Case 580B CK Service Repair Manual Maintenance 580 B

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

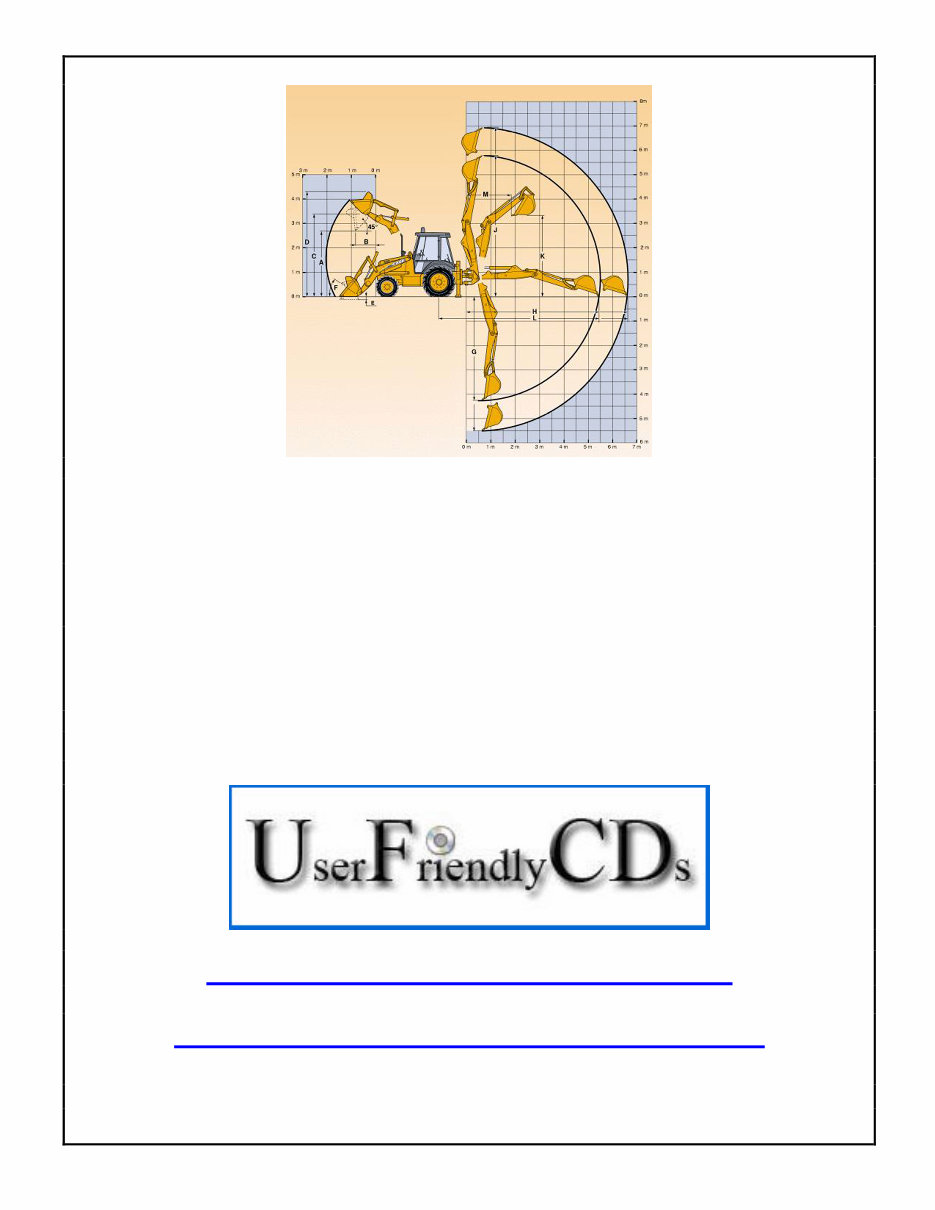

Case 580CK Model B

Backhoe • Loader • Tractor

Service Manual

v 8.0

http://stores.ebay.com/UserFriendlyCDs

http://www.ioffer.com/selling/userfriendlycds

© 2006, 2009 UserFriendlyCDs

TABLE OF CONTENTS

SERIES/ SECTION SECTION NO.

10 SERIES - GENERAL

General Specifications, 580B Tractors 11

Detailed Specifications, 580B Tractors 12

Lubrication, Shuttle Tractors 13

Lubrication, Hydrostatic Tractors 13

Lubrication, Loader & Backhoe 13

20 SERIES - ENGINE

Cylinder Head & Valves, Diesel 22

Cylinder Head & Valves, Spark Ignition 22

Engine Block Assemblies 23

Air Cleaner System 24

30 SERIES - FUEL SYSTEM

Fuel System & Filters 31

Roosa Master Model DB Fuel Injection Pump 32

Roosa Master Fuel Injectors 33

Model 267 Carburetor 35

40 SERIES - HYDRAULICS

Hydraulic Diagrams, Trouble Shooting, Testing, & Service 42

Hydraulic System & Power Steering Oil Filters 42

Torque Converter - Power Shuttle Hydraulic Pump 43

Equipment Pump 43

Three-Point Hitch Cylinders 44

Loader Control Valve 44a

Backhoe Control Valve 44b

Stabilizer Control Valve 44c

Three-Point Hitch Control Valve 44d

Cylinder Removal/Installation 45

Loader Cylinders 45

Backhoe Cylinder 46

Auxiliary Cylinder 47

Hydra-Guide Hydraulics Guidance System 47

Boom Lockout System 49

50 SERIES - STEERING

Power Steering Pump & Hand Pump 52

Steering Control Valve 53

Steering Cylinders & Adjustment 54

Steering Axle & Wheel Bearings 55

60 SERIES - POWER TRAIN

Torque Converter, Power Shuttle Countershaft, Control Valves, & Adjustment 61

Power Shuttle Clutch Pack, Rockford Clutch 62

Power Shuttle Clutch Pack, Twin Disc 63

Hydrostatic Drive, Gear Train, Control Linkage 64

Four-Speed Transmission & Final Drive 65

Mechanical Shuttle 66

Duel Range Assembly 67

11-Inch Traction Clutch 68

Independent Power Take-Off 69

NOTE: The following sections also relate to the Power Train:

Torque Converter-Power Shuttle Hydraulic Pump 43

70 SERIES - BRAKES

Differential Brakes, Differential Lock, and Parking Brakes. 74

80 SERIES - ELECTRICAL

Wiring Diagram, Tractor 81

Wiring Diagram Fork Lift Tractor 81

90 SERIES - MOUNTED EQUIPMENT

Miscellaneous Equipment (Includes Rear Attachment Support Arms,

Counterweights, Moldboard, Logging & Pallet Forks, & Rollbar) 91

Loader 92

Backhoe 93

Three-Point Hitch 97

100 SERIES - HOW IT WORKS - TROUBLE SHOOTING

Hydraulic Testing - Torque Converter - Power Shuttle 101

How It Works - Hydrostatic Power Steering. 151

How It Works - Torque Converter with Rockford Power Shuttle. 162

How It Works - Torque Converter with Twin Disc Power Shuttle 163

How It Works - Hydrostatic Transmission. 164

NOTE: Also refer to sections in the 40 Series, Hydraulics, for troubleshooting and how it works

information relating to the equipment hydraulics system.

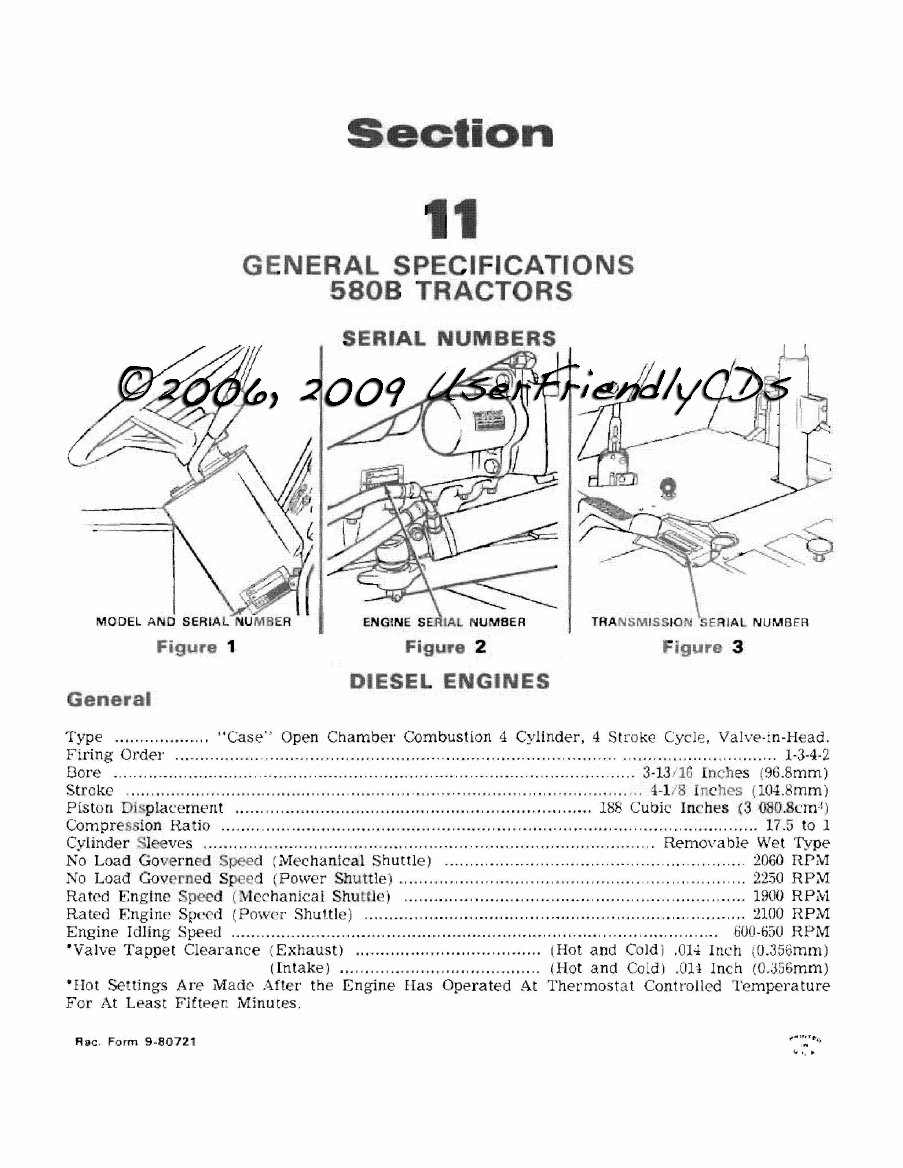

Figure 1 Figure 2

DIESEL ENGINES

Type ................. "Case" Open Chamber Combustion 4 Cylinder, 4 Stroke Cycle, VaIve-in-Head.

Firing Order ................................................................................................................. 1-3-4-2

Him ..................................................................................................... 3+13(1 I~Ic (96.81~m

Stroke ............. , ...................................... ,,., ................................. ,... 4-1; Inches ( lO4.Smm)

Piston Displacement .............................................................. 188 Cubic Inches (3

Compression Ratio .................................................... , .... , ................ , ........................ 17.5 to 1

Cylinder Sleeves .................................................................................... Removable Wet Type

No Load Govern d (Mechanical Shuttle) .......................................................... 2060 RPM

No Load Gave d (Power Shuttle) ã..ã..ã, ....... , ................................. 2250 RPM

Rated Engine echanical Shuttle) ............................... , ...... ,, .... , ......... , ...... 1900 RPM

Rated Engine Speed (Power Shuttle) ...... * ................ ............ -.. .................................. 2100 RPM

Engine Idling Speed ........................................................................................... 600-650 RPM

'Valve Tappet Clearance (Exhaust) ...*. ................ ã.+. (Hot and Cold) ,014 Inch (0.356mm

(Intake) ...................................... (Hot and Cold) .014 Inch (O.356rnm)

'Hot Settings Are Made? After the Engine Has Operated At Thermostat Controlled Temperature

For At Least Fifteen Minutes.

Bac. Form 9-80721

Piston and Connecting Rods

Rings per Piston ..................................................................... , ................. ,...,., ......... 3

Number of Compression Ring's ............................................................................................. 2

... Number of Oil Rings ...................... ............ + .......... + .................... ã ................... + ................ 1

Type Pins ........................................................................................ .-.. ..... Full Floating Type

Type Bearing .............................. Replaceable Precision, Steel Back, Copper-Lead Alloy Liners,

Number of Bearings ............................... , ...................................................................... - 5

Type Bearings ........ + ................ Replaceable Precision, Steel Back, Copper-Lead Alloy Liners.

Engine Lubricating System

Oil Pressure .................. 50 to 70 Pounds (3.5 to 4.9 kgicrn2 with Engine Warm and Operating

at Rated Engine Speed.

Type System , ...................................................................... Pressure and Spray Circulation

Oil Pump .......................................................................................................... .... Gear Type

Oil Filter ....................... , .... ............ , .... ............ .............................. ,.,... Full Flow Spin OH Type

Fuel System

fuel Injection Pump .......................................................................................... Roosa-Master

Pump Timing ..,..., ........................................... *.. ......... ,...,. 8 Degrees Before Top Dead Center

Fuel Injectors ........................................................................................................ Pencil Type

(Opening Pressure 2800 PSI).

Fuel Transfer Pump ., ........................... ,, ,.,..ã ...... , ................... ,. Vane Type, Integral Part of

Injection Pump.

Governor ....... ,-, .................................. Mechanical, Fly-Weight, Integral Part of Injection Pump.

1st Stage Fuel Filter ......................................................................................... Replaceable Type

2nd Stage Fuel Filter ... .,,.,,,,Ã ....... , ...... , ...... ,-.--.., ..... , ............................ Replaceable Type

Fuel Tank Water Trap and Drain ........................................... ,. Located in Base of Fuel Tank

Fuel Tank Capacity ...................................................................... 22 U.S. Gallons (83,3 liters)

Fuel Level Gauge .................... ãà ............................... Electric, Located on Instrument Panel,

General

Type .......................................................................... 4 Cylinder, 4 Stroke Cycle, Valve-in-Head

Firing Order ...,..,. -, ......................... .. ..... ., ...... ... .. .... .. ... ..... ............................................ 1-3 4-2

Bore (188G) .., ............................... ..-- ............................. .., ., ............. 3-13/16 Inches (96Am tn)

(159G ã,,,. ...- ,-.. ........ .,,- .................................... , ..................... 3-1j2 Inches (SS.Pmmj

Stroke ....................................................................... - ......... , ............ 4-1/8 Inches (104,Smrn)

Compression Ratio (188G) ................................................................ , .................... 7,5 to 1

(159G) ..................................... .. ....... - ............. , ...... , ..................... 7,42 to 1

Piston Displacement ........................................................................................ 377 Cubic Inches

No Load Governed Speed ( lWG I ............................................................ , ....... , ......... 2250 RPM

(159G) ............................. ,,.,...,.,,ã..,...,à ..... .,.ã.... ,,.. 2250 RPM

RatM Engine Speed (188G1 ............. .+... ......................................................... 2100 RPM

( 159G 1 ................................................................................... 1900 RPM

......... Engine Idling Speed ............................................. ,..., ................................. . 600 RPM

Â¥Val Tappet Clearance (Intake) ................................. (Hot and Cold) ,014 Inches (0,356mm)

(Exhaust) .................. , .... ..... ,. ...,.. ..... + ...... (Cold) ,020 Inches (Oh50Smrn

(Hot) ,014 Inches (0.356mrn

Exhaust Valve Rotators ......................................................................................... Positive Type

Â¥H Settings Arc Made After The Engine Has Operated At Thermostat Controlic-d Temperature

For At Least Fifteen Minutes.

Piston and Connecting Rods

Rings per Piston ......................................................................................................................... 4

.................................................................................................... Number of Compression Rings 3

.................................................................................................................. Number of Oil Rings 3

Type P'm .............................................................................. ,, ............ Full Floating Tyw

Type Bearings , ....................... , .... Replaceable, Precision Steel Back, Copper Lead Alloy Liners.

Main Bearings

Number of Bearings ......................... , ................ , ............. - ................................................ 3

Type Bearings ........................... Replaceable, Precision Steel Back, Copper Lead Alloy Liners.

Engine Lubricating System

Oil Pressure ................... 24 to 32 Pounds (1.7 to 2.3 kg/cm2) with Engine Warm and Operating

at Rated Engine Speed

Type System ......................................................... , ...................... Pressure Spray Circulation

Oil Pump ..... , ...................... , ................ , ................................................. , ................. Gear Type

Oil Filter ............................................................................................ Full Flow, Spin on Type

Fuel System

Fuel Tank Capacity .............................................................. ,... Ã £ , . 22 U.S. Gallons (83.3 liters)

Carburetor ............... , .................. Zenith (wfsolenoid shu t-off) 1-1/4 Inch SAK Flange (31,7rnm

Fuel Strainer ............................................... , ............... ,.. In Sediment Bowl Under Fuel Tank

.. Fuel Filter ....................... . ........ .. ......... , .... I ....................... .. Mounted on Fuel Strainer Head

Distributor Ignition

Contact Point Gap .......................................................................................................... -020 Inch

Dwell Angle .................................. ,..,,. ..................................................................................... 700

Spark Plugs ..................................... , ..................... ,, .............................. Prestolite 18 8

Plug Gap ............................. ...... , .................................. , ..................... ,., .............. .025 Inch

Thread ............... , ............................................................................................... 18 MM

Shank Length ...................................................................................................... 3/2 Inch

Engine Timing

Static Timing UWG) ..... ..x.... ....................................................................................... TDC

(159G) ............. ...-.. ,, ..................................................................... ....... ... 3QATDC

Running Timing (18SG) ....................................................................... 34" BTDC at Rated Speed

(mG) ...... ,. -, ........................... ,-, ...... , ............ , ..... ;JOifBTD at Rated Speed

GENERAL SPECIFICATIONS

Cooling System

Capacity (188D & 188G) .............................................................. 16-1 '2 U.S. Quarts (15.6 liters)

..... (159G ..................................................... ...-.. 14 U,S. Quarts (13.3 liters)

Type of System ................................ .., ............. -- .......... Pressurized Thcrmosia t Con trolled

Impeller Type Pump,

Radiator ., ........ ,,,, .... ,., .................................. ,..,,..Ã .., ................. Heavy Duty Fin &Ed Tube Type

Thermostat ................................... Starts to Open at Approximately 1779F. Fully Open at 202".

Pressure Cap Required .......................... ,.,..., ......................... , ................................... 4 PSI

WtieJi using a proper operating pressure cap, the engine temperature can safely rise to 2,30T'.

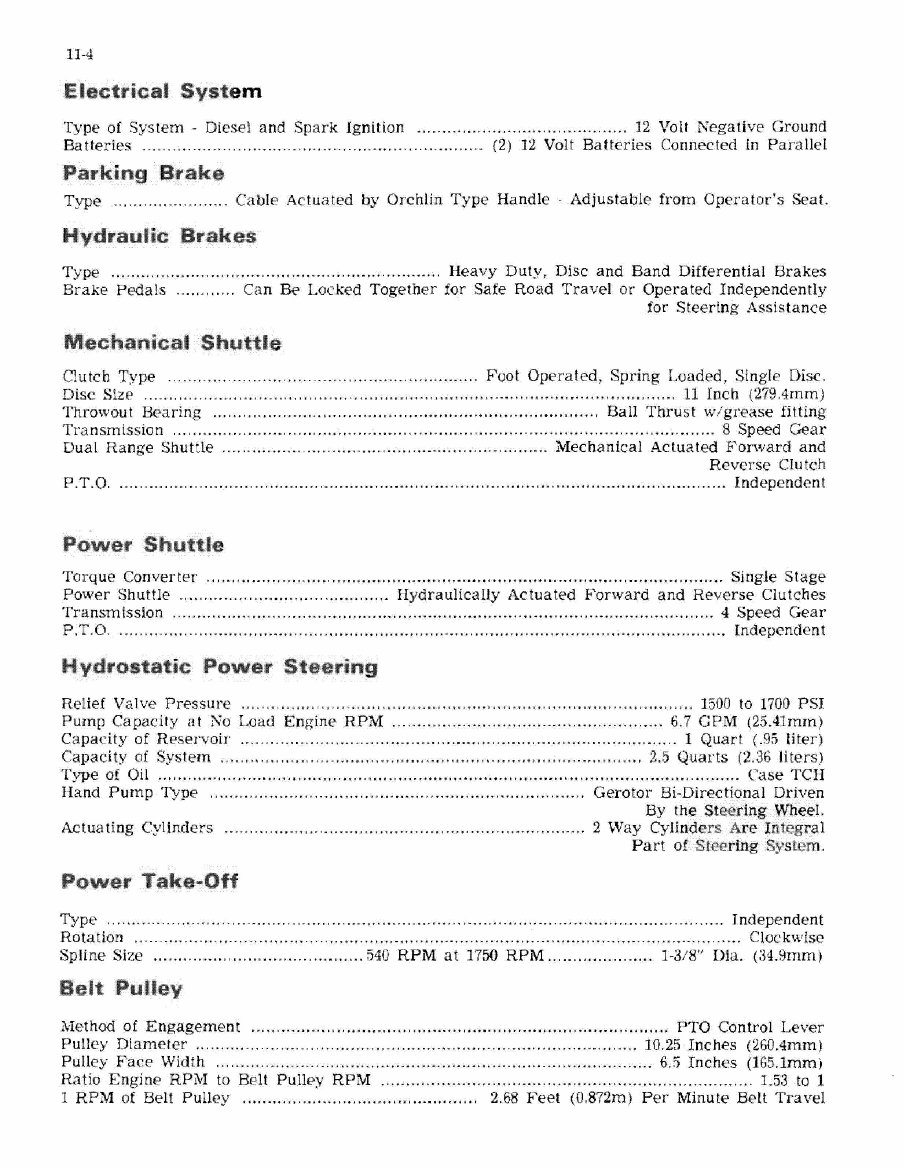

Electrical System

Type of System - Diesel and Spark Ignition ..,-.. .............................. 12 Volt Negative Ground

Batteries ............................................................... (2) 12 Volt Batteries Connected in Parallel

Parking Brake

Type ....................... Cable Actuated by Orchlin Type Handle . Adjustable from Operator's Seat.

Hydraulic Brakes

Type ............................................................... Heavy Duty, Disc and Band Differential Brakes

Brake Pedals .......... Can Be Locked Together for Safe Road Travel or Operated Independently

for Steering Assistance

Clutch Type .............................................................. Foot Opera fed, Spring Loaded, Single Disc.

Disc Size ...................... , ................... ..... ,.,-,,ã..È,,..,ã-- ...... ,,--,..r ....... ,..,ã,., 11 Inch {279,4mrn

Throwout Bearing ...................................................................... Ball Thrust wfgrease fitting

Transmission ......................................................................................................... 8 Speed Gear

Dual Range Shuttle ............................................................... Mechanical Actuated Forward and

Reverse Clutch

P.T.O. ......................................... ,, .................. +.ã.,... ...... ~., .............. , ..... , ...... Independent

Power Shuttle

Torque Converter ............................................................................................ Single Stage

Power Shuttle ....................................... Hydraulically Actuated Forward and Reverse Clutches

Transmission ........................................................................................................... 4 Speed Gear

P,TdO .............................. ..,..,,.,.,,.ã.,.,.,..,,,,. b,,à ............................. ,,,ã,... ..... Independent

Hydrostatic Power Steering

Relief Valve Pressure ............... ã ........... ,.,à ............................................... 1500 to 1700 PSI

Pump Capacity at No Load Engine RPM .................................................. 6.7 GPM (25.41mm

Capacity of Reservoir .................................................................................. 1 Quart (-95 liter)

Capacity of System ã..,,à ....................................................... , ............. 2.5 Quarts (236 liters)

Type of Oil ...................................................... .... ....... ... ...................... , ................. Case TCH

Hand Pump Type ..................................................................... Gerotor Bi-Directional Driven

By the Steering Wheel.

Actuating Cylinders ....................................... ,. ..... .............. , .... -. 2 Way Cylinders Are Integral

Part of Steering System.

Power Take-Off

Type ................................................................................................................. Independent

Rotation ............................................................................................................. -. Clockwise

Spline Size .................................... ,540 RPM at 1750 RPM .................. 1-318" Dia. (34.9mm)

Method of Engagement .......................................................................... PTO Control Lever

Pulley Diameter .............................................................................. -. 10.25 Inches (260.4mrn

Pulley Face Width ..., ..... ,-.+ ..................... ., ........................................ 6.5 Inches (165.1mm

.......................................................................... Ratio Engine RPM to Belt Pulley RPM 1.53 to 1

............... ................ 1 RPM of Belt Pulley ..+..., ..... Ã 2.68 Feet (Q.S72m) Per Minute Belt Travel

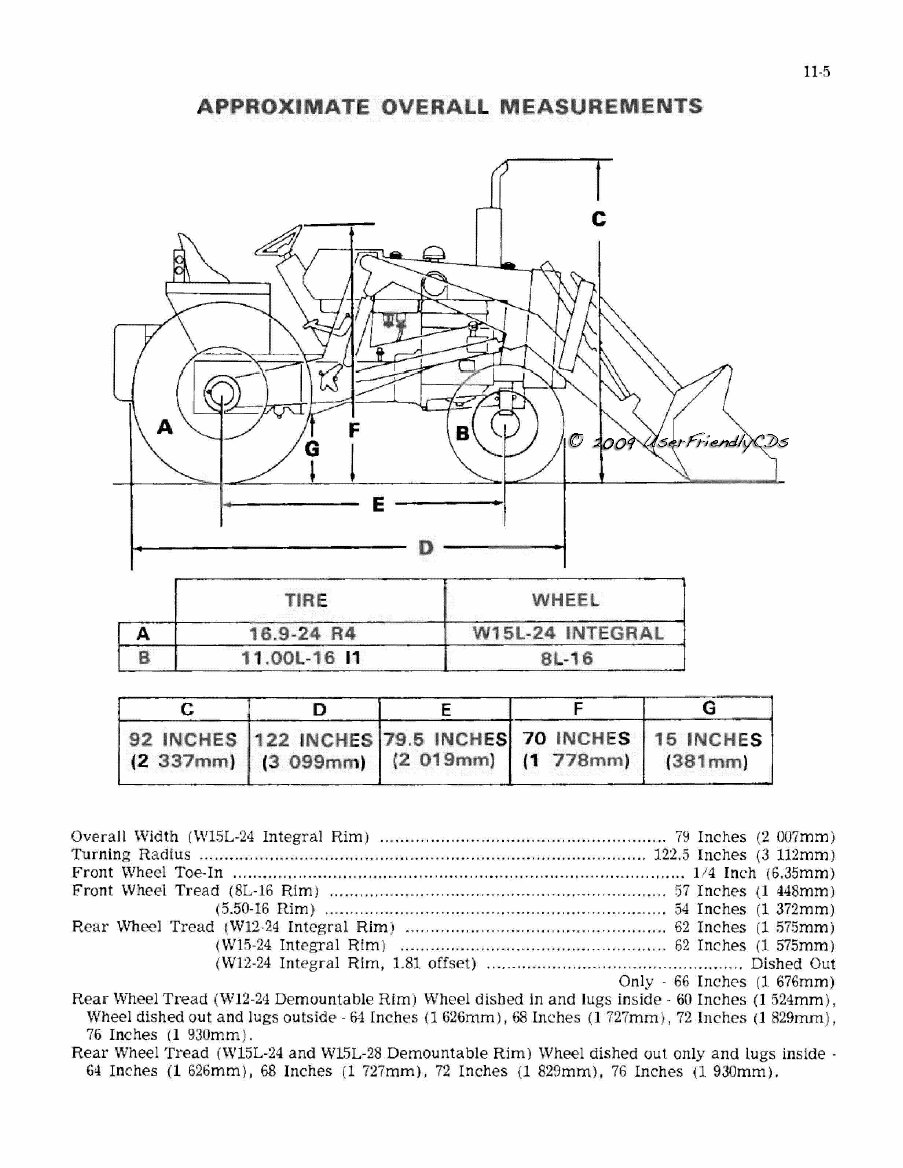

. 79 Inches (2 007mm)

122.5 Inches (3 112mm)

. 1/4 Inch (6.35rnm)

57 Inches (1 448rnrn)

54 Inches (1 372mm)

....................................................................

62 Inches (1 575rnmj

........ .... * .... (W15-24 Integral Rim) ,.,..+. .-..,.+ .................. 62 Inches (1 575rnrn)

.................. ...................... (W12-24 Integral Rim, 1.81 offset) L...4.a..,. Dished Out

Only - 66 Inches (1 676mm)

Rear Wheel Tread (W12-24 Demountable Rim) Wheel dished in and lugs inside - 60 Inches (1 524mm)

Wheel dished out and lugs outside - 64 Inches (1 626mrn) 68 Inches (1 727mm), 72 Inches (1 829mrn),

76 Inches (1 930rnrn),

Rear Wheel Tread (W15L-2 and WEL-28 Demountable Rim) Wheel dished out only and lugs inside -

64 Inches (1 626mrn) 68 Inches (1 727mm), 72 Inches (1 829mrn1, 76 Inches (1 930mm).

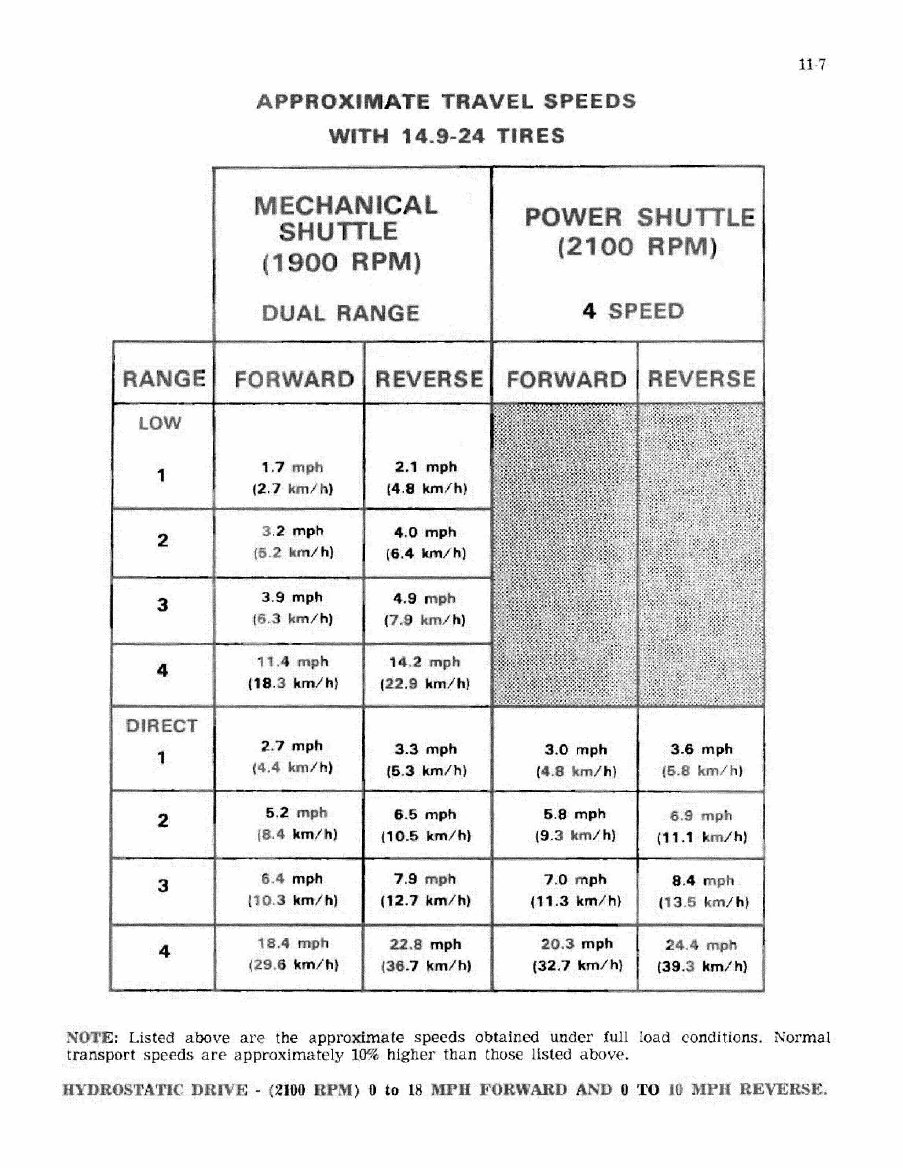

ATE TRAVEL SPEEDS

WITH 14.8-24 TIRES

LOW

1

1 DIRECT

NOTE: Listed above are the approximate speeds obtained under full load conditions. Normal

transport speeds are approximately 10% higher than those listed above.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$37.99

Viewed 52 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$37.99

Our comprehensive manual for the Case 580 Model B Construction King provides approximately 649 pages of detailed information on service and repairs. This manual covers all phases of repairs and service, making it an invaluable resource for both professional mechanics and DIY enthusiasts. Whether you need to perform routine maintenance or tackle more complex repairs, this manual contains everything you need to know.