MITSUBISHI

Outlander

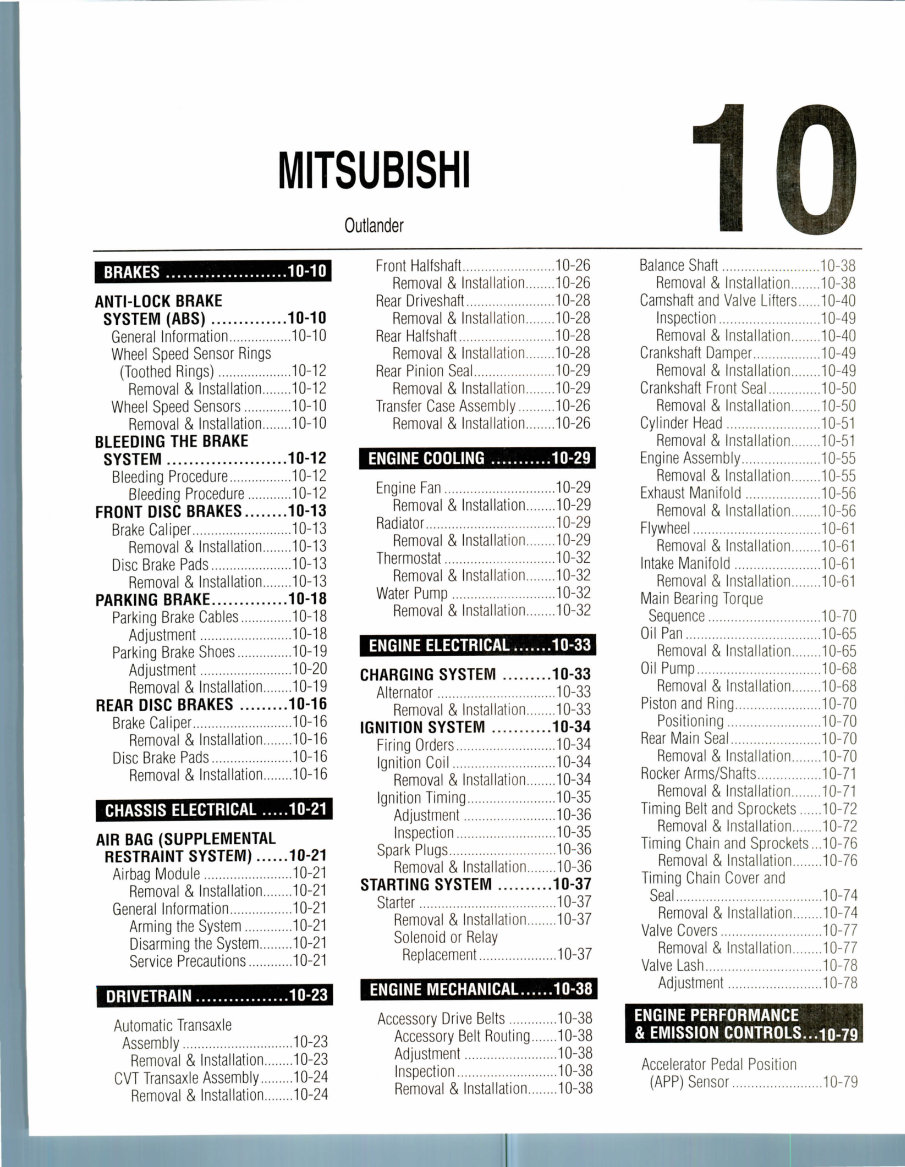

BRAKES 10-10

ANTI-LOCK BRAKE

SYSTEM (ABS) 10-10

General Information 10-10

Wheel Speed Sensor Rings

(Toothed Rings) 10-12

Removal & Installation 10-12

Wheel Speed Sensors 10-10

Removal & Installation 10-10

BLEEDING THE BRAKE

SYSTEM 10-12

Bleeding Procedure 10-12

Bleeding Procedure 10-12

FRONT DISC BRAKES 10-13

Brake Caliper 10-13

Removal & Installation 10-13

Disc Brake Pads 10-13

Removal & Installation 10-13

PARKING BRAKE 10-18

Parking Brake Cables 10-18

Adjustment 10-18

Parking Brake Shoes 10-19

Adjustment 10-20

Removal & Installation 10-19

REAR DISC BRAKES 10-16

Brake Caliper 10-16

Removal & Installation 10-16

Disc Brake Pads 10-16

Removal & Installation 10-16

CHASSIS ELECTRICAL 10-21

AIR BAG (SUPPLEMENTAL

RESTRAINT SYSTEM) 10-21

Airbag Module 10-21

Removal & Installation 10-21

General Information 10-21

Arming the System 10-21

Disarming the System 10-21

Service Precautions 10-21

DRIVETRAIN .10-23

Automatic Transaxle

Assembly 10-23

Removal & Installation 10-23

CVT Transaxle Assembly 10-24

Removal & Installation 10-24

Front Halfshaft 10-26

Removal & Installation 10-26

Rear Driveshaft 10-28

Removal & Installation 10-28

Rear Halfshaft 10-28

Removal & Installation 10-28

Rear Pinion Seal 10-29

Removal & Installation 10-29

Transfer Case Assembly 10-26

Removal & Installation 10-26

ENGINE COOLING 10-29

Engine Fan 10-29

Removal & Installation 10-29

Radiator 10-29

Removal & Installation 10-29

Thermostat 10-32

Removal & Installation 10-32

Water Pump 10-32

Removal & Installation 10-32

ENGINE ELECTRICAL 10-33

CHARGING SYSTEM 10-33

Alternator 10-33

Removal & Installation 10-33

IGNITION SYSTEM 10-34

Firing Orders 10-34

Ignition Coil 10-34

Removal & Installation 10-34

Ignition Timing 10-35

Adjustment 10-36

Inspection 10-35

SparkPlugs 10-36

Removal & Installation 10-36

STARTING SYSTEM 10-37

Starter 10-37

Removal & Installation 10-37

Solenoid or Relay

Replacement 10-37

ENGINE MECHANICAL 10-38

Accessory Drive Belts 10-38

Accessory Belt Routing 10-38

Adjustment 10-38

Inspection 10-38

Removal & Installation 10-38

Balance Shaft 10-38

Removal & Installation 10-38

Camshaft and Valve Lifters 10-40

Inspection 10-49

Removal & Installation 10-40

Crankshaft Damper 10-49

Removal & Installation 10-49

Crankshaft Front Seal 10-50

Removal & Installation 10-50

Cylinder Head 10-51

Removal & Installation 10-51

Engine Assembly 10-55

Removal & Installation 10-55

Exhaust Manifold 10-56

Removal & Installation 10-56

Flywheel 10-61

Removal & Installation 10-61

Intake Manifold 10-61

Removal & Installation 10-61

Main Bearing Torque

Sequence 10-70

Oil Pan 10-65

Removal & Installation 10-65

Oil Pump 10-68

Removal & Installation 10-68

Piston and Ring 10-70

Positioning 10-70

Rear Main Seal 10-70

Removal & Installation 10-70

Rocker Arms/Shafts 10-71

Removal & Installation 10-71

Timing Belt and Sprockets 10-72

Removal & Installation 10-72

Timing Chain and Sprockets...10-76

Removal & Installation 10-76

Timing Chain Cover and

Seal 10-74

Removal & Installation 10-74

Valve Covers 10-77

Removal & Installation 10-77

Valve Lash 10-78

Adjustment 10-78

ENGINE PERFORMANCE

& EMISSION CONTROLS...10-79

Accelerator Pedal Position

(APP) Sensor 10-79

If) O MITSUBISHI

OUTLANDER

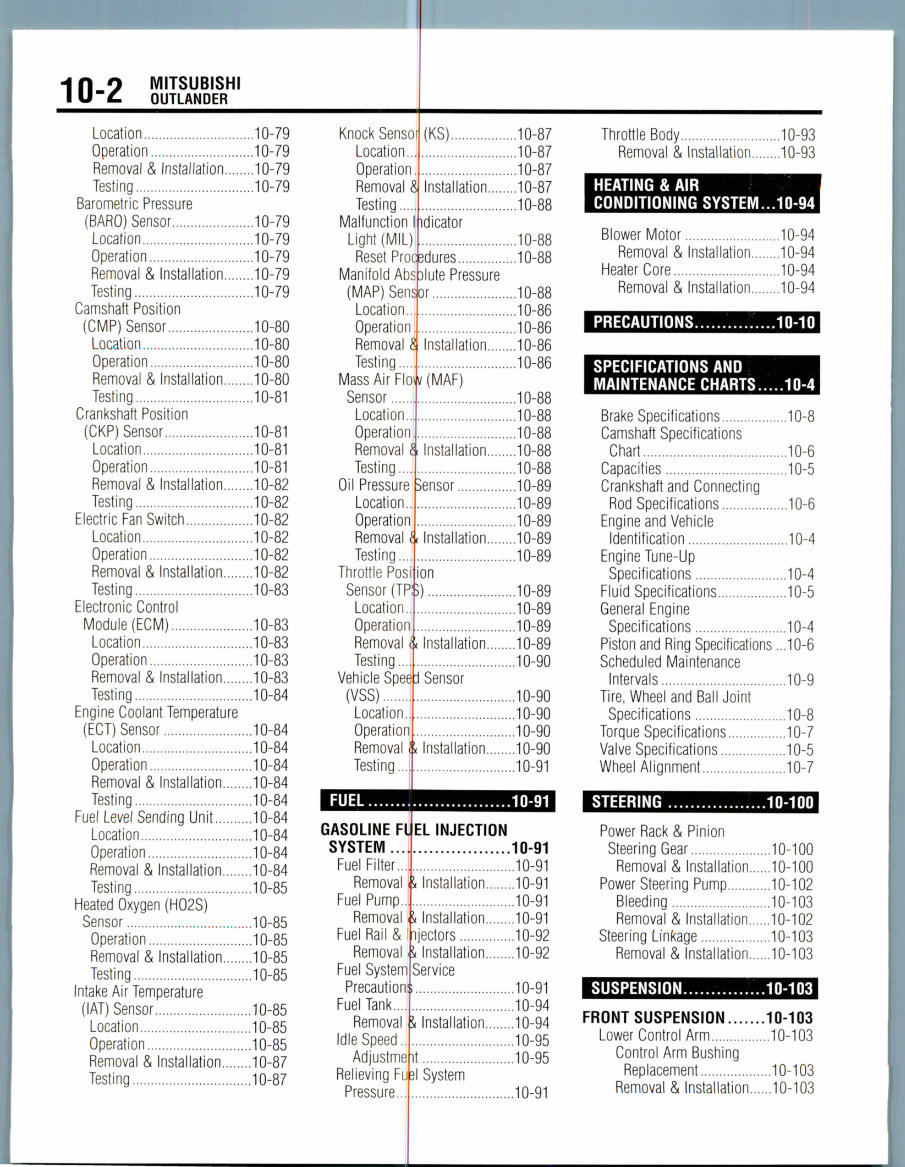

Location 10-79

Operation 10-79

Removal & Installation 10-79

Testing 10-79

Barometric Pressure

(BARO)Sensor 10-79

Location 10-79

Operation 10-79

Removals. Installation 10-79

Testing 10-79

Camshaft Position

(CMP) Sensor 10-80

Location 10-80

Operation 10-80

Removal & Installation 10-80

Testing 10-81

Crankshaft Position

(CKP) Sensor 10-81

Location 10-81

Operation 10-81

Removal & Installation 10-82

Testing 10-82

Electric Fan Switch 10-82

Location 10-82

Operation 10-82

Removal & Installation 10-82

Testing 10-83

Electronic Control

Module (ECM) 10-83

Location 10-83

Operation 10-83

Removal & Installation 10-83

Testing 10-84

Engine Coolant Temperature

(ECT) Sensor 10-84

Location 10-84

Operation 10-84

Removal & Installation 10-84

Testing 10-84

Fuel Level Sending Unit 10-84

Location 10-84

Operation 10-84

Removal & Installation 10-84

Testing 10-85

Heated Oxygen (H02S)

Sensor 10-85

Operation 10-85

Removal & Installation 10-85

Testing 10-85

Intake Air Temperature

(IAT) Sensor 10-85

Location 10-85

Operation 10-85

Removal & Installation 10-87

Testing 10-87

Knock Senso

Location..

Operation

Removal 8

Testing ....

Malfunction

Light (MIL)

Reset Proc

Manifold Abs

(MAP) Sens

Location..

Operation

Removal I

Testing ....

Mass Air Flo

Sensor

Location..

Operation

Removal I

Testing ....

Oil Pressure

Location..

Operation

Removal I

Testing ....

Throttle Posi

Sensor(TP

Location..

Operation

Removal i

Testing ....

Vehicle Spee

(VSS)

Location.,

Operation

Removal I

Testing ....

(KS).

Installation.

..10-

..10-

..10-

..10-

..10-

87

87

87

87

Throttle Body 10-93

Removal & Installation 10-93

HEATING & AIR

CONDITIONING SYSTEM... 10-94

idicator

.10-

.10- edures

)lute Pressure

or 10-

10-

10-

Installation 10-

10-

(MAF)

10-

10-

10-

Installation 10-

10-

:!ensor 10-

10-

10-

Installation 10-

10-

on

) 10-

10-

10-

Installation 10-

10-

Sensor

10-

10-

10-

Installation 10-

...10-

Blower Motor 10-94

Removal & Installation 10-94

Heater Core 10-94

Removal & Installation 10-94

PRECAUTIONS 10-10

SPECIFICATIONS AND

MAINTENANCE CHARTS 10-4

-90

-90

90

-90

91

Brake Specifications 10-8

Camshaft Specifications

Chart 10-6

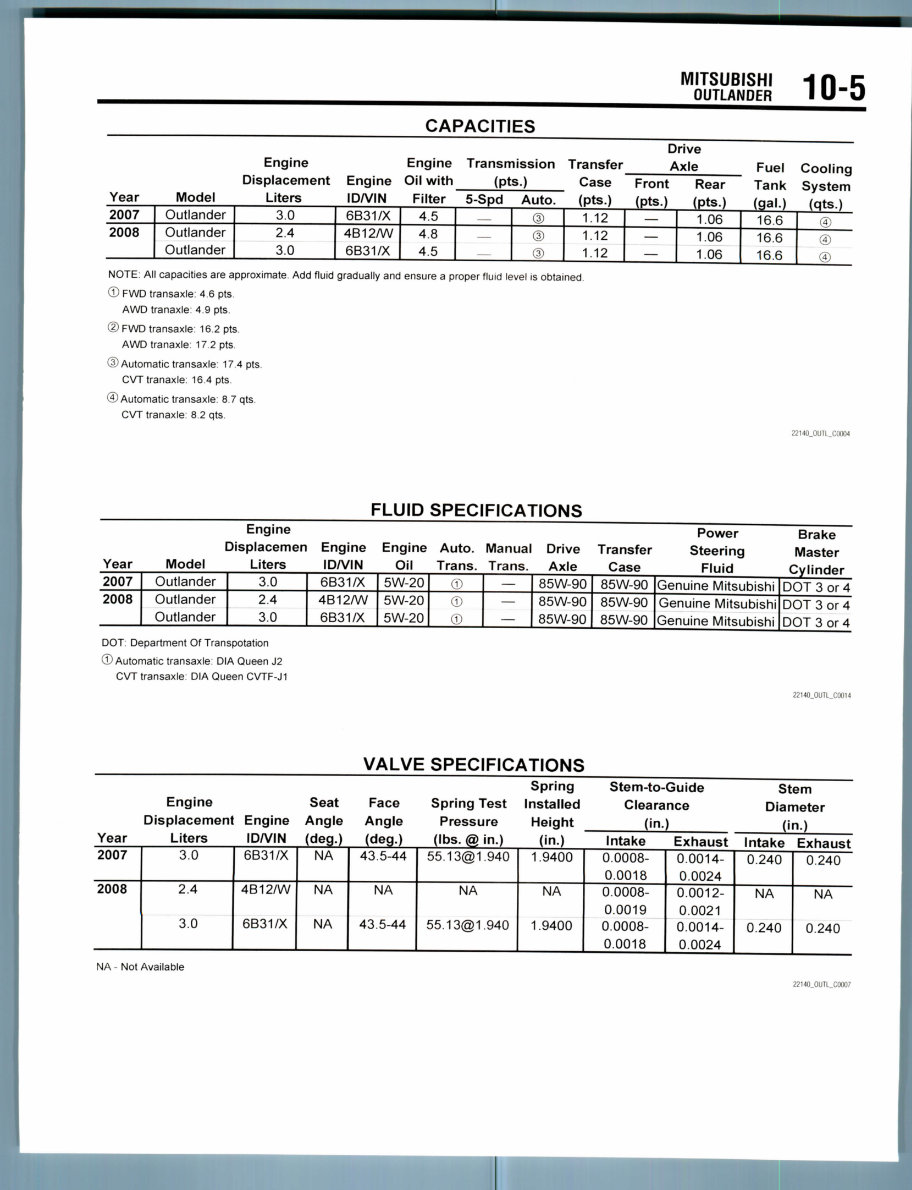

Capacities 10-5

Crankshaft and Connecting

Rod Specifications 10-6

Engine and Vehicle

Identification 10-4

Engine Tune-Up

Specifications 10-4

Fluid Specifications 10-5

General Engine

Specifications 10-4

Piston and Ring Specifications ...10-6

Scheduled Maintenance

Intervals 10-9

Tire, Wheel and Ball Joint

Specifications 10-8

Torque Specifications 10-7

Valve Specifications 10-5

Wheel Alignment 10-7

FUEL 10-91 II STEERING 10-100

GASOLINE FL EL INJECTION

SYSTEM...

Fuel Filter..

Removal

Fuel Pump.

Removal ^ Installation 10-91

Fuel Rail &

Fuel System

10-91

10-91

Installation 10-91

...10-91

njectors 10-92

Removal ^Installation 10-92

Service

Precaution^ 10-91

Fuel Tank...

Removal

Idle Speed

10-94

Installation 10-94

...10-95

Adjustmeit 10-95

Relieving Fu

Pressure

System

.10-91

Power Rack & Pinion

Steering Gear 10-100

Removal & Installation 10-100

Power Steering Pump 10-102

Bleeding 10-103

Removal & Installation 10-102

Steering Linkage 10-103

Removal & Installation 10-103

SUSPENSION.. 10-103

FRONT SUSPENSION 10-103

Lower Control Arm 10-103

Control Arm Bushing

Replacement 10-103

Removal & Installation 10-103

MITSUBISHI

OUTLANDER

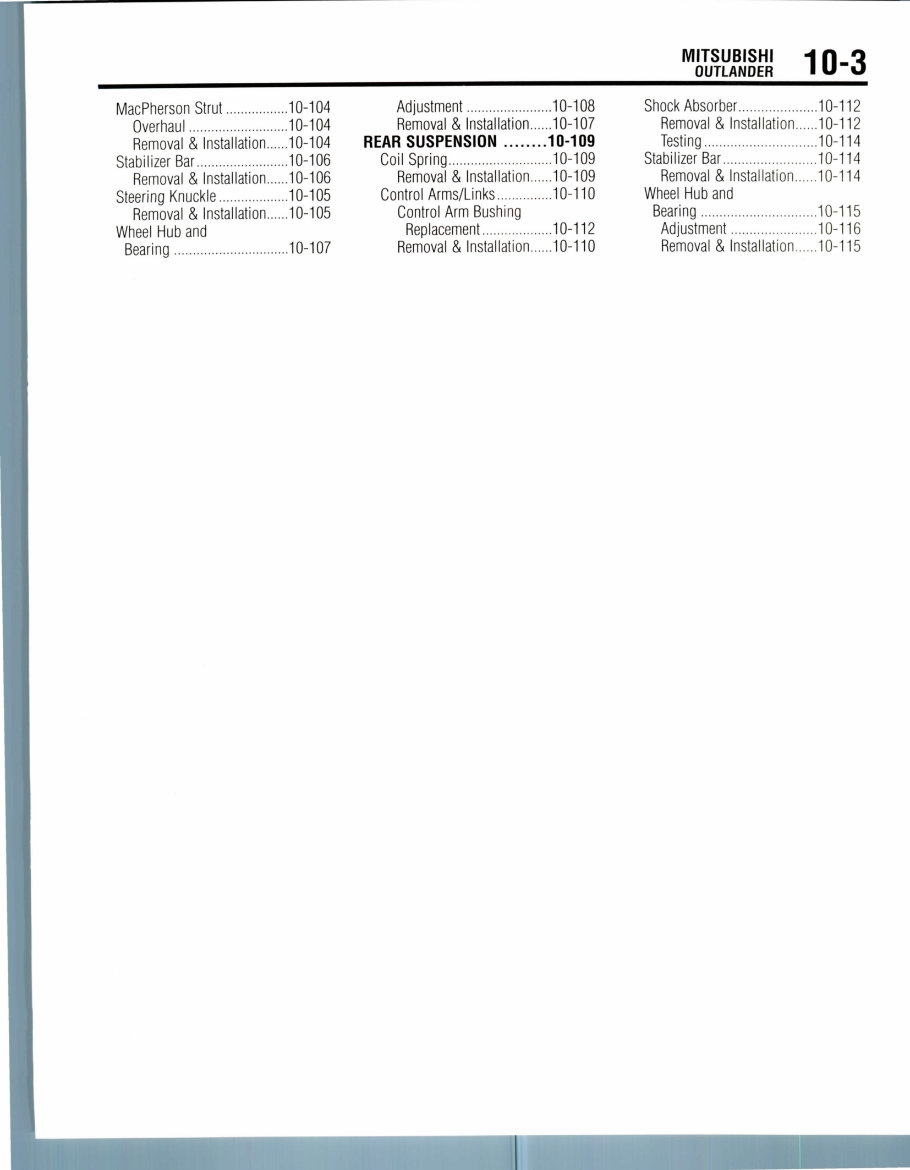

MacPherson Strut 10-104

Overhaul 10-104

Removal & Installation 10-104

Stabilizer Bar 10-106

Removal & Installation 10-106

Steering Knuckle 10-105

Removal & Installation 10-105

Wheel Hub and

Bearing 10-107

Adjustment 10-108

Removal & Installation 10-107

REAR SUSPENSION 10-109

Coil Spring 10-109

Removal & Installation 10-109

Control Arms/Links 10-110

Control Arm Bushing

Replacement 10-112

Removal & Installation 10-110

Shock Absorber 10-112

Removal & Installation 10-112

Testing 10-114

Stabilizer Bar 10-114

Removal & Installation 10-114

Wheel Hub and

Bearing 10-115

Adjustment 10-116

Removal & Installation 10-115

in.4 MITSUBISHI

OUTLANDER

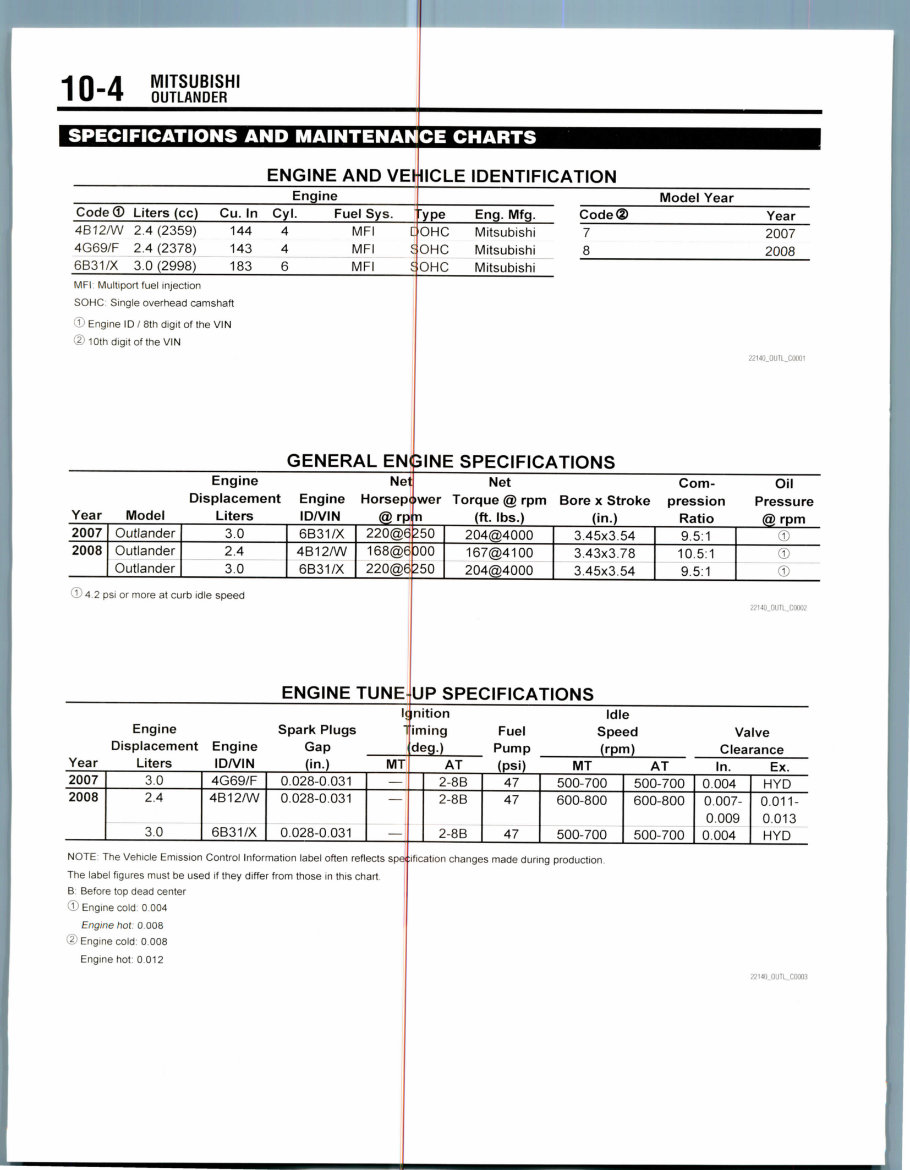

SPECIFICATIONS AND MAINTENANCE CHARTS

ENGINE AND VEHICLE IDENTIFICATION

Engine

Code®

4B12/W

4G69/F

6B31/X

Liters (cc)

2.4 (2359)

2.4 (2378)

3.0 (2998)

Cu. In

144

143

183

Cyl. Fuel Sys.

4

4

6

MFI

MFI

MFI

Model Year

•ype

OHC

OHC

OHC

Eng. Mfg.

Mitsubishi

Mitsubishi

Mitsubishi

Code®

7

8

Year

2007

2008

MFI Multiport fuel injection

SOHC: Single overhead camshaft

© Engine ID / 8th digit of the VIN

© 10th digit of the VIN

GENERAL EN 5INE SPECIFICATIONS

Engine Ne

Displacement Engine Horsep

Year Model Liters ID/VIN @r

2007

2008

Outlander

Outlander

Outlander

3.0

2.4

3.0

6B31/X

4B12/W

6B31/X

220@

168@

220@

Net Com- Oil

»wer Torque @ rpm Bore x Stroke pression Pressure

n (ft. Ibs.) (in.) Ratio @ rpm

150

DOO

250

204@4000

167@4100

204@4000

3.45x3.54

3.43x3.78

3.45x3.54

9.5:1

10.5:1

9.5:1

X

®

©

22140_OUTL_C0001

© 4.2 psi or more at curb idle speed

ENGINE TUNE UP SPECIFICATIONS

Engine Spark Plugs

Displacement Engine Gap

Year Liters IDA/IN (in.)

2007

2008

3.0

2.4

3.0

4G69/F

4B12/W

6B31/X

0.028-0.031

0.028-0.031

0.028-0.031

MT

nition

iming

deg.)

AT

2-8B

2-8B

2-8B

Fuel

Pump

(psi)

47

47

47

Idle

Speed Valve

(rpm) Clearance

MT AT In. Ex.

500-700

600-800

500-700

500-700

600-800

500-700

0.004

0.007-

0.009

0.004

HYD

0.011-

0.013

HYD

NOTE: The Vehicle Emission Control Information label often reflects sp>

The label figures must be used if they differ from those in this chart

B: Before top dead center

© Engine cold: 0 004

Engine hot: 0.008

C2) Engine cold: 0 008

Engine hot: 0.012

22140_OUTL_C0003

MITSUBISHI

OUTLANDER 10-5

CAPACITIES

Engine Engine

Displacement Engine Oil with

Year Model Liters ID/VIN Filter

2007

2008

Outlander

Outlander

Outlander

3.0

2.4

3.0

6B31/X

4B12/W

6B31/X

4.5

4.8

4.5

Transmission

(Pts.)

5-Spd Auto.

—

©

©

©

Transfer

Case

(Pts.)

1.12

1.12

1.12

Drive

Axle

Front Rear

(pts.) (pts.)

—

1.06

1.06

1.06

Fuel Cooling

Tank System

(gal.) (qts.)

16.6

16.6

16.6

®

®

®

NOTE: All capacities are approximate Add fluid gradually and ensure a proper fluid level is obtained.

© FWD transaxle: 46 pts

AWD tranaxle: 4.9 pts.

© FWD transaxle: 16.2 pts.

AWD tranaxle: 17 2 pts.

©Automatictransaxle: 17.4 pts.

CVT tranaxle: 16.4 pts

©Automatic transaxle: 8.7 qts.

CVT tranaxle: 82 qts.

22140_OUTL_C0004

FLUID SPECIFICATIONS

Engine Power Brake

Displacemen Engine Engine Auto. Manual Drive Transfer Steering Master

Year Model Liters IDA/IN Oil Trans. Trans. Axle Case Fluid Cylinder

2007

2008

Outlander

Outlander

Outlander

3.0

2.4

3.0

6B31/X

4B12/W

6B31/X

5W-20

5W-20

5W-20

©

©

©

—

85W-90

85W-90

85W-90

85W-90

85W-90

85W-90

Genuine Mitsubishi

Genuine Mitsubishi

Genuine Mitsubishi

DOT 3 or 4

DOT 3 or 4

DOT 3 or 4

DOT: Department Of Transpotation

©Automatic transaxle: DIA Queen J2

CVT transaxle: DIA Queen CVTF-J1

22140_OUTL_C0014

VALVE SPECIFICATIONS

Spring

Engine Seat Face Spring Test Installed

Displacement Engine Angle Angle Pressure Height

Year Liters ID/VIN (deg.) (deg.) (Ibs. @ in.) (in.)

2007

2008

3.0

2.4

3.0

6B31/X

4B12/W

6B31/X

NA

NA

NA

43.5-44

NA

43.5-44

55.1 3@1. 940

NA

55.1 3@1. 940

1.9400

NA

1.9400

Stem-to-Guide Stem

Clearance Diameter

(in.) (in.)

Intake Exhaust Intake Exhaust

0.0008-

0.0018

0.0008-

0.0019

0.0008-

0.0018

0.0014-

0.0024

0.0012-

0.0021

0.0014-

0.0024

0.240

NA

0.240

0.240

NA

0.240

NA - Not Available

22140_OUTl_C0007

You're Reading a Preview

What's Included?

Lifetime Access

Access Contents & Bookmarks

Print one or all pages of your manual

Add to Cart

$36.99

$48.99