2002-2014 Mazda6 Service & Repair Manual

- 2002-2014 Mazda6 Service & Repair Manual

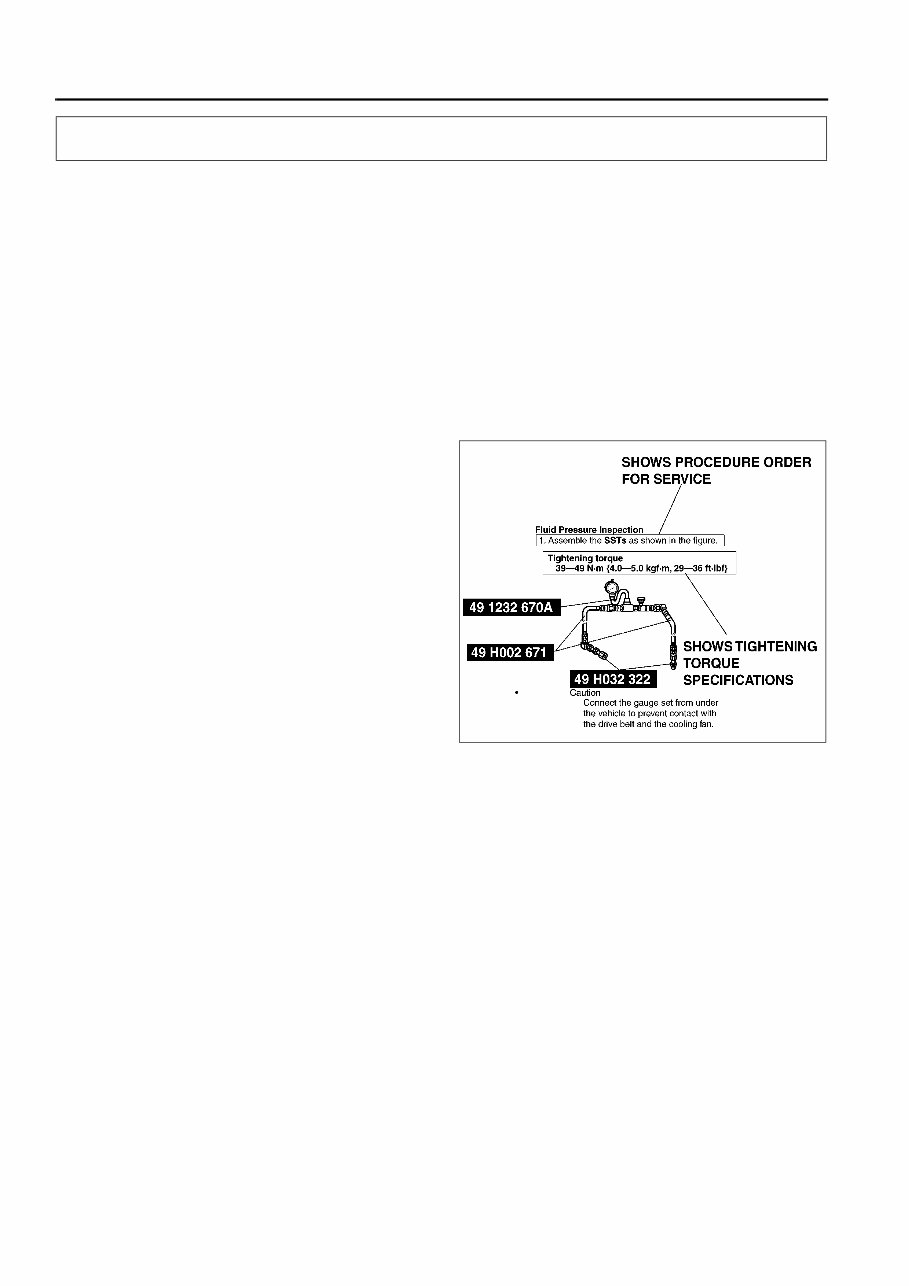

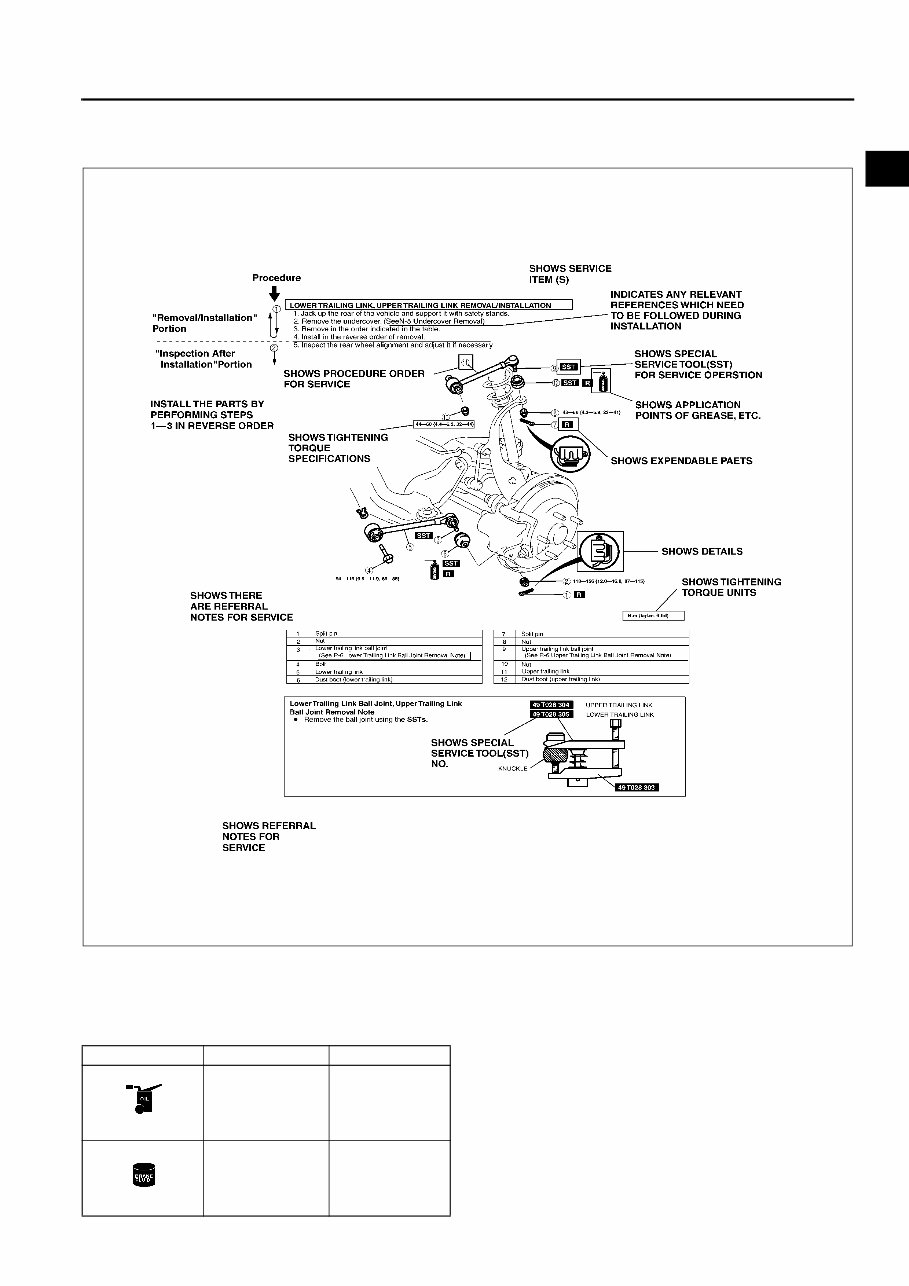

Fixing problems on your vehicle is a Do-It-Yourself approach with this repair manual as it contains every troubleshooting and replacement procedure provided by the manufacturer, including step-by-step instructions, clear images, and exploded-view illustrations.

The durability of your vehicle is unquestionable, but you also know that no matter how tough it is, regular maintenance is definitely required. And even when properly maintained, with time, some parts will eventually wear out and will need to be replaced.

Luckily, that's where a good repair manual will come in handy, providing you with the manufacturer's recommended troubleshooting charts and replacement procedures; basically, everything you need to fix your vehicle. As a result, you’ll be able to save on repairs, increase your vehicle’s reliability, and keep the repair shop at bay — what’s not to like, right?

The manual contains every troubleshooting and replacement procedure provided by the manufacturer, including step-by-step instructions, exploded-view illustrations, and clear images.

No need to flip through hundreds of pages to find specific information; no more greasy, torn, or lost pages anymore! Carry them around, search them, screenshot them, bookmark them — much better than a traditional bound manual if you ask me.

Of course, if you prefer to have a physical copy, nothing prevents you from printing it out too.

Printable: Yes

Language: English

Compatibility: Pretty much any electronic device, incl. PC & Mac computers, Android and Apple smartphones & tablet, etc.

Requirements: Adobe Reader (free)