2017 Ford Escape - M2 (C520 NA) Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Workshop Manual

WARNING: Before beginning any service procedure in this manual, refer to health and safety warnings in section

100-00 General Information. Failure to follow this instruction may result in serious personal injury.

Refer to: Health and Safety Precautions

100-00 General Information 2017 Escape

Description and Operation Procedure revision date: 03/10/2021

About this Manual

Introduction

WARNING: Before beginning any service procedure in this manual, refer to health and safety warnings in

section 100-00 General Information. Failure to follow this instruction may result in serious personal injury.

For additional information, refer to: Health and Safety Precautions (100-00 General Information, Description and

Operation).

This manual describes and directs repair procedures specified by Ford Motor Company for the vehicle. Critical health and

safety precautions are included. Anyone who deviates from these instructions risks compromising personal safety or vehicle

integrity.

SECTION CONTENT

This manual is divided into groups, each containing sections numbered based on the component part number. Section

contents may include:

Specifications

Fluid capacities, component specifications and torque values not covered in other procedures

Description and Operation

Overview of the system, component locations, and system operation

Diagnosis and Testing

Symptom charts, DTC charts and diagnostic tests

See the Diagnosis and Testing Information in this document

General Procedures

Service adjustments, electronic programming and other special procedures

Removal and Installation

Component removal and installation instructions

Removal

Component removal instructions

Installation

Component installation instructions

Disassembly and Assembly

Component disassembly and assembly instructions

Disassembly and Assembly of Subassemblies

Assembly disassembly and assembly instructions

IMPORTANT INFORMATION

Section number 100-00 General Information contains the following important information (including this document):

Critical Health and Safety Precautions - service safety precautions applicable to the entire manual.

For additional information, refer to: Health and Safety Precautions (100-00 General Information, Description and

Operation).

A Symbols Glossary - definitions of the action directed by each symbol.

For additional information, refer to: Symbols Glossary (100-00 General Information, Description and Operation).

Diagnostic Methods - support information for diagnostics.

For additional information, refer to: Diagnostic Methods (100-00 General Information, Description and Operation).

Warnings, Notices and Notes

WARNINGS

Warnings provide information to avoid personal injury and to make sure service actions on critical safety systems are

performed correctly. Warnings that apply to an entire system or workshop manual section are located in section 100-00

Description and Operation, Health and Safety Precautions.

For additional information, refer to: Health and Safety Precautions (100-00 General Information, Description and

Operation).

NOTICES (in some publications, CAUTIONS)

Notices provide information to avoid damage to the vehicle or a component.

NOTES

Notes provide information critical for a complete and effective repair.

Warnings, Notices, or Notes that apply to an entire procedure will be placed at the beginning of the procedure. Warnings,

Notices, or Notes that apply to a single step are placed at the beginning of the step. Those that apply to a group of steps will

be placed at the first step requiring it.

Safety Relevant Systems

Repair of a vehicle safety relevant system is to be achieved only by replacement of the failed component(s), unless specified

otherwise in the procedure. Repair of a vehicle safety relevant system component should not be attempted.

If directed during assembly of system components, lubricate any seal(s) only with the specified material. Failure to follow

this instruction may result in seal failure and leakage.

Specified Chemicals or Materials

Throughout this manual, chemicals or materials are specified that must be used to properly complete a service procedure or

diagnostic step. In the event a specific material is not readily available, a substitute material meeting the same specification

may be used. Ford has not reviewed third party products for compliance with environmental, health or safety regulations and

is not responsible for their use. Use of third party products is at your own risk. Additionally, such products may cause

degraded performance, premature failures, and/or vehicle component damage. All chemicals or materials used for vehicle

servicing should be checked for compliance with local environmental and health and safety regulations.

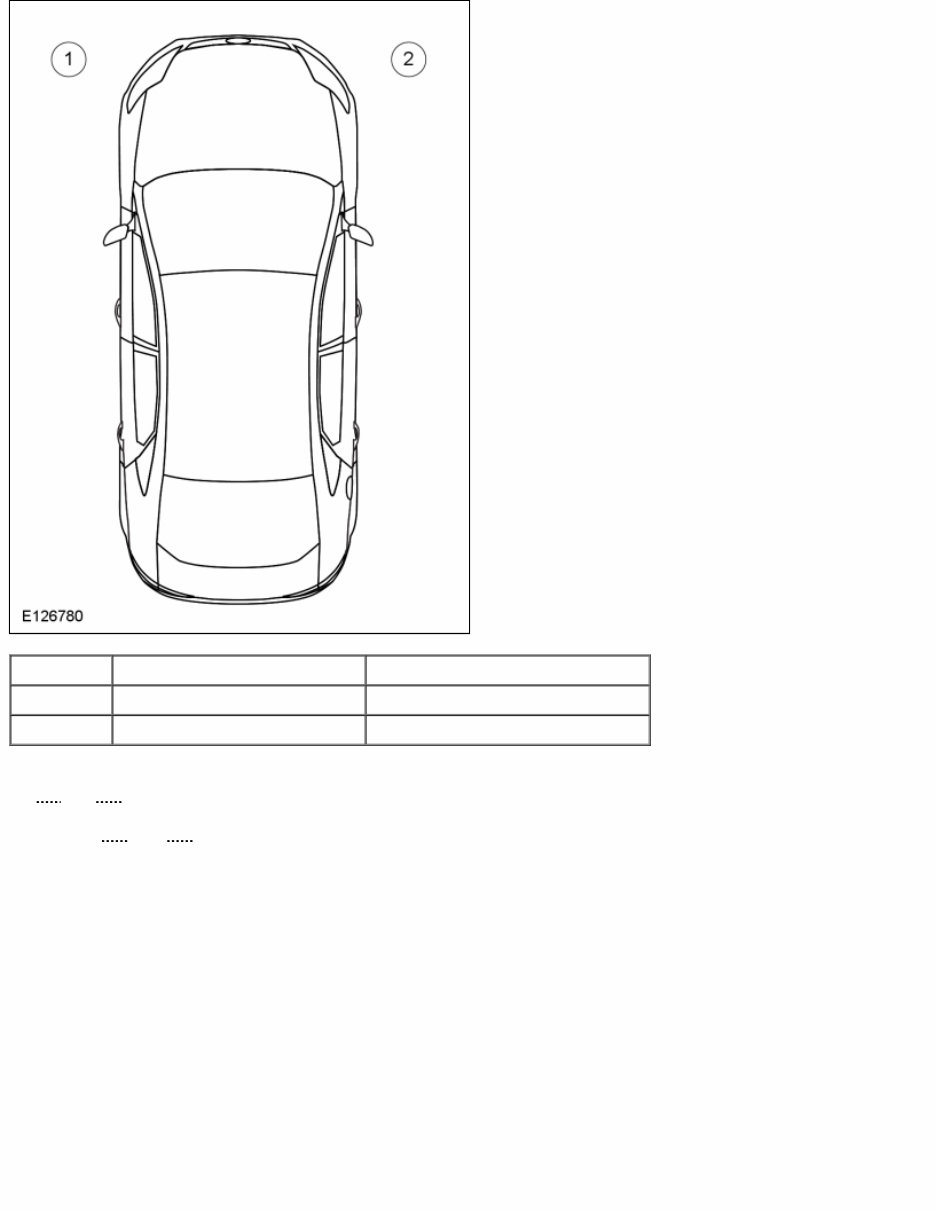

LH and RH Designations

All LH and RH designations are oriented from the driver's seat position looking forward.

Vehicle LH and RH definition

Item Part Number Description

1 — LH (left-hand)

2 — RH (right-hand)

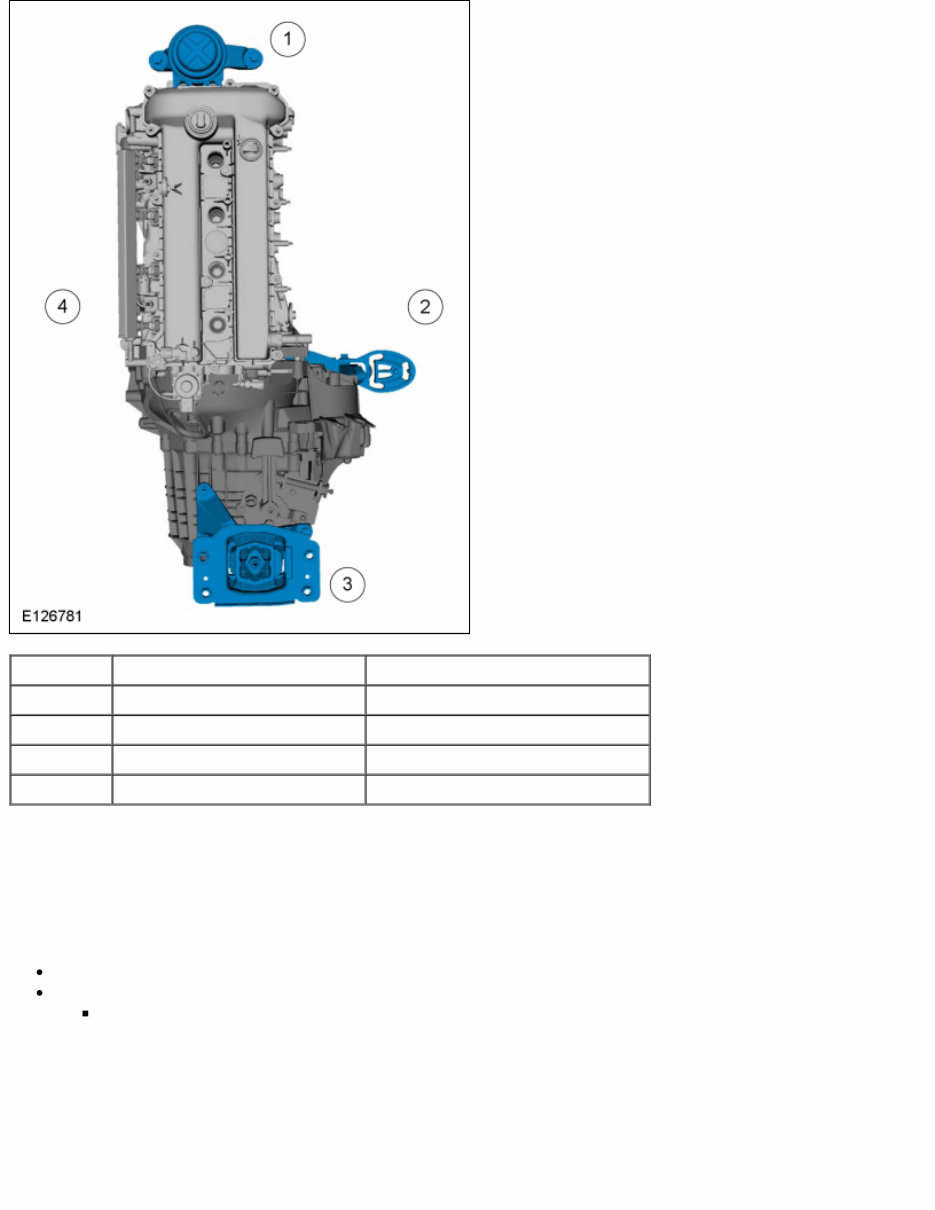

All LH and RH engine designations are oriented from the flywheel position looking toward the crankshaft pulley.

Powertrain LH and RH definition

Item Part Number Description

1 — Front

2 — RH (right-hand)

3 — Rear

4 — LH (left-hand)

Standard Practices

The following rules apply, unless specified differently in the procedure:

FASTENERS

Reuse standard fasteners.

Replace fasteners with self-locking features.

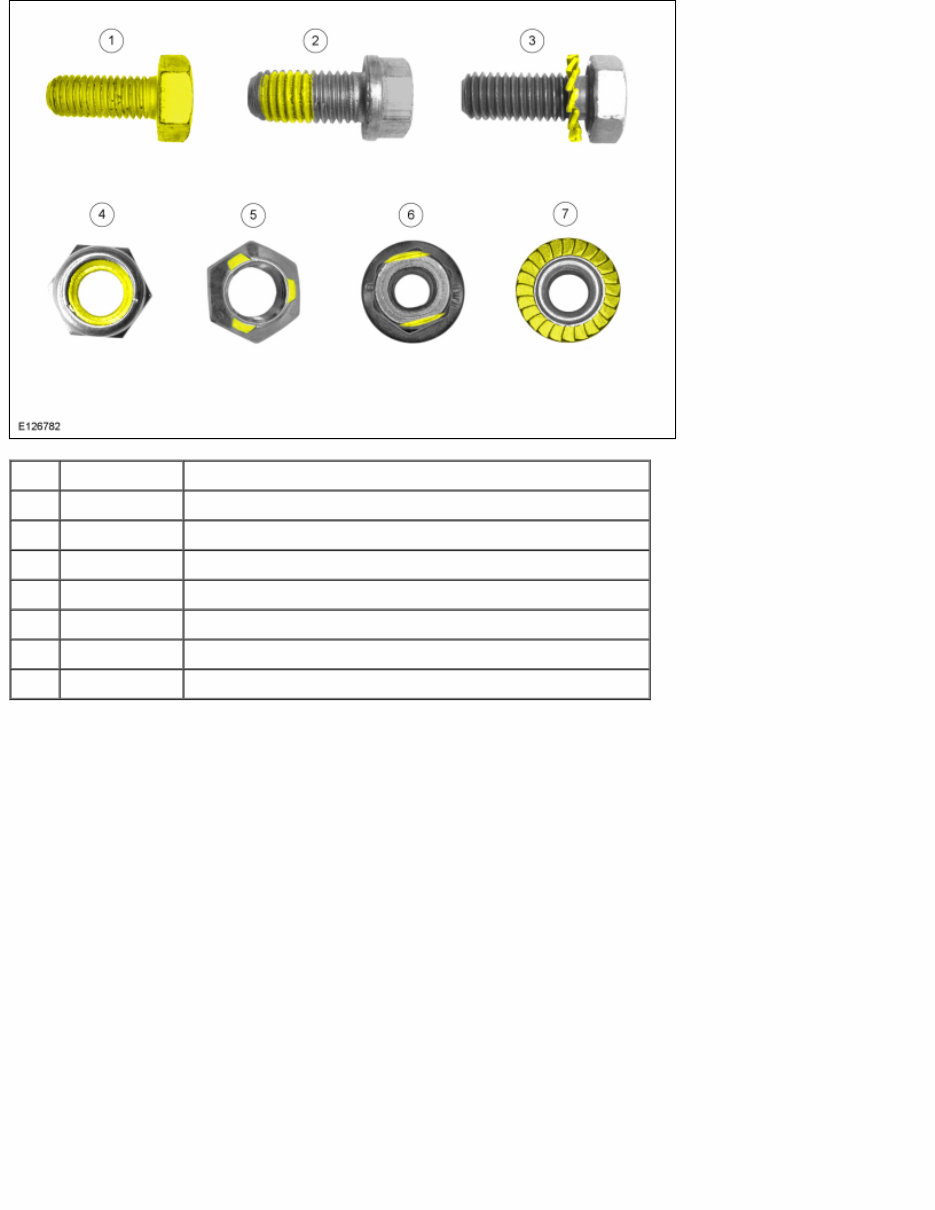

Examples of fastener self-locking coatings or mechanical locking (with the locking features highlighted yellow)

are shown in the illustration.

Examples of self-locking nuts and bolts

Item Part Number Description

1 — Completely coated self-locking bolt

2 — Partially coated self-locking bolt

3 — Self-locking bolt with a locking washer

4 — Self-locking nut with a plastic locking insert

5 — Self-locking nut with thread deformation (3 indentations)

6 — Self-locking nut with thread deformation (to oval shape)

7 — Self-locking nut with integrated locking ring

THREAD FORMING FASTENERS

The following is a general description of best practices to be followed during handling of thread forming fasteners and

mating components.

Manual Torque Application

Hand tools are required for installation of a thread forming fastener. Do NOT use power tools, as the possibility for over-

torqueing or stripped threads exists. If a fastener is over-torqued, the joint can fail.

Hand Start Fasteners in Reverse

To avoid the possibility of cross-threading pre-existing threads during fastener replacement, begin by first hand-inserting the

new fastener and rotating counter-clockwise. This reverse rotation allows for the location of existing fastener threads to

ensure the fastener does not cross-thread upon thread re-engagement. Once the existing fastener threads are located, hand-

start individual fasteners manually until finger tight.

Risks of Over-Torque

Consult the Workshop Manual procedure when torqueing thread forming fasteners and follow torque specification as listed.

Make sure the fastener is fully seated against the mating component with no gap during reassembly.

Corrosion

During fastener replacement, inspect both fastener and mating component for signs of rust or other corrosion. If corrosion is

found, replace corroded components with new components.

Stripped Threads

If internal (mating component) threads or external (fastener) threads appear stripped or galled, replace both fastener and

mating component. When tightening, if minimum torque is not reached, internal threads on mating component may have

stripped. Remove the fastener to inspect and replace mating component if stripped threads are found.

Face Seals

When replacing fasteners, inspect mating component surface for debris, damage, disturbance, wear, or abrasion and replace

any seals or gaskets if damage is found.

SEALS AND GASKETS

Replace seals and gaskets, unless specified differently in the procedure.

EXTERIOR TRIM PARTS

Replace exterior trim parts fastened with glue or adhesive tape, unless specified differently in the procedure.

Mechanical Procedures

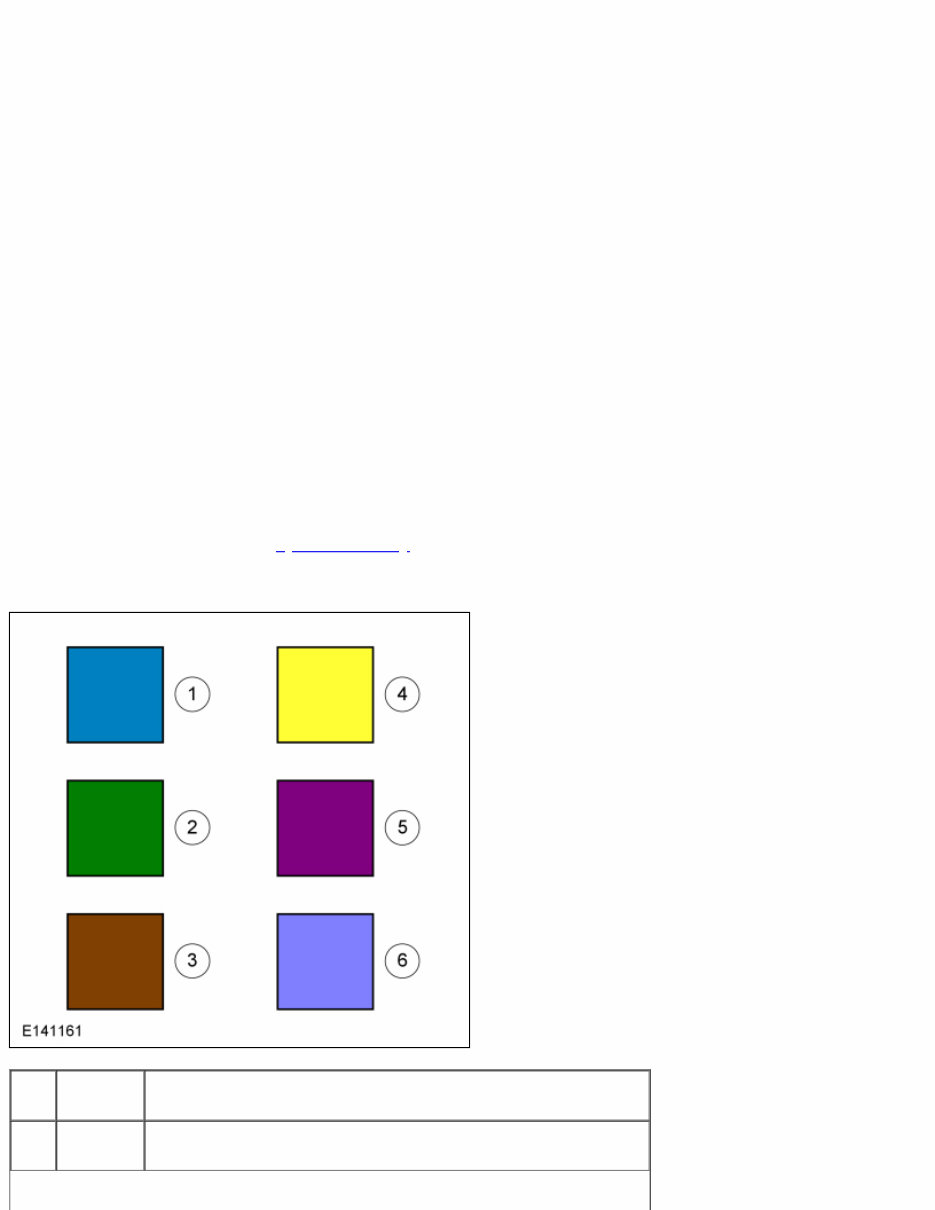

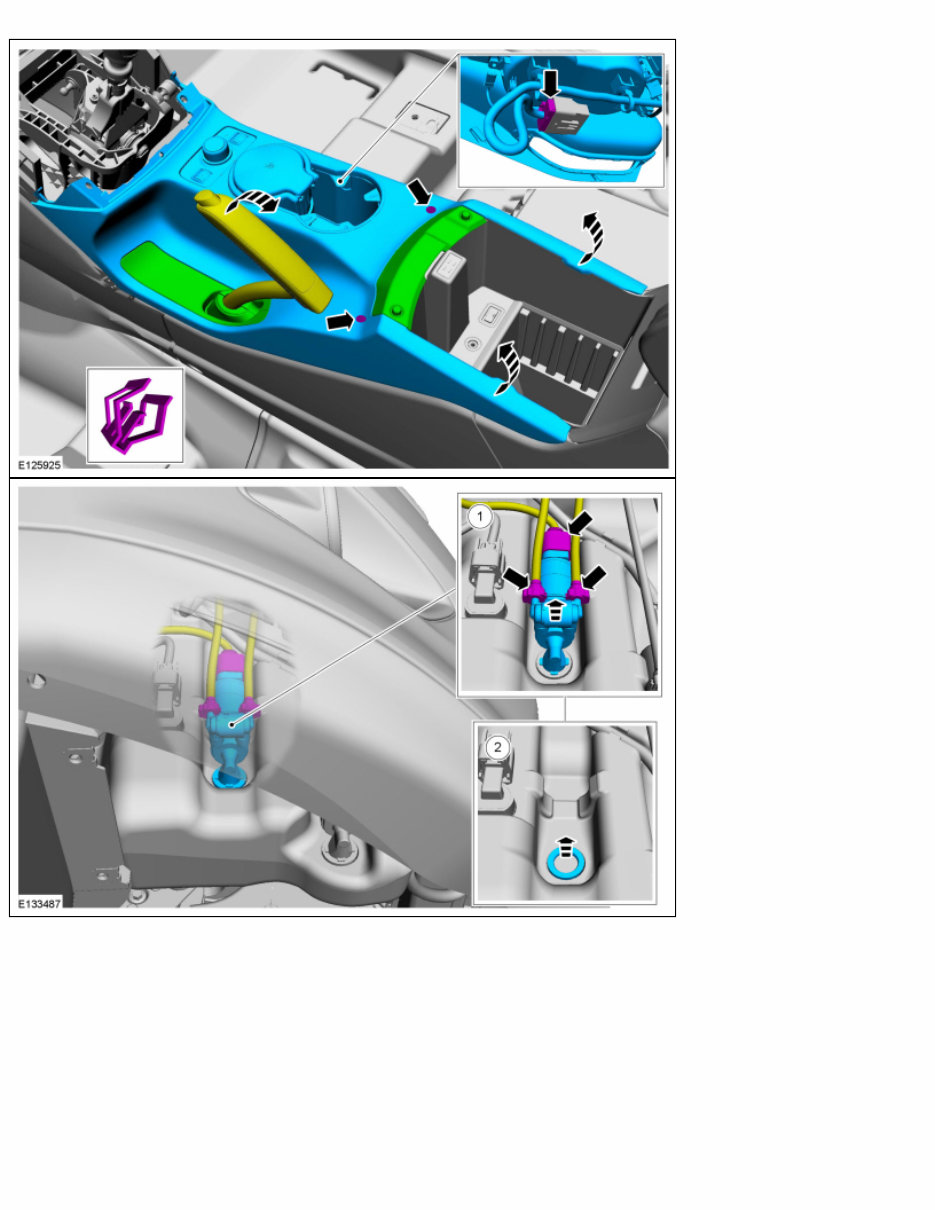

Illustrations in this manual may be used instead of written step instructions. Color-coding (see color scheme illustration) is

used to communicate the required step action or actions. Service action icons may be used to add information regarding the

required action.

For additional information, refer to: Symbols Glossary (100-00 General Information, Description and Operation).

Illustration Color-coding

Item

Part

Number Description

1 — Blue - Target or primary component to be removed/installed (or

disassembled/assembled).

2 — Green - Components that need to be removed prior to or installed

after the target/primary.

3 — Brown - Components that need to be removed prior to or installed

after the target/primary.

4 — Yellow - Components to be set aside for access, but not removed.

Also highlighted areas to inspect or adjust.

5 — Magenta - Electrical connectors and fasteners such as nuts, bolts,

clamps, or clips to be: detached, attached, loosened, moved,

removed or installed.

6 — Pale Blue - Special tool(s), general equipment, or common tools

used in an uncommon way.

Other color coding

Alternating Blue and White

Chemical, adhesive or sealer apply areas

Red

Sectioned or cut-away areas

Grey

Background components shown for location information

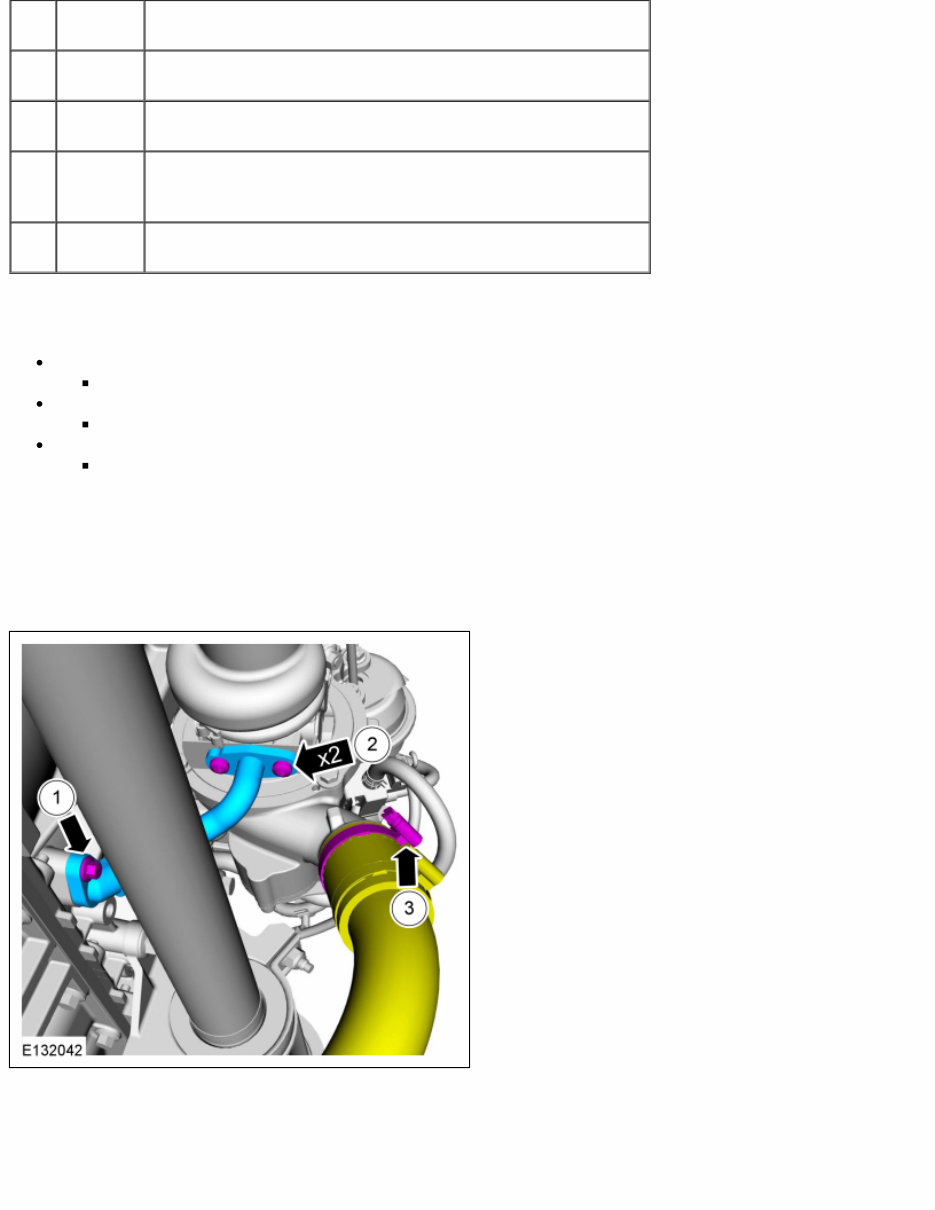

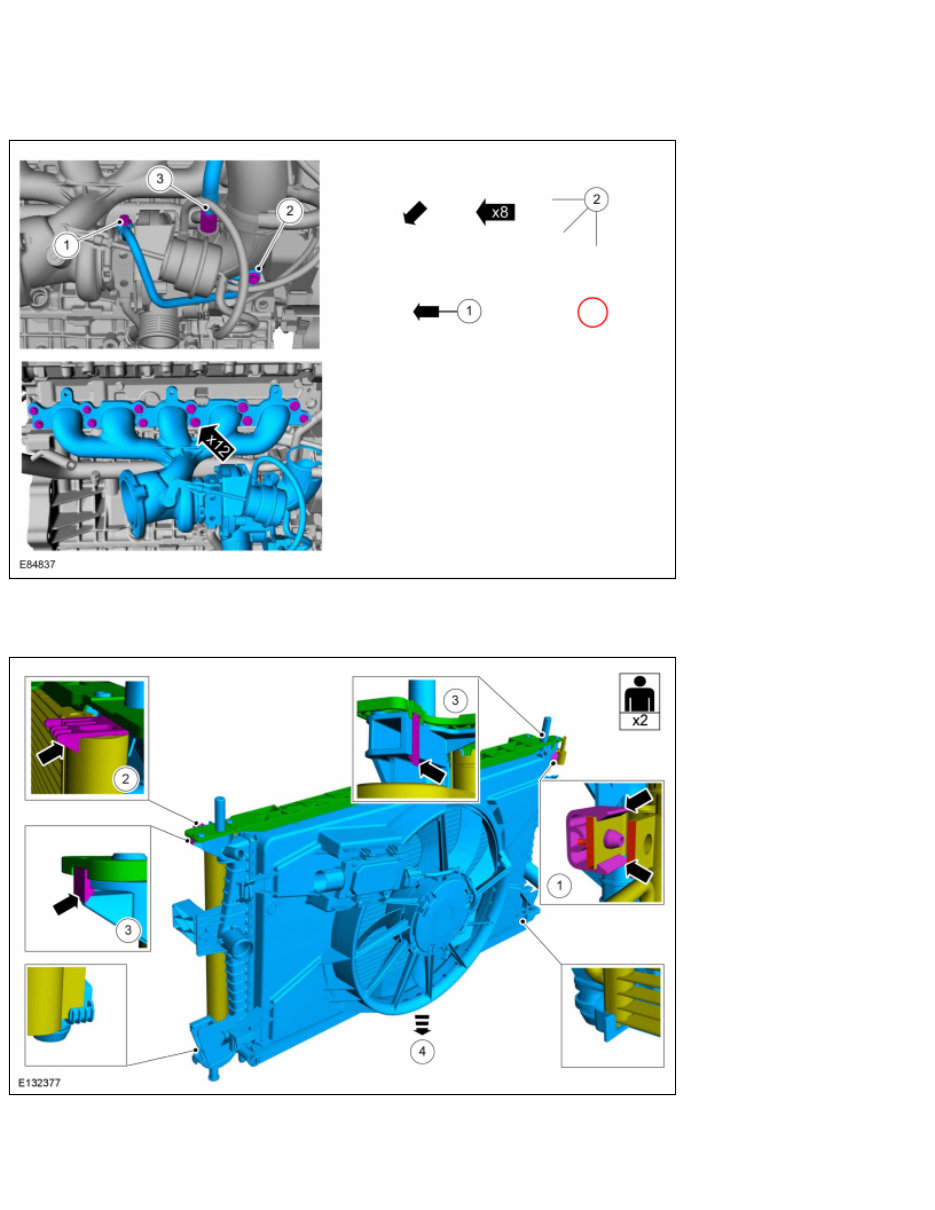

ILLUSTRATION TASK SEQUENCE

Components that must be removed or installed in a specific sequence are identified with a numbered callout. Any associated

step text is numbered accordingly.

Simple procedure example showing color-coding and task sequence.

Black arrows are used to draw attention to components (usually fasteners). Arrows with multiples specified (here, x2)

identify an identical number of fasteners or items. Callouts (numbers inside circles) show a required sequence or tightening

torque.

In the illustration, the callouts indicate the removal sequence, which is reversed for installation. The yellow coloring of the

hose indicates it is to be positioned aside (not removed). Two identical (magenta-colored) fasteners are indicated by the x2

arrow. The fasteners in this illustration require different torques (same torque for the x2 fasteners) so numbered callouts are

used to identify them with torque values in the associated step text. The (magenta-colored) hose clamp is another fastener to

be removed.

Examples of fastener removal sequence and an identical service action for 12 fasteners. Other possible symbols are

shown on the right.

Example of fastener sequence information with two persons required for the service action

HIDDEN DETAILS

Separate detail boxes or transparent components may be used to show hidden items in an illustration.

Example of hidden fastener information

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$37.99

$49.99

Viewed 14 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$37.99

$49.99

The 2017 Ford Escape - M2 (C520 NA) manual provides in-depth technical information for both professional mechanics and DIY enthusiasts. This comprehensive guide covers troubleshooting, repair, and maintenance procedures for the vehicle, allowing readers to gain a deeper understanding of its inner workings.

- Gain knowledge on the vehicle's systems, components, and assemblies

- Learn step-by-step procedures for troubleshooting and repair

- Discover detailed specifications and diagrams for maintenance and repair

- Suitable for professionals, technicians, and dedicated DIY enthusiasts

With this manual, you'll be equipped to address complex issues and perform comprehensive maintenance, enabling you to keep your Ford Escape in optimal condition and extend its lifespan.