Collection of 5 files - Complete Factory Case 530CK Loader Backhoe Repair Service Manual & Illustrated Parts Catalog & Operators

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

I

!i\THIS SAFETY ALERT SYMBOL INOICATES IMPORTANT SAFETY

'

MESSAGES IN THIS MANUAL. WHEN YOU SEE THIS SYMBOL,

CAREFULL Y READ THE MESSAGE THAT FOLLOWS AND BE

• ALERT TO THE POSSIBILITY OF PERSONAL INJURY OR

DEA TH. M1718

Safety Decals on this machine use the words Danger, Warning or

Caution, which are defined as follows:

• DANGER: Indicates an immediate hazardous situation which. if

not avoided. will result in death or serious injury. The color

associated with Danger is RED.

• WARNING: Indicates a potentially hazardous situation which. if

not avoided will result in serious injury. The color associated with

Warning is ORANGE.

• CAUTION: Indicates a potentially hazardous situation which. if

not avoided. may result in minor or moderate injury. It may also

be used to alert against unsafe practices. The color associated

with Caution is YELLOW.

IMPROPER OPERATION OF THIS MACHINE CAN CAUSE INJURY OR

DEATH. BEFORE USING THIS MACHINE, MAKE CERTAIN THAT EVERY

OPERATOR:

• Is instructed in safe and proper use of the machine.

• Reads and understands the Manual(s) pertaining to the machine.

• Reads and understands ALL Safety Decals on the ma~hine.

• Clears the area of other persons.

• Learns and practices safe use of machine controls in a safe, clear area

before operating this machine on a job site

It is your responsibility to observe pertinent laws and regulations and follow

Case Corporation instructions on machine operation and maintenance.

<CI 1996 Case Corporation

CASE and IH are registered trade marks of Case Corporation

••

CABE®·

"32"

r

•

•

INTRODUCTION

'"

Q)

"C

oj

0

...:I

I

'"

0

-

"

oj

....

f-<

"

Q)

:;

-

"

0

'"

""'

"

"

oj

::c:

-

..c:

blJ

.~

~

~

Q)

'"

.§O

""'

•

•

• •

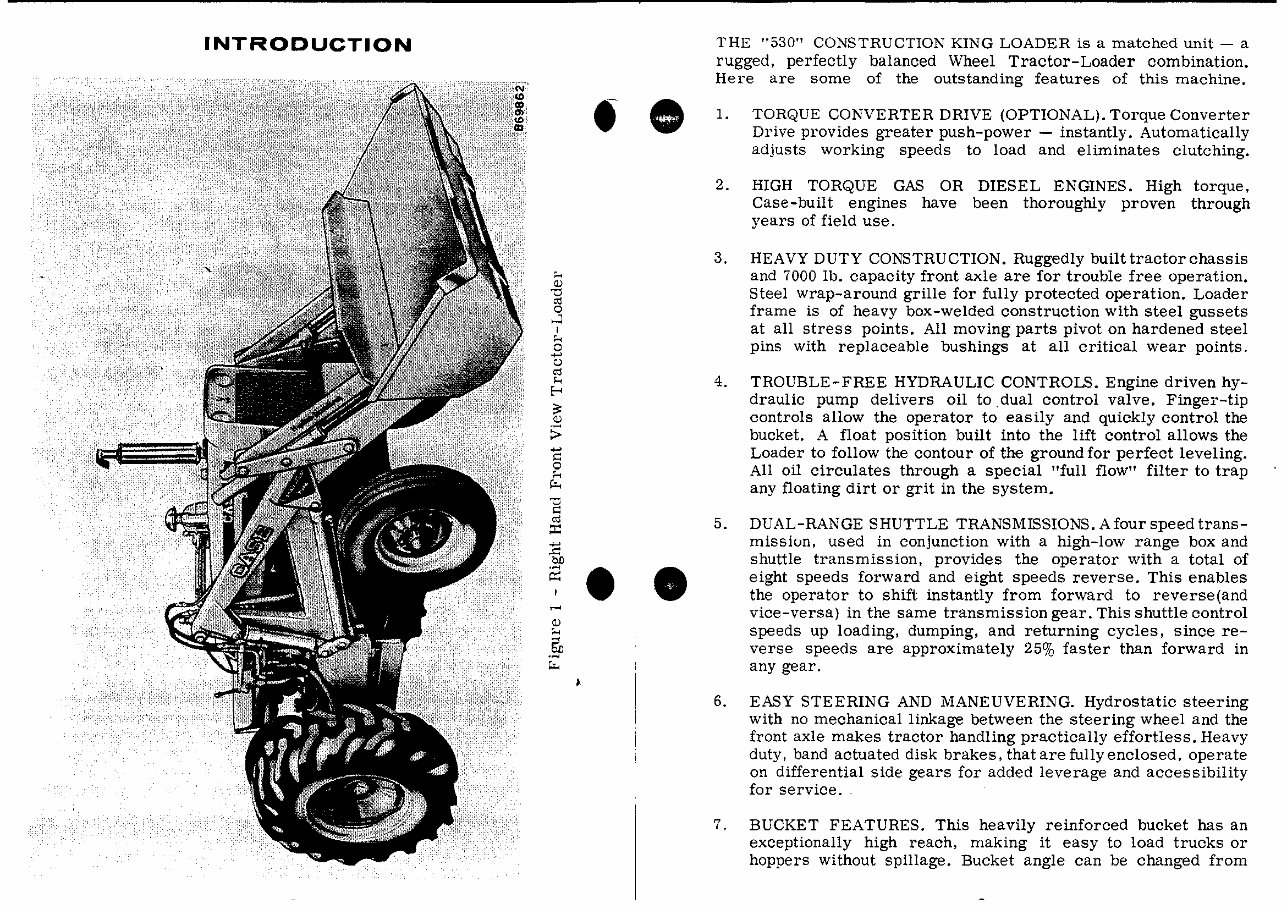

THE "530" CONSTRUCTION KING LOADER is a matched unit - a

rugged. perfectly balanced Wheel Tractor-Loader combination.

Here are some of the outstanding features of this machine .

1. TORQUE CONVERTER DRIVE (OPTIONAL). Torque Converter

Drive provides greater push-power - instantly. Automatically

adjusts working speeds to load and eliminates clutching.

2. HIGH TORQUE GAS OR DIESEL ENGINES. High torque.

Case-built engines have been thoroughly proven through

years of field use.

3. HEAVY DUTY CONSTRUCTION. Ruggedly built tractor chassis

and 7000 lb. capacity front axle are for trouble free operation.

Steel wrap-around grille for fully protected operation. Loader

frame is of heavy box-welded construction with steel gussets

at all stress pOints. All moving parts pivot on hardened steel

pins with replaceable bushings at all critical wear points.

4. TROUBLE-FREE HYDRAULIC CONTROLS. Engine driven hy-

draulic pump delivers oil to dual control valve. Finger-tip

controls allow the operator to easily and quickly control the

bucket. A float position built into the lift control allows the

Loader to follow the contour of the ground for perfect leveling.

All oil circulates through a special "full flow" filter to trap

any floating dirt or grit in the system.

5. DUAL-RANGE SHUTTLE TRANSMISSIONS. Afoul' speed trans-

missiun. used in conjunction with a high-low range box and

shuttle transmission. provides the operator with a total of

eight speeds forward and eight speeds reverse. This enables

the operator to shift instantly from forward to reverse(and

vice-versa) in the same transmission gear. This shuttle control

speeds up loading. dumping. and returning cycles. since re-

verse speeds are approximately 25% faster than forward in

any gear.

6. EASY STEERING AND MANEUVERING. Hydrostatic steering

with no mechanical linkage between the steering wheel and the

front axle makes tractor handling practically effortless. Heavy

duty. band actuated disk brakes. that are fully enclosed. operate

on differential side gears for added leverage and accessibility

for service ..

7. BUCKET FEATURES. This heavily reinforced bucket has an

exceptionally high reach. making it easy to load trucks or

hoppers without spillage. Bucket angle can be changed from

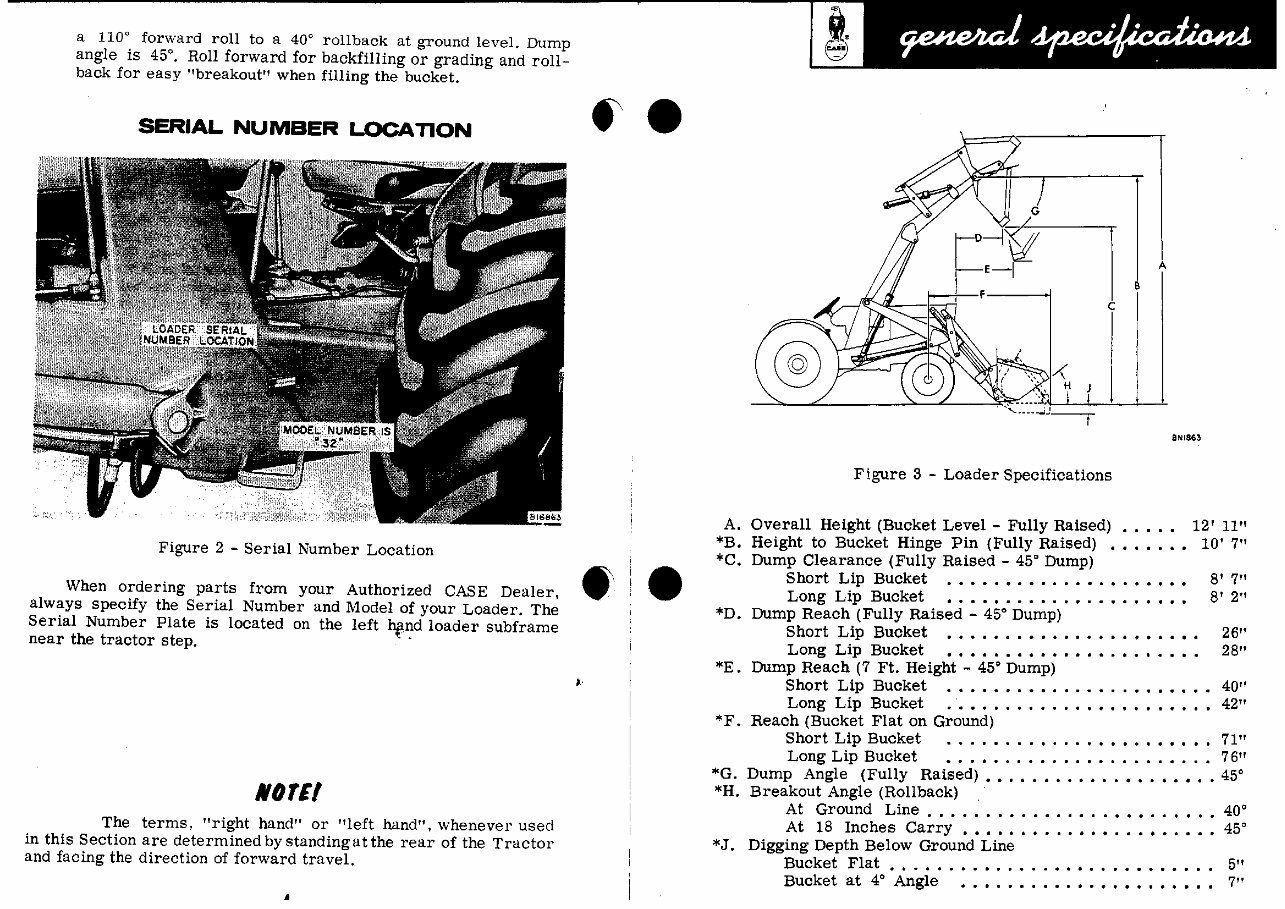

a 1100 forward roll to a 40' rollback at ground level. Dump

angle is 45'. Roll forward for backfilling or grading and roll-

back for easy "breakout" when filling the bucket.

SERIAL NUMBER LOCATlON

Figure 2 - Serial Number Location

When ordering parts from your Authorized CASE Dealer.

always specify the Serial Number and Model of your Loader. The

Serial Number Plate is located on the left hf',nd loader subframe

near the tractor step. . .

NOrtl

The terms, "right hand" or "left hand". whenever useci

in this Section are determined by stanciing at the rear of the Tractor

and facing the direction of forward travel.

•

.,.

•

,.

A

B

c

SNI863

Figure 3 - Loader Specifications

A. Overall Height (Bucket Level - Fully Raised) •• • •• 12' 11"

*B. Height to Bucket Hinge Pin (Fully Raised) ••.•.•• 10' 7"

*C. Dump Clearance (Fully Raised - 45' Dump)

Short Lip Bucket ..................... 8' 7"

Long Lip Bucket •••••.•••.••..••.•••• 8' 2"

*D. Dump Reach (Fully Raised - 45' Dump)

Short Lip Bucket ••••••.••••.•••••••••• 26"

Long Lip Bucket •••••••••••••••••••••• 28"

*E. Dump Reach (7 Ft. Height - 45' Dump)

Short Lip Bucket ......................... 40"

Long Lip Bucket .••••...•..••••.•••••.• 42"

*F. Reach (Bucket Flat on Ground)

Short Lip Bucket ......... , ............. 71"

Long Lip Bucket • • • • • . . • • . • • • • • . . • . • • . • 76"

*G. Dump Angle (Fully Raised) ••.••••.••..•••••••. 45'

*H. Breakout Angle (Rollback)

At Ground Line •.•••••••••..•.••••...•.• 40'

At 18 Inches Carry ••.••.•..••••.•••••••• 45'

*J. Digging Depth Below Ground Line

Bucket Flat . . .. .. . . . . . . . . . . . . . . . . . . . . . . .. 5

'1

Bucket at 4

0

Angle ...................... 7"

,.

*

,.

..

..

..

*

*

..

*

*

*

of<

*

*

..

*

Overall Width of Tractor

Standard Loader Only Models (56"-64" Tread) •• 71-79"

Standard Loader-Backhoe Models (62" Tread)... 77"

Height (To Top of Loader Frame) • • • . • • • • • • • • •• 62"

Overall Length (Bucket Flat on Ground to Rear of

Counterweight) ........ •..• ..... •• .... • 15' 7"

Ground Clearance (At Loader) ••.•• . . • • • • • • • • •• 12"

Tread, Front ............................. 54"

Tread, Rear (Adjustable Rims Standard on Loader

Only Models) ••• • • . • • • . • • . . . • • • • • • • •• 56-64"

Tread, Rear (Fixed Standard on Loader-Backhoe

Models) . • . . . • . • • • • . • • • • • • • • • • • • • • . . •• 62"

Wheel Base (Diesel) ••.•••.•••••••••••••• 78-7/16"

(Gasoline) •••••••••..•••••••.• 77-3/16"

Front Axle .••.•••• Extra Heavy Duty, 7000 lb. Capacity

(Dynamic Loading)

Grading Angle ........................ Up to 110'

Hydraulic Lift Capacity (To Full Height) ••.• 3000 lbs.

Breakout Force (Maximum) •.•••.•.••.••.• 6200 lbs.

RaiSing Time to Full Height • ..... ••.••.. 5.0 Seconds

Lowering Time from Full Height .•• ...... 3.5 Seconds

Bucket Dump Time ...• ............... 1.0 Seconds

Tire Sizes

Front . . . . . . . . . . . . . . . . . . . . . . . . ..

Rear .••..•.•..•.• ••••••• ..... •

Hydraulic System

7.50 x 16, 10 ply

14.9 x 24, 6 ply

System Pump . . • • • • • • • • • . •. Dir.e?t Drive, Gear Type

Pump Capacity

(Standard Clutch Models) ••. 20 G.P.M. @ 1900 R.P.M.

@ 2000 P.S.I. .'

(Torque Converter Models) •• 22 G.P.M. @ 2100 R.P.M.

@ 2000 P.S.I.

Reservoir Refill Capacity

(Loader Only Models) ••.•••••.•.•• 5.5 U.S. Gallons

(Loader-Backhoe Models) •..••••••• 11 U.S. Gallons

Filter. • • • •. Return line, full flow, replaceable micronic

element

Control Valve ••• Dual Control Valve with Independent Levers

For Raising or Tilting the Bucket

Main Relief Valve P,:essure Setting .••• 1950 to 2000 P.S.I.

f'.

• •

•

•

Secondary Relief Valve Pressure Settings

Front of Valve (2) ••••.•••••••• 2400 to 2600 P.S.I.

Rear of Valve (1) ..... ••••..•. 1675 to 1875 P.S.I.

Oil Recommendation •••••.••••.• Case Hi-Lo TCH Oil

Hydraulic Lines. . . .• Steel tubing with brazed or flared

fittings. Wire braid high pressure

hose with crimped fittings (full-flow) •

Hydraulic Cylinders

Type ..••.•..••.• Double-acting with chrome plated rods

Lift Cylinders (2) 3x 31-1/2" Stroke, 1-1/2" Piston Rod

Bucket Cylinders (2) 2-1/2 x 20" Stroke, 1-1/2" Piston Rod

Hydra-Leveling Cylinder (1) ••.•• 3 x 9-15/16" Stroke

1-3/4" Piston Rod

Shipping Weight

Shipping Weight (With 013022 Bucket - Less Counterweights)

Gasoline Engine with Torque Converter. • .• 5525 lbs.

Gasoline Engine without Torque Converter •• 5375lbs.

Diesel Engine with Torque Converter ••••• 5725 lbs.

Diesel Engine without Torque Converter 5575 lbs.

'Specifications conform to Society of Automotive Engineers (SAE)

or Industrial Equipment Manufacturers Council (IEMC) definitions

whichever is applicable .

IMPORTANT!

Case Company reserves the right to change these speci-

fications without notice and without inc.urring any obligations relating

to such changes.

The lubrication of your Loader will require only a few minutes

of regular daily attention and will greatly increase the life of the

,:,ac~ine. Use only high-grade oil and grease of unvarying speci-

fIcatIOn. Always buy lubricants from a reputable Dealer who handles

a reliable product.

Basic Tractor Lubrication

For lubrication of the baSic Tractor. refer to the "530" Con-

struction King WheeH Tractor Operator's Instruction Manual.

Recommended Lubricant

Pressure Fittings .•••..•..•.. Lithium "soap-base" grease

Grade Recommendations - Below 32

0

F. . ............ •. #1

32

0

F. to 90

0

F. . ............ #2

Above 90

0

F. . .............. #3

Pressure Fittings

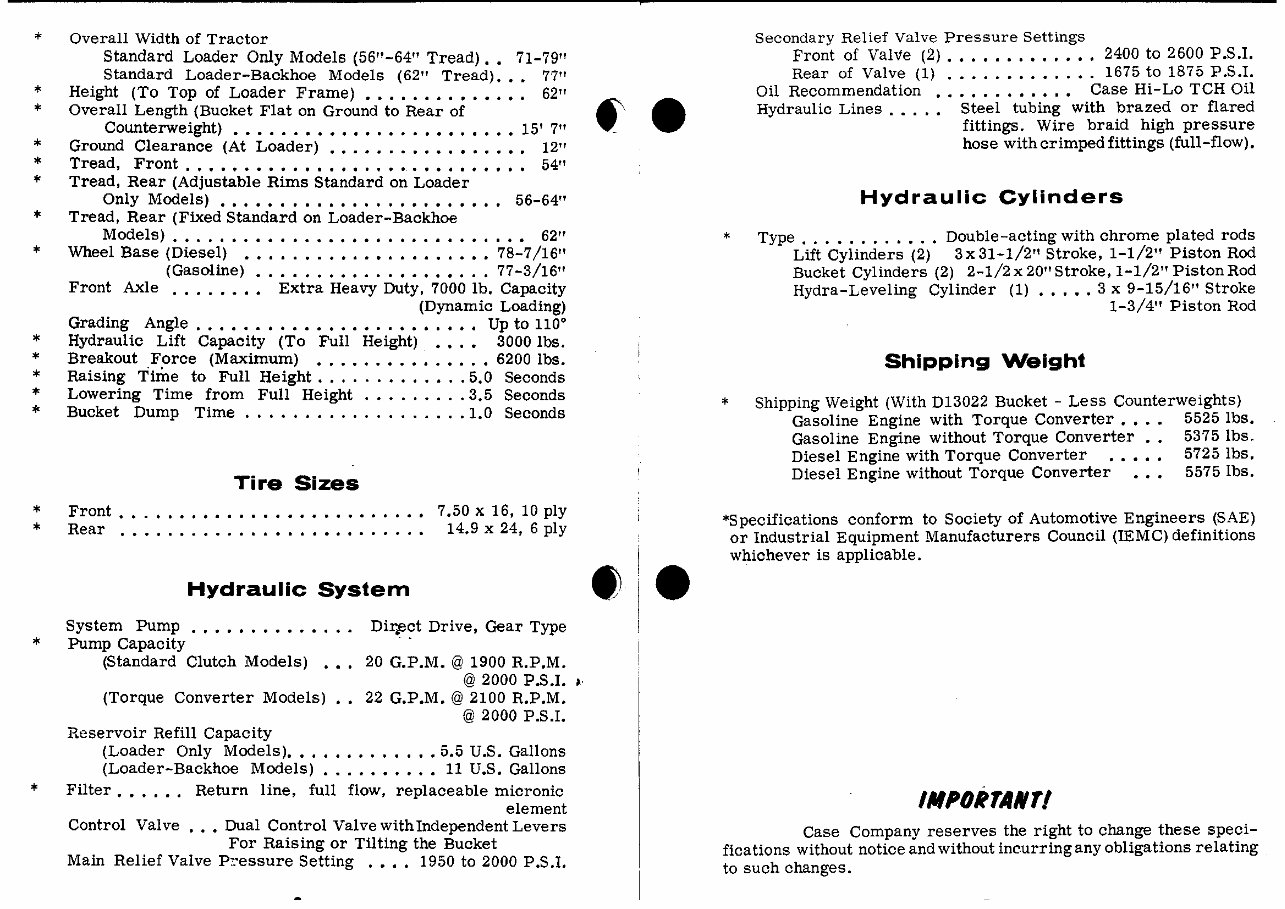

Figure 4 - Loader Pressure Fittings

f ."

• •

Before applying a grease gun to pressure fittings, wipe all

accumulated dirt from each fitting tip.

LOCATION

1. Cross Shaft

2. Dump Cylinder

3. Hydra-Leveling

Cylinder

4. Lift Cylinder

5. Dump Linkage

NO, OF FITTINGS *TIME INTERVAL

1 on each side

1 front, 1 trunnion each side

10 Hours

10 Hours

1 each end

1 front. 1 rear each side

3 on each side

10 Hours

10 Hours

10 Hours

*If Loader is operating in mud or water, lubricate immersed fit-

tings several times daily.

HYDRAULIC SYSTEM

A superior type hydraulic oil is the key to trouble free per-

formance and low maintenance for hydraulic systems.

Case Hi-Lo TCH Oil was developed exclusively to meet the

requirements of complex hydraulic systems and machined com-

ponents. It is a non-foaming oil for all weather use. It remains

stable from _55

0

F. to 230

0

F. Your Authorized Case Dealer has

this oil in stock or can order it for you .

AVAILABLE IROM YOUR CAfE fJEALER

Reservoir Refill Capacity (Loader only) •.•• 5-1/2 U.S. Gallons

(Loader-Backhoe) .,. 11 U.S. Gallons

*Oil Recommendations ••••• .... ••... Case Hi-Lo TCH Oil

*As an alternate oil, a heavy-duty motor oil meeting American f: •

Petroleum Institute service designation. MS-DG. may be used. -

Use only a good grade oil with non-foaming characteristics.

Viscosity Recommendations (Above 32' F.)

(Below 32' F.)

SAE 10-W

*SAE 5-W

*If SAE 5-W oil is not obtainable, Automatic Transmission

Oil, type nAn may b~ used.

IMPORTANTI

DIRT IS THE ENEMY OF ANY HYDRAULIC SYSTEM. THE

BEST WAY 'TO FIGHT THIS ENEMY IS TO PREVENT ITS

ENTRY INTO THE SYSTEM. WHEN ADDING OIL BE SURE

OIL, FUNNELS, AND CONTAINERS ARE CLEAN.

NO TEl

CHEAP GRADES OF OIL ARE NOT SUITABLE FOR USE IN

THE HYDRAULIC SYSTEM.

Checking Hydraulic Oil Level

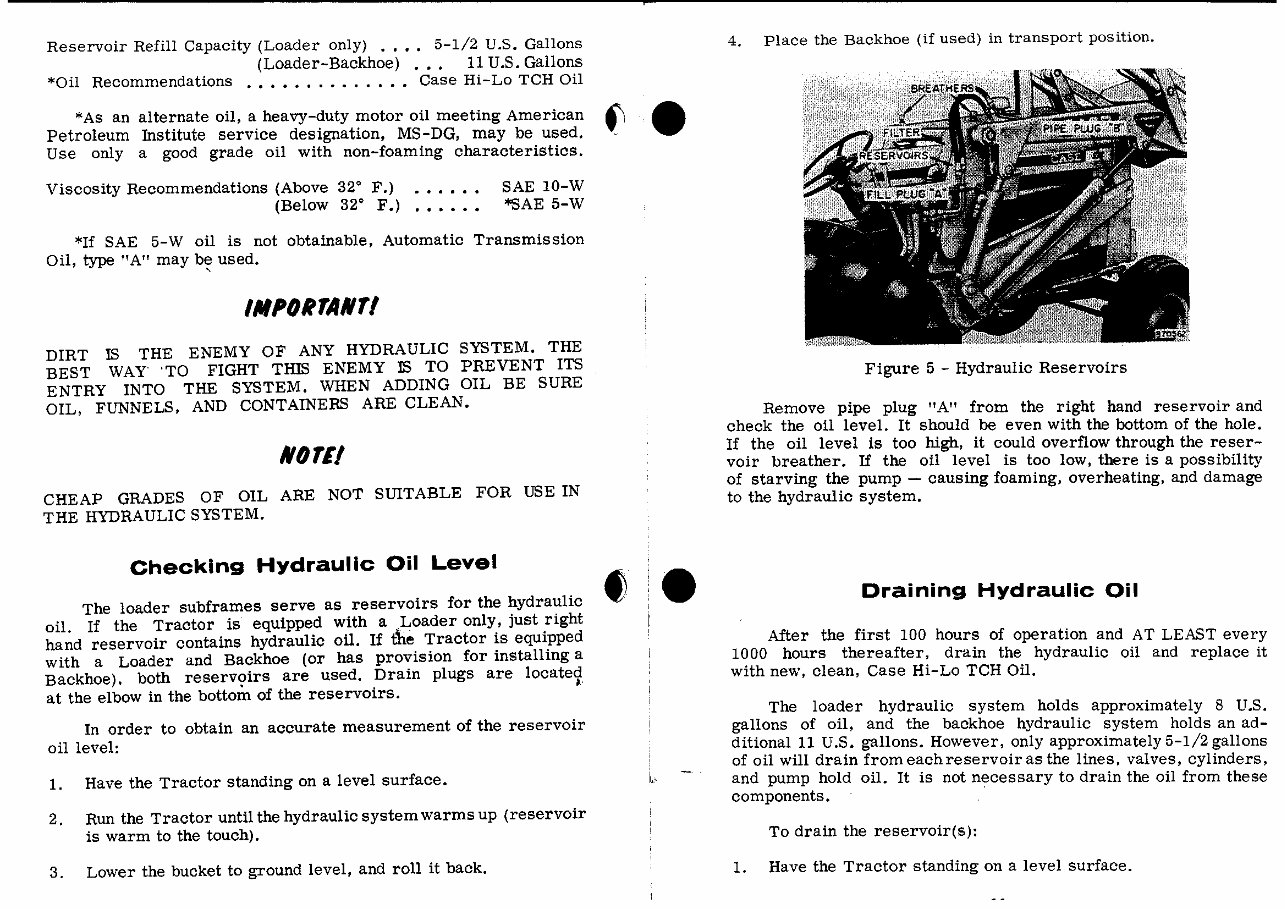

The loader subframes serve as reservoirs for the hydraulic

oil. If the Tractor is equipped with a Loader only, just right

hand reservoir contains hydraulic oil. If the Tractor is equipped

with a Loader and Backhoe (or has provision for installing a

Backhoe). both reservc:>irs are used. Drain plugs are locateq,

at the elbow in the bottom of the reservoirs.

In order to obtain an accurate measurement of the reservoir

oil level:

1. Have the Tractor standing on a level surface.

2. Run the Tractor until the hydraulic system warms up (reservoir

is warm to the touch).

3. Lower the bucket to ground level, and roll it back.

•

I.'

4. Place the Backhoe (if used) in transport position.

Figure 5 - Hydraulic Reservoirs

Remove pipe plug nAn from the right hand reservoir and

check the oil level. It should be even with the bottom of the hole.

If the oil level is too high. it could overflow through the reser-

voir breather. If the oil level is too low, there is a possibility

of starving the pump - causing foaming, overheating, and damage

to the hydraulic system.

Draining Hydraulic Oil

After the first 100 hours of operation and AT LEAST every

1000 hours thereafter, drain the hydraulic oil and replace it

with new. clean, Case Hi-Lo TCH Oil.

The loader hydraulic system holds approximately 8 U.S.

gallons of oil. and the backhoe hydraulic system holds an ad-

ditional 11 U.S. gallons. However, only approximately 5-1/2 gallons

of oil will drain from each reservoir as the lines. valves, cylinders,

and pump hold oil. It is not necessary to drain the oil from these

components. '

To drain the reservoir(s):

1. Have the Tractor standing on a level surface.

2. Run the Tractor until the hydraulic system warms up (reser-

voir is warm to the touch),

3. Lower the bucket to ground level and roll it back.

4. Place the Backhoe (if used) in transport position.

5. Remove pipe plug "A" from the right hand reservoir, see

Figure 5.

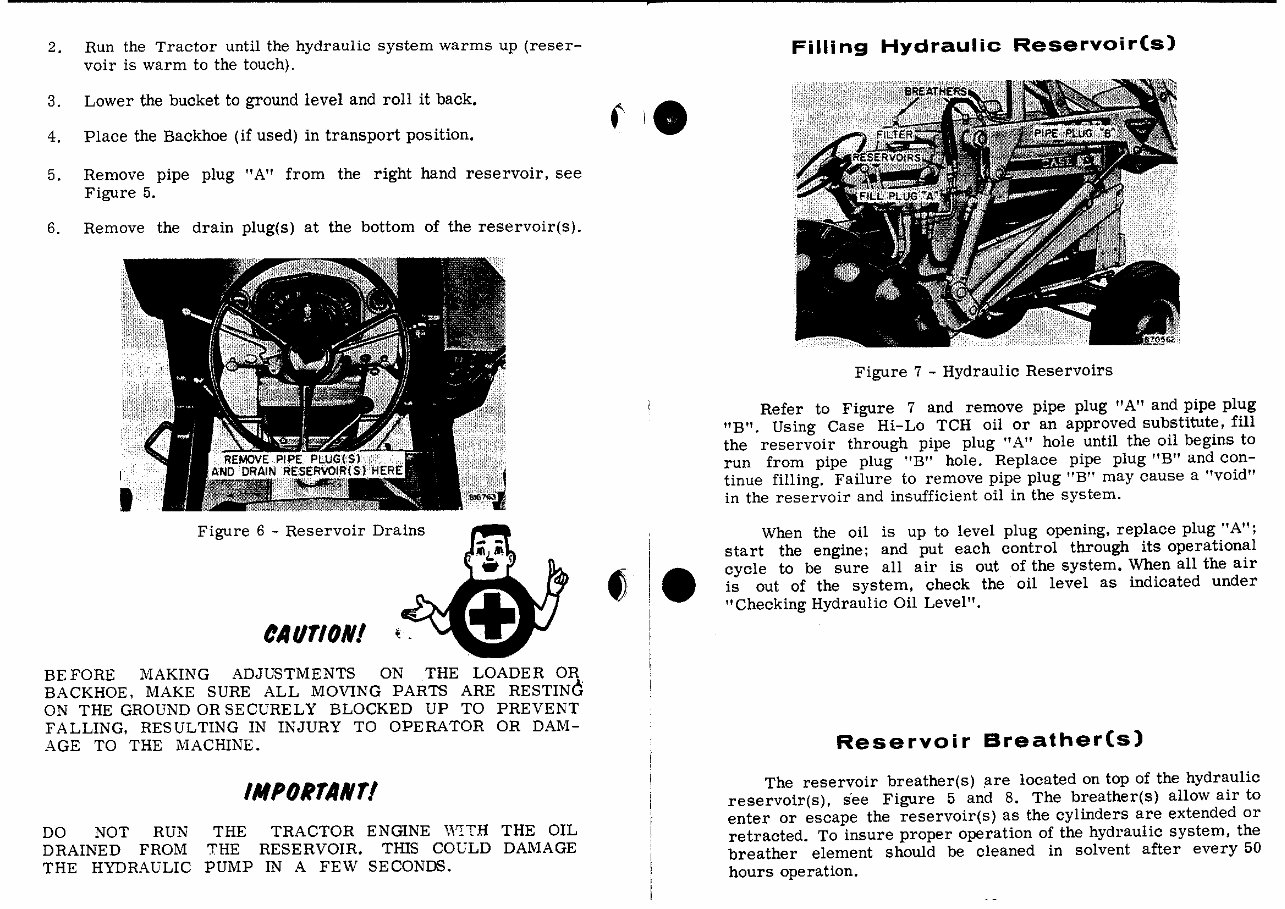

6. Remove the drain plug(s) at the bottom of the reservoir(s).

Figure 6 - Reservoir Drains

CAUTION!

BEFORE MAKING ADJUSTMENTS ON THE LOADER OR

BACKHOE, MAKE SURE ALL MOVING PARTS ARE RESTINC'

ON THE GROUND OR SECURELY BLOCKED UP TO PREVENT

FALLING, RESULTING IN INJURY TO OPERATOR OR DAM-

AGE TO THE MACHINE.

DO NOT RUN

DRAINED FROM

THE HYDRAULIC

IMPORTANT!

THE TRACTOR ENGINE WITH THE OIL

THE RESERVOIR. THIS COULD DAMAGE

PUMP IN A FEW SECONDS.

Filling Hydraulic Reservoir(s)

Figure 7 - Hydraulic Reservoirs

Refer to Figure 7 and remove pipe plug "A" and pipe plug

"B". Using Case Hi-Lo TCH oil or an approved substitute, fill

the reservoir through pipe plug "A" hole until the oil begins to

run from pipe plug "B" hole. Replace pipe plug "B" and con-

tinue filling. Failure to remove pipe plug "B" may cause a "void"

in the reservoir and insufficient oil in the system.

When the oil is up to level plug opening, replace plug" A";

start the engine; and put each control through its operational

cycle to be sure all air is out of the system. When all the air

is out of the system, check the oil level as indicated under

"Checking Hydraulic Oil Level".

Reservoir Breather(s)

The reservoir breather(s) ,are located on top of the hydraulic

reservoir(s), see Figure 5 and 8. The breather(s) allow air to

enter or escape the reservoir(s) as the cylinders are extended or

retracted. To insure proper operation of the hydraulic system. the

breather element should be cleaned in solvent after every 50

hours operation.

,

Figure 8 - Reservoir Breathers

Hydraulic System Filter

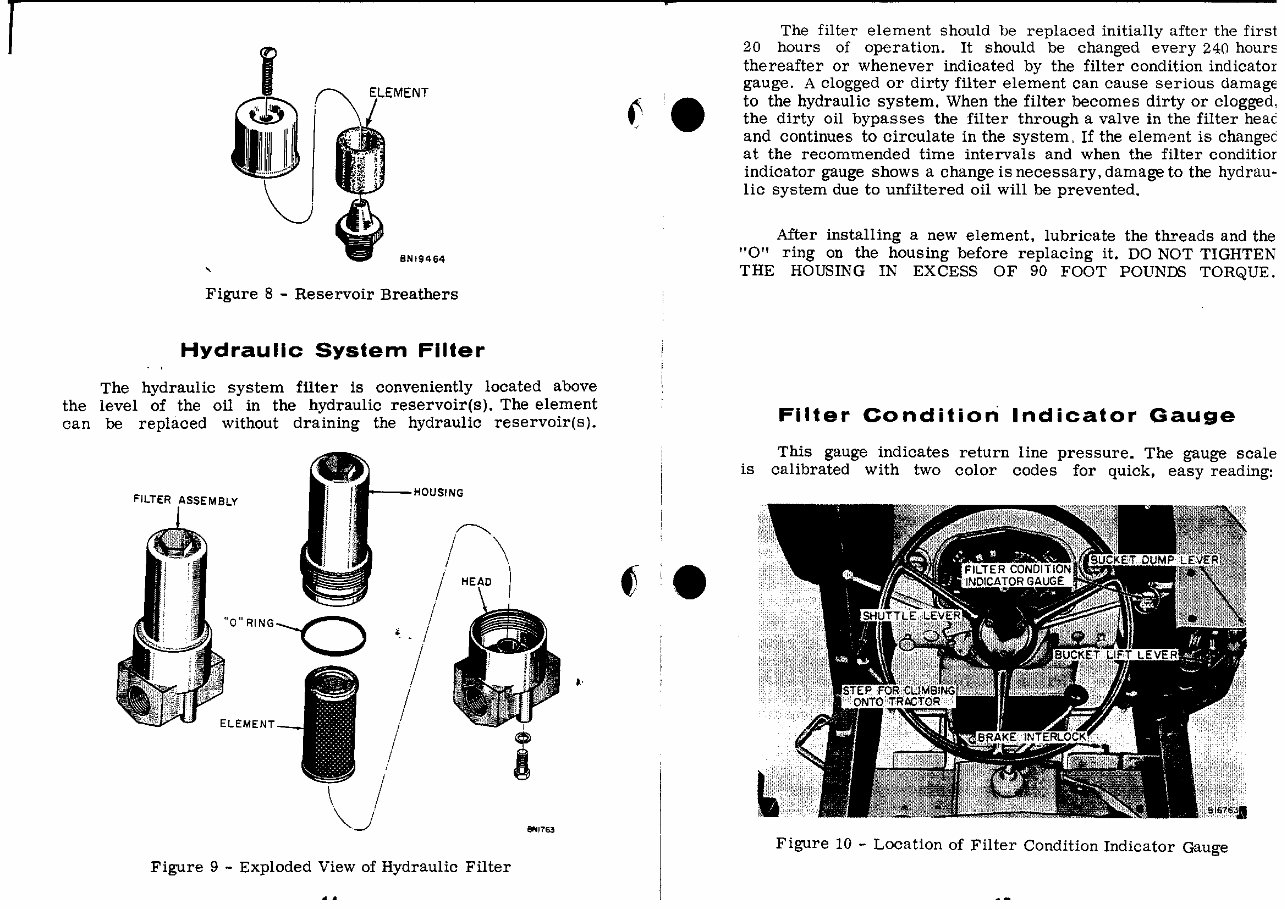

The hydraulic system filter is conveniently located above

the level of the oil in the hydraulic reservoir(s). The element

can be replaced without draining the hydraulic reservoir(s).

FILTER ASSEMBLY

"O"RING--Q

ELEMENT

---HeWSING

.~

/ \

/ )

, /

/

/

/

Figure 9 - Exploded View of Hydraulic Filter

.'

91'111763

~ .•

•

The filter element should be replaced initially after the first

20 hours of operation. It should be changed every 240 hourE

thereafter or whenever indicated by the filter condition indicator

gauge. A clogged or dirty filter element can cause serious damag€

to the hydraulic system. When the filter becomes dirty or Clogged,

the dirty oil bypasses the filter through a valve in the filter heat

and continues to circulate in the system, If the elem3nt is changec

at the recommended time intervals and when the filter conditior

indicator gauge shows a change is necessary, damage to the hydrau-

lic system due to unfiltered oil will be prevented.

After installing a new element, lubricate the threads and the

"0" ring on the housing before replacing it. DO NOT TIGHTEN

THE HOUSING IN EXCESS OF 90 FOOT POUNDS TORQUE.

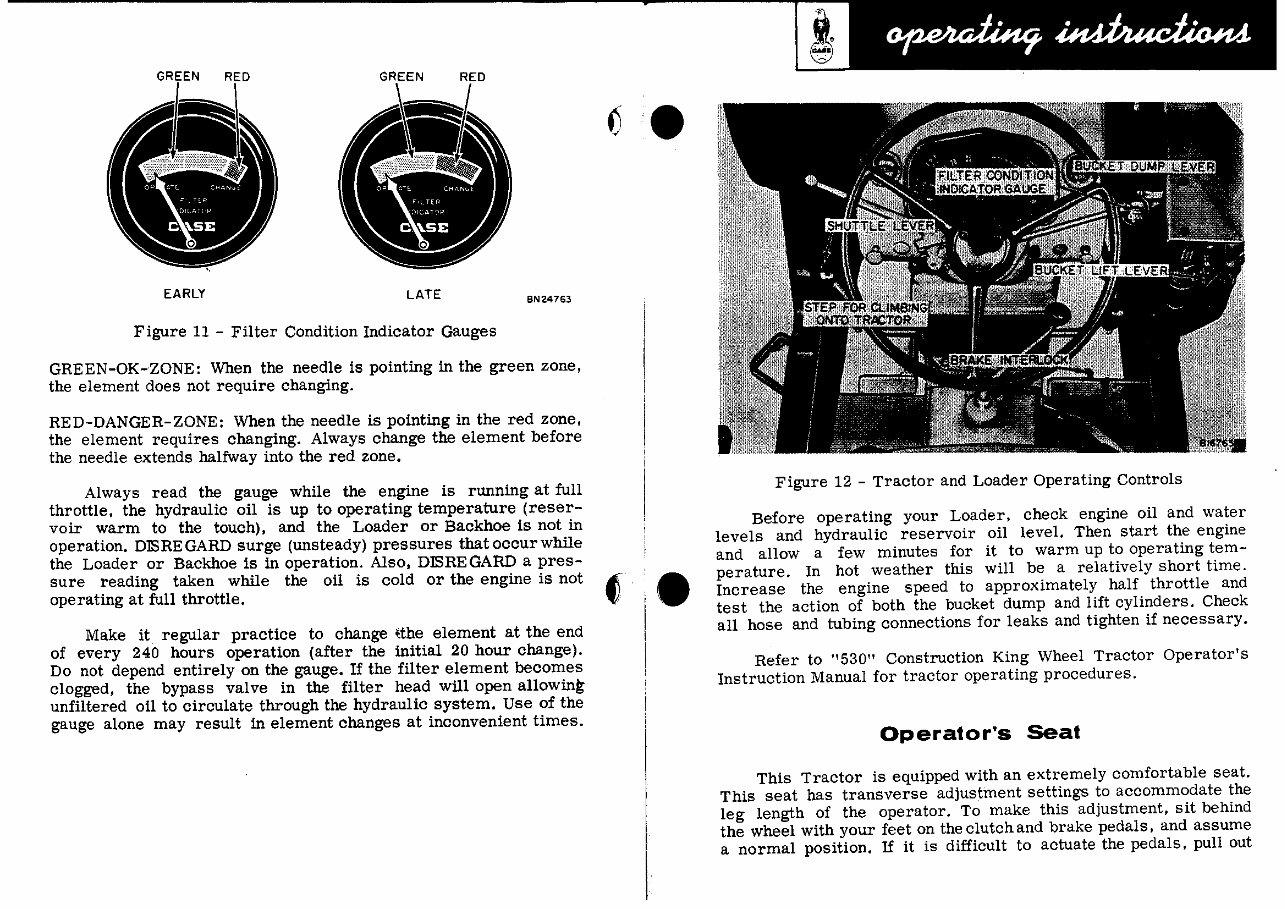

Filter Condition Indicator Gauge

This gauge indicates return line pressure. The gauge scale

is calibrated with two color codes for quick, easy reading:

Figure 10 - Location of Filter Condition Indicator Gauge

EARLY LATE

8N24763

Figure 11 - Filter Condition Indicator Gauges

GREEN-OK-ZONE: When the needle is pointing in the green zone,

the element does not require changing.

RED-DANGER-ZONE: When the needle is pointing in the red zone,

the element requires changing. Always change the element before

the needle extends halfway into the red zone.

Always read the gauge while the engine is running at full

throttle, the hydraulic oil is up to operating temperature (reser-

voir warm to the touch), and the Loader or Backhoe is not in

operation. DlSRE GARD surge (unsteady) pressures that occur while

the Loader or Backhoe is in operation. Also, DlSREGARD a pres-

sure reading taken while the oil is cold or the engine is not ~

operating at full throttle. ~

Make it regular practice to change Uhe element at the end

of every 240 hours operation (after the initial 20 hour change).

Do not depend entirely on the gauge. If the filter element becomes

clogged, the bypass valve in the filter head will open allowing

unfiltered oil to circulate through the hydraulic system. Use of the

gauge alone may result in element changes at inconvenient times.

•

Figure 12 - Tractor and Loader Operating Controls

Before operating your Loader, check engine oil and water

levels and hydraulic reservoir oil level. Then start the engine

and allow a few minutes for it to warm up to operating tem-

perature. In hot weather this will be a relatively short time .

Increase the engine speed to approximately half throttle and

test the action of both the bucket dump and lift cylinders. Check

all hose and tubing connections for leaks and tighten if necessary.

Refer to "530" Construction King Wheel Tractor Operator's

Instruction Manual for tractor operating procedures.

Operator's Seat

This Tractor is equipped with an extremely comfortable seat.

This seat has transverse adjustment settings to accommodate the

leg length of the operator. To make this adjustment, sit behind

the wheel with your feet on the clutch and brake pedals, and assume

a normal position. If it is difficult to actuate the pedals, pull out

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$54.99

Viewed 77 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$54.99

- This collection includes the following products:

- Case 530 530CK Loader Backhoe Service Repair Manual - IMPROVED

- Case 530CK 530 Construction King Backhoe Loader Illustrated Parts Manual Catalog

- Case 530CK 530 Construction King Tractor Engine Illustrated Parts Manual Catalog

- Case 530CK Loader Backhoe Operators Owner Instruction Manual - IMPROVED

- Case 530CK Tractor Operators Owner Instruction Manual - IMPROVED

- All 5 manuals are available for less than other sellers charge for 1 manual.

- These manuals are useful for both professional mechanics and DIY enthusiasts.

- Additional Information: Documents may require the newest version of Acrobat Reader to display correctly. Should you have any problems reading your document, please initially try upgrading to the latest version of Adobe Acrobat Reader.

- If you only want one of these, let me know, and I will beat anyone's price.