2011-2012 Jeep Wrangler Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

2010-2016 JEEP WRANGLER

SERVICE AND REPAIR MANUAL

2013 ENGINE

Cooling System - Wrangler

DESCRIPTION

DESCRIPTION

The cooling system regulates engine operating temperature. It allows the engine to reach normal operating

temperature as quickly as possible, maintains normal operating temperature and prevents overheating.

The cooling system also provides a means of heating the passenger compartment and cooling the automatic

transmission fluid. The cooling system is pressurized and uses a centrifugal water pump to circulate coolant

throughout the system.

COOLING SYSTEM COMPONENTS

The cooling system consists of:

Charge Air Cooler (Diesel engine)

2 Speed Electric Cooling Fan

Aluminum-core radiator with plastic side tanks

Coolant recovery container

Water pump

Combination A/C condenser/transmission oil cooler (automatic transmission)

Thermostat

Hoses and hose clamps

OPERATION

OPERATION

When engine is cold the thermostat is closed. The cooling system has no flow through the radiator. The

coolant flows through the engine, water pump, and heater.

When engine is warm, the thermostat is full open. The coolant flows through the engine, radiator, heater,

and water pump.

On the diesel engine coolant flows through the engine, radiator, heater, and water pump.

As coolant expands, some coolant will move to the coolant recovery container. Once the coolant cools,

the coolant from the coolant recovery container will move back to the radiator. (Gas engine only)

DIAGNOSIS AND TESTING

PRELIMINARY CHECKS

2013 ENGINE Cooling System - Wrangler 2013 ENGINE Cooling System - Wrangler

ENGINE COOLING SYSTEM OVERHEATING

Establish what driving conditions caused the complaint. Abnormal loads on the cooling system such as the

following may be the cause:

Prolonged idle

Very high ambient temperature

Overloaded Truck

Slow traffic

Traffic jams

High speed or steep grades

Snow Plow restricting airflow through cooling module

Debris on front of the grill or the cooling module that is restricting airflow

Driving techniques that avoid overheating are:

Idle with A/C off when temperature gauge is at end of normal range.

Increasing engine speed up to 2000 RPM with transmission in park or neutral for more airflow is

recommended.

If equipped with a snow plow. Activate the snow plow mode.

TRAILER TOWING:

Consult Trailer Towing section of the Owner's Manual. Do not exceed the limits.

RECENT SERVICE OR ACCIDENT REPAIR:

Determine if any recent service has been performed on vehicle that may affect the cooling system. This may be:

Engine adjustments (incorrect timing)

Slipping engine accessory drive belt(s)

Brakes (possibly dragging)

Changed parts. Incorrect water pump or pump rotating in wrong direction due to belt not correctly routed

Reconditioned radiator or cooling system refilling (possibly under filled or air trapped in system).

Service to electrically controlled viscous fan clutch

These charts are to be used as a quick-reference only.

COOLING SYSTEM DIAGNOSIS CHART

NOTE: If investigation reveals none of the previous items as a cause for an engine

overheating complaint, refer to the COOLING SYSTEM DIAGNOSIS CHART .

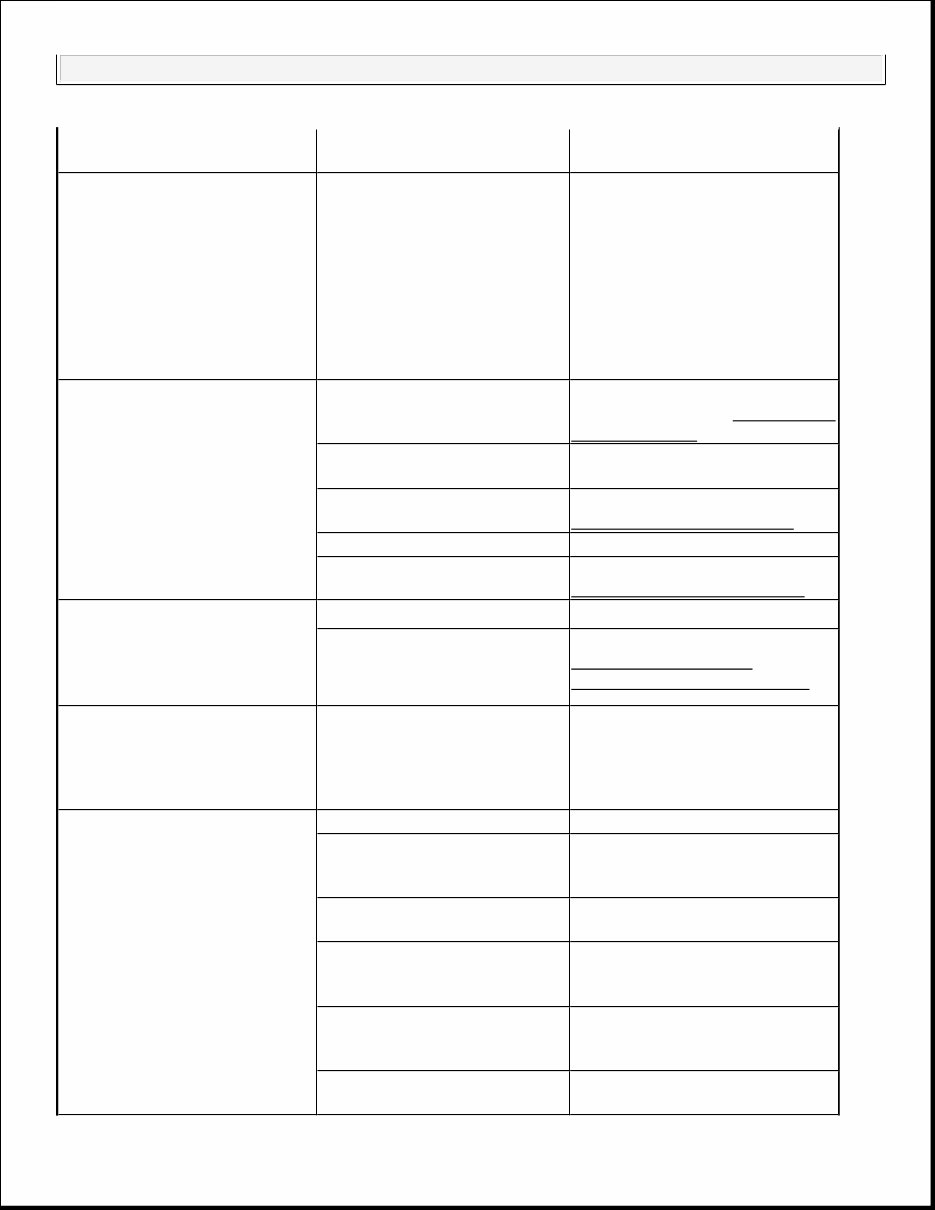

CONDITION POSSIBLE CAUSES CORRECTION

2013 ENGINE Cooling System - Wrangler

TEMPERATURE GAUGE

READS LOW

NOTE:

Information on dash cluster is

displayed based on broadcast

data from PCM. DTC will be set

for engine sensor circuit issues.

1. Vehicle is equipped with a

heavy duty cooling system.

1. None. System operating

normally.

2. Thermostat stuck open 2. Inspect and test thermostat. Refer

to THERMOSTAT, DIAGNOSIS

AND TESTING .

3. Coolant level low. 3. Fill cooling system. Refer to

STANDARD PROCEDURE .

4. Temperature gauge not

functioning correctly.

4. Check cluster. Refer to

DIAGNOSIS AND TESTING .

5. Engine sensor stuck in range 5. Monitor sensor with scan tool to

verify sensor reading changes with

increasing temperature.

6. Engine sensor failed out of

range.

6. A DTC will be set.

7. Electronically Controlled

Viscous Fan Drive/mechanical

viscous fan not operating

properly.

7. Check Electronically Controlled

Viscous Fan Drive.

TEMPERATURE GAUGE

READS HIGH. COOLANT MAY

OR MAY NOT BE LEAKING

FROM SYSTEM

NOTE:

Temperature information

displayed on dash cluster and

EVIC are based on broadcast

data from PCM. If engine

temperatures exceed

thresholds, power is reduced

and a message of 'Oil Temp

High - Speed May be Reduced'

is displayed on the EVIC.

NOTE:

Beginning in MY2010, a 200 F

thermostat is used in the Ram

2500/3500 pickup with the

Cummins Turbo Diesel. It is

normal for the coolant

temperature gauge to read

higher than in previous model

1. Vehicle overloaded, high

ambient (outside) temperatures

with A/C turned on, stop and go

driving or prolonged operation at

idle speeds.

1. Temporary condition, repair not

required. Notify customer of

vehicle operation instructions

located in Owner's Manual.

2013 ENGINE Cooling System - Wrangler

years.

2. Electronically-controlled

viscous fan clutch not

functioning correctly.

2. Troubleshoot and if necessary

repair the electronic viscous fan

clutch.

3. Temperature gauge not

functioning correctly.

3. Check cluster. Refer to

DIAGNOSIS AND TESTING .

4. Air trapped in cooling system 4. Drain and refill cooling system.

Refer to STANDARD

PROCEDURE .

5. Radiator cap faulty. 5. Replace radiator cap.

6. Plugged A/C or radiator

cooling fins.

6. Clean all debris away from A/C

and radiator cooling fins.

7. Coolant mixture incorrect. 7. Drain cooling system and refill

with correct mixture. Refer to

STANDARD PROCEDURE .

8. Thermostat stuck shut. 8. Inspect and test thermostat Refer

to THERMOSTAT, DIAGNOSIS

AND TESTING .

9. Bug screen or winter front

being used.

9. Remove bug screen or winter

front.

10. Electronically controlled

viscous fan drive not operating

properly.

10. Check viscous fan.

11. Cylinder head gasket leaking. 11. Check for leaking head gaskets.

Refer to DIAGNOSIS AND

TESTING .

12. Heater core leaking. 12. Replace heater core. Refer to

CORE, HEATER, REMOVAL .

13. Cooling system hoses

leaking.

13. Tighten clamps or Replace

hoses.

14. Brakes dragging. 14. Check brakes. Refer to

DIAGNOSIS AND TESTING .

15. Accessory drive belt. 15. Inspect and replace as

necessary. Refer to BELT,

SERPENTINE, DIAGNOSIS

AND TESTING .

16. Water Pump. 16. Inspect and replace as

necessary.

17. Engine sensor stuck in range. 17. Monitor sensor with scan tool

to verify sensor reading changes

increase in temperature.

18. Temperature sensor failed -

Too High

18. Clear the existing overheat

fault. Drive the vehicle until

thermostat opens. Verify that fault

code does not return and coolant

2013 ENGINE Cooling System - Wrangler

does not reach threshold of 230

degrees F.

TEMPERATURE GAUGE

READING INCONSISTENT

(ERRATIC, CYCLES OR

FLUCTUATES)

NOTE:

Information on dash cluster is

displayed based on broadcast

data from PCM. DTC will be set

for engine sensor circuit issues.

1. Heavy duty cooling system,

extreme cold ambient (outside)

temperature or heater blower

motor in high position.

1. None. System operating

normally.

2. Temperature gauge or sensor

defective.

2. Check cluster or engine coolant

temp sensor. Refer to DIAGNOSIS

AND TESTING .

3. Temporary heavy usage or

load.

3. None. Normal condition.

4. Air trapped in cooling system. 4. Fill cooling system. Refer to

STANDARD PROCEDURE .

5. Water pump. 5. Replace water pump.

6. Air leak on suction side of

water pump.

6. Check for leak. Refer to

DIAGNOSIS AND TESTING .

RADIATOR CAP LEAKING

STEAM AND OR COOLANT

INTO RESERVOIR BOTTLE.

(TEMPERATURE GAUGE MAY

READ HIGH)

1. Radiator cap defective. 1. Replace radiator cap.

2. Radiator neck surface

damaged.

2. Replace radiator. Refer to

RADIATOR, ENGINE

COOLING, INSTALLATION .

HOSE OR HOSES COLLAPSE

WHEN ENGINE IS COOLING.

1. Vacuum created in cooling

system on engine cool-down is

not being relieved through

coolant reservoir/overflow

system.

1. Replace radiator cap, check vent

hose between radiator and reservoir

bottle for blockage also check

reservoir bottle vent for blockage.

NOISY FAN 1. Fan blade(s) loose, damaged. 1. Replace fan blade assembly.

2. Electronically controlled

viscous fan drive/mechanical

viscous fan.

2. None. Normal condition.

3. Fan blades striking

surrounding objects.

3. Locate contact point and repair

as necessary.

4. Electronically controlled

viscous fan drive/mechanical

viscous fan bearing concern.

4. Check viscous fan drive.

5. Electronically controlled

viscous fan/mechanical viscous

fan stuck on.

5. Check viscous fan drive.

6. Obstructed air flow through

radiator.

6. Remove obstruction.

2013 ENGINE Cooling System - Wrangler

LEAK TESTING

ULTRAVIOLET LIGHT METHOD

INADEQUATE AIR

CONDITIONER

PERFORMANCE (COOLING

SYSTEM SUSPECTED)

1. Radiator and/or A/C condenser

air flow obstructed.

1. Remove obstruction and/or

clean.

2. Electronically controlled

viscous fan drive/mechanical

viscous fan not working.

2. Check viscous fan drive.

3. Air seals around radiator

damaged or missing.

3. Inspect air seals, repair or replace

as necessary.

INADEQUATE HEATER

PERFORMANCE. GAUGE

MAY OR MAY NOT READ

LOW.

1. Heavy duty cooling system,

and cooler ambient temperatures.

1. None. Normal condition.

2. Obstruction in heater hoses. 2. Remove hoses, remove

obstruction.

3. Electronically controlled

viscous fan/mechanical viscous

fan stuck on.

Check viscous fan drive.

4. Water pump damaged. 4. Replace water pump.

HEAT ODOR 1. Damaged or missing exhaust

system heat shields.

1. Repair or replace damaged or

missing exhaust system heat

shields. Refer to SHIELD, HEAT,

DESCRIPTION .

2. Electronically controlled

viscous fan drive//mechanical

viscous fan damaged.

2. Check viscous fan drive.

2013 ENGINE Cooling System - Wrangler

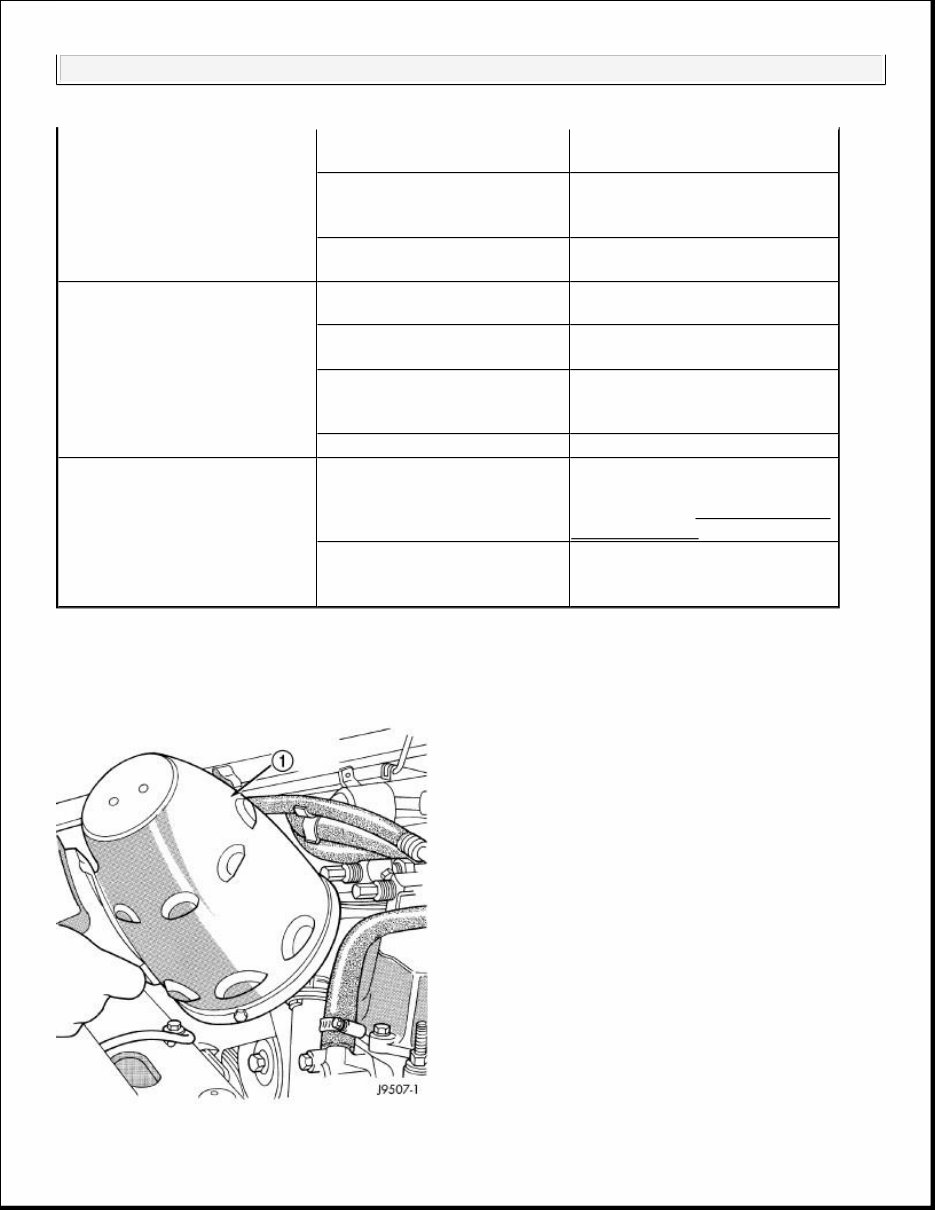

Fig. 1: Leak Detection Using Black Light

Courtesy of CHRYSLER GROUP, LLC

All Jeep models have a leak detection additive added to the cooling system before they leave the factory. The

additive is highly visible under ultraviolet light (black light). If the factory original coolant has been drained,

pour one ounce of additive into the cooling system. The additive is available through the parts department.

Place the heater control unit in HEAT position. Start and operate the engine until the radiator upper hose is

warm to the touch. Aim the commercially available black light tool at the components to be checked. If leaks

are present, the black light will cause the additive to glow a bright green color.

The black light can be used along with a pressure tester to determine if any external leaks exist.

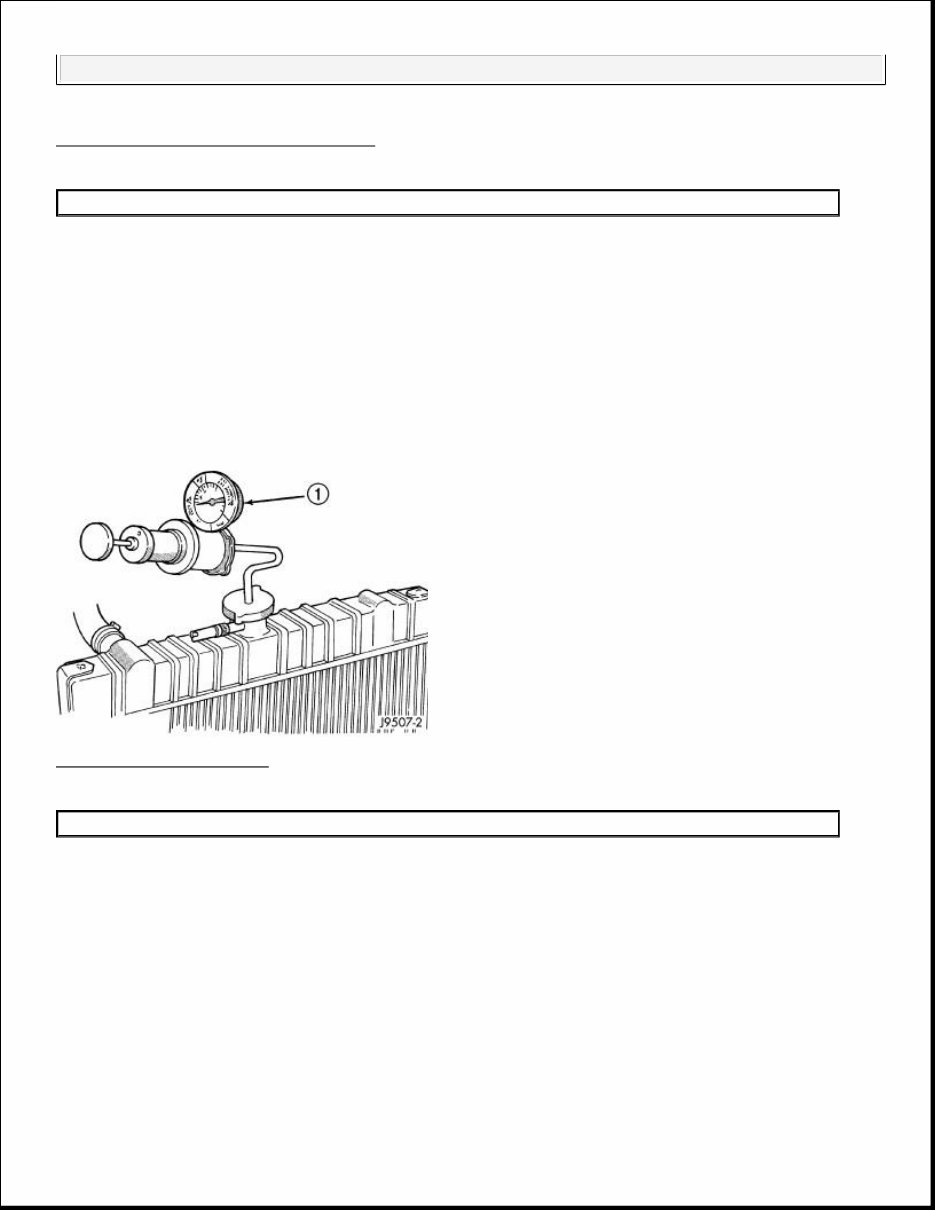

PRESSURE TESTER METHOD

Fig. 2: Pressurizing System

Courtesy of CHRYSLER GROUP, LLC

The engine should be at the normal operating temperature. Recheck the system cold if the cause of coolant loss

is not located during warm engine examination.

Carefully remove the radiator pressure cap from the filler neck and check the coolant level. Push down on the

cap to disengage it from the stop tabs. Wipe the inner part of the filler neck and examine the lower inside

sealing seat for nicks, cracks, paint, dirt and solder residue. Inspect the reserve/overflow tank tube for internal

obstructions. Insert a wire through the tube to be sure it is not obstructed.

1 - TYPICAL BLACK LIGHT TOOL

1 - TYPICAL COOLING SYSTEM PRESSURE TESTER

WARNING: Hot, pressurized coolant can cause injury by scalding.

2013 ENGINE Cooling System - Wrangler

Inspect the cams on the outside part of the filler neck. If the cams are bent, seating of pressure cap valve and

tester seal will be affected. Replace cap if cams are bent.

Attach pressure tester (special tool #7700, Tester, Cooling System) (or an equivalent) to the radiator filler neck.

Operate the tester pump to apply 124 kPa (18 psi) pressure to the system. If the hoses enlarge excessively or

bulge while testing, replace as necessary. Observe the gauge pointer and determine the condition of the cooling

system according to the following criteria:

Holds Steady: If the pointer remains steady for two minutes, there are no serious coolant leaks in the

system. However, there could be an internal leak that does not appear with normal system test pressure.

Inspect for interior leakage or do the Internal Leakage Test. Do this if it is certain that coolant is being

lost and no leaks can be detected.

Drops Slowly: Shows a small leak or seepage is occurring. Examine all connections for seepage or slight

leakage with a flashlight. Inspect the radiator, hoses, gasket edges and heater. Seal any small leak holes

with a Sealer Lubricant or equivalent. Repair leak holes and reinspect the system with pressure applied.

Drops Quickly: Shows that a serious leakage is occurring. Examine the system for serious external

leakage. If no leaks are visible, inspect for internal leakage. Large radiator leak holes should be repaired

by a reputable radiator repair shop.

INTERNAL LEAKAGE INSPECTION

Remove the engine oil pan drain plug and drain a small amount of engine oil. Coolant, being heavier than

engine oil, will drain first. Another way of testing is to operate the engine and check for water globules on the

engine oil dipstick. Also inspect the automatic transmission oil dipstick for water globules. Inspect the

automatic transmission fluid cooler for leakage. Operate the engine without the pressure cap on the radiator

until thermostat opens.

Attach a pressure tester to the filler neck. If pressure builds up quickly, a leak exists as a result of a faulty

cylinder head gasket or crack in the engine. Repair as necessary.

If there is no immediate pressure increase, pump the pressure tester until the indicated pressure is within the

system range. Vibration of the gauge pointer indicates compression or combustion leakage into the cooling

system.

WARNING: DO NOT ALLOW PRESSURE TO EXCEED 124 KPA (18 PSI). TURN THE

ENGINE OFF. TO RELEASE THE PRESSURE, ROCK THE TESTER FROM

SIDE TO SIDE. WHEN REMOVING THE TESTER, DO NOT TURN THE

TESTER MORE THAN 1/2 TURN IF THE SYSTEM IS UNDER PRESSURE.

WARNING: Do not disconnect the spark plug wires while the engine is operating.

CAUTION: Do not operate the engine with a spark plug shorted for more than a

minute. The catalytic converter may be damaged.

2013 ENGINE Cooling System - Wrangler

Isolate the compression leak by shorting each spark plug to the cylinder block. The gauge pointer should stop or

decrease vibration when spark plug for leaking cylinder is shorted. This happens because of the absence of

combustion pressure.

COMBUSTION LEAKAGE TEST (WITHOUT PRESSURE TESTER)

DO NOT WASTE reusable coolant. If the solution is clean, drain the coolant into a clean container for reuse.

Remove thermostat. Refer to THERMOSTAT, REMOVAL .

Remove accessory drive belt. Refer to BELT, SERPENTINE, REMOVAL .

Add coolant to the radiator to bring the level to within 6.3 mm (1/4 in) of the top of the thermostat housing.

Start the engine and accelerate rapidly three times (to approximately 3000 RPM) while observing the coolant. If

internal engine combustion gases are leaking into the cooling system, bubbles will appear in the coolant. If

bubbles do not appear, there is no internal combustion gas leakage.

STANDARD PROCEDURE

CLEANING/REVERSE FLUSHING

Reverse flushing of the cooling system is the forcing of water through the cooling system. This is done using air

pressure in the opposite direction of normal coolant flow. It is usually only necessary with very dirty systems

with evidence of partial plugging.

CHEMICAL CLEANING

If visual inspection indicates the formation of sludge or scaly deposits, use a radiator cleaner, Mopar® Radiator

Kleen or equivalent, before flushing. This will soften scale and other deposits and aid the flushing operation.

WARNING: Do not remove the cylinder block drain plugs or loosen the radiator

draincock with the system hot and under pressure. Serious burns from

coolant can occur.

CAUTION: Avoid overheating. Do not operate the engine for an excessive period of

time. Open the draincock immediately after the test to eliminate boil over

of coolant.

CAUTION: The cooling system normally operates at 97 - 110 kPa (14 -16 psi)

pressure. Exceeding this pressure may damage the radiator or hoses.

CAUTION: Be sure instructions on the container are followed.

2013 ENGINE Cooling System - Wrangler

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

$51.99

Viewed 43 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

$51.99

The 2011-2012 Jeep Wrangler Service & Repair Manual is a comprehensive guide for maintaining and repairing your Jeep Wrangler during the 2011-2012 model years. Whether you are a professional mechanic or a DIY enthusiast, this manual provides detailed instructions and clear diagrams to help you complete any repair or maintenance task with confidence.

- Comprehensive information on engine, transmission, electrical system, suspension, steering, brakes, and more

- Covers all Jeep Wrangler models released between 2011 and 2012

- Step-by-step instructions for each repair or maintenance procedure

- Easy-to-follow diagrams for a clear understanding of components and systems

- Specifications, troubleshooting guides, and expert tips for optimal performance and longevity

- Authored by Jeep experts to ensure accurate and reliable information

- Enables you to perform repairs and maintenance on your own, saving time and money

Whether you need to replace a part, carry out routine maintenance, or address a more complex repair, the 2011-2012 Jeep Wrangler Service & Repair Manual is your essential resource. With this manual at hand, you can confidently keep your Jeep Wrangler in peak condition for years to come.