2003 Toyota Tundra Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

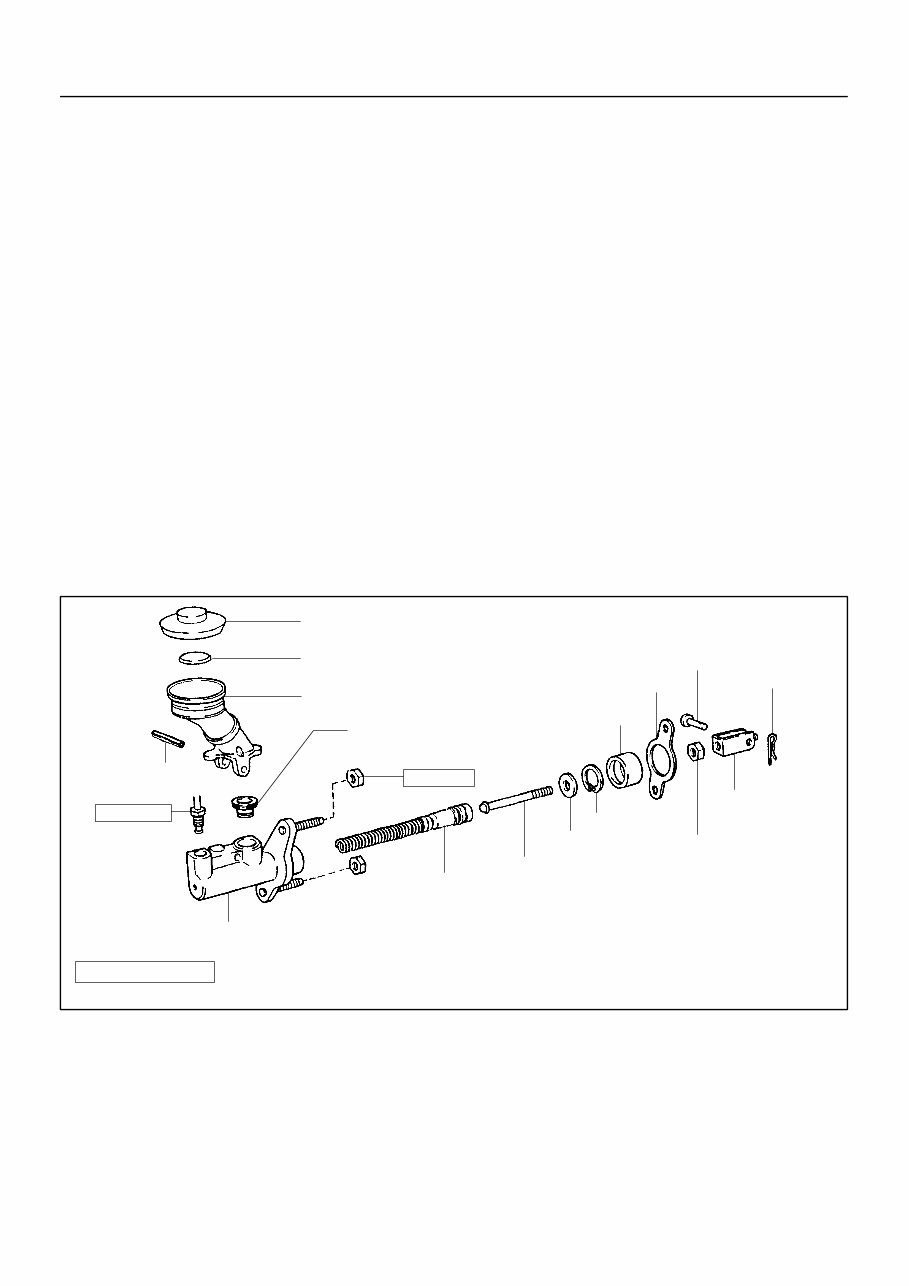

IN00U–36

N17080

Filler Cap

Float

Reservoir

A Grommet

Clip

Slotted Spring Pin

: Specified torque

A Non–reusable part

Cylinder

Piston

Push Rod

Washer

Snap Ring

Boot

A Gasket

Lock Nut

Clevis Pin

Clevis

N·m (kgf·cm, ft·lbf)

12 (120, 9)

15 (155, 11)

– INTRODUCTION HOW TO USE THIS MANUAL

IN–1

1 AuthorĂ: DateĂ:

2003 TOYOTA TUNDRA (RM956U)

HOW TO USE THIS MANUAL

GENERAL INFORMATION

1. INDEX

An INDEX is provided on the first page of each section to guide you to the item to be repaired. To assist you

in finding your way through the manual, the section title and major heading are given at the top of every page.

2. PRECAUTION

At the beginning of each section, a PRECAUTION is given that pertains to all repair operations contained

in that section.

Read these precautions before starting any repair task.

3. TROUBLESHOOTING

TROUBLESHOOTING tables are included for each system to help you diagnose the problem and find the

cause. The fundamentals of how to proceed with troubleshooting are described on page IN–17.

Be sure to read this before performing troubleshooting.

4. PREPARATION

Preparation lists the SST (Special Service Tools), recommended tools, equipment, lubricant and SSM (Spe-

cial Service Materials) which should be prepared before beginning the operation and explains the purpose

of each one.

5. REPAIR PROCEDURES

Most repair operations begin with an overview illustration. It identifies the components and shows how the

parts fit together.

Example:

Illustration:

what to do and where

21. CHECK PISTON STROKE OF OVERDRIVE BRAKE

(a)

Task heading : what to do

SST 09350–30020 (09350–06120)

Set part No. Component part No.

Detailed text : how to do task

(b)

Piston stroke: 1.40 Ċ 1.70 mm (0.0551 Ċ 0.0669 in.)

Specification

Place SST and a dial indicator onto the overdrive brake pis-

ton as shown in the illustration.

Measure the stroke applying and releasing the compressed

air (392 Ċ 785 kPa, 4 Ċ 8 kgf/cm

2

or 57 Ċ 114 psi) as shown

in the illustration.

IN–2

– INTRODUCTION HOW TO USE THIS MANUAL

2 AuthorĂ: DateĂ:

2003 TOYOTA TUNDRA (RM956U)

The procedures are presented in a step–by–step format:

Y The illustration shows what to do and where to do it.

Y The task heading tells what to do.

Y The detailed text tells how to perform the task and gives other information such as specifications

and warnings.

Example:

This format provides the experienced technician with a FAST TRACK to the information needed. The upper

case task heading can be read at a glance when necessary, and the text below it provides detailed informa-

tion. Important specifications and warnings always stand out in bold type.

6. REFERENCES

References have been kept to a minimum. However, when they are required you are given the page to refer

to.

7. SPECIFICATIONS

Specifications are presented in bold type throughout the text where needed. You never have to leave the

procedure to look up your specifications. They are also found in Service Specifications section for quick ref-

erence.

8. CAUTIONS, NOTICES, HINTS:

Y CAUTIONS are presented in bold type, and indicate there is a possibility of injury to you or other

people.

Y NOTICES are also presented in bold type, and indicate the possibility of damage to the components

being repaired.

Y HINTS are separated from the text but do not appear in bold. They provide additional information to

help you perform the repair efficiently.

9. SI UNIT

The UNITS given in this manual are primarily expressed according to the SI UNIT (International System of

Unit), and alternately expressed in the metric system and in the English System.

Example:

Torque: 30 N·m (310 kgf·cm, 22 ft·lbf)

IN01P–04

B02417

A

B

B02418

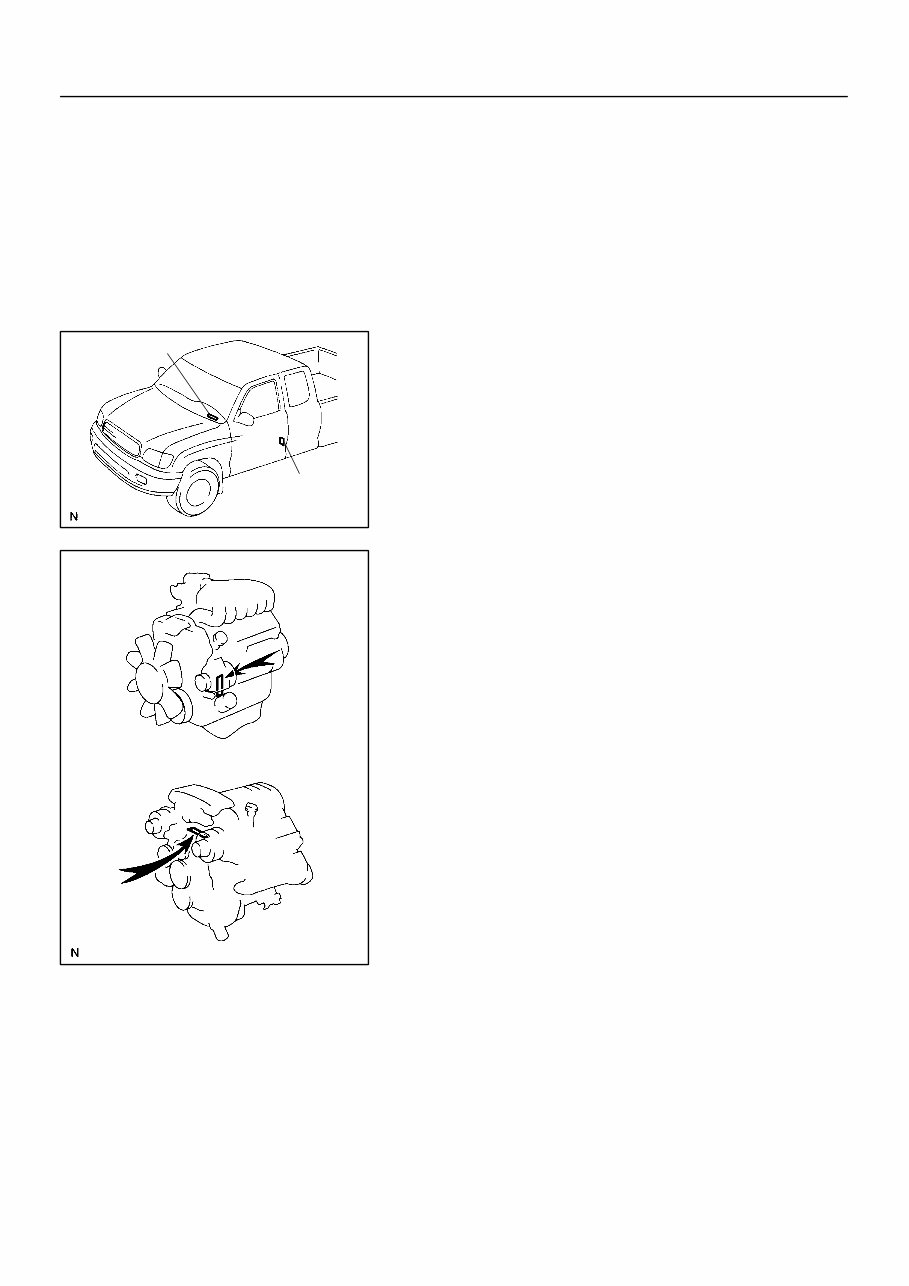

5VZ–FE Engine

2UZ–FE Engine

– INTRODUCTION IDENTIFICATION INFORMATION

IN–3

3 AuthorĂ: DateĂ:

2003 TOYOTA TUNDRA (RM956U)

IDENTIFICATION INFORMATION

VEHICLE IDENTIFICATION AND

ENGINE SERIAL NUMBER

1. VEHICLE IDENTIFICATION NUMBER

The vehicle identification number is stamped on the vehicle

identification number plate and certification label.

A: Vehicle Identification Number Plate

B: Certification Label

2. ENGINE SERIAL NUMBER

The engine serial number is stamped on the engine block, as

shown in the illustration.

IN0CO–12

FI1066

Z11554

Seal Lock Adhesive

IN–4

– INTRODUCTION REPAIR INSTRUCTIONS

4 AuthorĂ: DateĂ:

2003 TOYOTA TUNDRA (RM956U)

REPAIR INSTRUCTIONS

GENERAL INFORMATION

BASIC REPAIR HINT

(a) Use fender, seat and floor covers to keep the vehicle

clean and prevent damage.

(b) During disassembly, keep parts in the appropriate order

to facilitate reassembly.

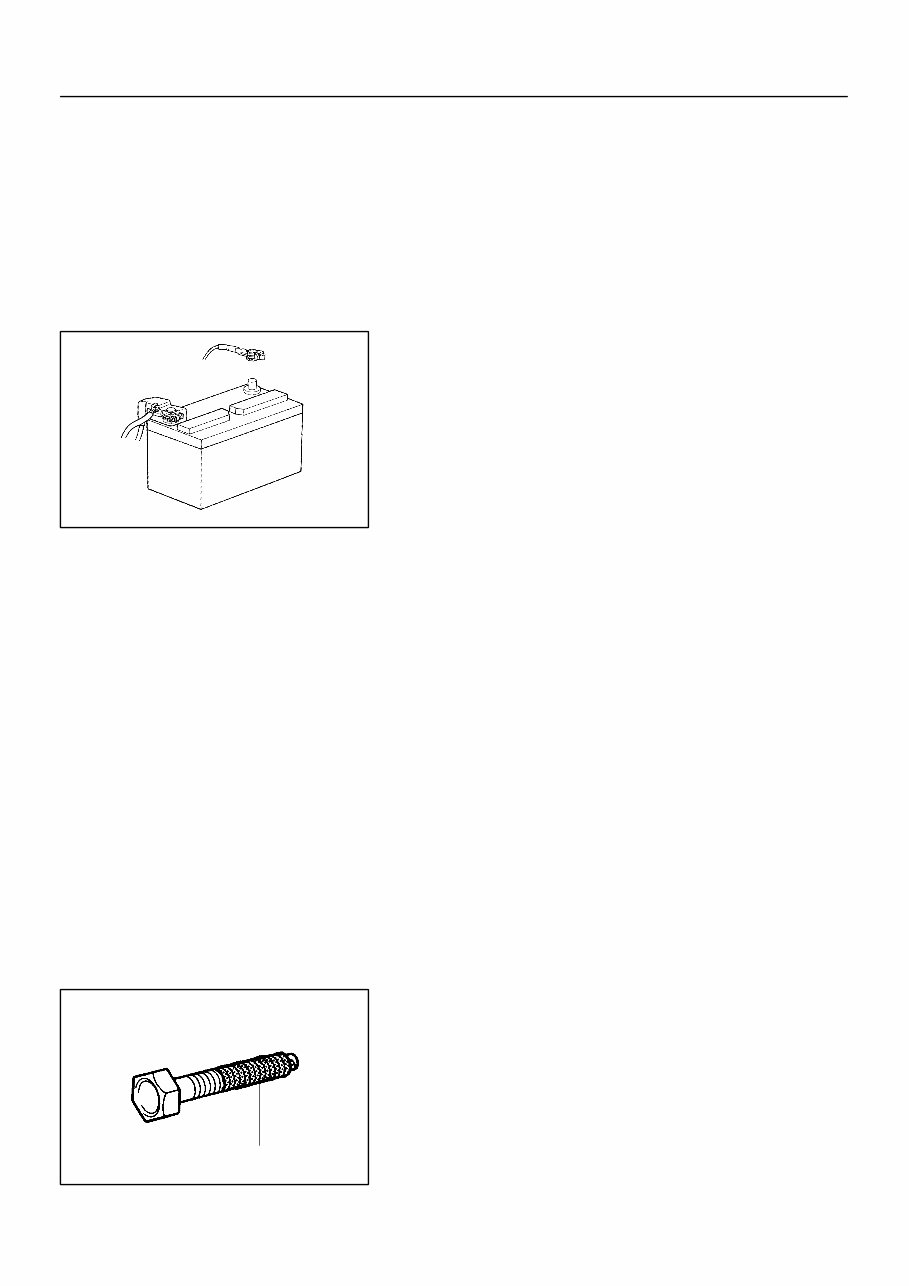

(c) Installation and removal of battery terminal:

(1) Before performing electrical work, disconnect the

negative (–) terminal cable from the battery.

(2) If it is necessary to disconnect the battery for in-

spection or repair, first disconnect the negative (–)

terminal cable.

(3) When disconnecting the terminal cable, to prevent

damage to battery terminal, loosen the cable nut

and raise the cable straight up without twisting or

prying it.

(4) Clean the battery terminals and cable ends with a

clean shop rag. Do not scrape them with a file or oth-

er abrasive objects.

(5) Install the cable ends to the battery terminals after

loosening the nut, and tighten the nut after installa-

tion. Do not use a hammer to tap the cable ends

onto the terminals.

(6) Be sure the cover for the positive (+) terminal is

properly in place.

(d) Check hose and wiring connectors to make sure that they

are connected securely and correctly.

(e) Non–reusable parts

(1) Always replace cotter pins, gaskets, O–rings, oil

seals, etc. with new ones.

(2) Non–reusable parts are indicated in the component

illustrations by the ” ” symbol.

(f) Precoated parts

Precoated parts are bolts, nuts, etc. that are coated with

a seal lock adhesive at the factory.

(1) If a precoated part is retightened, loosened or

caused to move in any way, it must be recoated with

the specified adhesive.

(2) When reusing precoated parts, clean off the old

adhesive and dry with compressed air. Then apply

the specified seal lock adhesive to the bolt, nut or

threads.

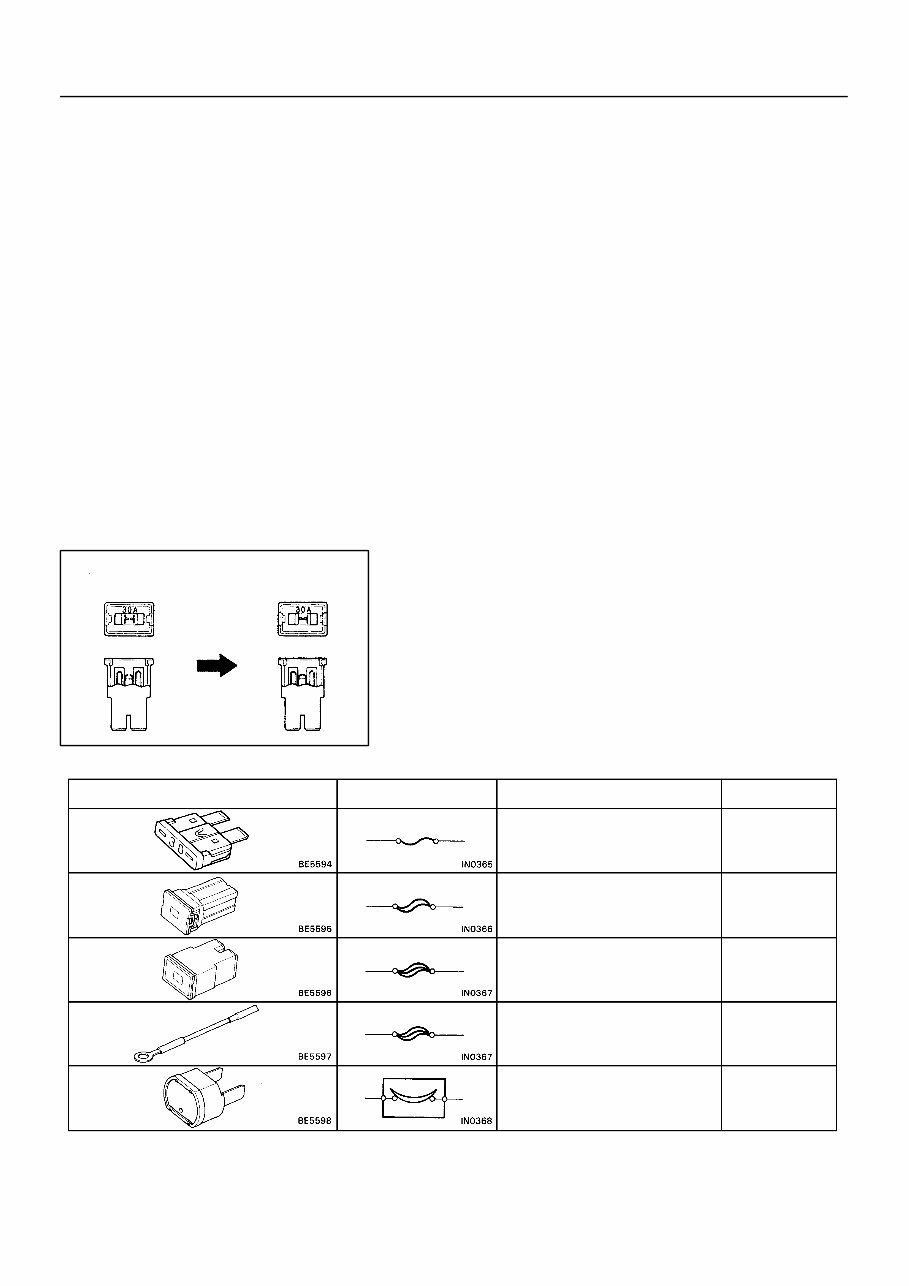

BE1367

Medium Current Fuse and High Current Fuse

Equal Amperage Rating

V00076

Abbreviation Part Name Symbol Illustration

FUSE

MEDIUM CURRENT FUSE

HIGH CURRENT FUSE

FUSIBLE LINK

CIRCUIT BREAKER

FUSE

M–FUSE

H–FUSE

FL

CB

– INTRODUCTION REPAIR INSTRUCTIONS

IN–5

5 AuthorĂ: DateĂ:

2003 TOYOTA TUNDRA (RM956U)

(3) Precoated parts are indicated in the component il-

lustrations by the ”Y” symbol.

(g) When necessary, use a sealer on gaskets to prevent

leaks.

(h) Carefully observe all specifications for bolt tightening

torques. Always use a torque wrench.

(i) Use of special service tools (SST) and special service ma-

terials (SSM) may be required, depending on the nature

of the repair. Be sure to use SST and SSM where speci-

fied and follow the proper work procedure. A list of SST

and SSM can be found in Preparation section in this

manual.

(j) When replacing fuses, be sure the new fuse has the cor-

rect amperage rating. DO NOT exceed the rating or use

one with a lower rating.

IN0253

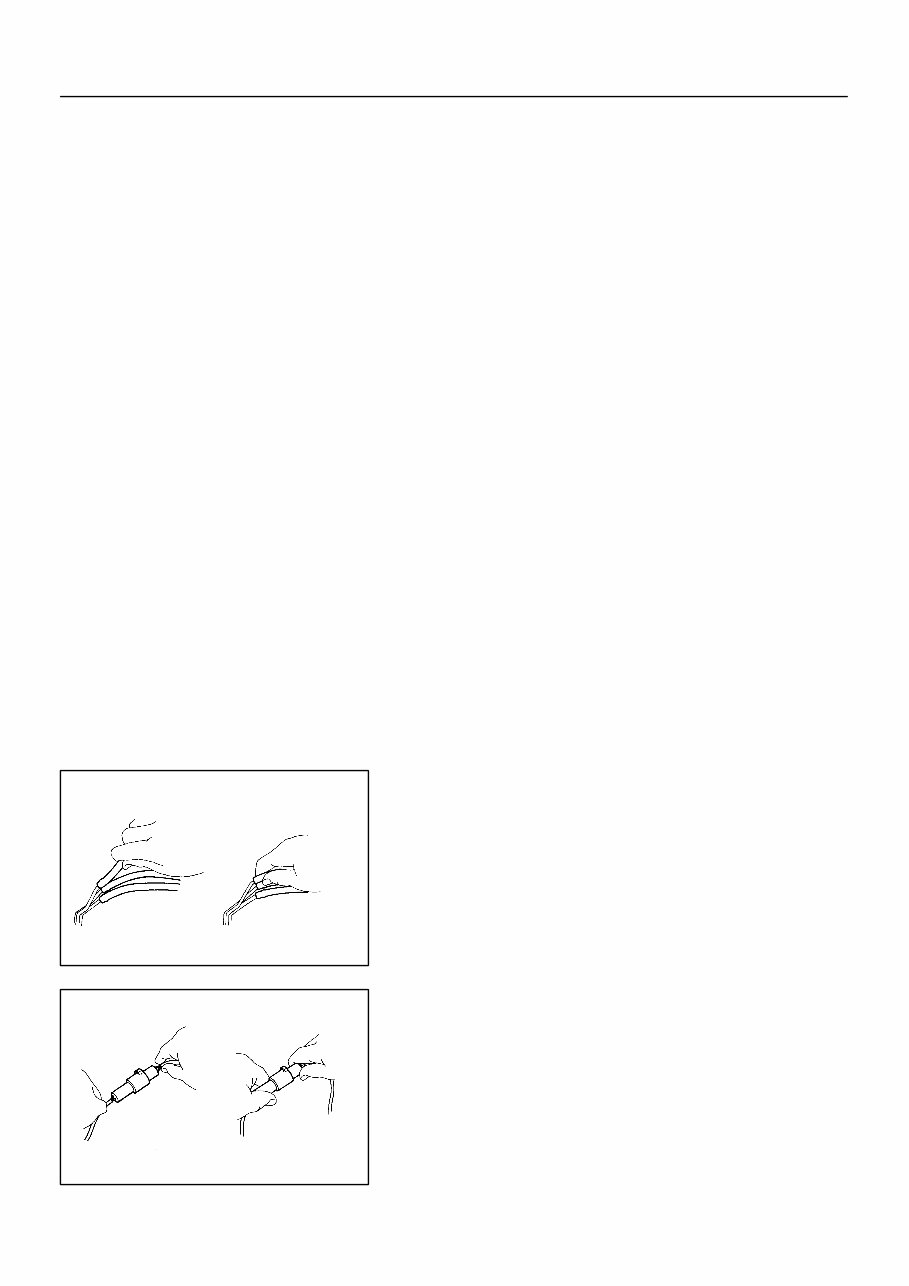

WRONG CORRECT

IN0252

WRONG CORRECT

IN–6

– INTRODUCTION REPAIR INSTRUCTIONS

6 AuthorĂ: DateĂ:

2003 TOYOTA TUNDRA (RM956U)

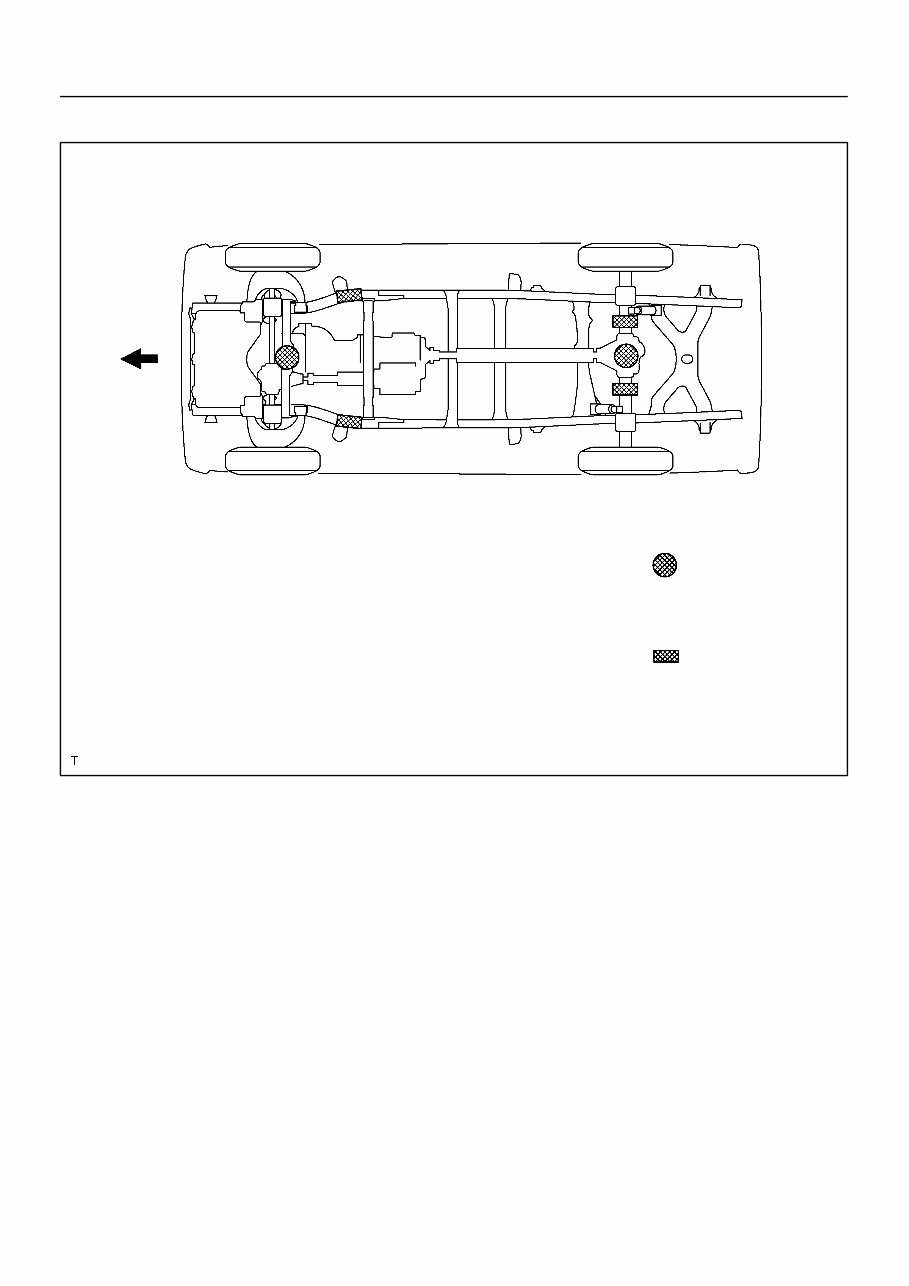

(k) Care must be taken when jacking up and supporting the

vehicle. Be sure to lift and support the vehicle at the prop-

er locations (See page IN–8).

A Cancel the parking brake on the level place and

shift the transmission in Neutral (or N position).

A When jacking up the front wheels of the vehicle at

first place stoppers behind the rear wheels.

A When jacking up the rear wheels of the vehicle at

first place stoppers before the front wheels.

A When either the front or rear wheels only should be

jacked up, set rigid racks and place stoppers in front

and behind the other wheels on the ground.

A After the vehicle is jacked up, be sure to support it

on rigid racks . It is extremely dangerous to do any

work on a vehicle raised on a jack alone, even for

a small job that can be finished quickly.

(l) Observe the following precautions to avoid damage to the

following parts:

(1) Do not open the cover or case of the ECU unless

absolutely necessary. (If the IC terminals are

touched, the IC may be destroyed by static electric-

ity.)

(2) To disconnect vacuum hoses, pull off the end, not

the middle of the hose.

(3) To pull apart electrical connectors, pull on the con-

nector itself, not the wires.

(4) Be careful not to drop electrical components, such

as sensors or relays. If they are dropped on a hard

floor, they should be replaced and not reused.

(5) When steam cleaning an engine, protect the elec-

tronic components, air filter and emission–related

components from water.

(6) Never use an impact wrench to remove or install

temperature switches or temperature sensors.

IN0002

Example

– INTRODUCTION REPAIR INSTRUCTIONS

IN–7

7 AuthorĂ: DateĂ:

2003 TOYOTA TUNDRA (RM956U)

(7) When checking continuity at the wire connector, in-

sert the tester probe carefully to prevent terminals

from bending.

(8) When using a vacuum gauge, never force the hose

onto a connector that is too large. Use a step–down

adapter for adjustment. Once the hose has been

stretched, it may leak air.

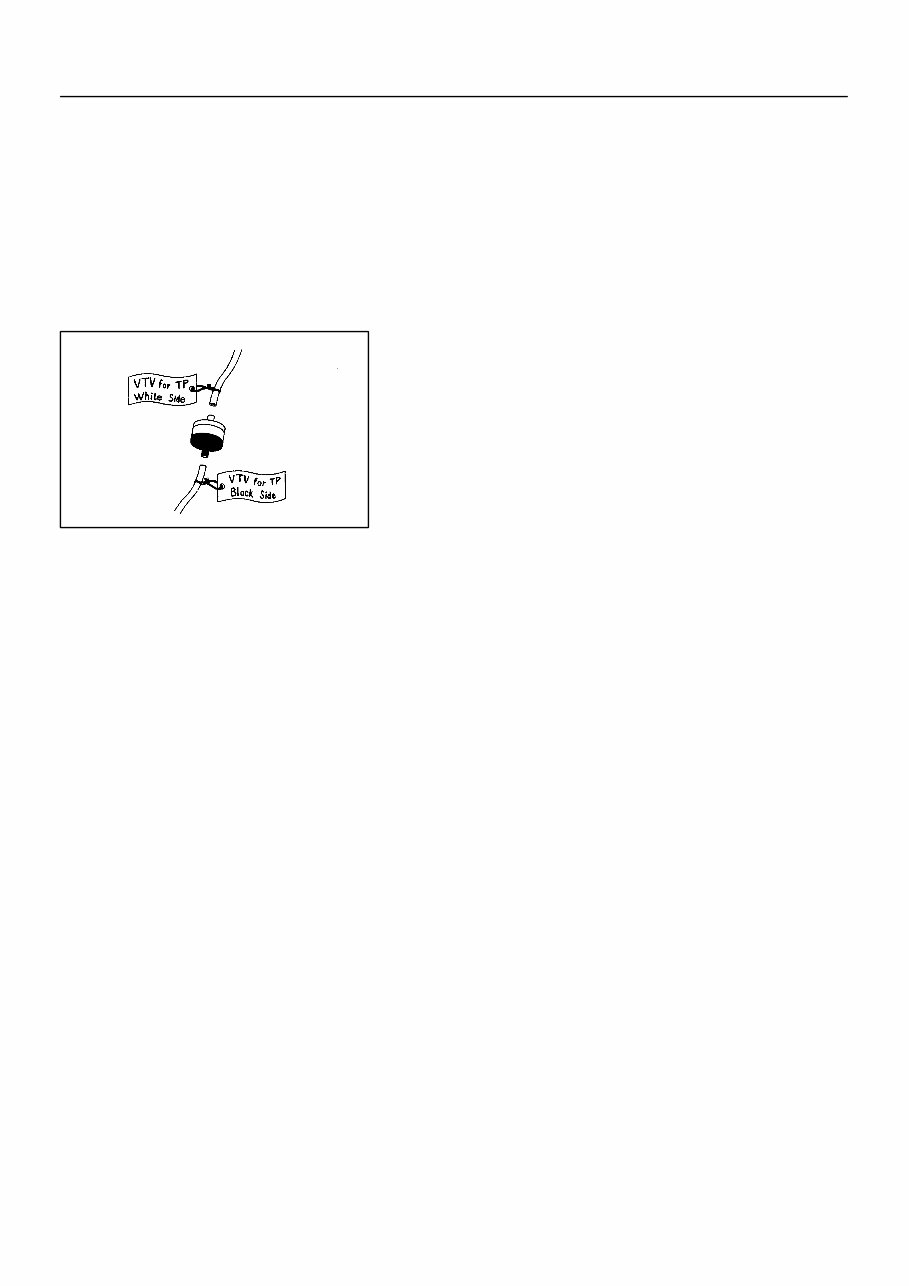

(m) Installation and removal of vacuum hose:

(1) When disconnecting vacuum hoses, use tags to

identify how they should be reconnected to.

(2) After completing a job, double check that the vacu-

um hoses are properly connected. A label under the

hood shows the proper layout.

(n) Unless otherwise stated, all resistance is measured at an

ambient temperature of 20°C (68°F). Because the resis-

tance may be outside specifications if measured at high

temperatures immediately after the vehicle has been run-

ning, measurement should be made when the engine has

cooled down.

IN0DY–01

B07972

JACK POSITION A A A A A A A A A A A A A A A A A A

Front A A A A A A A A A Center of crossmember

Rear A A A A A A A A A Center of rear axle housing

SUPPORT POSITION

Safety stand A A A A A A A A A A A A A A A A

Front

IN–8

– INTRODUCTION REPAIR INSTRUCTIONS

8 AuthorĂ: DateĂ:

2003 TOYOTA TUNDRA (RM956U)

VEHICLE LIFT AND SUPPORT LOCATIONS

IN0DB–04

BO4111

Negative Cable

– INTRODUCTION FOR ALL OF VEHICLES

IN–9

9 AuthorĂ: DateĂ:

2003 TOYOTA TUNDRA (RM956U)

FOR ALL OF VEHICLES

PRECAUTION

1. FOR VEHICLES EQUIPPED WITH SRS AIRBAG AND

SEAT BELT PRETENSIONER

(a) The TOYOTA TUNDRA is equipped with an SRS (Sup-

plemental Restraint System), such as the driver airbag,

front passenger airbag assembly and seat belt preten-

sioner.

Failure to carry out service operations in the correct se-

quence could cause the supplemental restraint system to

unexpectedly deploy during servicing, possibly leading to

a serious accident.

Further, if a mistake is made in servicing the supplemental

restraint system, it is possible the SRS may fail to operate

when required. Before servicing (including removal or

installation of parts, inspection or replacement), be sure

to read the following items carefully, then follow the cor-

rect procedure described in this manual.

(b) GENERAL NOTICE

(1) Malfunction symptoms of the supplemental re-

straint system are difficult to confirm, so the diag-

nostic trouble codes become the most important

source of information when troubleshooting. When

troubleshooting the supplemental restraint system,

always inspect the diagnostic trouble codes before

disconnecting the battery (See page DI–490).

(2) Work must be started after 90 seconds from the

time the ignition switch is turned to the ”LOCK” posi-

tion and the negative (–) terminal cable is discon-

nected from the battery.

(The supplemental restraint system is equipped

with a back–up power source so that if work is

started within 90 seconds of disconnecting the neg-

ative (–) terminal cable from the battery, the SRS

may deploy.)

When the negative (–) terminal cable is discon-

nected from the battery, memory of the clock and

audio systems will be cancelled. So before starting

work, make a record of the contents memorized by

the each memory system. Then when work is fin-

ished, reset the clock and audio systems as before.

To avoid erasing the memory of each memory sys-

tem, never use a back–up power supply from anoth-

er battery.

F04784

Mark

IN–10

– INTRODUCTION FOR ALL OF VEHICLES

10 AuthorĂ: DateĂ:

2003 TOYOTA TUNDRA (RM956U)

(3) Even in cases of a minor collision where the SRS

does not deploy, the steering wheel pad (See page

RS–12), front passenger airbag assembly (See

page RS–26) and seat belt pretensioner (See page

BO–140 ) should be inspected.

(4) Never use SRS parts from another vehicle. When

replacing parts, replace them with new parts.

(5) Before repairs, remove the airbag sensor if shocks

are likely to be applied to the sensor during repairs.

(6) Never disassemble and repair the airbag sensor as-

sembly, steering wheel pad, front passenger airbag

assembly or seat belt pretensioner.

(7) If the airbag sensor assembly, steering wheel pad,

front passenger airbag assembly or seat belt pre-

tensioner has been dropped, or if there are cracks,

dents or other defects in the case, bracket or con-

nector, replace them with new ones.

(8) Do not directly expose the airbag sensor assembly,

steering wheel pad, front passenger airbag assem-

bly or seat belt pretensioner to hot air or flames.

(9) Use a volt/ohmmeter with high impedance (10 kΩ/V

minimum) for troubleshooting of the electrical cir-

cuit.

(10) Information labels are attached to the periphery of

the SRS components. Follow the instructions on the

notices.

(11) After work on the supplemental restraint system is

completed, check the SRS warning light (See page

DI–490).

(c) SPIRAL CABLE (in Combination Switch)

The steering wheel must be fitted correctly to the steering

column with the spiral cable at the neutral position, other-

wise cable disconnection and other troubles may result.

Refer to SR–28 concerning correct steering wheel instal-

lation.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$36.99

Viewed 39 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$36.99

The 2003 Toyota Tundra Service & Repair Manual is a comprehensive guide designed to assist in maintaining and repairing your 2003 Toyota Tundra. Whether you're a professional mechanic or a DIY enthusiast, this manual is an invaluable resource for keeping your Tundra in optimal condition.

Key Features:

- Complete coverage for all 2003 Toyota Tundra models

- Detailed step-by-step instructions for all repair and maintenance procedures

- Illustrated diagrams and photographs to aid in understanding complex tasks

- Troubleshooting tips and common problems diagnosis

- Comprehensive wiring diagrams for electrical systems

- Specifications and technical data for engine, transmission, and other components

Models covered:

- 2003 Toyota Tundra SR5

- 2003 Toyota Tundra Limited

- 2003 Toyota Tundra V6

- 2003 Toyota Tundra V8

- 2003 Toyota Tundra Access Cab

- 2003 Toyota Tundra Regular Cab

- 2003 Toyota Tundra Double Cab

Invest in the 2003 Toyota Tundra Service & Repair Manual today and take control of your vehicle's maintenance. With this manual by your side, you can confidently tackle any repairs or maintenance tasks, saving time and money in the long run. Keep your Toyota Tundra in peak condition with the help of this essential manual!