 High Altitude ................................................................. 140

10.14 BS 65-V ............................................................................................ 141

10.15 BS 650 .............................................................................................. 142

8 wc_br0114549en_010TOC.fm

Table of Contents Rammmer Repair

10.16 DS 70 ................................................................................................ 144

10.17 DS 720 .............................................................................................. 146

Rammer Repair Safety Information

wc_si000514gb.fm 9

1 Safety Information

1.1 Signal Words Found in this Manual

This manual contains DANGER, WARNING, CAUTION, NOTICE, and

NOTE signal words which must be followed to reduce the possibility

of personal injury, damage to the equipment, or improper service.

NOTICE: Used without the safety alert symbol, NOTICE indicates a situation which, if not avoided,

could result in property damage.

Note: A Note contains additional information important to a procedure.

This is the safety alert symbol. It is used to alert you to potential personal hazards.

Obey all safety messages that follow this symbol.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in death

or serious injury.

To avoid death or serious injury from this type of hazard, obey all safety mes-

sages that follow this signal word.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

To avoid possible death or serious injury from this type of hazard, obey all safety

messages that follow this signal word.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

To avoid possible minor or moderate injury from this type of hazard, obey all

safety messages that follow this signal word.

Safety Information Rammer Repair

10 wc_si000514gb.fm

1.2 Machine Description and Intended Use

This machine is a vibratory rammer. The Wacker Neuson Rammer

consists of a gasoline or diesel engine, a clutch, a fuel tank, a spring-

loaded ramming system, a ramming shoe, and a handle. The engine

transmits power through the ramming system and ramming shoe,

generating percussive impact force to compact soil. The operator

guides and controls the machine from behind using the handle.

This machine is intended to be used for compacting cohesive, mixed,

and granular soils in confined areas.

This machine has been designed and built strictly for the intended use

described above. Using the machine for any other purpose could

permanently damage the machine or seriously injure the operator or

other persons in the area. Machine damage caused by misuse is not

covered under warranty.

The following are some examples of misuse:

• Using the machine as a ladder, support, or work surface

• Using the machine to carry or transport passengers or equipment

• Using the machine as a hammer or for other demolition work

• Attaching the machine to any other machine

• Operating the machine outside of factory specifications

• Operating machine in a manner inconsistent with all warnings

found on the machine and in the Operator’s Manual

This machine has been designed and built in accordance with the

latest global safety standards. It has been carefully engineered to

eliminate hazards as far as practicable and to increase operator

safety through protective guards and labeling. However, some risks

may remain even after protective measures have been taken. They

are called residual risks. On this machine, they may include exposure

to:

• Heat, noise, exhaust, and carbon monoxide from the engine

• Fire hazards from improper refueling techniques

• Fuel and its fumes

• Personal injury from improper lifting techniques or operating

techniques

To protect yourself and others, make sure you thoroughly read and

understand the safety information presented in this manual before

operating the machine.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 69 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

- This is a complete factory service repair workshop manual for the BS and DS series rammers.

- The Service Manual contains easy-to-read text sections with top quality diagrams and instructions.

- It provides step-by-step instructions and highly detailed exploded pictures and diagrams to guide you through any repair efficiently.

- The Workshop Manual covers every single detail on your machine, making it especially helpful for carb adjustments.

- It covers the following models:

- BS 50-4 0009386, 0009415, 0620108, 0620071, 0620077, 0620078

- BS 50-2 0009380, 0009382, 0009384, 0009410, 0009411, 0009413, 0620025, 0620048, 0620609, 0620610, 0620733, 0620609, 0620610, 0620733

- BS 50-2i 0009332, 0009338, 0009383, 0009412, 0009414, 0009416, 0009473, 0620026, 0620611

- BS 500 0007550, 0008048, 0008049, 0008204, 0009074, 0009075

- BS 500-4 0009329

- BS 500-oi 0009165, 0009343

- BS 500S 0009211

- BS 60-4 0009340, 0009422, 0620000, 0620051, 0620109, 0620110, 0620072, 0620073, 0620074, 0620483, 0620563, 0620812, 0620813, 0620816, 0620819, 0620820

- BS 60-2 0009388, 0009391, 0009417, 0009418, 0009421, 0620612

- BS 60-2i 0009339, 0009393, 0009419, 0009420, 0620613, 0620614

- BS 600 0007551, 0008205, 0008207, 0009076, 0009077, 0009307

- BS 600-4 0009331

- BS 600-oi 0009166, 0009262

- BS 600S 0009212

- BS 70-2 0009397, 0009399, 0009424, 0009425, 0009427

- BS 70-2i 0009341, 0009401, 0009426, 0009428

- BS 700 0007552, 0008051, 0008052, 0008206, 0009078, 0009079, 0009308

- BS 700-oi 0009167, 0009328

- BS 65-V 0009396, 0009423

- BS 650 0008209

- DS 70 0009342, 0009402