Chrysler Valiant VF Series workshop manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

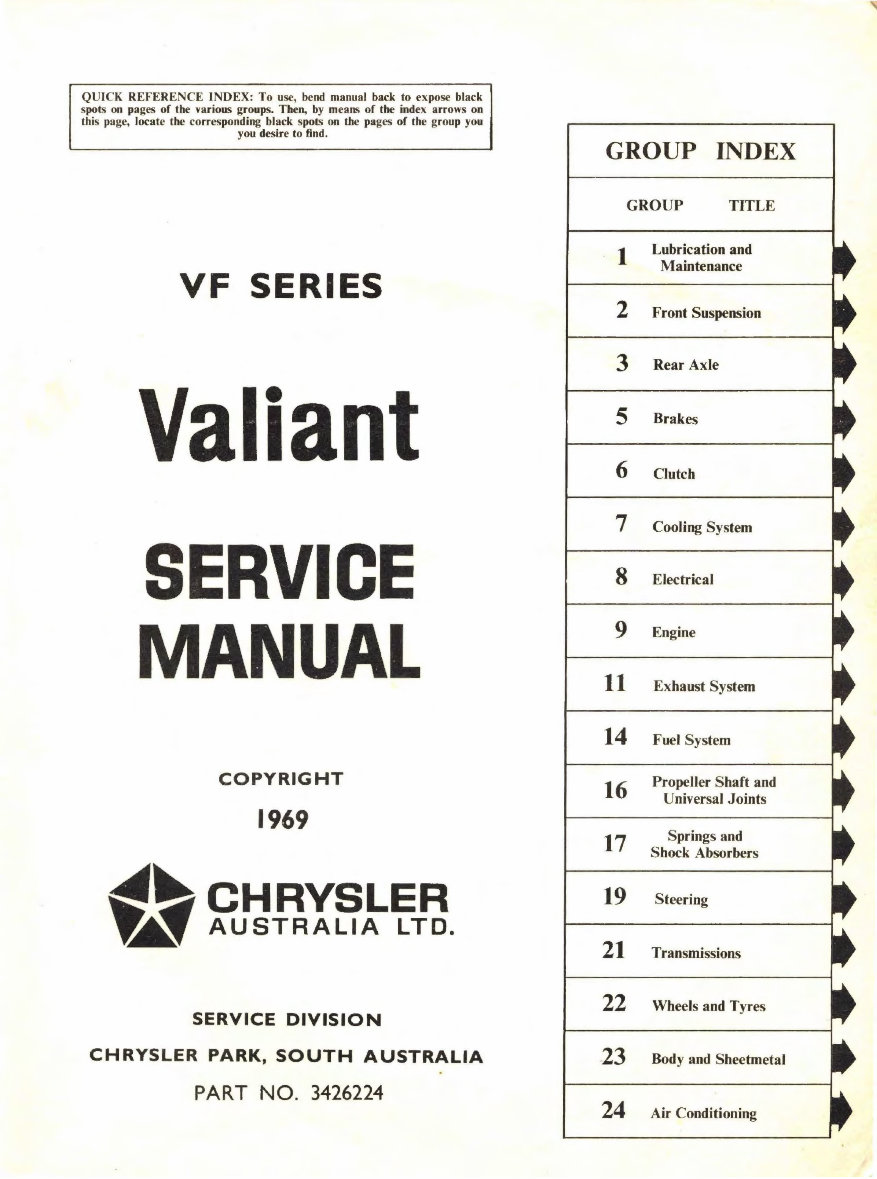

QUICK REFERENCE INDEX: To use, bend manual back to expose black

spots on pages of the various groups. Then, by means of the index arrows on

this page, locate the corresponding black spots on the pages of the group you

you desire to find.

VF SERIES

Valiant

SERVICE

MANUAL

COPYRIGHT

1969

d~CHRVSLER

~ AUSTRALIA LTD.

SERVICE DIVISION

CHRYSLER PARK, SOUTH AUSTRALIA

PART NO. 3426224

GROUP INDEX

GROUP TITLE

1

Lubrication and

Maintenance

2 Front Suspension

3 Rear Axle

5 Brakes

6 Clutch

7 Cooling System

8 Electrical

9 Engine

11 Exhaust System

14 Fuel System

16

17

19

21

22

.23

24

Propeller Shaft and

Universal Joints

Springs and

Shock Absorbers

Steering

Transmissions

Wheels and Tyres

Body and Sheetmetal

Air Conditioning

This manual has been prepared to provide service personnel with service

information for Valiant vehicle models shown on the following page. It

covers many conditions that may be encountered and their possible

causes and remedies. Each section contains practical disassembly, repair

and assembly procedures.

Included in the manual are numerous illustrations showing the proper

service tools in use. Specifications are tabulated at the beginning of each

section for quick reference.

Chrysler Australia Limited reserves the right to make changes in design

or to make additions to, or improvements in its product, without imposing

any obligation upon itself to install them on its products previously

manufactured.

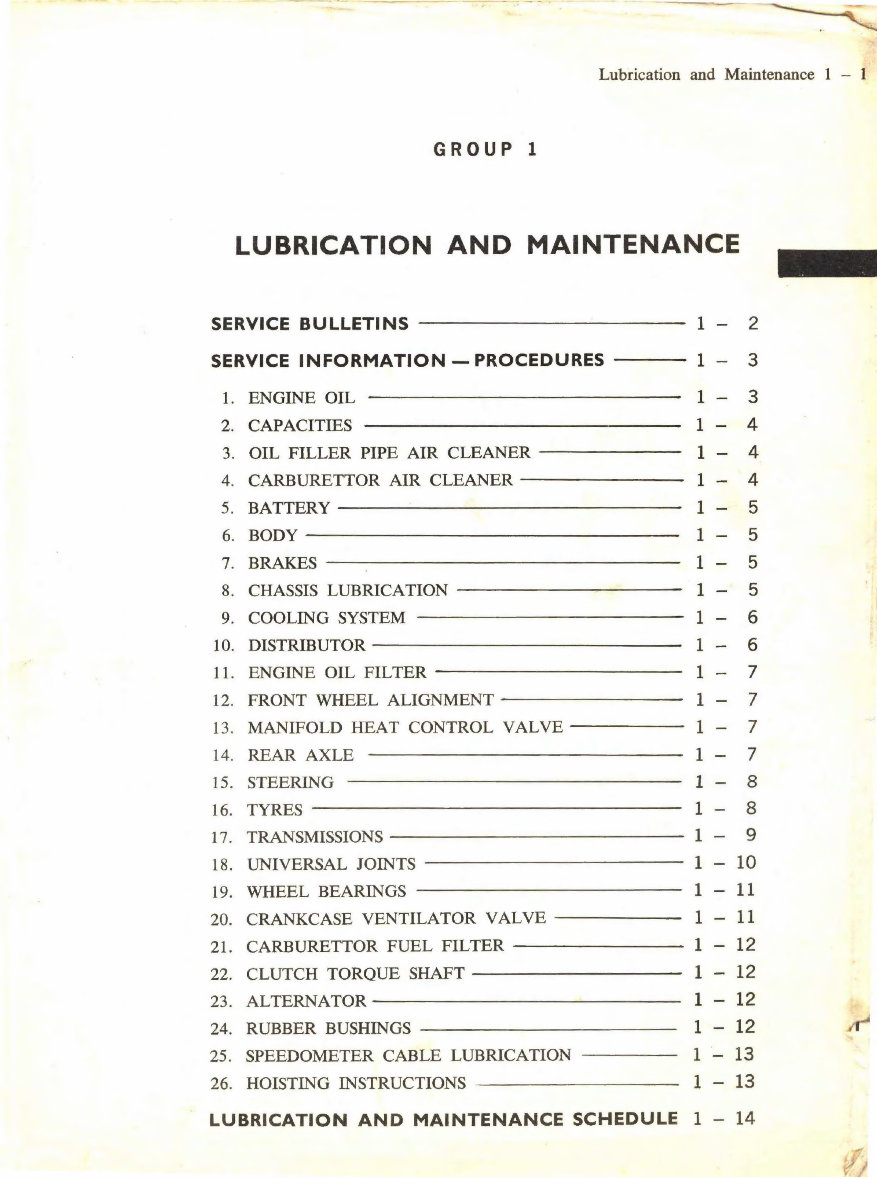

Lubrication and Maintenance 1 - 1

GROUP 1

LUBRICATION AND MAINTENANCE

SERVICE BULLETINS 1 - 2

SERVICE INFORMATION- PROCEDURES 1 - 3

1. ENGINE OIL 1 - 3

2. CAPACITIES 1 - 4

3. OIL FILLER PIPE AIR CLEANER 1 - 4

4. CARBURETTOR AIR CLEANER 1 - 4

5. BATTERY 1 - 5

6. BODY 1 - 5

7. BRAKES 1 - 5

8. CHASSIS LUBRICATION 1 - 5

9. COOLING SYSTEM 1 - 6

10. DISTRIBUTOR 1 - 6

11. ENGINE OIL FILTER 1 - 7

12. FRONT WHEEL ALIGNMENT 1 - 7

13. MANIFOLD HEAT CONTROL VALVE 1 - 7

14. REAR AXLE 1 - 7

15. STEERING 1 - 8

16. TYRES 1 - 8

17. TRANSMISSIONS 1 - 9

18 . UNIVERSAL JOINTS 1 - 10

19. WHEEL BEARINGS 1 - 11

20. CRANKCASE VENTILATOR VALVE 1 -11

21. CARBURETTOR FUEL FILTER 1 - 12

22. CLUTCH TORQUE SHAFT 1 - 12

23. ALTERNATOR 1 - 12

24. RUBBER BUSHINGS 1 - 12 .I

25. SPEEDOMETER CABLE LUBRICATION 1 - 13

26. HOISTING INSTRUCTIONS 1 - 13

LUBRICATION AND MAINTENANCE SCHEDULE 1 - 14

if)

Lubrication and Maintenance 1 - 2

SERVICE BULLETIN REFERENCE

DATE NUMBER SUBJECT CHANGES

-

.

::-

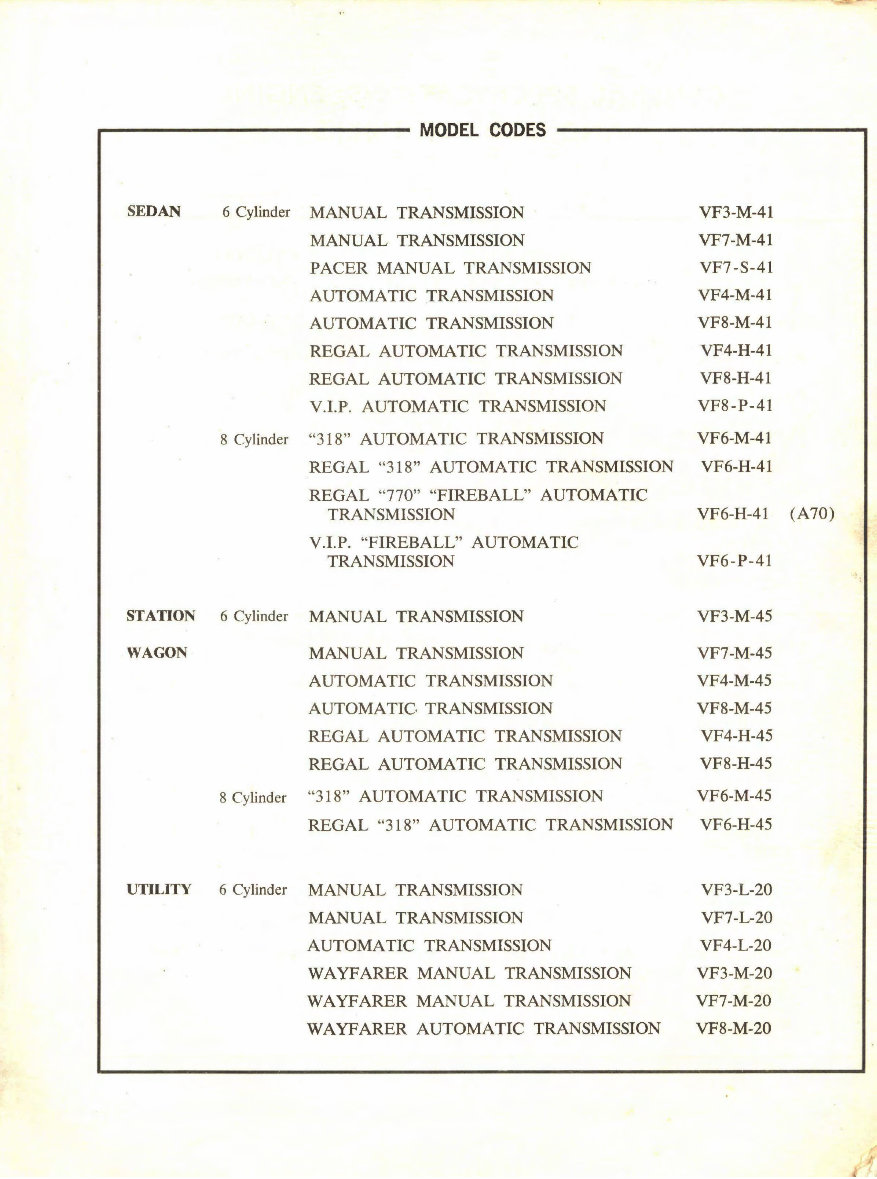

~--------------------- MODEL CODES ----------------------~

SEDAN 6 Cylinder MANUAL TRANSMISSION

MANUAL TRANSMISSION

PACER MANUAL TRANSMISSION

AUTOMATIC TRANSMISSION

AUTOMATIC TRANSMISSION

REGAL AUTOMATIC TRANSMISSION

REGAL AUTOMATIC TRANSMISSION

V.I.P. AUTOMATIC TRANSMISSION

8 Cylinder "318" AUTOMATIC TRANSMISSION

REGAL "318" AUTOMATIC TRANSMISSION

REGAL "770" "FIREBALL" AUTOMATIC

TRANSMISSION

V.I.P. "FIREBALL" AUTOMATIC

TRANSMISSION

STATION 6 Cylinder MANUAL TRANSMISSION

WAGON MANUAL TRANSMISSION

AUTOMATIC TRANSMISSION

AUTOMATIC TRANSMISSION

REGAL AUTOMATIC TRANSMISSION

REGAL AUTOMATIC TRANSMISSION

8 Cylinder "318" AUTOMATIC TRANSMISSION

REGAL "318" AUTOMATIC TRANSMISSION

UTILITY 6 Cylinder MANUAL TRANSMISSION

MANUAL TRANSMISSION

AUTOMATIC TRANSMISSION

WAYFARER MANUAL TRANSMISSION

WAYFARER MANUAL TRANSMISSION

WAYFARER AUTOMATIC TRANSMISSION

VF3-M-41

VF7-M-41

VF7 -S-41

VF4-M-41

VF8-M-41

VF4-H-41

VF8-H-41

VF8-P-41

VF6-M-41

VF6-H-41

VF6-H-41

VF6-P-41

VF3-M-45

VF7-M-45

VF4-M-45

VF8-M-45

VF4-H-45

VF8-H-45

VF6-M-45

VF6-H-45

VF3-L-20

VF7-L-20

VF4-L-20

VF3-M-20

VF7-M-20

VF8-M-20

(A70)

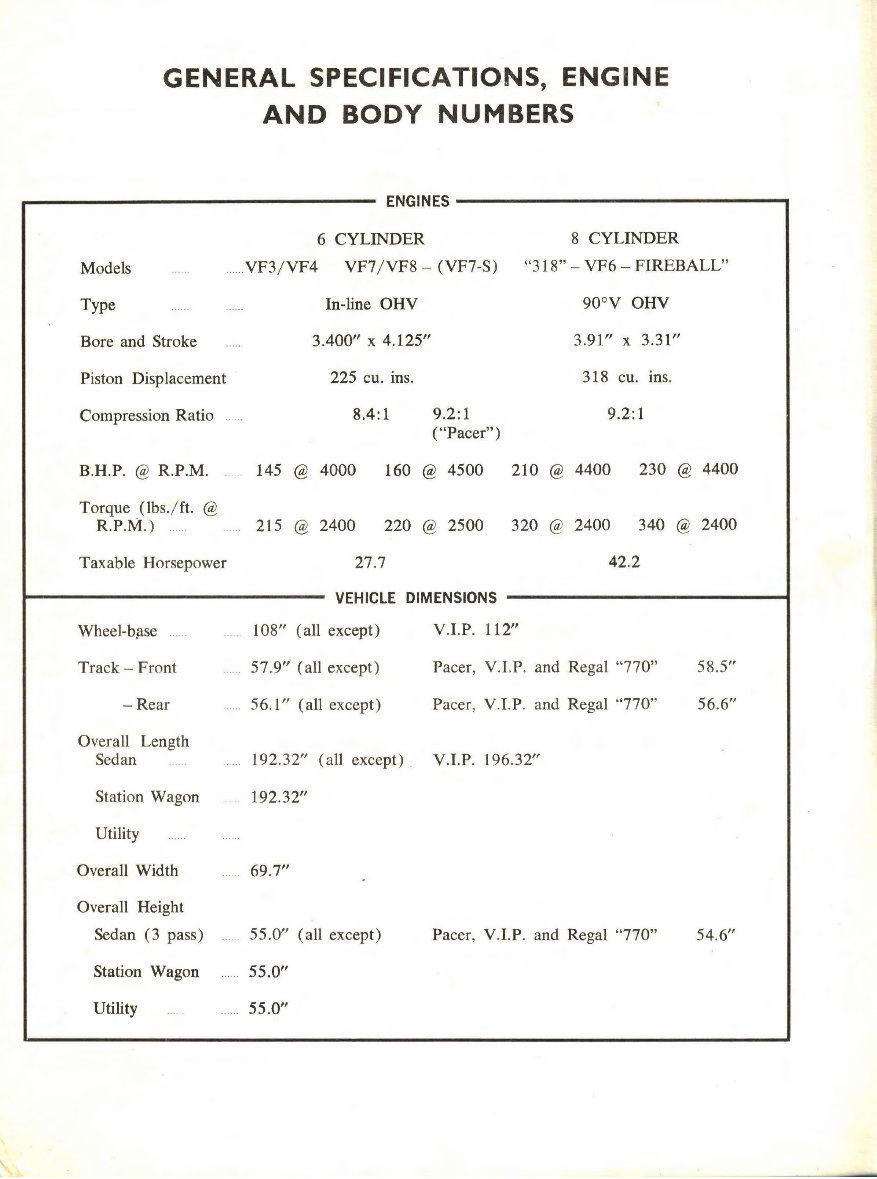

GENERAL SPECIFICATIONS, ENGINE

AND BODY NUMBERS

ENGINES---------------

6 CYLINDER 8 CYLINDER

Models VF3/VF4 VF7/VF8- (VF7-S) "318"- VF6- FIREBALL"

Type In-line OHV 90°V OHV

Bore and Stroke 3.400" x 4.125" 3.91" x 3.31"

Piston Displacement 225 cu. ins. 318 cu. ins.

Compression Ratio 8.4:1 9.2:1

("Pacer")

9.2:1

B.H.P. @ R.P.M. 145 @ 4000 160 @ 4500 210 @ 4400 230 @ 4400

Torque (lbs./ ft. @

R.P.M.) 215 @ 2400 220 @ 2500 320 @ 2400 340 @ 2400

Taxable Horsepower 27.7 42.2

1--------------- VEHICLE DIMENSIONS -------------1

Wheel-b.ase 108" (all except) V.I.P. 112"

Track - Front 57. 9" (all except) Pacer, V.I.P. and Regal "770"

-Rear 56.1" (all except) Pacer, V.I.P. and Regal "770"

Overall Length

Sedan 192.32" (all except) . V.I.P. 196.32"

Station Wagon 192.32"

Utility

Overall Width 69.7"

Overall Height

Sedan ( 3 pass) 55.0" (all except)

Station Wagon 55.0"

Utility 55.0"

Pacer, V.I.P. and Regal "770"

58.5"

56.6"

54.6"

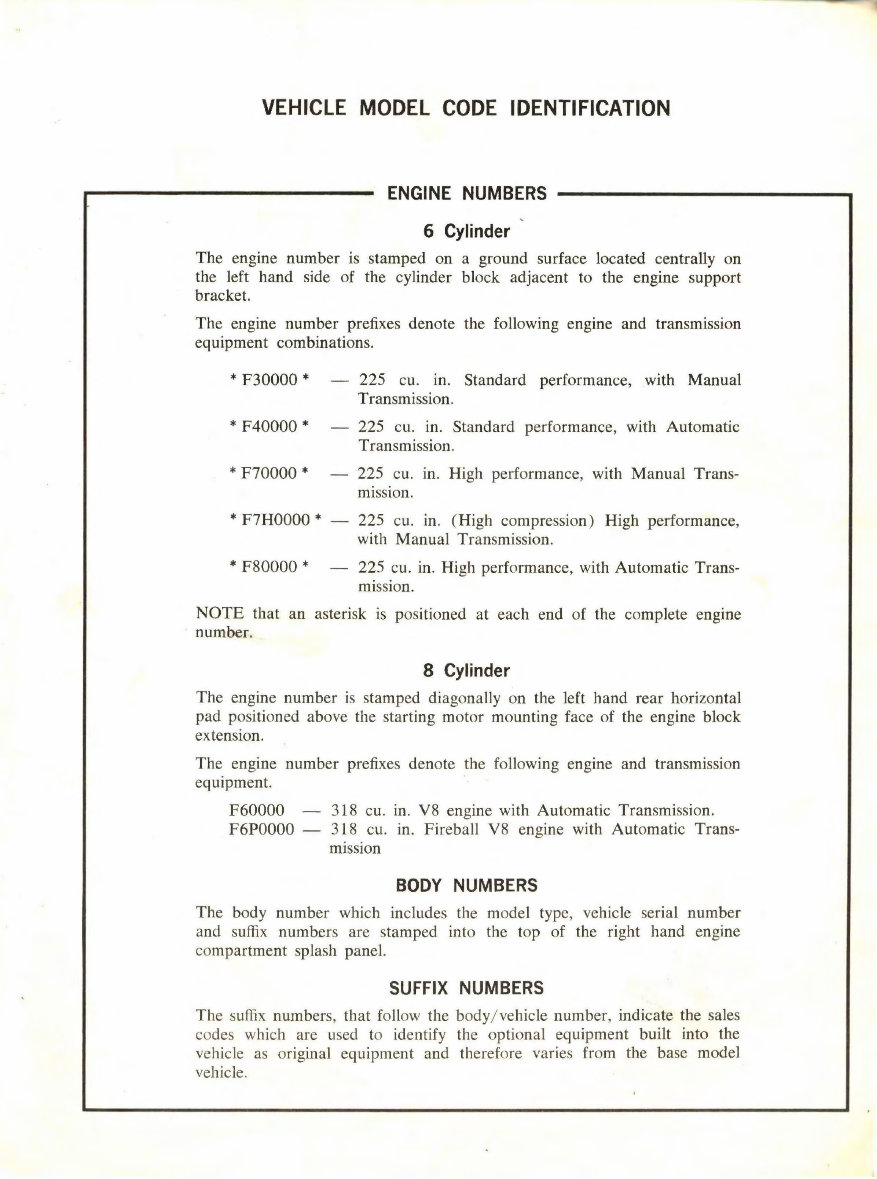

VEHICLE MODEL CODE IDENTIFICATION

ENGINE NUMBERS

6 Cylinder

The engine number is stamped on a ground surface located centrally on

the left hand side of the cylinder block adjacent to the engine support

bracket.

The engine number prefixes denote the following engine and transmission

equipment combinations.

* F30000 * - 225 cu. m. Standard performance, with Manual

Transmission.

* F40000 * - 225 cu. in. Standard performance, with Automatic

Transmission.

* F70000 * 225 cu. in. High performance, with Manual Trans-

mission.

* F7HOOOO * - 225 cu. in. (High compression) High performance,

with Manual Transmission.

* F80000 * - 225 cu. in. High performance, with Automatic Trans-

mission.

NOTE that an asterisk is positioned at each end of the complete engine

number.

8 Cylinder

The engine number is stamped diagonally on the left hand rear horizontal

pad positioned above the starting motor mounting face of the engine block

extension.

The engine number prefixes denote the following engine and transmission

equipment.

F60000 - 318 cu. in. V8 engine with Automatic Transmission.

F6POOOO - 318 cu. in. Fireball V8 engine with Automatic Trans-

mission

BODY NUMBERS

The body number which includes the model type, vehicle serial number

and suffix numbers are stamped into the top of the right hand engine

compartment splash panel.

SUFFIX NUMBERS

The suffix numbers, that foll ow the body/ vehicle number, indicate the sales

codes which are used to identify the optional equipment built into the

vehicle as original equipment and therefore varies from the base model

vehicle.

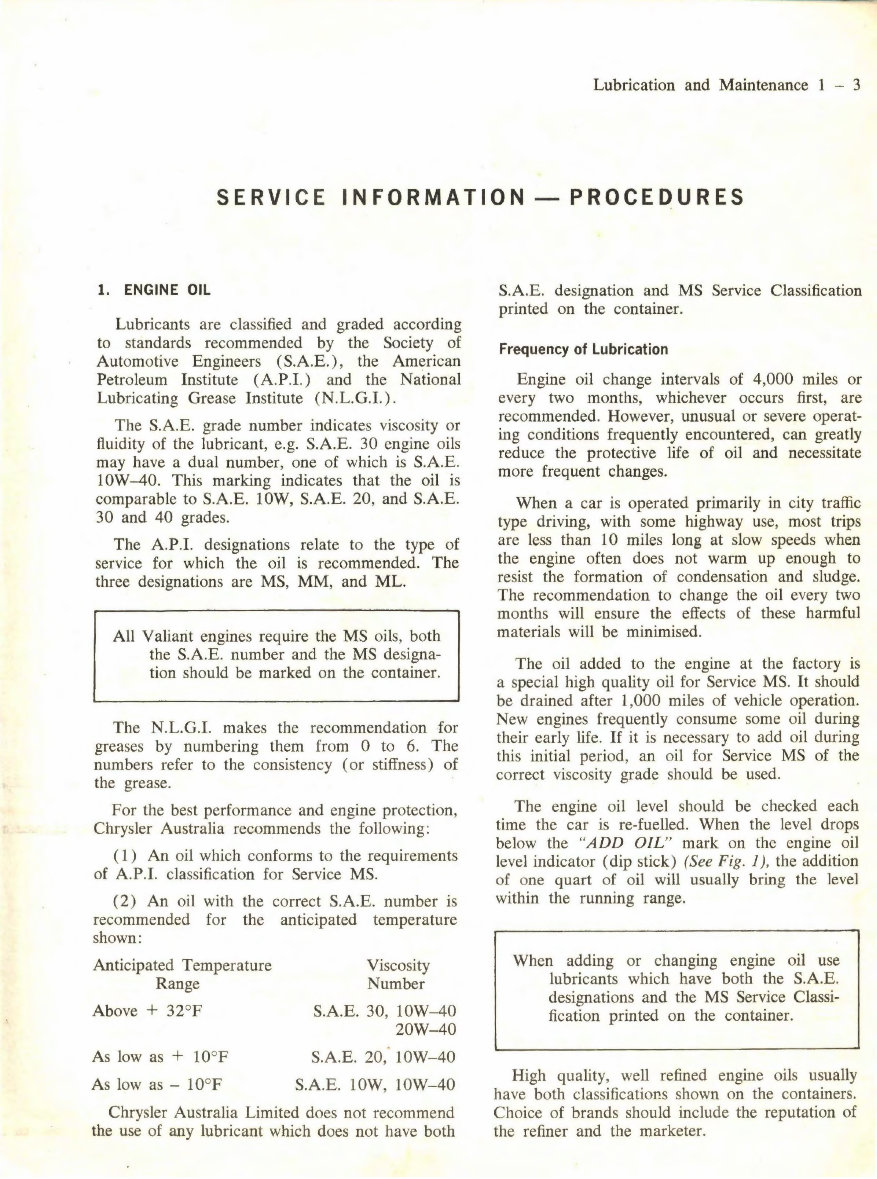

Lubrication and Maintenance 1 - 3

SERVICE INFORMATION- PROCEDURES

1. ENGINE OIL

Lubricants are classified and graded according

to standards recommended by the Society of

Automotive Engineers ( S.A.E.), the American

Petroleum Institute (A.P.I.) and the National

Lubricating Grease Institute (N.L.G.I.).

The S.A.E. grade number indicates viscosity or

fluidity of the lubricant, e.g. S.A.E. 30 engine oils

may have a dual number, one of which is S.A.E.

lOW-40. This marking indicates that the oil is

comparable to S.A.E. lOW, S.A.E. 20, and S.A.E.

30 and 40 grades.

The A.P.I. designations relate to the type of

service for which the oil is recommended. The

three designations are MS, MM, and ML.

All Valiarit engines require the MS oils, both

the S.A.E. number and the MS designa-

tion should be marked on the container.

The N.L.G.I. makes the recommendation for

greases by numbering them from 0 to 6. The

numbers refer to the consistency (or stiffness) of

the grease.

For the best performance and engine protection,

Chrysler Australia recommends the following:

( 1 ) An oil which conforms to the requirements

of A.P.I. classification for Service MS.

(2) An oil with the correct S.A.E. number is

recommended for the anticipated temperature

shown:

Anticipated Temperature

Range

Above + 32°F

As low as + l0 °F

As low as - l0°F

Viscosity

Number

S.A.E. 30, lOW-40

20W-40

S.A.E. 20,' lOW-40

S.A.E. lOW, lOW-40

Chrysler Australia Limited does not recommend

the use of any lubricant which does not have both

S.A.E. designation and MS Service Classification

printed on the container.

Frequency of Lubrication

Engine oil change intervals of 4,000 miles or

every two months, whichever occurs first, are

recommended. However, unusual or severe operat-

ing conditions frequently encountered, can greatly

reduce the protective life of oil and necessitate

more frequent changes.

When a car is operated primarily in city traffic

type driving, with some highway use, most trips

are less than 10 miles long at slow speeds when

the engine often does not warm up enough to

resist the formation of condensation and sludge.

The recommendation to change the oil every two

months will ensure the effects of these harmful

materials will be minimised.

The oil added to the engine at the factory is

a special high quality oil for Service MS. It should

be drained after 1,000 miles of vehicle operation.

New engines frequently consume some oil during

their early life. If it is necessary to add oil during

this initial period, an oil for Service MS of the

correct viscosity grade should be used.

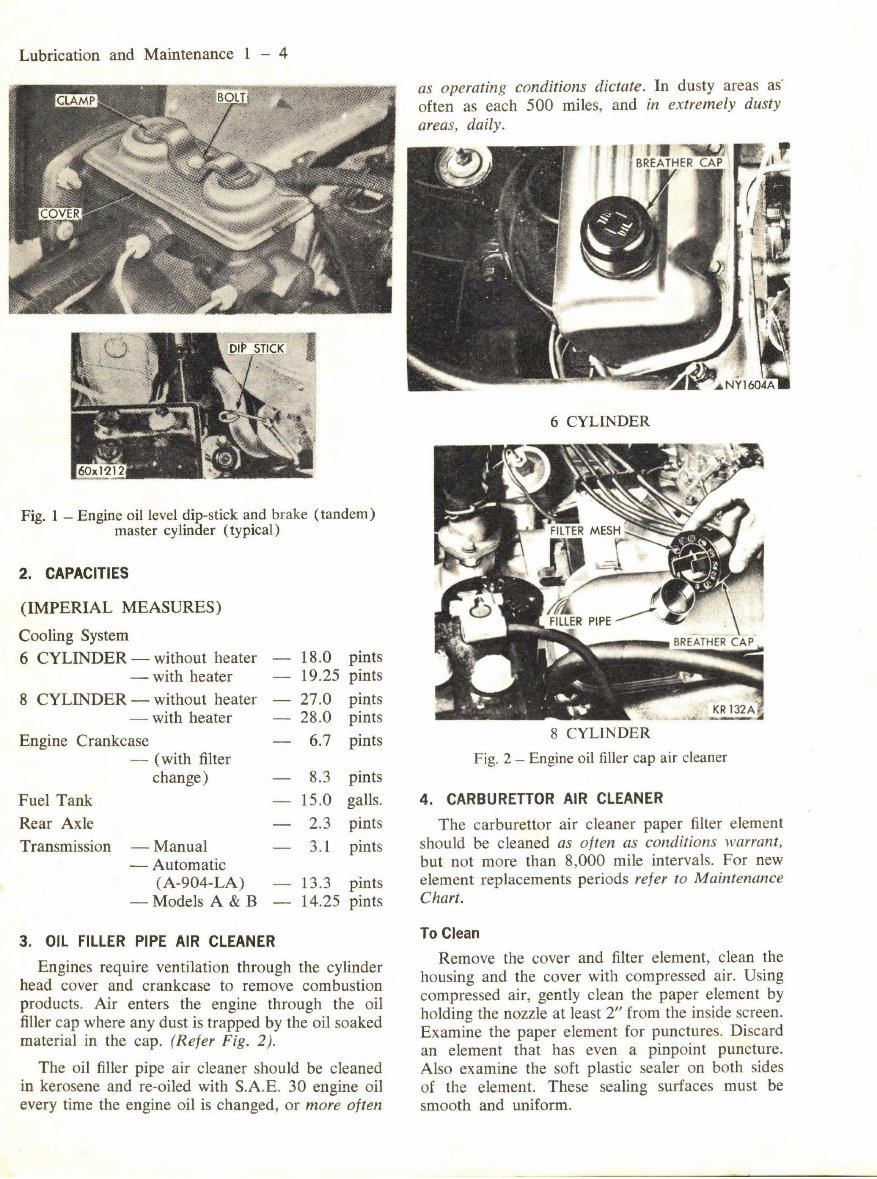

The engine oil level should be checked each

time the car is re-fuelled. When the level drops

below the "ADD OIL" mark on the engine oil

level indicator (dip stick) (See Fig. 1 ), the addition

of one quart of oil will usually bring the level

within the running range.

When adding or changing engine oil use

lubricants which have both the S.A.E.

designations and the MS Service Classi-

fication printed on the container.

High quality, well refined engine oils usually

have both classifications shown on the containers.

Choice of brands should include the reputation of

the refiner and the marketer.

Lubrication and Maintenance 1 - 4

Fig. 1 - Engine oil level dip-stick and brake (tandem)

master cy Iinder (typical)

2. CAPACITIES

(IMPERIAL MEASURES)

Cooling System

6 CYLINDER - without heater 18.0 pints

-with heater 19.25 pints

8 CYLINDER - without heater 27.0 pints

- with heater 28.0 pints

Engine Crankcase 6.7 pints

- (with filter

change) 8.3 pints

Fuel Tank 15 .0 galls.

Rear Axle 2.3 pints

Transmission -Manual 3.1 pints

-Automatic

(A-904-LA) 13.3 pints

-Models A & B 14.25 pints

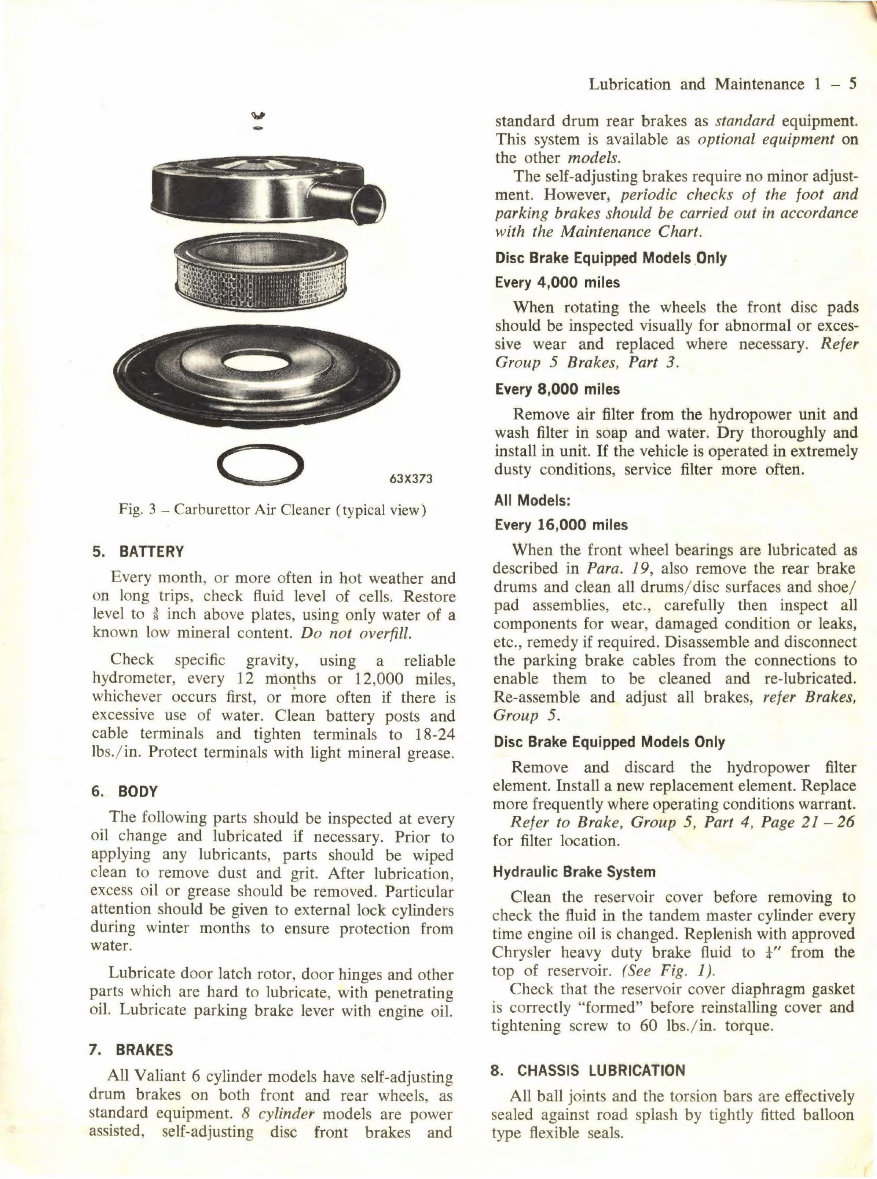

3. OIL FILLER PIPE AIR CLEANER

Engines require ventilation through the cylinder

head cover and crankcase to remove combustion

products. Air enters the engine through the oil

filler cap where any dust is trapped by the oil soaked

material in the cap. (Refer Fig. 2).

The oil filler pipe air cleaner should be cleaned

in kerosene and re-oiled with S.A.E. 30 engine oil

every time the engine oil is changed, or more often

as operating conditions dictate. In dusty areas as

often as each 500 miles, and in extremely dusty

areas, daily.

6 CYLINDER

8 CYLINDER

Fig. 2 - Engine oil filler cap air cleaner

4. CARBURETTOR AIR CLEANER

The carburettor air cleaner paper filter element

should be cleaned as often as conditions warrant,

but not more than 8,000 mile intervals. For new

element replacements periods refer to Maintenance

Chart.

To Clean

Remove the cover and filter element,· clean the

housing and the cover with compressed air. Using

compressed air, gently clean the paper element by

holding the nozzle at least 2" from the inside screen.

Examine the paper element for punctures. Discard

an element that has even a pinpoint puncture.

Also examine the soft plastic sealer on both sides

of the element. These sealing surfaces must be

smooth and uniform.

63X373

Fig. 3 - Carburettor Air Cleaner (typical view)

5. BATTERY

Every month, or more often in hot weather and

on long trips, check fluid level of cells. Restore

level to i inch above plates, using only water of a

known low mineral content. Do not overfill.

Check specific gravity, using a reliable

hydrometer, every 12 months or 12,000 miles,

whichever occurs first, or more often if there is

excessive use of water. Clean battery posts and

cable terminals and tighten terminals to 18-24

lbs./ in. Protect terminals with light mineral grease.

6. BODY

The following parts should be inspected at every

oil change and lubricated if necessary. Prior to

applying any lubricants, parts should be wiped

clean to remove dust and grit. After lubrication,

excess oil or grease should be removed. Particular

attention should be given to external lock cylinders

during winter months to ensure protection from

water.

Lubricate door latch rotor, door hinges and other

parts which are hard to lubricate, with penetrating

oil. Lubricate parking brake lever with engine oil.

7. BRAKES

All Valiant 6 cylinder models have self-adjusting

drum brakes on both front and rear wheels, as

standard equipment. 8 cylinder models are power

assisted, self-adjusting disc front brakes and

Lubrication and Maintenance 1 - 5

standard drum rear brakes as standard equipment.

This system is available as optional equipment on

the other models.

The self-adjusting brakes require no minor adjust-

ment. However, periodic checks of the foot and

parking brakes should be carried out in accordance

with the Maintenance Chart.

Disc Brake Equipped Models . Only

Every 4,000 miles

When rotating the wheels the front disc pads

should be inspected visually for abnormal or exces-

sive wear and replaced where necessary. Refer

Group 5 Brakes, Part 3.

Every 8,000 miles

Remove air filter from the hydropower unit and

wash filter in soap and water. Dry thoroughly and

install in unit. If the vehicle is operated in extremely

dusty conditions, service filter more often.

All Models:

Every 16,000 miles

When the front wheel bearings are lubricated as

described in Para. 19, also remove the rear brake

drums and clean all drums/ disc surfaces and shoe/

pad assemblies, etc., carefully then inspect all

components for wear, damaged condition or leaks,

etc., remedy if required. Disassemble and disconnect

the parking brake cables from the connections to

enable them to be cleaned and re-lubricated.

Re-assemble and adjust all brakes, refer Brakes,

Group 5.

Disc Brake Equipped Models Only

Remove and discard the hydropower filter

element. Install a new replacement element. Replace

more frequently where operating conditions warrant.

Refer to Brake, Group 5, Part 4, Page 21-26

for filter location.

Hydraulic Brake System

Clean the reservoir cover before removing to

check the fluid in the tandem master cylinder every

time engine oil is changed. Replenish with approved

Chrysler heavy duty brake fluid to t" from the

top of reservoir. (See Fig. 1 ).

Check that the reservoir cover diaphragm gasket

is correctly "formed" before reinstalling cover and

tightening screw to 60 lbs./ in. torque.

8. CHASSIS LUBRICATION

All ball joints and the torsion bars are effectively

sealed against road splash by tightly fitted balloon

type flexible seals.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$27.99

Viewed 16 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$27.99

This is a comprehensive workshop manual for the Chrysler Valiant VF Series. Suitable for the home workshop mechanic or professional technician, this manual will help you maintain your Chrysler Valiant VF with very easy step-by-step instructions and lots of diagrams.

This manual is suitable for the following Chrysler Valiant models made by Chrysler Australia between 1969-1970:

- VF Valiant Sedan

- VF Valiant Regal Sedan

- VF Valiant Station Wagon

- VF Valiant Regal Station Wagon

The following Engines and Transmissions are covered in this manual:

- Engines: Slant 6 - 225, 318 - V8

- Transmissions: 3 Speed Manual, Torqueflite Models A & B (6 cylinder), Torqueflite Model A904 LA (V8)

Below is a list of topics covered in this Chrysler Valiant VF manual:

- Fully bookmarked & interactive index

- Lubrication and Maintenance

- Front Suspension

- Rear Axle

- Brakes

- Clutch

- Cooling System

- Electrical

- Engine (318 V8 and 225 Slant 6)

- Exhaust System

- Fuel System

- Propeller Shaft and Universal Joints

- Springs and Shock Absorbers

- Steering

- Transmissions

- Wheels and Tyres

- Body and Sheetmetal

- Air Conditioning