AR01.30-P-7162T Check/face-grind cylinder head contact surfaces 27.9.12

ENGINE 651 in MODEL 204, 212

ENGINE 648.961 in MODEL 211.023/026/223/226

ENGINE 646.961 in MODEL 211.006/206/606

ENGINE 647.961 in MODEL 211.016/216/616

ENGINE 646.951 in MODEL 211.004

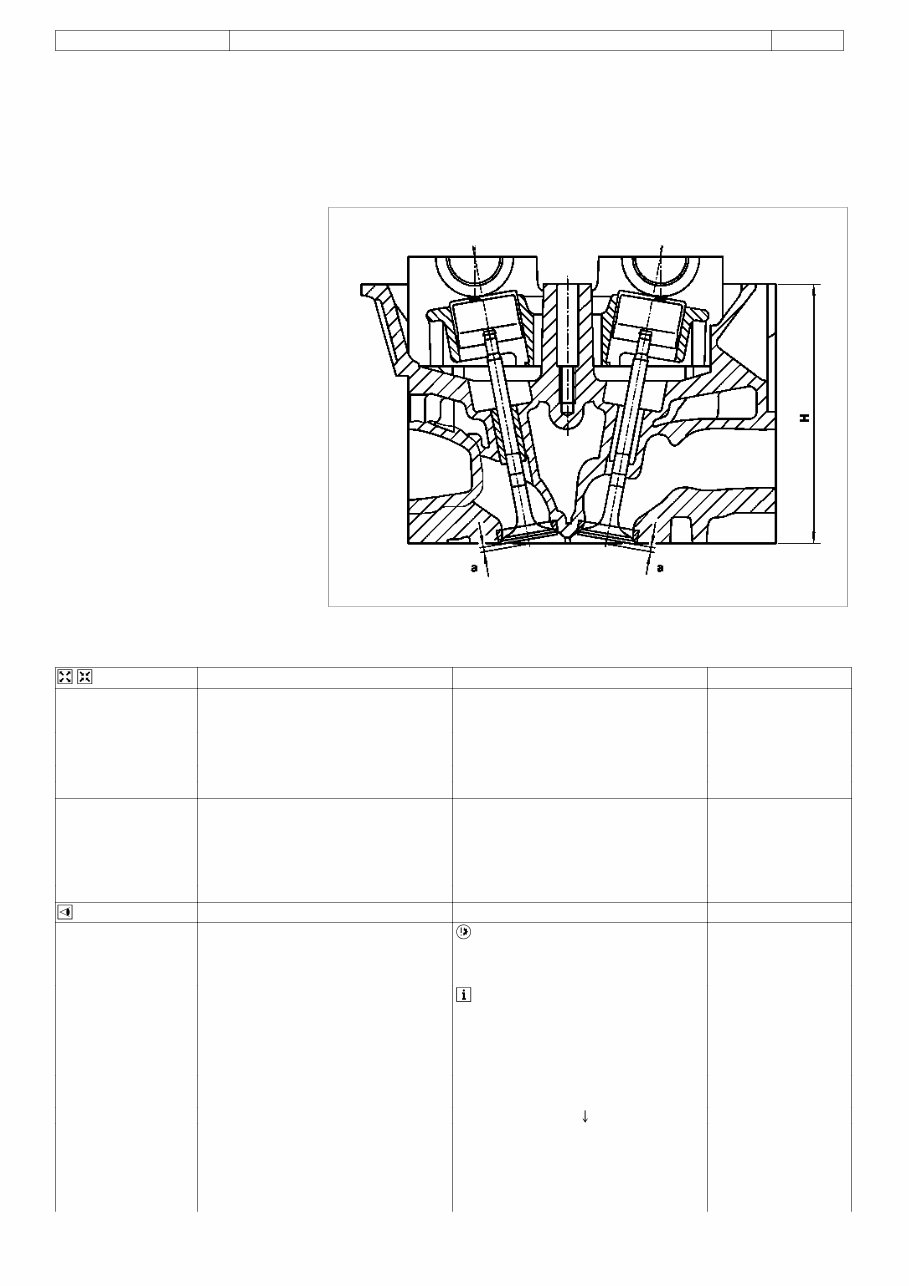

a Valve setback with new valves and valve

seat rings

H Overall height of cylinder head without

camshaft housing

P01.30-0344-06

Remove/install

1 Remove cylinder head ENGINE 648.961 in MODEL AR01.30-P-5800TA

211.023/026/223/226

ENGINE 646.951 in MODEL 211.004 AR01.30-P-5800T

ENGINE 646.961 in MODEL 211.006/206/606

ENGINE 647.961 in MODEL 211.016/216/616 AR01.30-P-5800TB

ENGINE 651 in MODEL 204, 212 AR01.30-P-5800CD

2 Remove valves ENGINE 648.961 in MODEL AR05.30-P-3511HB

211.023/026/223/226

ENGINE 646.961 in MODEL 211.006/206/606

ENGINE 646.951 in MODEL 211.004

ENGINE 647.961 in MODEL 211.016/216/616

ENGINE 651 in MODEL 204, 212 AR05.30-P-3511CD

Check

3 Check cylinder head contact surface for

The camshaft case must not be

flatness, porous or damaged locations; face-

machined.

grind if necessary

The basic bores for the camshaft bearing will

be changed otherwise.

Only face cylinder head contact surface if

porous or damaged points are present. It is

not necessary to rework minor variations in

the flatness in the longitudinal direction.

These are compensated for again when the

cylinder head is tightened.

Where required, following inspection of

cylinder head separating surface:

Measure total height of cylinder head without

camshaft case (H), note the measured value

and compare with tabular value. Face grind

contact surface of cylinder head Measure

total height of cylinder head without

camshaft case (H) again.

Page 1 of 2 © Daimler AG, 11/9/16, G/01/15, ar01.30-p-7162t, Check/face-grind cylinder head contact surfaces

ENGINE 651 in MODEL 204, 212 ENGINE 648.961 in MODEL 211.023/026/223/226 ENGINE 646.961 in MODEL 211.006/206/606 ENGINE 647.961 in MODEL 211.016/216/616 ENGINE 646.951 in .

Height of cylinder head (H), without camshaft *BE01.30-P-1003-02E

housing

4 Measure valve setback

There is no further correct valve

clearance compensation available if the

reference dimension for the valve setback is

not reached for new valves and new valve

seat rings (a). Where required, replace valve

seat ring or cylinder head.

Valve setback (a) with new valves and new *BE01.30-P-1001-02E

valve seat rings

5 Install in the reverse order

Check values for cylinder head

Number Designation ENGINE ENGINE

646.951/961/962/963 648.960/961

/966, 647.961

BE01.30-P-1003-02E Height of cylinder head (H), without camshaft New mm 126,85...127,15 126,85...127,15

housing

Wear limit after mm 126,65 126,65

machining

For AR01.30-P-7162HB AR01.30-P-7162HB

picture,

see

Check values for cylinder head

Number Designation ENGINE 651

BE01.30-P-1003-02E Height of cylinder head (H), without camshaft New mm 134,35...134,65

housing

Wear limit after mm 134,15

machining

For -

picture,

see

Check values for cylinder head

Number Designation ENGINE ENGINE

646.951/961/962/963 648.960/961

/966, 647.961

BE01.30-P-1001-02E Valve setback (a) with new valves and new Exhaust valve mm 1,0...1,4 1,0...1,4

valve seat rings

Intake valve mm 1,1...1,5 1,1...1,5

For picture, see – –

Check values for cylinder head

Number Designation ENGINE 651

BE01.30-P-1001-02E Valve setback (a) with new valves and new Exhaust valve mm 0,7...1,1

valve seat rings

Intake valve mm 1,0...1,4

For picture, see –

Page 2 of 2 © Daimler AG, 11/9/16, G/01/15, ar01.30-p-7162t, Check/face-grind cylinder head contact surfaces

ENGINE 651 in MODEL 204, 212 ENGINE 648.961 in MODEL 211.023/026/223/226 ENGINE 646.961 in MODEL 211.006/206/606 ENGINE 647.961 in MODEL 211.016/216/616 ENGINE 646.951 in .

AR05.00-P-2010CD Check hydraulic valve clearance compensating elements 23.4.12

ENGINES 651 in MODELS 166, 172, 204, 207, 212, 218, 221

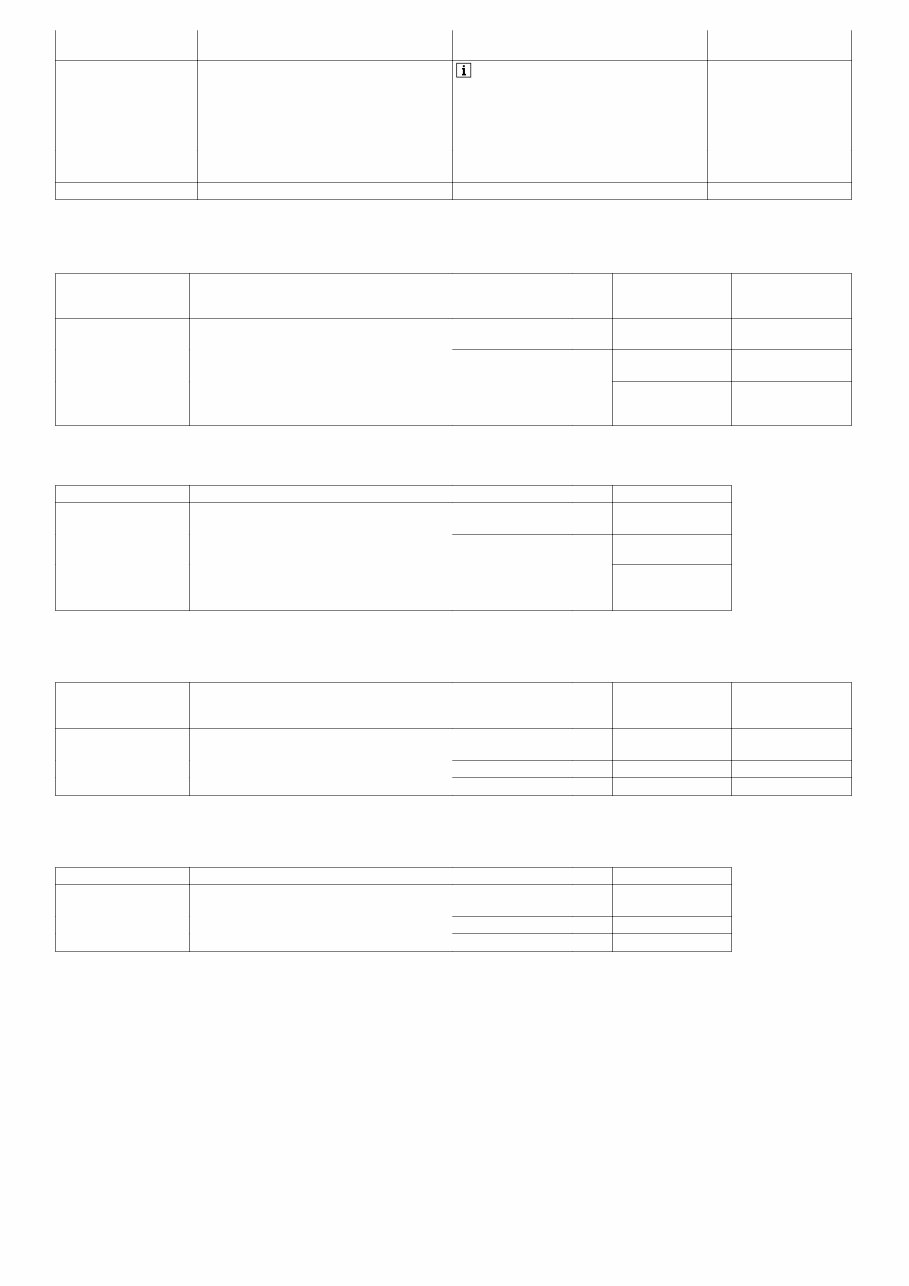

2 Compensating element

3 Cam

4 Roller-type cam follower

5 Tool

P05.00-2063-11

Remove/install

1 Check engine oil level, correct if necessary

The engine oil level must lie between

"Min" and "Max". Engine damage can occur

otherwise.

Risk of accident Secure vehicle to prevent it from moving by

Danger!

caused by vehicle starting AS00.00-Z-0005-01A

off by itself when engine is running. Risk of itself.

injury Wear closed and snug-fitting work clothes. caused by contusions and burns

during starting procedure or when working Do not touch hot or rotating parts.

near the engine as it is running

2 Start engine and bring to operating

Coolant temperature 60 to 80°C.

temperature

3 Remove cylinder head cover AR01.20-P-5014CD

Checking

4.1 Rotate engine at crankshaft using a Except code (B03) ECO start-stop function

counterholder in direction of engine rotation

until the cam (3) on the compensation

element (2) to be tested is on its base circle

The engine must not be turned back. The

timing chain can skip and cause engine

damage otherwise.

*651589004000

Counterholder

4.2 Rotate engine at crankshaft using a suitable With code (B03) ECO start/stop function

tool in direction of engine rotation until the

cam (3) on the compensation element (2) to

be tested is on its base circle

The engine must not be turned back. The

timing chain can skip and cause engine

damage otherwise.

5 Press down compensation element (2) over

Do not use a steel tool. Press

cam follower (4) by hand using the

compensation element (2) downwards using

appropriate tool (5)

normal force of the hand.

If a number of compensation elements

(2) drop, check oil ducts and oil feed bores

for the compensation elements (2) for

fouling; blow out oil ducts with compressed

air in the direction of flow of the oil if

necessary.

If a compensation element (2) drops

much more than other compensation

elements (2), replace the compensation

element (2) in question

See:

Remove/install compensation element (2). AR05.00-P-2011CD

6 Install in the reverse order

Page 1 of 2 © Daimler AG, 11/9/16, G/01/15, ar05.00-p-2010cd, Check hydraulic valve clearance compensating elements

ENGINES 651 in MODELS 166, 172, 204, 207, 212, 218, 221

651 589 00 40 00

Counterholder

Page 2 of 2 © Daimler AG, 11/9/16, G/01/15, ar05.00-p-2010cd, Check hydraulic valve clearance compensating elements

ENGINES 651 in MODELS 166, 172, 204, 207, 212, 218, 221

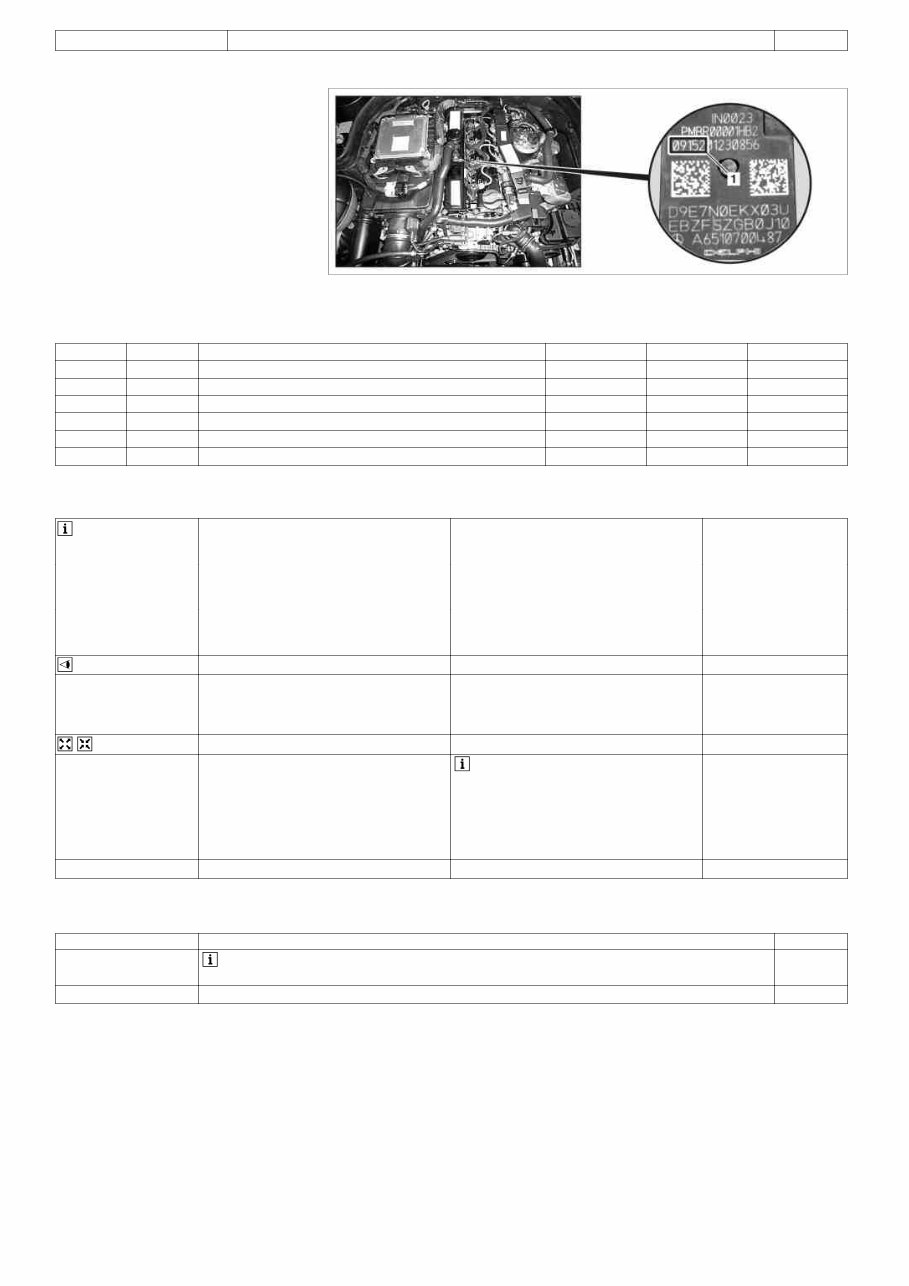

SM07.16-P-0005B Check injectors 22.7.10

ENGINES 651 in MODELS 204, 207, 212

1 Date of manufacture

P07.16-3645-04

Operation no. of operation texts or standard texts and flat rates

Category Op. no. Operation text Time Acc. no. Code

P 024762 Connect and disconnect Diagnosis Assistance System (DAS)

P 025059 Read out and erase fault memory (with DAS connected)

P 026748 Perform control unit adaptation (with DAS connected)

P 026872 Perform quick test

P 026873 Check (all) injectors

P 026874 Replace injectors (all) (after check)

List of affected vehicles Model 204 from SM07.16-P-0005-01BAA

WDC2049021F405147 to

WDD2042821F471917

Model 207 from SM07.16-P-0005-01BAB

WDD2073031F008596 to

WDD2073032F039959

Model 212 from SM07.16-P-0005-01BAC

WDD2120021A001295 to

WDD2122031A167495

Checking

1 Check manufacture date (1) for all If the manufacture date (1) for the injectors is injectors

up to 09316, continue with operation step 2 .

If the manufacture date (1) for the injectors is

as from 09317, end measure .

Remove/install

2 Remove/install/replace injectors AR07.16-P-1000CD

Part delivery is executed solely on the

basis of a TIPS case. The logistics Centers

(LCs) will not ship any more injectors without

instruction to do so by the Technical

Workshop Support.

It is not possible to order the injectors

through the usual order channels.

3 Clear fault memory

Parts ordering notes

Part no. Designation Quantity

Small parts such as stop nuts, sealing rings, cable ties, fluid etc. are no shown in the parts

listing. The required small parts are taken into account in the cost framework

A 651 070 20 87 Injector parts kit 1

Page 1 of 1 © Daimler AG, 11/9/16, G/01/15, sm07.16-p-0005b, Check injectors

ENGINES 651 in MODELS 204, 207, 212

You're Reading a Preview

What's Included?

Lifetime Access

Access Contents & Bookmarks

Print one or all pages of your manual

Add to Cart

$32.99

$42.99