Dodge 46RE Transmission Service Workshop Shop Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

INTRODUCTION

46RE, 47RE, 48RE,

No part of any ATSG publication may be reproduced, stored in any retrieval system or transmitted in any form or

by any means, including but not limited to electronic, mechanical, photocopying, recording or otherwise,

without written permission of Automatic Transmission Service Group. This includes all text illustrations,

tables and charts.

The information and part numbers contained in this booklet have

been carefully compiled from industry sources known for their

reliability, but ATSG does not guarantee its accuracy.

Copyright © ATSG 2011

1st Printing

April, 2011

AUTOMATIC TRANSMISSION SERVICE GROUP

18635 S.W. 107 AVENUE

CUTLER BAY, FLORIDA 33157

(305) 670-4161

1

DALE ENGLAND

FIELD SERVICE CONSULTANT

ED KRUSE

TECHNICAL CONSULTANT

WAYNE COLONNA

PRESIDENT

PETER LUBAN

TECHNICAL CONSULTANT

JIM DIAL

TECHNICAL CONSULTANT

GREGORY LIPNICK

TECHNICAL CONSULTANT

JON GLATSTEIN

TECHNICAL CONSULTANT

DAVID CHALKER

TECHNICAL CONSULTANT

GREG CATANZARO

TECHNICAL CONSULTANT

GERALD CAMPBELL

TECHNICAL CONSULTANT

We wish to thank Chrysler® Group for the information that has made this booklet possible.

The 46RE, 47RE and 48RE family of transmissions by the Chrysler Group, are fitted behind a wide variety of

engine sizes, including diesel, and across various vehicle lines. They are also available in 2WD and 4WD

configurations. Beginning at the start of production for model year 2005, Dodge trucks equipped with the 5.9L

diesel and 48RE transmission were equipped with an electronically controlled Transmission Throttle Valve

Actuator (TTVA). This Actuator has replaced the previous Throttle Valve Cable and all associated linkage.

A push-in Transmission Range Sensor was implemented in model year 2002 to replace the screw-in Park/Neutral

switch.

The 46RE, 47RE and 48RE transmissions are all four speed fully automatic units with an electronic governor.

They are equipped with a lock-up clutch in the torque converter. First through third gear ranges are provided by the

clutches, bands, low-roller clutch, and planetary gearsets in the transmission. Fourth gear is provided by the

overdrive unit (rear section) that contains an overdrive clutch, OD/direct clutch, overrun roller clutch, and planetary

gearset.

These units contain a front (direct) clutch, rear (forward) clutch, and OD/direct clutch which serve as the input

driving components. They also contain a kickdown (front) band, low/reverse (rear) band, overrun clutch, and the

overdrive clutch which serve as the holding components.

INDEX

DODGE, JEEP

46RE, 47RE, 48RE

2

Copyright © ATSG 2011

AUTOMATIC TRANSMISSION SERVICE GROUP

18635 S.W. 107 AVENUE

CUTLER BAY, FLORIDA 33157

(305) 670-4161

3

5

6

6

7

10

14

17

18

19

20

26

28

33

34

36

40

42

57

63

69

73

79

85

98

115

122

124

125

125

130

134

142

144

GENERAL DESCRIPTION AND VEHICLE APPLICATION CHART ....................................

INTERNAL COMPONENT LOCATIONS ..................................................................................

COMPONENT APPLICATION CHART, ID TAG LOCATION ................................................

FLUID SPECIFICATIONS ..........................................................................................................

EXTERNAL ELECTRONIC COMPONENTS ............................................................................

TRANSMISSION THROTTLE VALVE ACTUATOR WIRE SCHEMATIC .............................

CONTROL MODULE LOCATIONS ............................................................................................

ELECTRICAL CONNECTOR AND TERMINAL IDENTIFICATION .....................................

TRANSMISSION CONTROL RELAY INFORMATION ............................................................

TOW/HAUL-OVERDRIVE CANCEL SWITCH .........................................................................

VEHICLE WIRE SCHEMATICS ................................................................................................

DIAGNOSTIC TROUBLE CODES ..............................................................................................

INTERNAL ELECTRONIC COMPONENTS .............................................................................

LINE PRESSURE SPECS AND PRESSURE TAP LOCATIONS ..............................................

ELECTRONIC GOVERNOR INFORMATION ..........................................................................

GOVERNOR SOLENOID AND SENSOR DIAGNOSIS ............................................................

CASE PASSAGE IDENTIFICATION .........................................................................................

TRANSMISSION DISASSEMBLY ..............................................................................................

COMPONENT REBUILD

TRANSMISSION CASE ASSEMBLY ..................................................................................

OIL PUMP ASSEMBLY ........................................................................................................

FRONT (DIRECT) CLUTCH HOUSING ASSEMBLY .......................................................

REAR (FORWARD) CLUTCH HOUSING ASSEMBLY .....................................................

TRANSMISSION GEARTRAIN ASSEMBLY ......................................................................

OVERDRIVE UNIT ASSEMBLY .........................................................................................

OVERDRIVE ROLLER CLUTCH FREEWHEEL DIRECTION .......................................

CHECK BALL LOCATIONS .................................................................................................

VALVE BODY ASSEMBLY ...................................................................................................

VALVE BODY ADJUSTMENTS ...........................................................................................

TRANSMISSION ASSEMBLY .....................................................................................................

LOW ROLLER CLUTCH FREEWHEEL DIRECTION ............................................................

BAND ADJUSTMENTS ...............................................................................................................

OVERDRIVE SELECTIVE MEASUREMENTS ........................................................................

THRUST WASHER AND THRUST BEARING LOCATIONS ..................................................

TORQUE SPECIFICATIONS ......................................................................................................

GENERAL DESCRIPTION

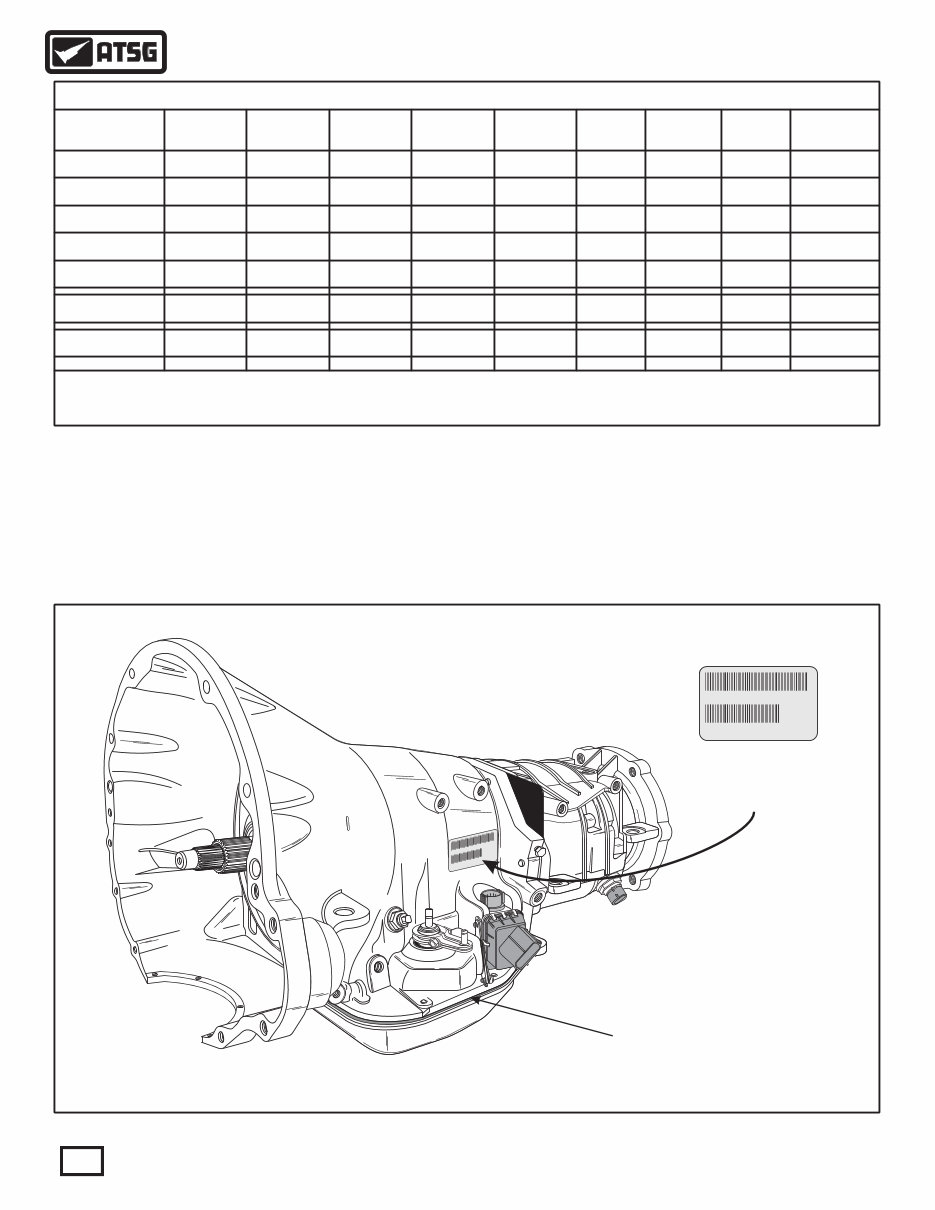

Figure 1

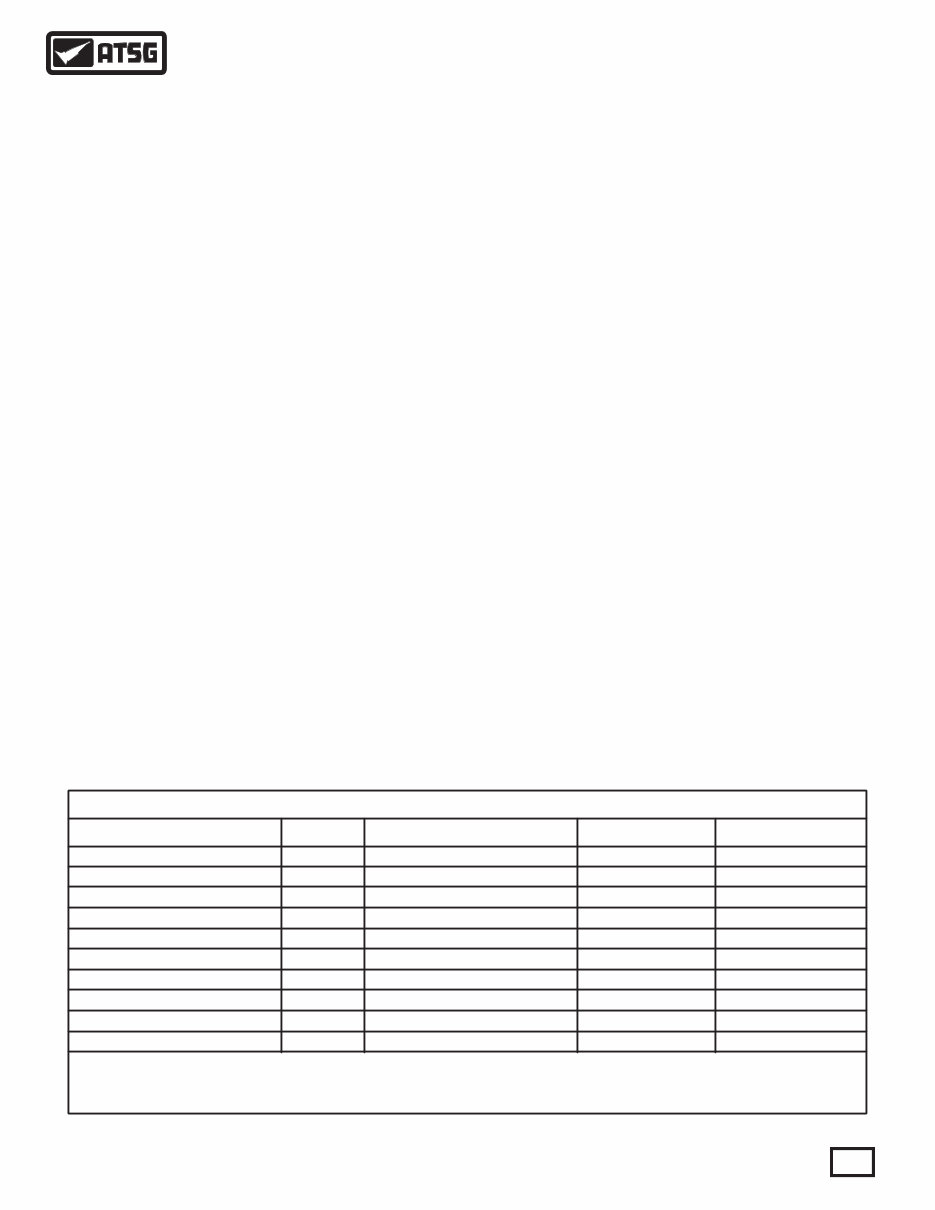

VEHICLE APPLICATION CHART

VEHICLE YEAR ENGINE COUNTRY TRANSMISSION

GRAND CHEROKEE

DODGE, DURANGO

DODGE, RAM PICK-UP

DODGE, RAM PICK-UP

DODGE, RAM PICK-UP

DODGE, RAM PICK-UP

DODGE, RAM PICK-UP

DODGE, VAN/WAGON

DODGE, DAKOTA

1998

1998-03

1995-02

1995-02

1995-02

2003-07

2003-07

1995-03

1998-00

4.7L (V8)

5.9L, (V8)

5.2L, 5.9L, (V8)

5.9L, (Diesel)

8.0L (V10)

5.9L (Diesel)

8.0L (V10)

5.9L, (V8)

5.2L (V8)

USA,

USA,

USA, MEX,

USA, MEX,

USA, MEX,

USA, MEX,

USA, MEX,

USA,

CAN, MEX,

46RE

46RE

46RE

47RE

47RE

48RE

48RE

46RE

46RE

3

Copyright © 2011 ATSG

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

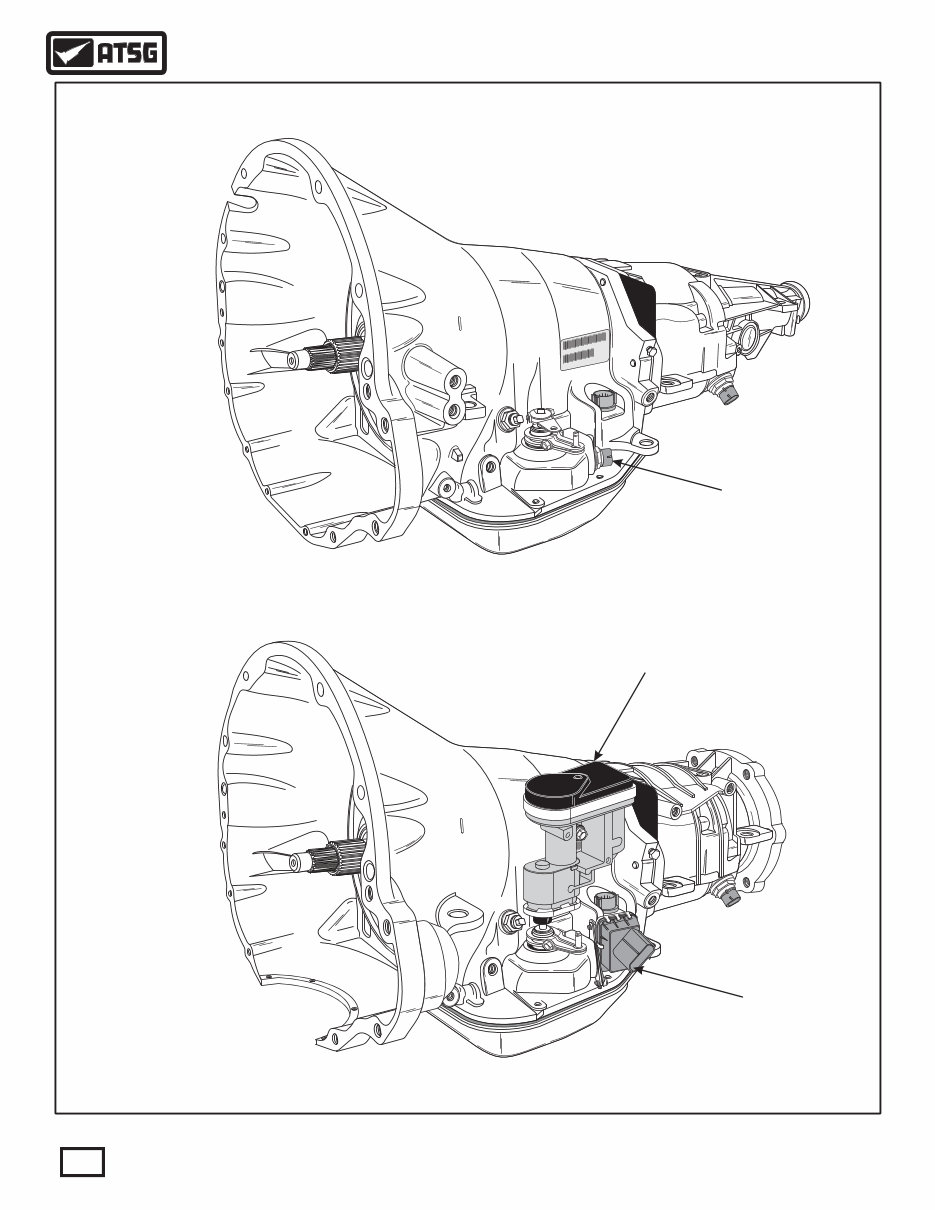

The 46RE, 47RE and 48RE family of transmissions by

the Chrysler Group are fitted behind a wide variety of

engine sizes and across various vehicle lines, as shown

in Figure 1. They are also available in 2WD and 4WD

configurations, as shown in Figure 2. Notice also in

Figure 2, at the start of production for model year 2005,

Dodge trucks equipped with the 5.9L diesel and 48RE

transmission, were equipped with an electronically

controlled Transmission Throttle Valve Actuator

(TTVA). This Actuator has replaced the previous

Throttle Valve Cable and all associated linkage. The

push-in Range Sensor was implemented in model year

2002.

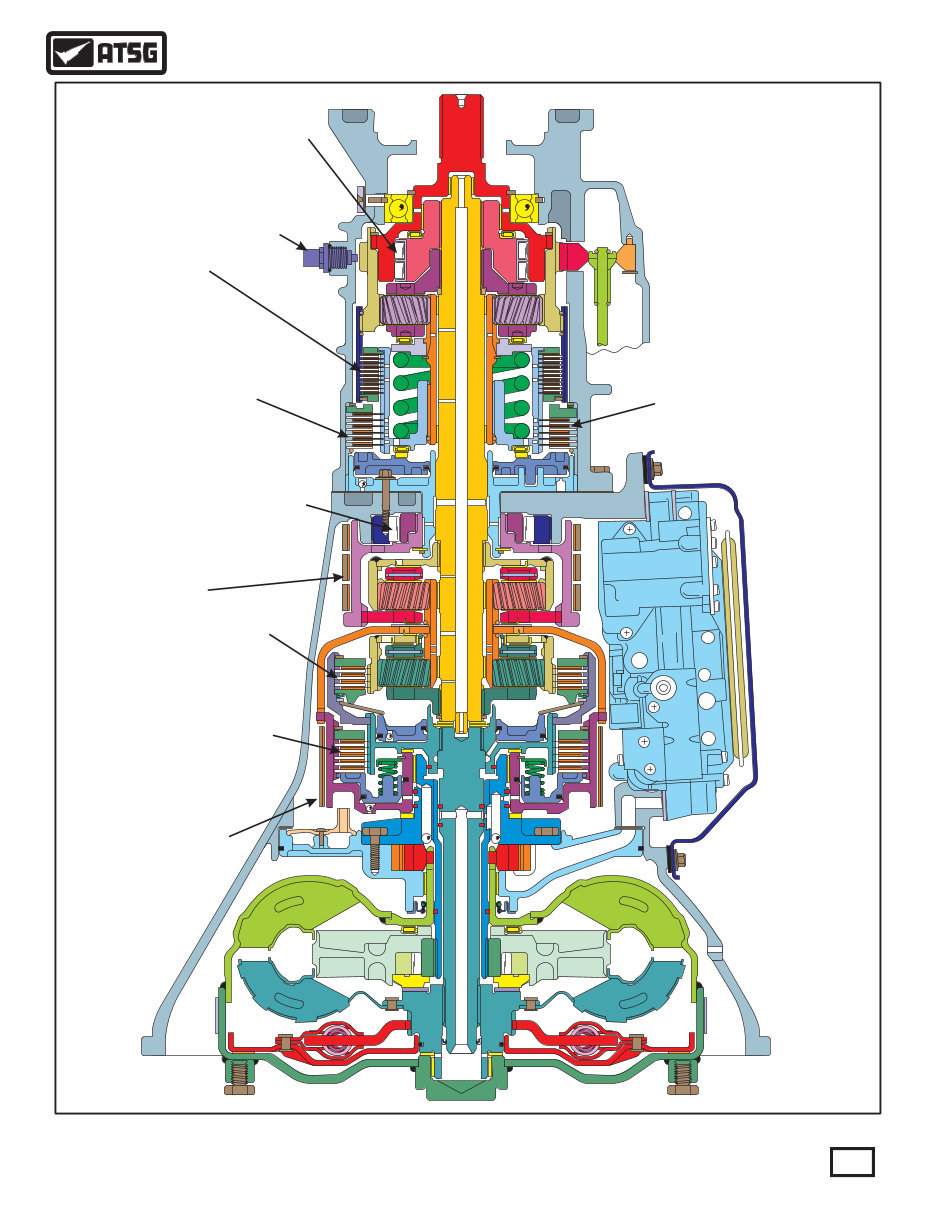

The 46RE, 47RE and 48RE transmissions are all four

speed fully automatic units with an electronic governor.

They are equipped with a lock-up clutch in the torque

converter. First through third gear ranges are provided

by the clutches, bands, low-roller clutch, and planetary

gearsets in the transmission. Fourth gear is provided by

the overdrive unit (rear section) that contains an

overdrive clutch, OD/direct clutch, overrun roller

clutch, and planetary gearset. Refer to Figure 3 for the

internal component locations and identification.

These units contain a front clutch, rear clutch, and

OD/direct clutch which serve as the input driving

components. They also contain a kickdown (front)

band, low/reverse (rear) band, overrun clutch, and the

overdrive clutch which all serve as the holding

components.

The driving and holding components combine to select

the necessary planetary gear components in the front,

rear, or overdrive planetary gearset and transfer the

engine power from the input shaft through to the output

shaft. Refer to Figure 4 for the component application

chart for which component is applied for each gear.

First, second and third gear shifts are controlled by an

electronic governor solenoid, that is mounted on the

valve body assembly. The shift into fourth gear and

torque converter clutch are controlled by individual

seperate solenoids that are also mounted on the valve

body assembly.

The valve body is mounted on the lower side of the

transmission and contains the valves necessary for

pressure regulation, fluid flow control and clutch or

band application. The valve body assembly has

received several upgrades and changes over the years.

The oil pump is mounted at the front of the

transmission and is driven by the torque converter hub.

The oil pump supplies the pressure necessary for clutch

and/or band application and transmission lubrication.

PK5 54 8AA 97 58 28 23 2 4 1 9

2

2

3

3

8

8

6

6

K 9 F1 9 TP TK 7 5 2 4 8

2 4 8 K 8 2 A P 5 5 3 A

3 28

AA

SIEMENS VDO

SIEMENS VDO

0

0

6

6

4

4

1

1

PK52 4238 A 297 589 85 A 41

K 94 8 TP TK 7 F1 9 2 5

2 P 5 5 3A K2 4 8 A 8

28 3

A A

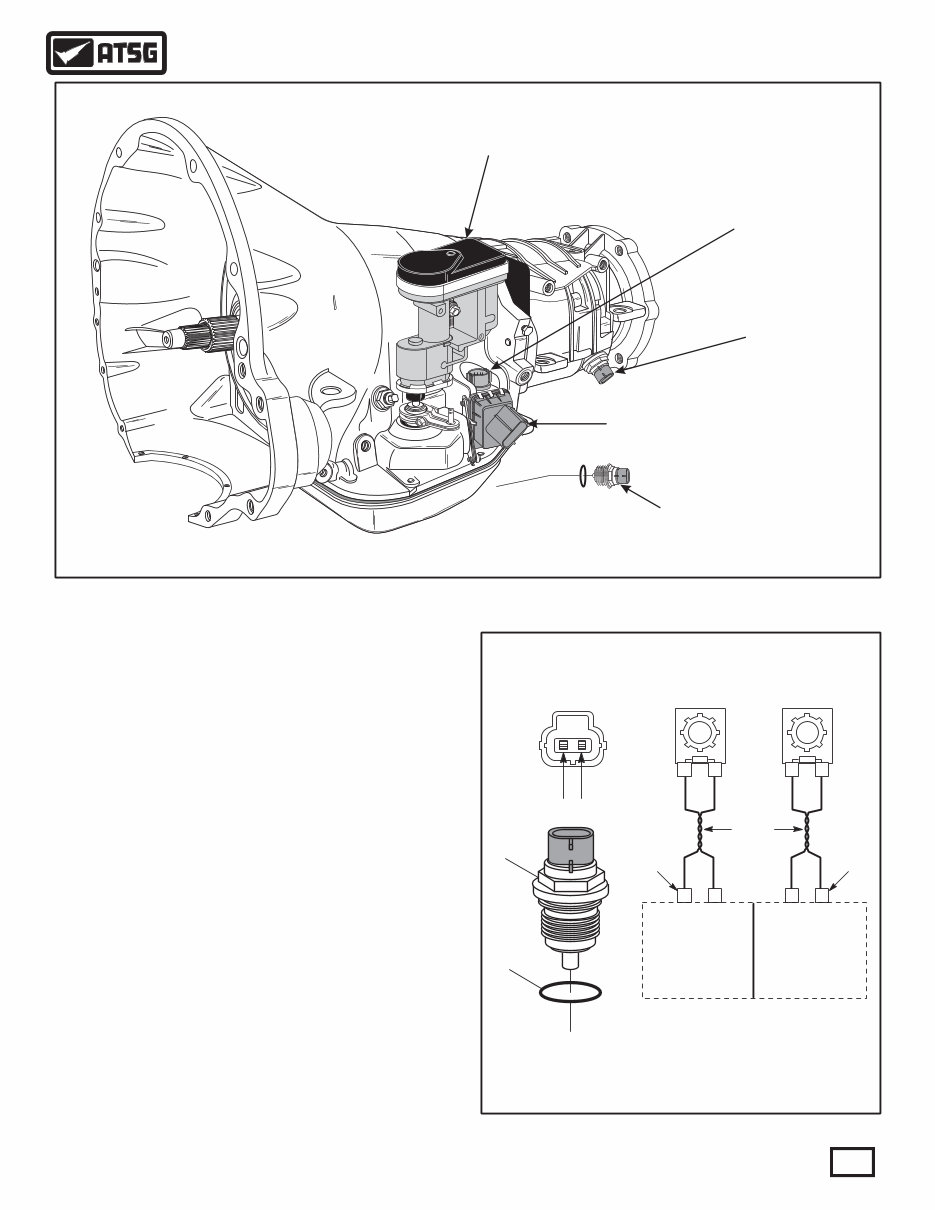

Figure 2

4

Copyright © 2011 ATSG

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

2WD Gas

Version

4WD Diesel

Version

Some Models Equipped With

Screw-In P/N Switch

(1995-2001 Models)

Some Models Equipped With

Push-In Range Sensor

(2002-Up All Models)

Throttle Valve Acuator

(2005-Up Diesel Models Only)

5

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

Copyright © 2011 ATSG

Figure 3

INTERNAL COMPONENT LOCATION AND IDENTIFICATION

FRONT

(INTERMEDIATE)

BAND

REAR

(LOW/REVERSE)

BAND

LOW ROLLER

CLUTCH

FRONT

(DIRECT)

CLUTCH

REAR

(FORWARD)

CLUTCH

OVERDRIVE

CLUTCH

(Diesel)

OVERDRIVE

CLUTCH

(Gasoline)

OVERDRIVE

ROLLER

CLUTCH

OUTPUT

SPEED

SENSOR

OVERDRIVE/DIRECT

CLUTCH

PK5 4 29 15 285 238AA 74 89

2

2

3

3

8

8

6

6

K 9 F1 TK 7 59 TP 2 4 8

2 4 K 8 2 8A P 5 5 3 A

3 28

A A

COMPONENT APPLICATION CHART

Gear Ratio

2.20

2.45

2.45

1.45

1.45

1.00

0.69

Front

Clutch

Front

Band

Rear

Clutch

Rear

Band

Low-Roller

Clutch

Overdrive

Clutch

OD/Direct

Clutch

OD Roller

Clutch

Reverse

OD-1st

Man-1st

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

Hold

Hold

ON

ON

ON

ON Hold

Hold

Hold

Hold

Hold

ON

ON

ON

ON ON ON

OD-2nd

Man-2nd

OD-3rd

OD-4th

Note: The torque converter clutch may be applied in 3rd or 4th gears. The torque converter clutch may also be engaged in Manual 2nd

gear position, if high transmission temperatures are detected by the TCM/PCM/ECM.

Figure 4

Figure 4A

Bar Code Label

Located Here

ID Numbers Also Etched Into

Case Pan Rail Here

IDENTIFICATION TAG LOCATION

IDENTIFICATION TAG AND FLUID REQUIREMENTS

Fluid Requirements

"ATF+4"

Copyright © 2011 ATSG

TPKTK2974F1589

PK52854238AA

238

AA

The Bar Code Label is located on the left hand side of

the transmission case, as shown in Figure 4A.

Transmission identification numbers are also etched

into the left side of case pan rail just above the oil pan

gasket, as shown in Figure 4A. Always refer to this

information when ordering replacement parts.

These units require "ATF+4" fluid, as shown in Figure

4A.

6

Copyright © 2011 ATSG

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

PK52854238AA 2974 1589

Part

Number

Build

Date

Serial

Number

{

{

{

7

Copyright © 2011 ATSG

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

EXTERNAL ELECTRONIC COMPONENTS

Output Speed Sensor (OSS)

PK5 54 8AA 97 58 28 23 2 4 1 9

2

2

3

3

8

8

6

6

K 9 F1 9 TP TK2 7 58 4

2 4 8 K 8 2 A P 5 5 3 A

3 28

AA

SIEMENS VDO

SIEMENS VDO

Throttle Valve Actuator

2005-Up Diesel Only

Output Speed

Sensor All Models

8-Way Case

Connector All Models

"Push-In" Range

Sensor 2002-Up

"Screw-In" Park/Neutral

Switch 1995-2001

EXTERNAL ELECTRONIC COMPONENT LOCATIONS

The Output Speed Sensor (OSS) is located in the

overdrive case housing, as shown in Figure 5, and is

positioned over the park gear. The OSS monitors

rotating speed of the output shaft.

The OSS is triggered by the external park lugs on the

rear planetary ring gear to determine the exact

transmission output shaft speed. The OSS signal, and

other inputs, are used by the TCM/PCM/ECM to

determine the required governor pressure for current

conditions. This has a direct effect on which gear is

chosen for the vehicle. The controller also uses this

information to schedule torque converter lock-up.

Should the OSS fail, the speed signal from the ABS

control module is used as a back-up, and code P0720

will be stored in TCM/PCM/ECM memory.

The OSS sensor and wire schematic for Gas and Diesel

is shown in Figure 6.

Figure 5

OUTPUT SPEED SENSOR (OSS)

Special Note:

The OSS is best checked using a scope under

operating conditions.

1

28

2

25

1

44

2

45

Twisted

Pair

C2

Conn

C2

Conn

OSS SIG

OSS GND

OSS GND

OSS SIG

ECM 2004-UP

(DIESEL)

PCM 1996-03

(GAS & DIESEL)

1 2

Output Speed Sensor

Harness Connector

(Face View)

13

14

Figure 6

13 OUTPUT SHAFT SPEED SENSOR (ALL MODELS).

14 OUTPUT SPEED SENSOR "O" RING SEAL.

Copyright © 2011 ATSG

8

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

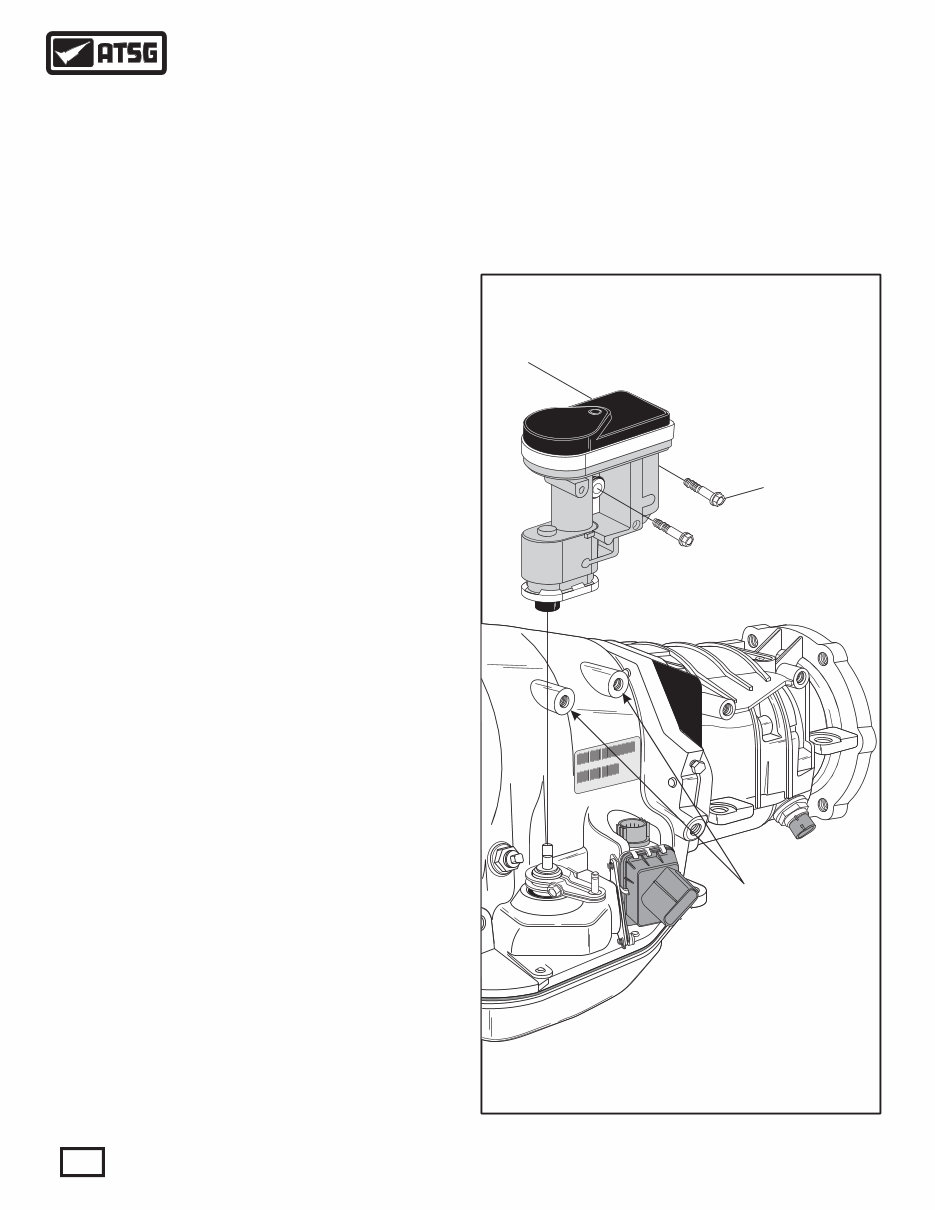

6 THROTTLE VALVE ACTUATOR (2005-UP DIESEL ONLY).

7 THROTTLE VALVE ACTUATOR BOLTS (2 REQUIRED).

6

7

EXTERNAL ELECTRONIC COMPONENTS (CONT'D)

Transmission Throttle Valve Acuator (TTVA)

Figure 7

Beginning at the start of production for the 2005 model

year, all Dodge trucks equipped with the 5.9L diesel

engine and the 48RE transmission, received an

electronically controlled Transmission Throttle Valve

Actuator (TTVA), as shown in Figure 7, for improved

shift control. The TTVA is mechanically connected to

the throttle valve in the valve body by the "D" shaped

opening in the bottom of the TTVA shaft and retained

with two mounting bolts, as shown in Figure 7. This

required two added bosses to the transmission case.

The TTVA has replaced the previous Throttle Valve

Cable and all associated mechanical linkage, on diesel

models only.

The TTVA consists of an electronic DC motor, two

potentiometers and a gear driven system that controls

all functions of the throttle valve in the valve body. The

position of the geartrain is monitored by the TTVA

Position sensor which supplies an input to the Engine

Control Module (ECM).

The TTVA is controlled by the ECM thru the inputs of

Accelerator Position Sensor 1 and 2. Refer to the charts

in Figure 8 for observed voltage and percent of opening,

from a working vehicle, of APP1 and APP2 to the

voltages that control the TTVA and the TTVA position

voltage feedback to the ECM. Refer to Figure 11 for

wiring schematic of the accelerator pedal position

sensor to assist you in the diagnosis process as

necessary.

Note: If the TTVA is removed or replaced, the ECM

will have to relearn it's "0" position. The ignition will

have to be turned on, with the engine off, for 30

seconds to accomplish "Auto Zero."

With the addition of the TTVA a new wiring harness was

required. Refer to Figure 10 for a partial wire schematic

of the TTVA and its connectors. Refer to Figure 9 for a

list of new Diagnostic Trouble Codes related to the

TTVA.

If a new case is required, it must be a 2005 or later case

because of the added bosses to the case to accommodate

the TTVA.

Added Case

Bosses

PK 85 238 A 29 4 89 52 4 A 7 15

K T K297 F1 9 P T 4 58

85 38A PK52 42 A

8 23

A A

SIEMENS VDO

SIEMENS VDO

Copyright © 2011 ATSG

9

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

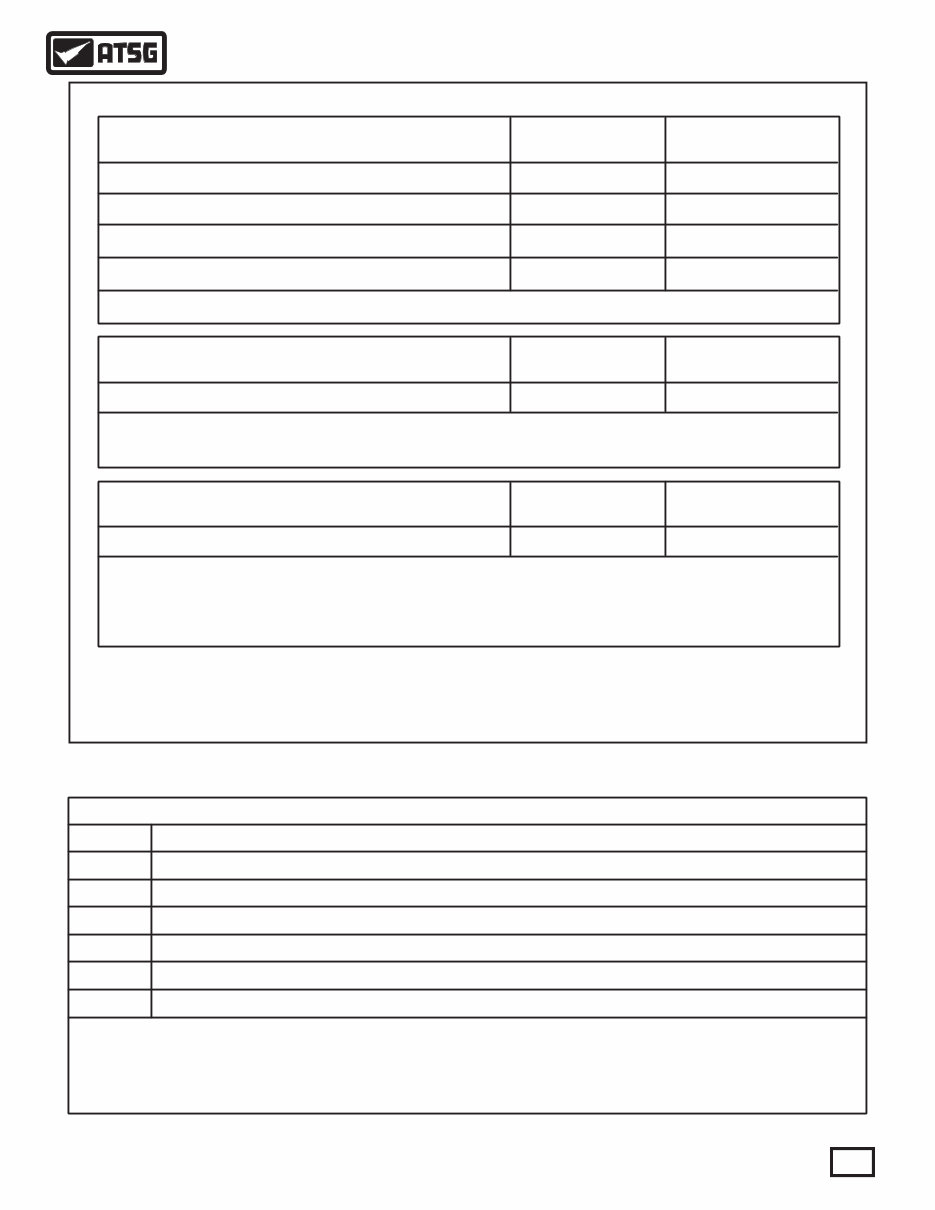

"OBSERVED" VOLTAGE AND PERCENTAGE CHARTS

TTVA Position Sensor (Voltage)

CLOSED

THROTTLE

TTVA POSITION SENSOR SIGNAL

WIDE OPEN

THROTTLE

3.78V .73V

Note: TTVA motor control and TTVA position sensor are subject to change, and there are no adjustments. The ECM will

re-calibrate its current "0" position when the ignition is turned on and the engine not running for 30 seconds.

TTVA + (Voltage)

CLOSED

THROTTLE

TTVA MOTOR VOLTAGE

WIDE OPEN

THROTTLE

2.0 -2.5V 0 -.70V

Note: Using a DVOM set to DC volts, backprobe terminal number 8 at the ECM C1 60-way connector with the red probe and

the black probe to a good ground (See Figure 10).

Note: On 2005 diesel models only, using a DVOM set to DC volts, backprobe terminal number 35 at the ECM C1 60-way

connector with the red probe and the black probe to a good ground (See Figure 10).

Note: On 2006-Up diesel models only, using a DVOM set to DC volts, backprobe terminal number 27 at the ECM C2 50-way

connector with the red probe and the black probe to a good ground (See Figure 10).

Accelerator Pedal Position Sensor 1 (Percent)

Accelerator Pedal Position Sensor 2 (Percent)

Accelerator Pedal Position Sensor 1 (Voltage)

Accelerator Pedal Position Sensor 2 (Voltage)

CLOSED

THROTTLE

WIDE OPEN

THROTTLE

2 %

.45V

96 %

4.56V

3 % 97 %

.24V

2.29V

ACCELERATOR POSITION SENSOR

Note: This test administered using a scanner.

DTC

TTVA Position Sensor Low (Electrical)

TTVA Position Sensor High (Electrical)

TTVA Acuator Stuck (Electrical/Mechanical)

TTVA Position Mechanical Performance (Mechanical)

TTVA Control Circuit (Electrical/Mechanical)

P1749

P1750

P1753

P1754

P1755

TRANSMISSION THROTTLE VALVE ACTUATOR CODES

DESCRIPTION

TTVA Position Sensor Minimum Range Performance (Mechanical) P1751

Note: Some of the DTC's listed can cause the voltage to the TTVA to be shut off by the ECM, this will in turn cause the

TTVA motor position to be in high TV mode.

Figure 8

Figure 9

Copyright © 2011 ATSG

Copyright © 2011 ATSG

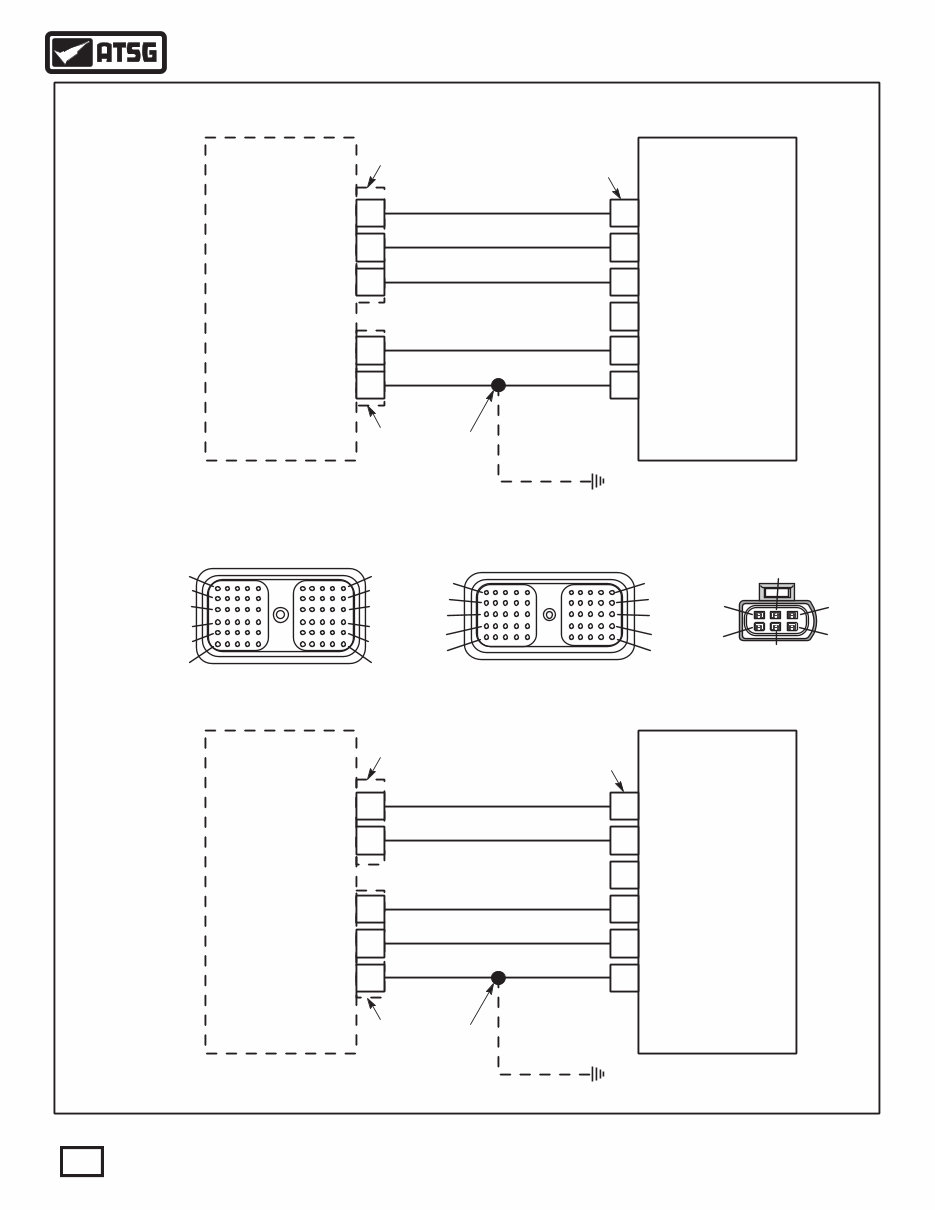

TRANSMISSION THROTTLE VALVE ACTUATOR

PARTIAL ELECTRICAL SCHEMATIC

1

2 6

5

3

4

2005

Diesel Models

Only

Connector

Views For

All Diesel

(2004-Up)

2006-Up

Diesel Models

Only

ECM - C2

50-Way Connector

(Face View)

ECM - C1

60-Way Connector

(Face View)

10

20

30

40

50

60

1

11

21

31

41

51

Note: numbers are marked

on connector

1

11

21

31

41

10

20

30

40

50

Note: numbers are marked

on connector

TTVA

6-Way Connector

(Face View)

Figure 10

35 1

20 5

6 24

23 2

8 3

4

5 VOLT SUPPLY

5 VOLT SPLY

TTVA POSITION SENS SIG

TTVA POSITION SENS SIG

NOT USED

TTVA MOTOR (+) TTVA MOTOR (+)

TTVA MOTOR (-) TTVA MOTOR (-)

SENSOR GND

ENGINE CONTROL SYSTEM

SENSOR GND

Transmission

Throttle Valve

Acuator (TTVA)

2005 ECM

Dk Blue/Dk Green

Yellow/Pink

Tan/Yellow

Orange

Tan/Orange

Dk Blue/Dk Green

Dk Blue/Dk Green

C2

Conn

Top Front Of

Transmission

C1

Conn

TTVA

Conn

27 1

20 5

6 24

23 2

8 3

4

5 VOLT SUPPLY

5 VOLT SPLY

TTVA POSITION SENS SIG

TTVA POSITION SENS SIG

NOT USED

TTVA MOTOR (+) TTVA MOTOR (+)

TTVA MOTOR (-) TTVA MOTOR (-)

SENSOR GND

ENGINE CONTROL SYSTEM

SENSOR GND

Transmission

Throttle Valve

Acuator (TTVA)

2006-UP ECM

Yellow/Pink

Tan/Yellow

Orange

Tan/Orange

Dk Blue/Dk Green Dk Blue/Dk Green

Dk Blue/Dk Green

Top Front Of

Transmission

C2

Conn

C1

Conn TTVA

Conn

{

{

{

10

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

Copyright © 2011 ATSG

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

Viewed 73 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

This workshop repair manual provides comprehensive information for servicing the 46RE automatic transmission. It is a valuable resource for both professional mechanics and DIY enthusiasts.