1967-1976 BMW 2002 Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

)

)_

~

).

J

INTR-ODUCTION

..

This repair manual is intended to ensure tha'l: the maintenance and repair work required for BMW cars is done in

the correct manner. Therefore this manual shou·ld be used by inspectors and fitters as it helps to supplement the

practical and theoretical knowledge they have acquired at our service training school. -

The relevant specifications are always provided at the begihning of each main group.

The specifications apply to standard cars that have not been involved in an accident and have not been modified

after leaving the factory.

Basical~ speaking, the Touring models are identical with the saloons so that in the specifications and values

quoted reference is only made to points in which the Touring models differ from the other cars.

The group system applied in this manual is taken from our flat rate catalogue.

For example, page,32·21/6 means:

32

-21

/6

main group

sub group

page in sub-group

The spElcial tools required for good repair work are listed in our special tool catalogue - order

No. 01 99 9 099 420. Photographs have been provided to. show how the special tools must be applied for the

ltidrvlt~ual processes and operations.

Removal/disassembly is always described for each operation. If fitting/assembly is not possible in the opposite

order a "note when fitting" is pr-ovided.

. '• . .

The f.b"floli'liing 'supplements are both alterations and additions. If the word "alteration" has been printed on the

she3t, ·take o~t the sheet already provided and insert the new one in its place. Sheets marked "addition" must

si~·ply,J>e added to the existing manual without removing any old sheets.

, . ~

.. Gln tl]e f<?llowing page a list should be provided of the supplements inserted in the repair manual.

Af>artrrom the improvements ann9unced by regular circular notes, we recommend that the spare parts catalogues

- whtcb have clear' illustrations- are used as an additional source of information.

0 .... .

o,

..

' 0

BAYERISCHE MOTOREN WERKE AG

CUSTOMER SERVICE DEPARTME-NT

Published by Bayerische Motoren Werke AG, Miinchen 40, Vl!est Germany, Customer Se~vice Department.

All rights reserved. Reprints only allowed with the written._;Q.ns~nt of the publisher.

Printed in Germany

Alteration

List of $upp~lements inserted

Supplement/order No. inserted on signature

r1·"'

.

)

··.""

. .

•

.J>,

3.73 Addition

BMW N 600 02.0

)

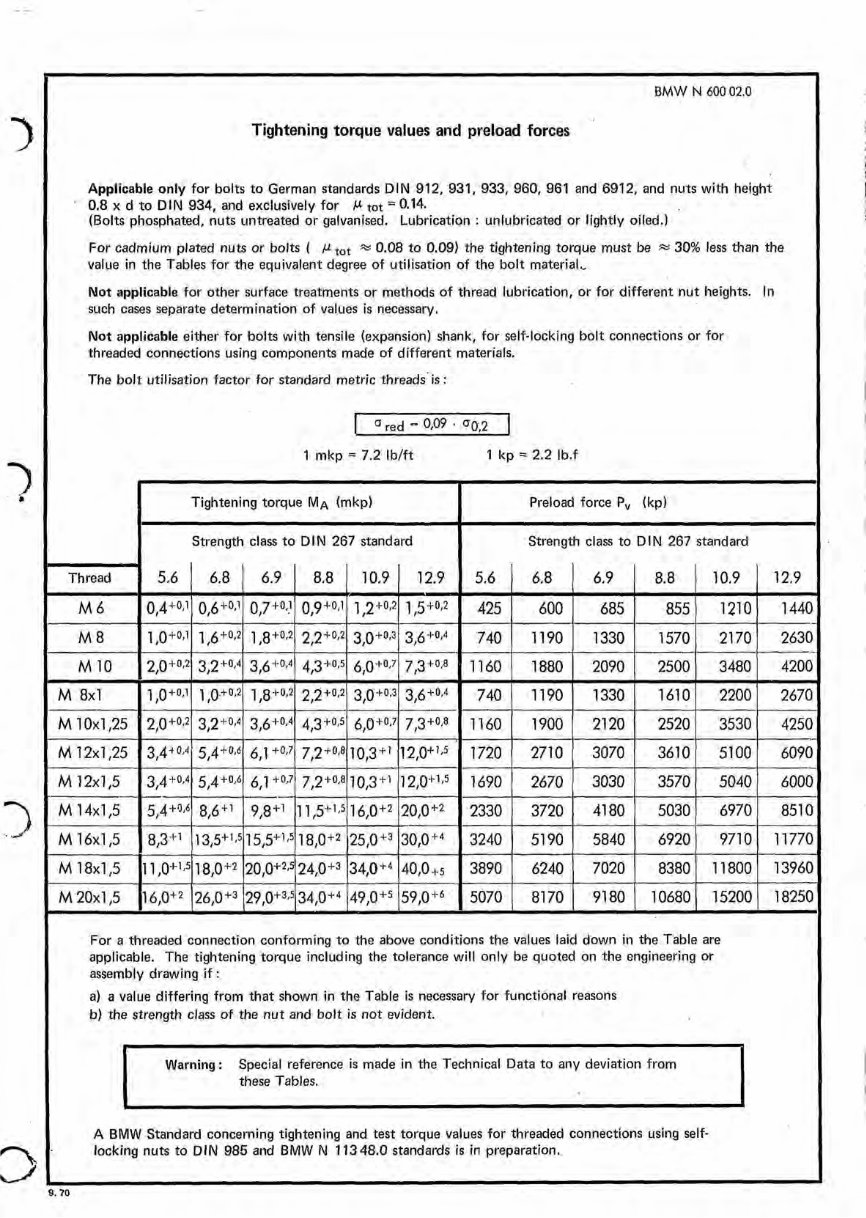

Tightening torque values and preload forces

Applicable only for bolts to German standards DIN 912, 931, 933, 960, 961 and 6912, and nuts with height

0.8 x d to DIN 934, and exclusively for /).tot= 0.14.

(Bolts phosphated, nuts untreated or galvanised. Lubrication : unlubricated or lightly oiled.)

For cadmium plated nuts or bolts ( 11 tot f":j 0.08 to 0.09) the tightening torque must be f":j 30% less than the

value in the Tables for the equivalent degree of utilisation of the bolt material._

Not applicable for other surface treatments or methods of thread lubrication, or for different nut heights. In

such cases separate determination of values is necessary.

Not applicable either for bolts with tensile (expansion) shank, for self-locking bolt connections or for

threaded connections using components made of different materials.

The bolt utilisation factor for standard metric threads· is :

I

(j red - 0,09 . oo,2

I

)

1 mkp = 7.2 lb/ft 1 kp = 2.2 lb.f

. .

Tightening torque MA (mkp) Preload force Pv (kp)

Strength class to DIN 267 standard Strength class to DIN 267 standard

Thread 5.6 6.8 6.9 8.8 10.9 12.9 5.6 6.8 6.9 8.8 10.9 12.9

M6

0,4+0,1 0,6+0,1 0,7+0,] 0,9+0,1 1,2+0,2 1,5 +0,2

425 600 685 855 1210 1440

-

M8

1,0+0,1 1,6 +0,2 1,8 +0,2 2,2+0,2 3,0+0,3 3,6 +0,4

740 1190 1330 1570 2170 2630

-

M 10

2,0+0,2 3,2+0,4 3,6+0,4 4,3+0,5 6,0+0,7 7,3+0,8

1160 1880 2090 2500 3480 4200

M 8x1

1,0+0,1 1,0·+0,2 1,8+0,2 2,2+0,2 3,0+0,3 3,6 +0,4

740 1190 1330 1610 2200 2670

M 10x1 ,25

2,0+0,2 3,2+0,4 3,6+0,4 4,3+0,5 6,Q+0.7 7,3+0,8

1160 1900 2120 2520 3530 4250

M 12x1 ,25

3,4-10,

4

5,4 +0,6 6,1 +0,7 7,2+0,8

10,3+

1

12,0+1,5

1720 2710 3070 3610 5100 6090

M 12x1,5

3,4 +0,4 5,4 +0,6 6,1 +0,7 7,2+0,8

10,3+

1

12,0+

1

·

5

1690 2670 3030 3570 5040 6000

M 14x1,5 5,4 +0,

6

8,6+

1

9,8+

1

11,5+

1

·

5

16,0+

2

20,0+2 2330 3720 4180 5030 6970 8510

M 16x1 ,5 8,3+

1

13,5+

1

·

5

15,5+

1

·

5

18,0+

2

25,0+

3

30,0+4 3240 5190 5840 6920 9710 11770

)

M 18x1 ,5 11 ,o+

1

·

5

18,0+

2

20,0+2,5

24,0+

3

34,0+

4

40,0+5 3890 6240 7020 8380 11800 13960

M 20x1,5 16,0+

2

26,0+

3

29,0+3,5

34,0+

4

49,0+

5

59,0+

6

5070 8170 9180 10680 15200 18250

For a threaded connection conforming to the above conditions the values laid down in the Table are

applicable. The tightening torque including the tolerance will only be quoted on the engineering or

assembly drawing if :

a) a value differing from that shown in the Table is necessary for functional reasons

b) the strength class of the nut and bolt is not evident.

Warning: Special reference is made in the Technical Data to any deviation from

these Tables.

A BMW Standard concerning tightening and test torque values for threaded connections using self-

locking nuts to DIN 985 and BMW N 113 48.0 standards is in preparation.

9. 70

BMW N 600 02.0

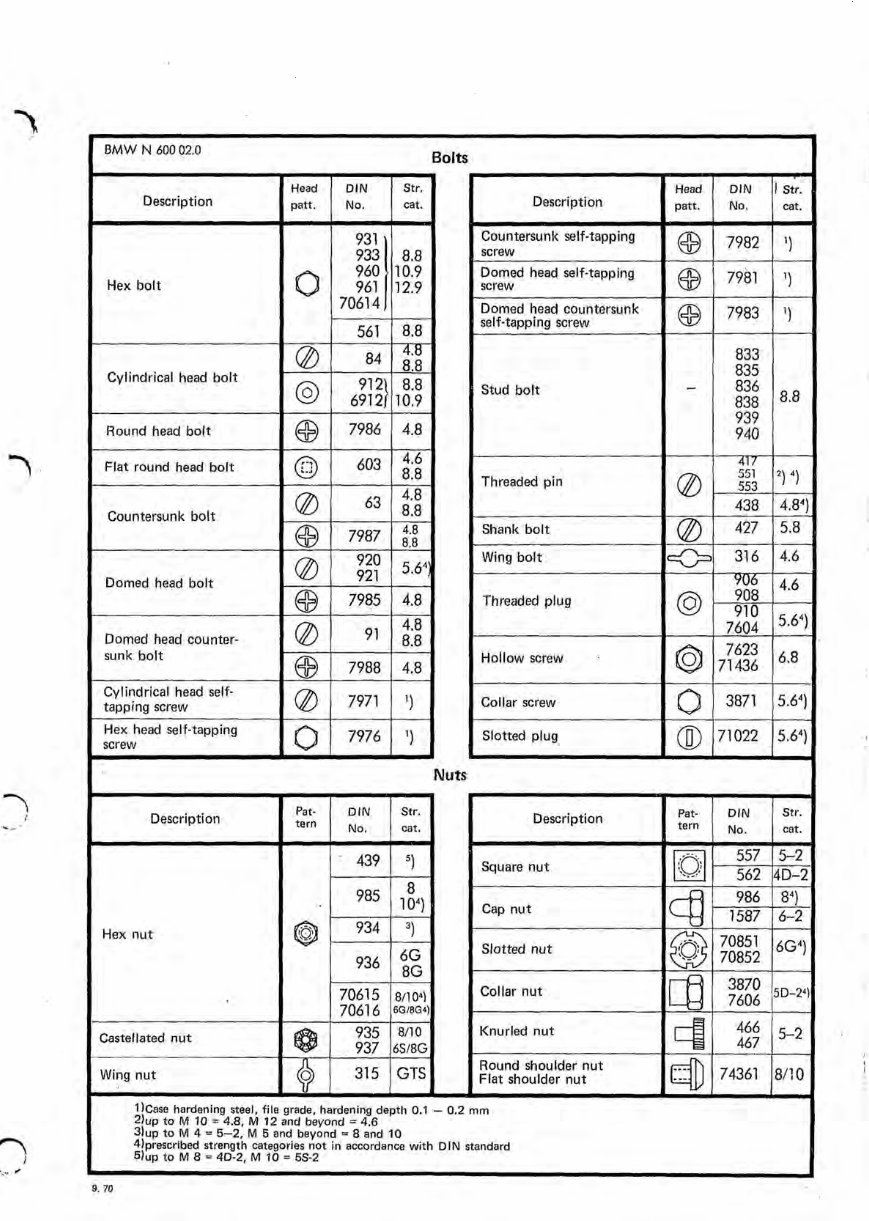

Bolts

Head DIN Str. Head DIN I Str.

Description

patt . No. cat.

Description

patt. No. cat.

9311

Countersunk self-tapping

@

7982

1)

933 8.8

screw

0

960 10.9 Domed head self-tapping

~

7981

1)

Hex bolt

961 12.9

screw

70614

Domed head countersunk

@

7983

1)

self-tapping screw

561 8.8

@ 84

4.8

833

8.8

835

Cylindrical head bolt

@

912}

8.8

Stud bolt -

836

6912 10.9

838

8.8

@

939

Round head bolt 7986 4.8

940

Flat round head bolt

@

603

4.6

417

.

8.8

0

551 2) 4)

Threaded pin

553

@

63

4.8

438 4.8

4

)

8.8

Countersunk bolt

0

427 5.8

@ 7987

4.8 Shank bolt

8.8 ·· -

@

920

Wing bolt

<>

316 4.6

5.6

4

Domed head bolt

921 'JUO-

4.6

~

7985 4.8 Threaded plug

@

908

910

0

4.8

7604

5.6

4

)

Domed head counter-

91

8.8

@

7623

6.8

sunk bolt

~

7988 4.8

Hollow screw

71436

Cylindrical head self·

@ 7971

1)

Collar screw

0

3871 5.6

4

)

tapping screw

Hex head self-tapping

0

7976

1) Slotted plug

®

71022 5.6

4

}

screw

Nuts

~

I

Description

Pat- DIN Str.

Description

Pat- DIN Str.

tern

No. cat.

tern

No. cat.

439

5)

[QJ

557 5-2

Square nut

562 140-2 -

985

8

et}

986

84)

1 04)

Cap nut

1587 6-2

@

934

3)

Hex nut

@

70851

Slotted nut

6G

4

)

936

6G

~

70852

8G

m

3870

70615 8/1 0

4

)

Collar nut

7606

SD-2

4

)

70616

6G/8G4)

@

935

8/10 Knurled nut

cl

466

5-2

Castellated nut

937 6S/8G

467

?,)

315 GTS

Round shoulder nut

cm

74361 8/10 Wing nut

Flat shoulder nut

.

1lcase hardening steel, file grade, hardening depth 0.1 - 0.2 mm

2)up to M 10 = 4.8, M 12 and beyond= 4.6

3)up to M 4 =5-2, M 5 and beyond = 8 and 10

4lprescribed strength categories not in accordance with DIN standard

5)up to M 8 = 4D-2, M 10 = 5S-2

9. 70

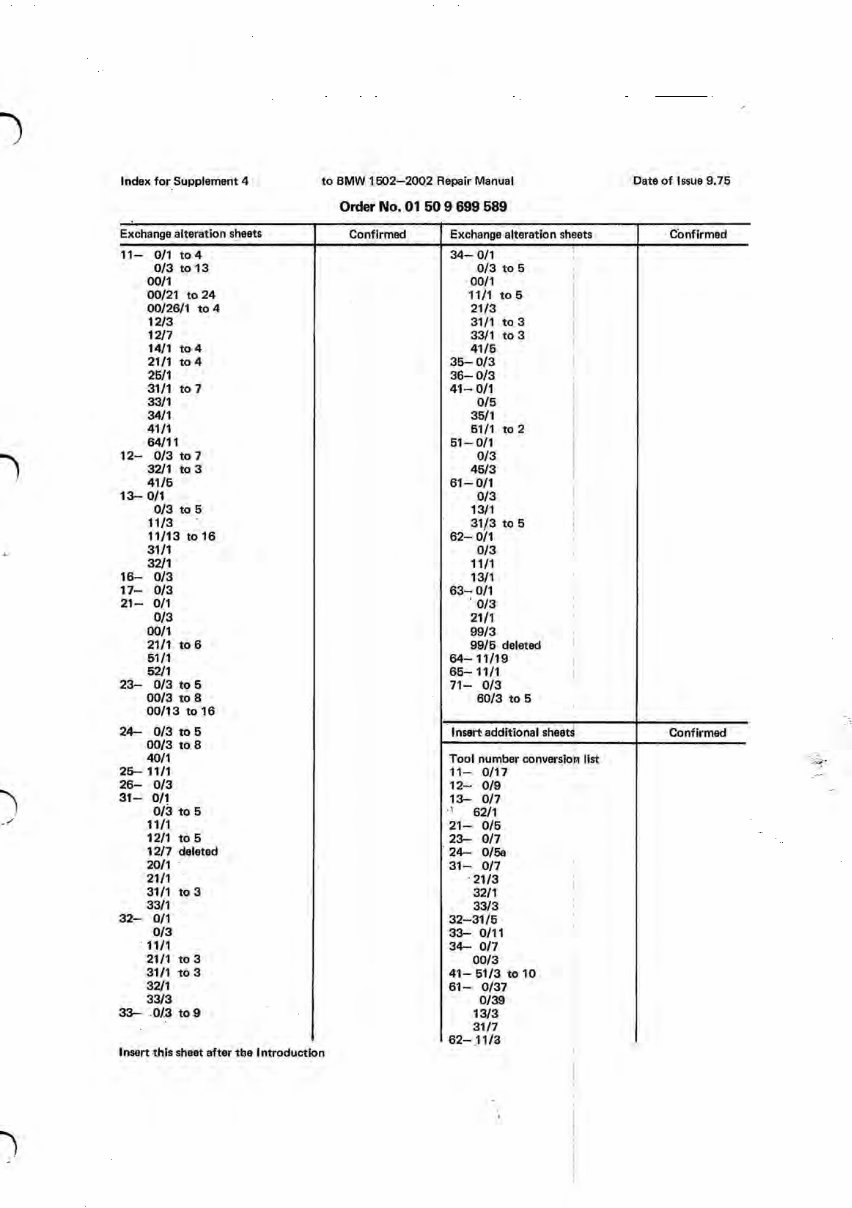

Index for Supplement 4 to BMW 1502-2002 Repair Manual Date of Issue 9.75

Order No. 01 50 9 699 589

Exchange alteration sheets Confirmed Exchange alteration sheets Confirmed

11- 0/1 to 4 34-0/1

0/3 to 13 0/3 to 5

00/1 00/1

00/21 to 24 11/1 to 5

I

00/26/1 to 4 21/3

i

12/3 31/1 to 3

12/7 33/1 to 3

14/1 to 4 41/5

21/1 to 4 35-0/3

26/1 36-0/3

31/1 to 7 41-0/1

33/1 0/5

34/1 35/1

41/1 51/1 to 2

64/11 51-0/1

12- 0/3 to 7 0/3

32/1 to 3 45/3

41/6 61-0/1

13- 0/1 0/3

0/3 to 5 13/1

11/3 31/3 to 5 I

11/13 to 16 62-0/1

31/1 0/3

32/1 11/1

16- 0/3 13/1

17- 0/3 63-0/1

21- 0/1 . 0/3

0/3 21/1

00/1 99/3

21/1 to 6 99/5 deleted

i

51/1 64- 11/19

52/1 65-11/1

23- 0/3 to 5 71- 0/3

00/3 to 8 60/3 to 5

00/13 to 16

24- 0/3 to 5 Insert additional sheet$ Confirmed

00/3 to 8

40/1 Tool number conversion list

25- 11/1 11- 0/17

26- 0/3 12- 0/9

31- 0/1 13- 0/7

0/3 to 5

.\

62/1

11/1 21- 0/5

12/1 to 5 23- 0/7

12/7 deleted 24- 0/5&

20/1 31- 0/7

21/1 . 21/3

31/1 to 3 32/1

33/1 33/3

32- 0/1 32-31/5

0/3 33- 0/11

. 11/1

34- 0/7

21/1 to 3 00/3

31/1 to 3 41- 51/3 to 10

32/1 61- 0/37

33/3 0/39

33- .0/3 to 9 13/3

31/7

62- 11 a

Insert -this sheet after the Introduction

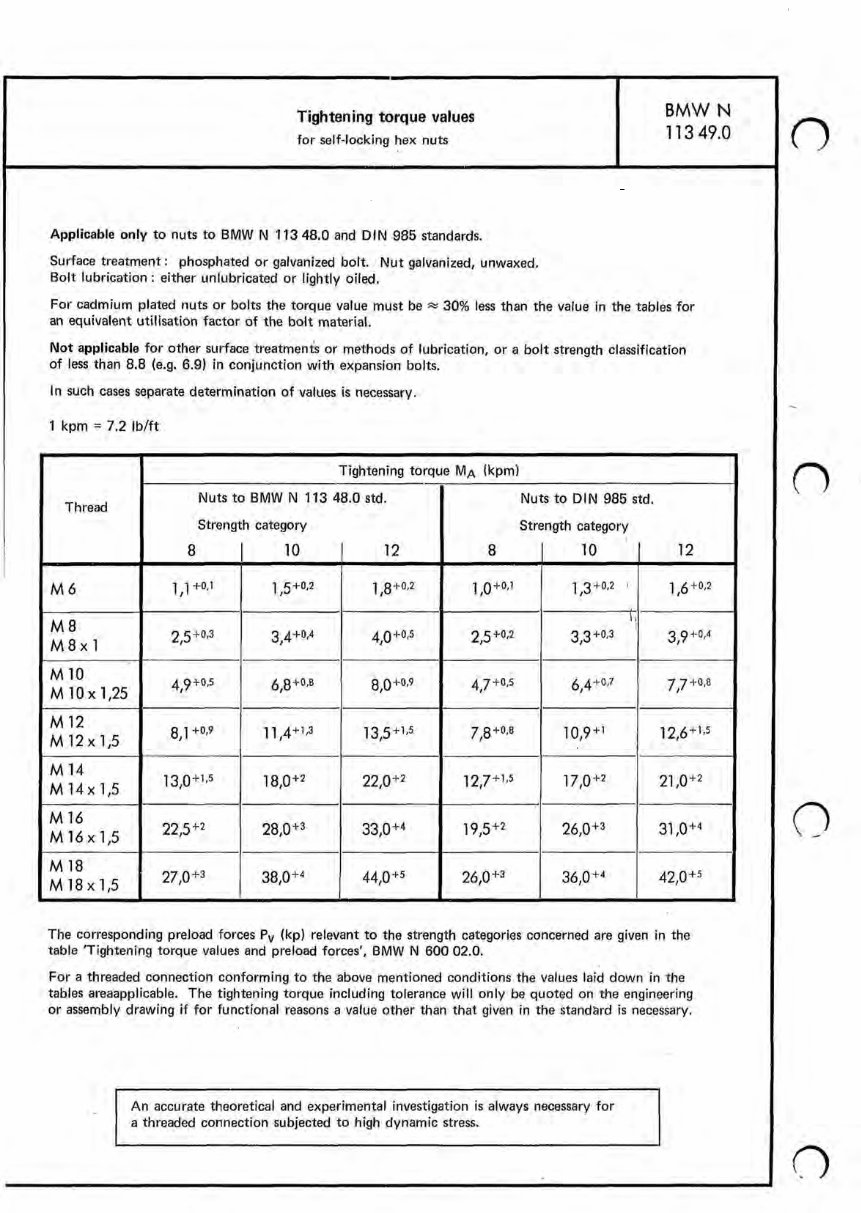

Tightening torque values

for self-locking hex nuts

Applicable only to nuts to BMW N 113 48.0 and DIN 985 standards.

Surface treatment: phosphated or galvanized bolt. Nut galvanized, unwaxed.

Bolt lubrication : either unlubricated or lightly oiled.

BMWN

113 49.0

For cadmium plated nuts or bolts the torque value must be ~ 30% less than the value in the tables for

an equivalent utilisation factor of the bolt material.

Not applicable for other surface treatments or methods of lubrication, or a bolt strength classification

of less than 8.8 (e.g. 6.9) in conjunction with expansion bolts.

In such cases separate determination of values is necessary.

1 kpm = 7.2 lb/ft

Tightening torque MA (kpm)

Thread

Nuts to BMW N 113 48.0 std. Nuts to DIN 985 std.

Strength category Strength category

8 10 12 8 10 12

M6

1,1 +0,1 1,5+0,2 1,8+0,2 1,0+0,1 1,3 +0,2

I

1,6 +0,2

MS

\;

!

MS X 1

2,5+0,3 3,4+0,4 4,0+0,5 2,5+0,2 3,3+0,3 3,9 +0,4

M 10

4,9+0,5 6,8+0,8 8,0+0,9 4,7+0,5 6,4+0 ,7 7,7+0,8

M 10 X 1,25

M 12

8,1 +0,9

11,4 +

1

·

3

13,5+

1

·

5

7,8+0,6

1 0,9+

1

12,6+

1

·

5

M 12 X 1,5

M 14

13,0+

1

·

5

18,0+

2

22,0+

2

12,7+

1

·

5

17,0+

2

21,0+

2

M 14 X 1,5

M 16

22,5+

2

28,0+

3

33,0+

4

19,5+

2

26,0+

3

31,0+

4

M 16 X 1,5

M 18

27,0+

3

38,0+

4

44,0+

5

26,0+

3

36,0+

4

42,0+

5

M 18 X 1,5

The corresponding preload forces Pv (kp) relevant to the strength categories concerned are given in the

table 'Tightening torque values and preload forces', BMW N 600 02.0.

For a threaded connection conforming to the above mentioned conditions the values laid down in the

tables areaapplicable. The tightening torque including tolerance will only be quoted on the engineering

or assembly drawing if for functional reasons a value other than that given in the standard is necessary.

An accurate theoretical and experimental investigation is always necessary for

a threaded connection subjected to high dynamic stress.

0

n

0

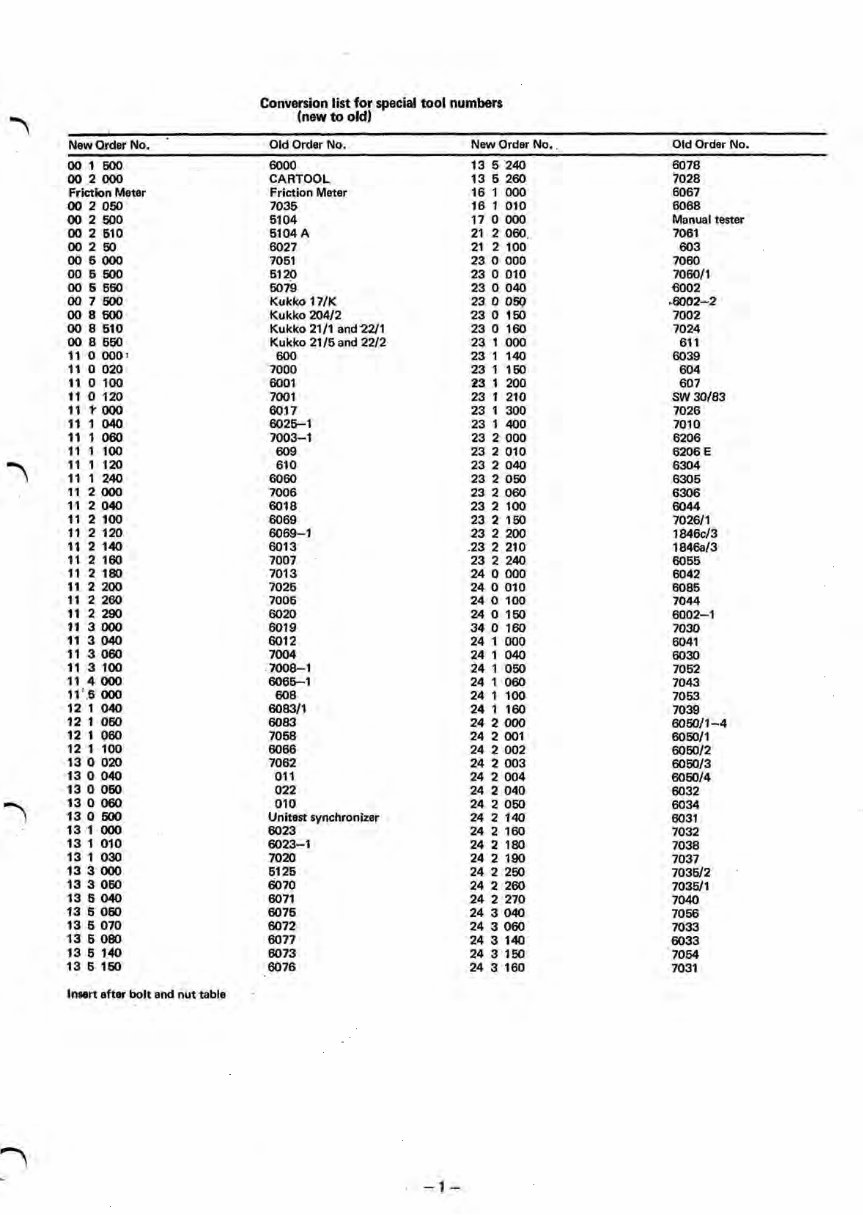

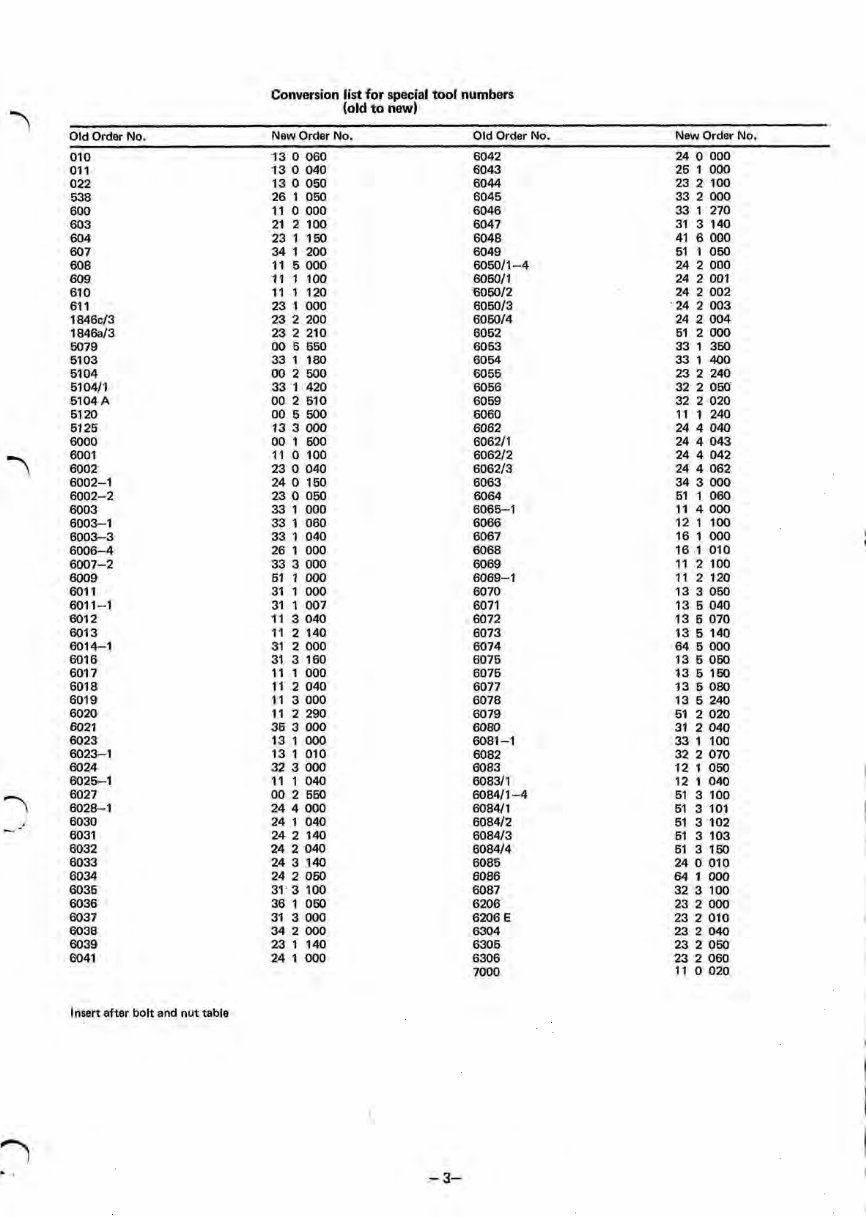

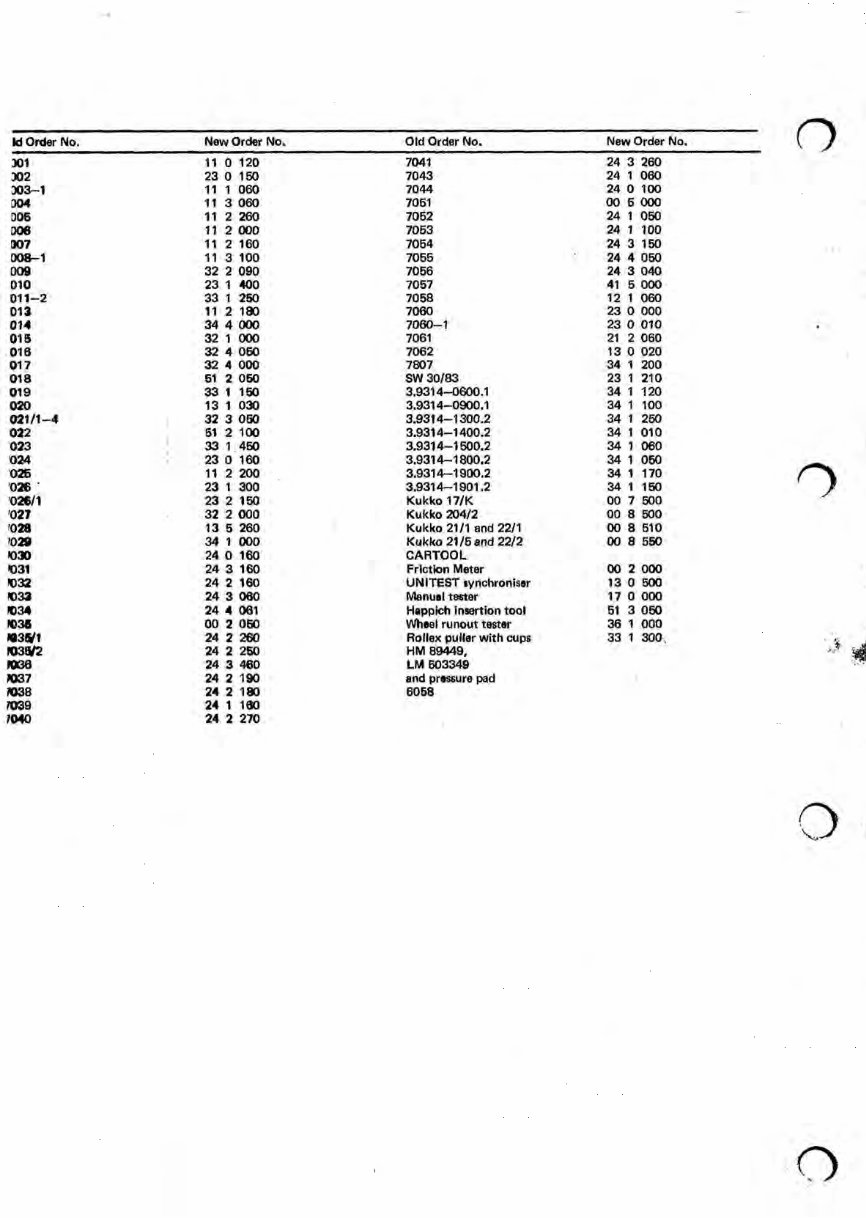

Conversion list for special tool numbers

(new to old)

New Order No. Old Order No. New Order No • . Old Order No.

00 1 500 6000 13 5 240 6078

00 2 000 CARTOOL 13 5 260 '7028

Friction Meter Friction Meter 16 1 000 6067

00 2 050 7035 16 1 010 6068

00 2 500 5104 17 0 000 Manual tester

00 2 510 5104A 21 2 060. 7061

00250 6027 21 2 100 603

00 5 000 7051 23 0 000 7060

00 5 500 5129 23 0 010 7060/1

00 5 650 5079 23 0 040 6002

00 7 500 Kukko 17/K 23 0 05Q

.60()2~2

00 8 500 Kukko 204/2 '23 0 150 7002

00 8 510 Kukko 21/1 and '22/1 23 0 160 7024

00 8 650 Kukko 21/5 and 22/2 23 1 000 611

11 0 ooor 600 23 1 140 6039

11 0 020 7000 23 1 150 604

11 0 100 6001 23 1 200 607

11 0 120 7001 23 1 210 SW 30/83

11 t 000 6017 23 1 300 7026

11 1 040 6025-1 23 1 400 7010

11 1 060 7003-1 23 2 000 6206

11 1 100 609 23 2 010 6206E

11 1 120 610 23 2 040 6304

11 1 240 6060 23 2 050 6305

11 2 000 7006 23 2 060 6306

11 2 040 6018 23 2 100 6044

11 2 100 6069 23 2 150 7026/1

11 2 120 6069-1 23 2 200 1846c/3

11 2 140 6013 . 23 2 210 1846a/3

11 2 160 7007 23 2 240 6055

11 2 180 7013 24 0 000 6042

11 2 200 7026 24 0 010 6085

11 2 260 7006 24 0 100 7044

11 2 290 6020 24 0 150 6002-1

11 3 000 6019 34 0 160 7030

11 3 040 6012 24 1 000 6041

11 3 060 7004 24 1 040 6030

11 3 100 . 7008-1 24 1 050 7052

11 4 000 6065-1 24 1 060 7043

11 '.5 000 608 24 1 100 7053

12 1 040 6083/1 24 1 160 7039

12 1 050 6083 24 2 000 6050/1-4

12 1 060 7068 24 2 001 6050/1

12 1 100 6066 .24 2 002 6050/2

13 0 020 7062 24 2 003 6050/3

·13 0 040 011 24 2 004 6050/4

13 0 050 022 24 2 040 6032

13 0 060 010 24 2 050 6034

13 0 600 Unitast synchronizer 24 2 140 6031

13 1 000 6023 24 2 160 7032

13 1 010 6023-1 24 2 180 7038

13 1 030 7020 24 2 190 7037

13 3 000 5125 24 2 250 7035/2

13 3 050 6070 24 2 260 7035/1

13 6 040 6071 24 2 270 7040

13 6 050 6075 24 3 040 7056

13 6 070 6072 24 3 060 7033

13 6 080 6077 24 3 140 6033

13 6 140 6073 24 3 150 7064

13 6 150 6076 24 3 160 7031

Insert after bolt and nut table

. -1-

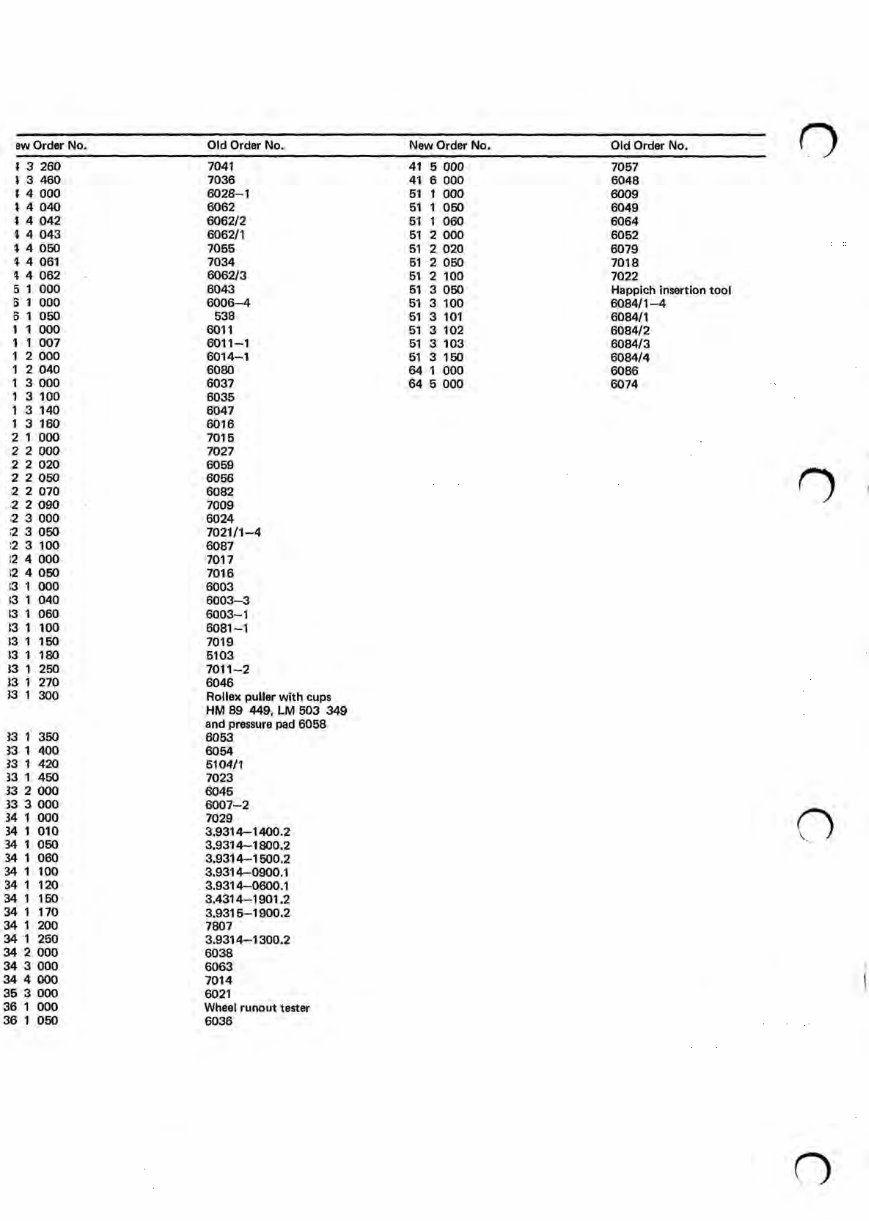

ew Order No.

J 3 260

J 3 460

J 4 000

' 4 040

'4 042

'4 043

!l4050

' 4 061

'4 062

5 1 000

6 1 000

6 1 050

1 1 000

1 1 007

1 2 000

1 2 040

1 3 000

1 3 100

1 3 140

1 3 160

2 1 000

2 2 000

2 2 020

2 2 050

·2 2 070

2 2 090

;2 3 000

:2 3 050

:2 3 100

12 4 000

12 4 050

13 1 000

13 1 040

13 1 060

13 1 100

13 1 150

13 1 180

13 1 250

13 1 270

13 1 300

33 1 350

33 1 400

33 1 420

33 1 450

33 2 000

33 3 000

34 1 000

34 1 010

34 1 050

34 1 060

34 1 100

34 1 120

34 1 150

34 1 170

34 1 200

34 1 250

34 2 000

34 3 000

34 4 000

35 3 000

36 1 000

36 1 050

Old Order No.

7041

7036

6028-1

6062

6062/2

6062/1

7055

7034

6062/3

6043

6006-4

538

6011

6011-1

6014-1

6080

6037

6035

6047

6016

7015

7027

6059

6056

6082

7009

6024

7021/1-4

6087

7017

7016

6003

6003-3

6003-1

6081-1

7019

5103

7011-2

6046

Rollex puller with cups

HM 89 449, LM 503 349

and pressure pad 6058

6053

6054

5104/1

7023

6045

6007-2

7029

3.9314-1400.2

3.9314-1800.2

3.9314-1500.2

3.9314-0900.1

3.9314-0600.1

3.4314-1901.2

3.9315-1900.2

7807

3.9314-1300.2

6038

6063

7014

6021

Wheel runout tester

6036

New Order No.

41 5 000

41 6 000

51 1 000

51 1 050

51 1 060

51 2 000

51 2 020

51 2 050

51 2 100

51 3 050

51 3 100

51 3 101

51 3 102

51 3 103

51 3 150

64 1 000

64 5 000

Old Order No.

7057

6048

6009

6049

6064

6052

6079

7018

7022

Happich insertion tool

6084/1-4

6084/1

6084/2

6084/3

6084/4

6086

6074

0

()

0

Conversion list for special tool numbers

""\

(old to new)

Old Order No. New Order No. Old Order No. New Order No.

010 13 0 060 6042 24 0 000

011 13 0 040 6043 25 1 000

022 13 0 050 6044 23 2 100

538 26 1 050 6045 33 2 000

600 11 0 000 6046 33 1 270

603 21 2 100 6047 31 3 140

604 23 1 150 6048 41 6 000

607 34 1 200 6049 51 1 050

608 11 5 000 6050/1-4 24 2 000

609 11 1 100 6050/1 24 2 001

610 11 1 120 "6050/2 24 2 002

611 23 1 000 6050/3 "24 2 003

1846c/3 23 2 200 6060/4 24 2 004

1846a/3 23 2 210 6052 51 2 000

5079 00 5 550 6053 33 1 350

5103 33 1 180 6054 33 1 400

5104 00 2 500 6055 23 2 240

5104/1 33 1 420 6056 32 2 050

5104A 00 2 510 6059 32 2 020

5120 00 5 500 6060 11 1 240

5125 13 3 000 6062 24 4 040

6000 00 1 500 6062/1 24 4 043

~

6001 11 0 100 6062/2 24 4 042

6002 23 0 040 6062/3 24 4 062

6002-1 24 0 150 6063 34 3 000

6002-2 23 0 050 6064 51 1 060

6003 33 1 000 6065-1 11 4 000

6003-1 33 1 060 6066 12 1 100

6003-3 33 1 040 6067 16 1 000

6006-4 26 1 000 6068 16 1 010

6007-2 33 3 000 6069 11 2 100

6009 51 1 000 6069-1 11 2 120

6011 31 1 000 6070 13 3 050

6011-1 31 1 007 6071 13 5 040

6012 11 3 040 '6072 13 5 070

6013 11 2 140 6073 13 5 140

6014-1 31 2 000 6074 64 5 000

6016 31 3 160 6075 13 5 050

6017 11 1 000 6075 13 5 150

6018 11 2 040 6077 13 5 080

6019 11 3 000 6078 13 5 240

6020 11 2 290 6079 51 2 020

6021 35 3 000 6080 31 2 040

6023 13 1 000 6081-1 33 1 100

6023-1 13 1 010 6082 32 2 070

6024 32 3 000 6083 12 1 050

6025-1 11 1 040 6083/1 12 1 040

~

6027 00 2 550 6084/1-4 51 3 100

6028-1 24 4 000 6084/1 51 3 101

I

6030 24 1 040 6084/2 51 3 102 )

~-

6031 24 2 140 6084/3 51 3 103

6032 24 2 040 6084/4 51 3 150

6033 24 3 .140 6085 24 0 010

6034 24 2 050 6086 64 1 000

6035 313 100 6087 32 3 100

6036 36 1 050 6206 23 2 000

6037 31 3 000 6206E 23 2 010

6038 34 2 000 6304 23 2 040

6039 23 1 140 6305 23 2 050

6041 24 1 000 6306 23 2 060

7000 11 0 020

Insert after bolt and nut table

-3-

Id Order No. New Order No. Old Order No. New Order No. ()

J01 11 0 120 7041 24 3 260

J02 23 0 150 7043 24 1 060

J03-1 11 1 060 7044 24 0 100

004 11 3 060 7051 00 5 000

006 11 2 260 7052 24 1 050

006 11 2 000 7053 24 1 100

007 11 2 160 7054 24 3 150

008-1 11 3 100 7055 24 4 050

009 32 2 090 7056 24 3 040

010 23 1 400 7057 41 5 000

011-2 33 1 250 7058 12 1 060

013 11 2 1fl> 7060 23 0 000

014 34 4 000 7060-1 23 0 010

01!5 32 1 000 7061 21 2 060

016 32 4 060 7062 13 0 020

017 32 4 000 7807 34 1 200

018 61 2 060 SW 30/83 23 1 210

019 33 1 160 3.9314-0600.1 34 1 120

020 13 1 030 3.9314-0900.1 34 1 100

021/1-4 32 3 050 3.9314-1300.2 34 1 250

022 51 2 100 3.9314-1400.2 34 1 010

' 023 33 1 . 460 3.9314-1500.2 34 1 060

'024 23 0 160 3.9314-1800.2 34 1 050

0

'026 11 2 200 3.9314-1900.2 34 1 170

' 026. 23 1 300 3.9314-1901.2 34 1 150

'021/1 23 2 150 Kukko 17/K 00 7 500

'027 32 2 000 Kukko 204/2 00 8 500

1028 13 5 260 Kukko 21/1 and 22/1 00 8 510

1028 34 1 000 Kukko 21/5 and 22/2 oo a 550

J030 24 0 160 CARTOOL

J031 24 3 160 Friction Meter 00 2 000

1032 24 2 160 UNITEST synchroniser 13 0 500

1033 24 3 060 Manual tester 17 0 000

1034 24 4 061 Happich insertion tool 51 3 060

IQ31 00 2 060 Wheel runout tester 36 1 000

1113!{1 24 2 260 Rollex puller with cups 33 1 300._

'.J

~

103!112 24 2 250 HM 89449,

JOC36 24 3 460 LM 503349

1037 24 2 190 and pressure pad

1038 24 2 1~ 6058

7039 24 1 100

7040 24 2 270

0

-0

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$35.99

$46.99

Viewed 10 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$35.99

$46.99

Complete service repair manual for the 1967-1976 BMW 2002. This high-quality manual is 100% complete and intact, with no missing or corrupt pages/sections. It includes detailed illustrations and step-by-step instructions, making it suitable for both DIY enthusiasts and professional mechanics. The manual is printable, allowing easy access in the garage or workshop. With over 400 pages, it provides comprehensive repair and service information. The file format is PDF, compatible with Windows, Mac, and Linux. It is scanned and printable without any restrictions.

- Complete service repair manual for the 1967-1976 BMW 2002

- 100% complete and intact, with no missing or corrupt pages/sections

- Detailed illustrations and step-by-step instructions

- Suitable for both DIY enthusiasts and professional mechanics

- Printable, allowing easy access in the garage or workshop

- Over 400 pages of comprehensive repair and service information

- File format: PDF, compatible with Windows, Mac, and Linux

- Scanned and printable without any restrictions

Direct preview link: BMW 2002 Manual 1967-1976