Start Mod el

Spa re P arts

S.T. Sc hed ul e

Worksh op Manual

Body Repa ir Manual

Graphic Na vig a tion

Electri c al Syst em

Troubl es h oo ting

Language

To start the consultabon, please select one of the secbons of the left menu.

-----------------------------------

1.1 Ferrari quality standards

When manufacturing a Ferrari vehicle, the primary goal is “to

achieve optimum product quality”. Consequently Ferrari defines

a number of quality standards. These quality standards apply

both to production and especially to customer service.

In the event of accident repairs, crash safety must be an absolute

priority. To maintain optimum crash safety, all structural work

must be done correctly as indicated.

The repair work may only be carried out by Ferrari-trained and

certified skilled personnel.

Only genuine parts should be used when carrying out the

repair. They have been tested by Ferrari and are compatible

for use with aluminium.

Follow the procedures exactly as given in the repair manual.

Any deviations from the procedures are permitted only after

consultation with and approval by Ferrari.

Using non-approved repair methods may compromise the

crash performance of the vehicle. This may ultimately lead to a

non-foreseeable safety and product liability risk.

Only Ferrari-approved tools may be used to carry out accident

repairs.

It is essential that corrosion prevention measures are performed

during and after the repair.

Copyright © 2010

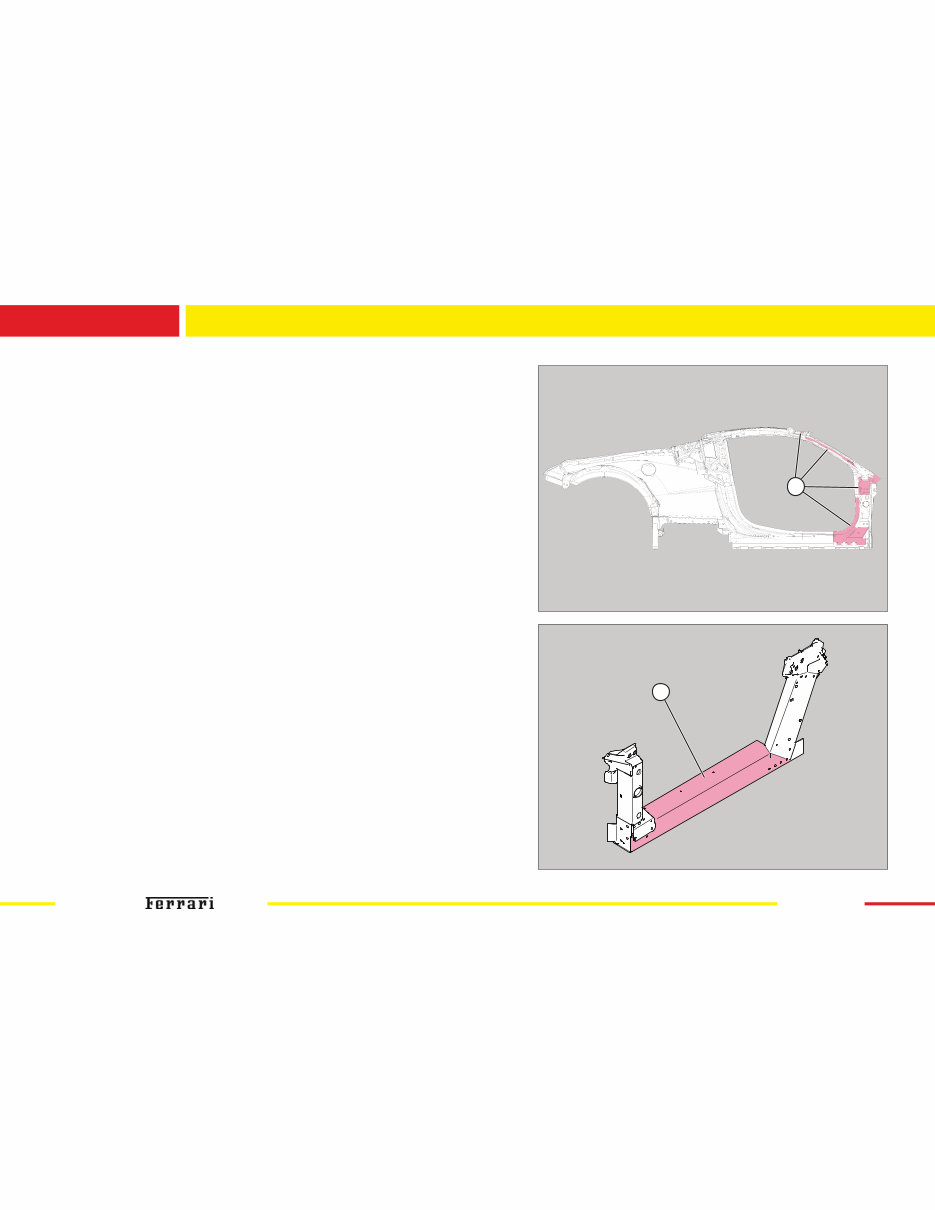

1.2 The bodywork concept of the Ferrari F458 Italia

In addition to extruded members, aluminium parts and sheet

metal elements, the Ferrari F458 Italia also features new joint

reinforcements for the space frame structure; together, they

form the bodywork structure.

These ultra-high strength steel reinforcements (A) , installed

in the two A -pillars, offer occupants greater safety in critical

situations.

A

The ultra-strong extruded sections of the A -pillars are concealed

below the steel reinforcements. The sections are joined to the

extruded members of the sill (B) by die-cast node joints.

The sill (B) of the Ferrari F458 Italia is oversized, as on a

B

cabriolet type vehicle. This means that the Ferrari F458 Italia

makes no compromises where crash safety is concerned.

Copyright © 2010

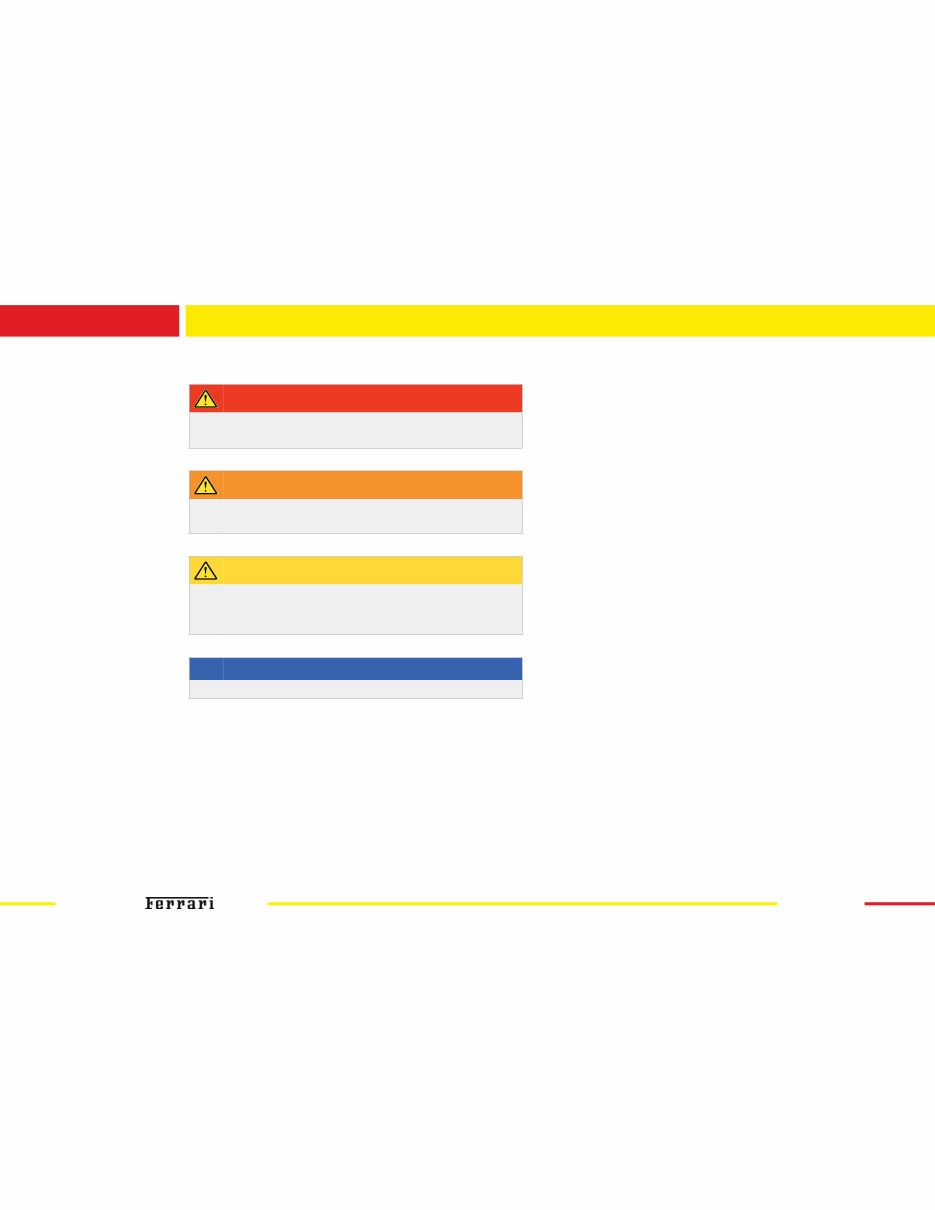

1.3 General safety instructions

Explanation of safety instructions

Danger!

“Danger” indicates imminent hazards that may result

in death or serious injury.

Warning!

“Warning” indicates potential hazards that may result

in death or serious injury.

Caution!

“Caution” indicates potential hazards that may result

in slight injury.

This symbol also indicates hazards to property.

NOTE!

“Note” indicates important information.

Copyright © 2010

1.3 General safety instructions

When carrying out any of the procedures described in this 1.3.2 Handling body and assembly components with sharp

repair manual, please observe all national accident safety

edges

regulations.

1.3.1 Lifting vehicles

Caution!

Risk of injury from sharp-edged burrs on body and

accessories.

Danger!

Risk of death from the vehicle toppling or slipping off

the vehicle lift.

• Align vehicle centrally between the vehicle lift columns.

• Raise the vehicle only at the specific locating points.

• Ensure the lifting pads are seated correctly, lifting the

vehicle slowly while monitoring the vehicle visually.

• Before removing any components and significantly shifting

the centre of gravity of the vehicle, ensure that the vehicle

itself is securely fastened to the vehicle.

Copyright © 2010

• Always wear protective gloves when working in the vicinity

of sharp-edged body and assembly components.

1.3 General safety instructions

1.3.3 Working in presence of aluminium dust

Warning!

Risk of explosion from high concentrations of aluminium

dust. Risk of injury from breathing in fine particulate.

• When carrying out any work that creates fine particles of

dust, wear a fine dust mask, safety goggles and protective

gloves.

• Any grinding work must be carried out with explosion-

protected air extraction systems; do not blow off dust

deposits with compressed air.

• Clean the work area and the extraction system regularly.

• To prevent a dust explosion, all extraction systems must

be earthed and suitable powder extinguishers must be

provided.

• Any vehicle parts in the repair area which may be damaged

by dust should be removed from the area or covered with

fire-resistant covers.

Copyright © 2010

1.3.4 Handling batteries

Warning!

Risk of explosion and fire from flying sparks during

grinding and welding work. Risk of damage to vehicle

components and other vehicles from flying sparks.

• Before carrying out any welding work, always remove both

battery terminal clamps and cover the battery terminals.

• Remove the vehicle battery before carrying out any work

that may produce sparks in the vicinity of the battery itself.

• Disconnect the battery earth strap when carrying out any

vehicle body repair work and when working on the airbag

system.

1.3 General safety instructions

1.3.5 Grinding and welding • When welding, wear suitable, non-flammable protective

clothing and gloves.

Warning!

Risk of explosion and fire when welding in the vicinity

of highly flammable substances. Irritation of the

respiratory tract caused by toxic gases produced

during welding. Risk of injury from the extremely bright

arc and welding splashes when welding. Risk of injury

as a result of inadvertent activation of pyrotechnic

safety components.

Risk of explosion and fire from flying sparks during

grinding and welding work. Risk of damage to vehicle

components and other vehicles from flying sparks.

• When carrying out grinding and welding work around the

fuel tank or fuel-carrying parts, ensure that these parts do

not heat up. If in doubt, remove such parts.

• Cover the grinding and welding area with fire-resistant

covers.

• Use the specific visor when welding.

• Partition off workstations with spark protection curtains.

• A fire extinguisher must always be accessible in the

immediate vicinity of the welding area.

• Remove or cover any vehicle parts located in the repair

area.

• Always carry out grinding and welding work with an

extraction system.

• Clean the air extraction system at regular intervals.

• Never carry out welding and grinding work at the same time

in the same room.

Copyright © 2010

1.3 General safety instructions

1.3.6 Removing sealants

Danger!

Risk of death from inhaling toxic vapours. Risk of burns

in the event of direct skin contact with hydrochloric

acid.

• Hydrochloric acid is produced when PVC sealant is heated

to over 180 °C.

• PVC sealant must only be removed with a rotary wire

brush or by heating to max. 180 °C with a hot air gun and

removing with a spatula.

• Always wear a dust mask and protective goggles when

removing sealant with a rotary brush.

• Always ensure there is sufficient air extraction and fresh air

ventilation.

Copyright © 2010

1.3.7 Handling chemicals

Caution!

Handling chemicals may cause allergic skin and

respiratory tract reactions.

• Always ensure that there is sufficient air extraction

and ventilation, and extract any vapours released by

adhesives.

• Prevent chemicals from coming into direct contact with the

eyes and skin.

• Wear protective gloves, protective goggles and, where

necessary, an apron.

• Immediately change out of work clothes that are soiled with

adhesive or solvent.

• At the end of the job, wash your hands and apply protective

cream.

• Always keep a bottle of eye wash ready for use.

• Only store adhesive products in the safety cupboard and

keep them away from naked flames and other sources of

ignition.

1.3 General safety instructions

1.3.8 Working with the air conditioning system

Warning!

Risk of injury from the charged air conditioning system

exploding during welding work.

Do not weld, solder or work with a hot air gun in the vicinity of

the components of a charged air conditioning system. Similarly,

do not perform any welding work on a vehicle if the work will

cause parts of the air conditioning system to heat up.

When carrying out a paint repair, object temperatures in the

drying oven or preheating zone must not exceed 80 °C as

the overpressure caused by heating process may cause the

system to explode.

Copyright © 2010

1.3.9 Handling the airbag system

Caution!

Risk of injury from activation of airbag units if earth

strap is not disconnected.

Disconnect the battery earth strap when carrying out any vehicle

body repair work and when working on the airbag system.

Wash hands thoroughly after touching airbag units that have

been fired.

1.3.10 Working with tools

Warning!

Risk of injury. All tools pose potential hazards to health

and life. Always observe the safety instructions and

warnings of the tool manufacturers.

1.4 Important information

1.4.1 Assessing the extent of the damage 1.4.2 Instructions for body repairs

In the case of accidents involving substantial areas of the

vehicle, examine the following components carefully to

prevent any damage to vehicle or suspension parts from going

undiscovered:

• Check tyres and wheel rims for damage.

• Check that the steering tie-rod, steering linkages and

steering system are working correctly. Also check for

external damage and cracks.

• Check all chassis components, such shock absorbers,

suspension and steering joints, links, axles, anti-roll bars

and their fasteners, for external damage or cracks.

• Check brake system components such as brake discs,

brake pads, brake callipers, hydraulic lines and hydraulic

hoses and their respective fastenings for external damage,

stretching or leaks.

• Check engine, gearbox, axle and exhaust system mounts

for damage.

• Before returning the vehicle to the customer following a

repair, test drive the vehicle carefully to ensure that it is

roadworthy.

• Repair work on the Ferrari F458 Italia must only be carried

out by repair personnel who have been trained, tested and

certified by the Ferrari Customer Service department.

• Use only Ferrari-approved tools, spare parts and

consumables for repair and maintenance work.

• If, in the course of the repair work, special cases arise that

are not envisaged by the repair instructions, contact the

Ferrari Technical Customer service to establish how to

proceed further.

• All the main repair operations possible for the Ferrari

F458 Italia are described in this repair manual. Combined

instructions may be used to differentiate between different

repair procedures. Only the right or left hand components

are illustrated in the description of a repair.

• To ensure that the original crash safety of the vehicle is

maintained after a body repair, always used the same

chassis joint points.

• Cuts that may affect the crash safety of the body, and

thereby the safety and roadworthiness of the vehicle, must

always be approved by Ferrari.

Copyright © 2010

You're Reading a Preview

What's Included?

Lifetime Access

Access PDF Contents & Bookmarks

Print one or all pages of your manual