Yanmar YM135 YM135D YM155 YM155D YM195 YM195D YM240 YM240D YM330 YM330D Tractor Workshop Service Repair Shop Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

SHOP MANUAL

YANMAR

Models YM135, YM135D, YM155, YM155D, YM195, YM195D,

YM240, YM240D, YM330 and YM330D

Tractor serial number is stamped on left side of clutch housing on transmission hous-

ing. Engine model and serial number is located on a data plate attached to right side of

engine for YM135, YM135D, YM155 and YM155D models. Engine model and serial number

is located on a data plate attached to left side of engine for YM195, YM195D, YM240,

YM240D, YM330 and YM330D models.

i

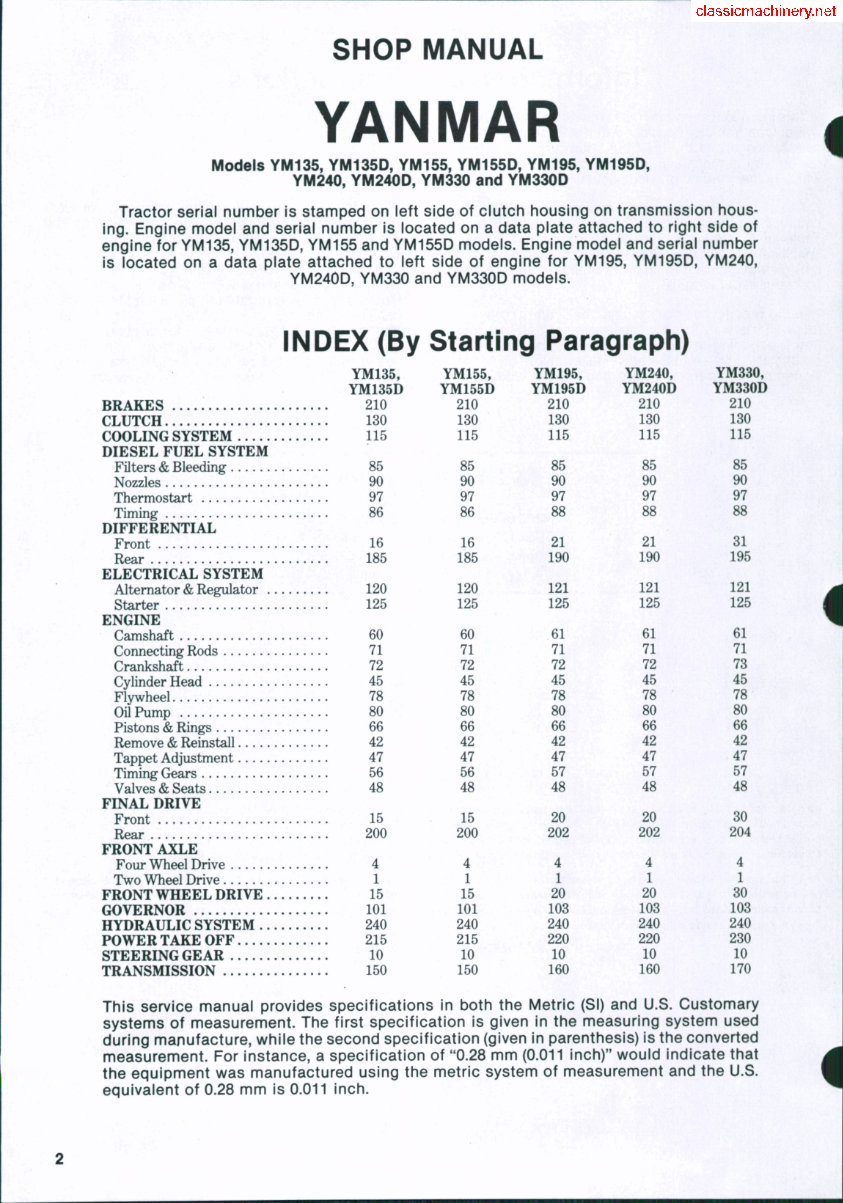

INDEX (By Starting Paragraph)

YM135,

YM135D

BRAKES 210

CLUTCH 130

COOLING SYSTEM 115

DIESEL FUEL SYSTEM

raters & Bleeding 85

Nozzles 90

Thermostart 97

Timing 86

DIFFERENTIAL

Front 16

Rear 185

ELECTRICAL SYSTEM

Alternator & Regulator 120

Starter 125

ENGINE

Camshaft 60

Connecting Rods 71

Crankshaft 72

Cylinder Head 45

Flywheel 78

Oil Pump 80

Pistons & Rings 66

Remove & Reinstall 42

Tappet Adjustment 47

Timing Gears 56

Valves & Seats 48

FINAL DRIVE

Front 15

Rear 200

FRONT AXLE

Four Wheel Drive 4

Two Wheel Drive 1

FRONT WHEEL DRIVE 15

GOVERNOR 101

HYDRAULIC SYSTEM 240

POWER TAKE OFF 215

STEERING GEAR 10

TRANSMISSION 150

This service manual provides specifications in both the Metric (SI) and U.S. Customary

systems of measurement. The first specification is given in the measuring system used

during manufacture, while the second specification (given in parenthesis) is the converted

measurement. For instance, a specification of "0.28 mm (0.011 inch)" would indicate that

the equipment was manufactured using the metric system of measurement and the U.S.

equivalent of 0.28 mm is 0.011 inch.

YM155,

YM155D

210

130

115

85

90

97

86

16

185

120

125

60

71

72

45

78

80

66

42

47

56

48

15

200

4

1

15

101

240

215

10

150

YM195,

YM195D

210

130

115

85

90

97

88

21

190

121

125

61

71

72

45

78

80

66

42

47

57

48

20

202

4

1

20

103

240

220

10

160

YM240,

YM240D

210

130

115

85

90

97

88

21

190

121

125

61

71

72

45

78

80

66

42

47

57

48

20

202

4

1

20

103

240

220

10

160

YM330,

YM330D

210

130

115

85

90

97

88

31

195

121

125

61

71

73

45

78

80

66

42

47

57

48

30

204

4

1

80

103

240

230

10

170

SHOP MANUAL Paragraphs 1-3

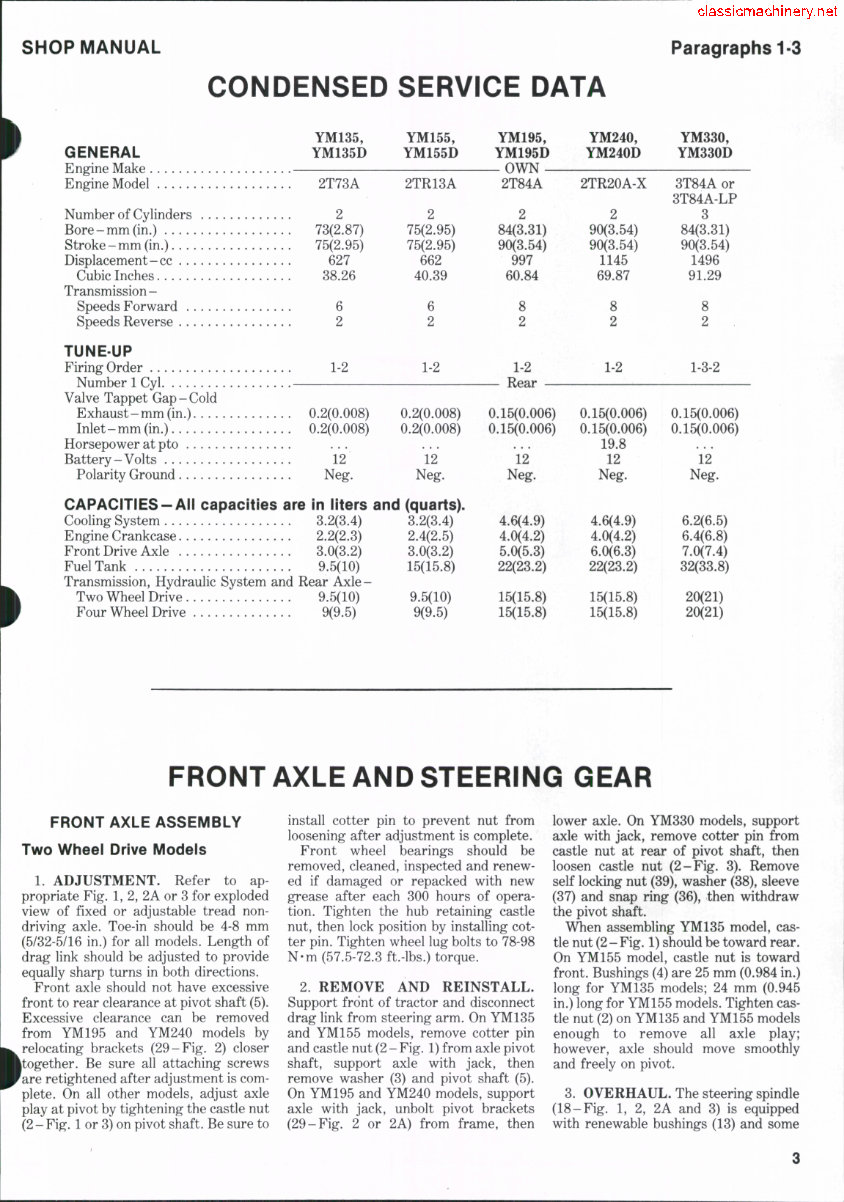

CONDENSED SERVICE DATA

YM135, YM155, YM195, YM240, YM330,

GENERAL YM135D YM155D YM195D YM240D YM330D

Engine Make OWN

Engine Model 2T73A 2TR13A 2T84A 2TR20A-X 3T84A or

3T84A-LP

Number of Cylinders 2 2 2 2 3

Bore-mm (in.) 73(2.87) 75(2.95) 84(3.31) 90(3.54) 84(3.31)

Stroke-mm (in.) 75(2.95) 75(2.95) 90(3.54) 90(3.54) 90(3.54)

Displacement-cc 627 662 997 1145 1496

Cubic Inches 38.26 40.39 60.84 69.87 91.29

Transmission -

Speeds Forward 6 6 8 8 8

Speeds Reverse 2 2 2 2 2

TUNE-UP

FiringOrder 1-2 1-2 1-2 1-2 1-3-2

Number 1 Cyl. Rear

Valve Tappet Gap-Cold

Exhaust-mm (in.) 0.2(0.008) 0.2(0.008) 0.15(0.006) 0.15(0.006) 0.15(0.006)

Inlet-mm (in.) 0.2(0.008) 0.2(0.008) 0.15(0.006) 0.15(0.006) 0.15(0.006)

Horsepower at pto ... ... ... 19.8

Battery-Volts 12 12 12 12 12

Polarity Ground Neg. Neg. Neg. Neg. Neg.

CAPACITIES-All capacities are in liters and (quarts).

Cooling System 3.2(3.4) 3.2(3.4) 4.6(4.9) 4.6(4.9) 6.2(6.5)

Engine Crankcase 2.2(2.3) 2.4(2.5) 4.0(4.2) 4.0(4.2) 6.4(6.8)

Front Drive Axle 3.0(3.2) 3.0(3.2) 5.0(5.3) 6.0(6.3) 7.0(7.4)

Fuel Tank 9.5(10) 15(15.8) 22(23.2) 22(23.2) 32(33.8)

Transmission, Hydraulic System and Rear Axle-

Two Wheel Drive 9.5(10) 9.5(10) 15(15.8) 15(15.8) 20(21)

Four Wheel Drive 9(9.5) 9(9.5) 15(15.8) 15(15.8) 20(21)

FRONT AXLE AND STEERING GEAR

FRONT AXLE ASSEMBLY

Two Wheel Drive Models

1. ADJUSTMENT. Refer to ap-

propriate Fig. 1, 2, 2A or 3 for exploded

view of fixed or adjustable tread non-

driving axle. Toe-in should be 4-8 mm

(5/32-5/16 in.) for all models. Length of

drag link should be adjusted to provide

equally sharp turns in both directions.

Front axle should not have excessive

front to rear clearance at pivot shaft (5).

Excessive clearance can be removed

from YM195 and YM240 models by

relocating brackets (29-Fig. 2) closer

^together. Be sure all attaching screws

Fare retightened after adjustment is com-

plete. On all other models, adjust axle

play at pivot by tightening the castle nut

(2- Fig. 1 or 3) on pivot shaft. Be sure to

install cotter pin to prevent nut from

loosening after adjustment is complete.

Front wheel bearings should be

removed, cleaned, inspected and renew-

ed if damaged or repacked with new

grease after each 300 hours of opera-

tion. Tighten the hub retaining castle

nut, then lock position by installing cot-

ter pin. Tighten wheel lug bolts to 78-98

N-m (57.5-72.3 ft.-lbs.) torque.

2. REMOVE AND REINSTALL.

Support front of tractor and disconnect

drag link from steering arm. On YM135

and YM155 models, remove cotter pin

and castle nut (2 - Fig. 1) from axle pivot

shaft, support axle with jack, then

remove washer (3) and pivot shaft (5).

On YM195 and YM240 models, support

axle with jack, unbolt pivot brackets

(29-Fig. 2 or 2A) from frame, then

lower axle. On YM330 models, support

axle with jack, remove cotter pin from

castle nut at rear of pivot shaft, then

loosen castle nut (2-Fig. 3). Remove

self locking nut (39), washer (38), sleeve

(37) and snap ring (36), then withdraw

the pivot shaft.

When assembling YM135 model, cas-

tle nut (2-Fig. 1) should be toward rear.

On YM155 model, castle nut is toward

front. Bushings (4) are 25 mm (0.984 in.)

long for YM135 models; 24 mm (0.945

in.) long for YM155 models. Tighten cas-

tle nut (2) on YM135 and YM155 models

enough to remove all axle play;

however, axle should move smoothly

and freely on pivot.

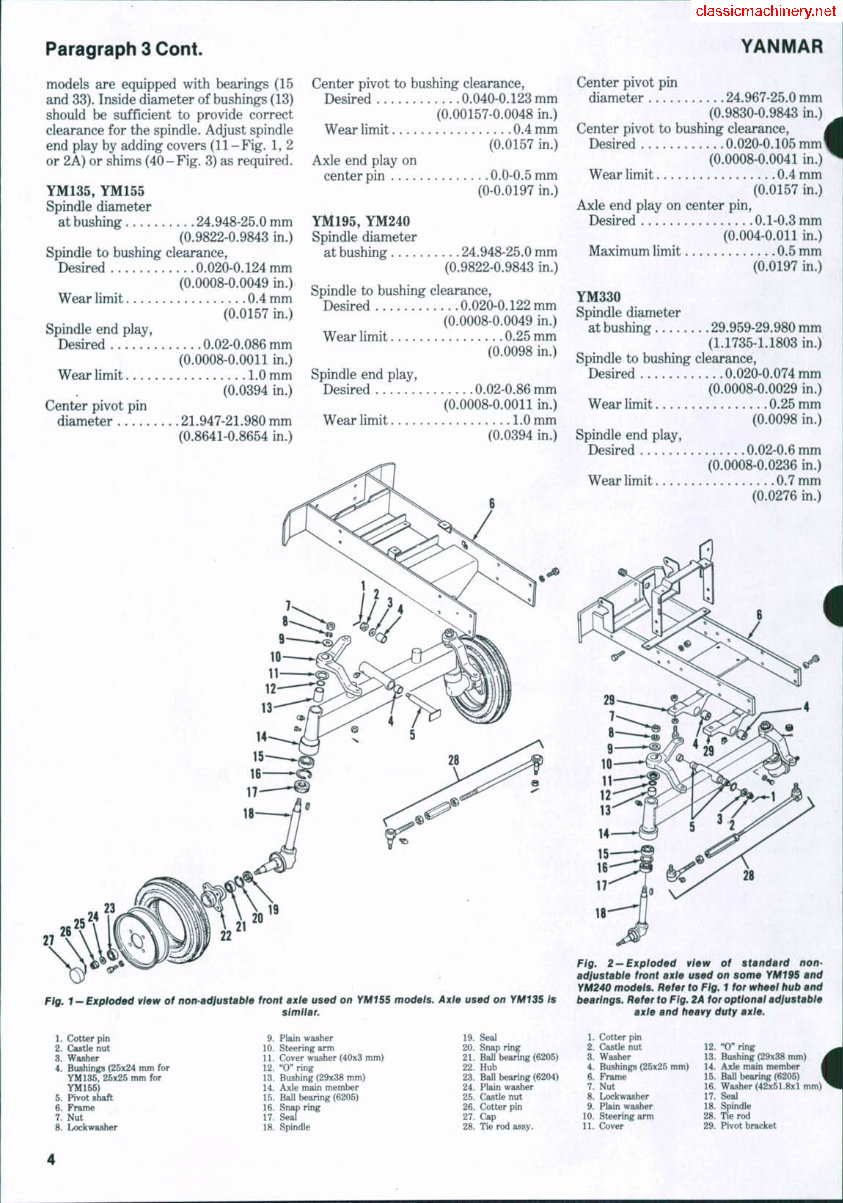

3. OVERHAUL. The steering spindle

(18-Fig. 1, 2, 2A and 3) is equipped

with renewable bushings (13) and some

Paragraph 3 Cont.

YANMAR

models are equipped with bearings (15

and 33). Inside diameter of bushings (13)

should be sufficient to provide correct

clearance for the spindle. Adjust spindle

end play by adding covers (11-Fig. 1, 2

or 2A) or shims (40-Fig. 3) as required.

YM135, YM155

Spindle diameter

at bushing 24.948-25.0 mm

(0.9822-0.9843 in.)

Spindle to bushing clearance,

Desired 0.020-0.124 mm

(0.0008-0.0049 in.)

Wear limit 0.4 mm

(0.0157 in.)

Spindle end play,

Desired 0.02-0.086 mm

(0.0008-0.0011 in.)

Wear limit 1.0 mm

(0.0394 in.)

Center pivot pin

diameter 21.947-21.980 mm

(0.8641-0.8654 in.)

Center pivot to bushing clearance.

Desired 0.040-0.123 mm

(0.00157-0.0048 in.)

Wear limit 0.4 mm

(0.0157 in.)

Axle end play on

center pin 0.0-0.5 mm

(0-0.0197 in.)

YM195, YM240

Spindle diameter

at bushing 24.948-25.0 mm

(0.9822-0.9843 in.)

Spindle to bushing clearance.

Desired 0.020-0.122 mm

(0.0008-0.0049 in.)

Wear limit 0.25 mm

(0.0098 in.)

Spindle end play,

Desired 0.02-0.86 mm

(0.0008-0.0011 in.)

Wear limit 1.0 mm

(0.0394 in.)

Center pivot pin

diameter 24.967-25.0 mm

(0.9830-0.9843 in.)

Center pivot to bushing clearance,

Desired 0.020-0.105 mm^

(0.0008-0.0041 in.)

Wear limit 0.4 mm

(0.0157 in.)

Axle end play on center pin,

Desired 0.1-0.3 mm

(0.004-0.011 in.)

Maximum limit 0.5 mm

(0.0197 in.)

YM330

Spindle diameter

at bushing 29.959-29.980 mm

(1.17354.1803 in.)

Spindle to bushing clearance,

Desired 0.020-0.074 mm

(0.0008-0.0029 in.)

Wear limit 0.25 mm

(0.0098 in.)

Spindle end play.

Desired .0.02-0.6 mm

(0.0008-0.0236 in.)

Wear limit 0.7 mm

(0.0276 in.)

Fig. 1 - Exploded vtew of non-adfustabte front ax/e used on YM155 models. Axle used on YM135 Is

similar.

Fig. 2—Exploded view of standard non-

adiustable front axle used on some YM195 and

YM240 models. Refer to Fig. 1 for wbeel bub and

bearings. Refer to Fig. 2A for optional adjustable

axle and beavy duty axle.

1. Cotter pin

2. Castle nut

3. Washer

4. Bushings (25x24 mm for

YM135, 25x25 mm for

YM155)

5. Pivot shaft

6. Frame

7. Nut

8. Lockwasher

9. Plain washer

10. Steering arm

11. Cover washer (40x3 mm)

12. "0" ring

13. Bushing (29x38 mm)

14. Axle main member

15. Ball bearing (6205)

16. Snap ring

17. Seal

18. Spindle

19. Seal

20. Snap ring

21. Ball bearing (6205)

22. Hub

23. Ball bearing (6204)

24. Plain washer

25. Castle nut

26. Cotter pin

27. Cap

28. Tie rod assy.

1. Cotter pin

2. Castle nut

3. Washer

4. Bushings (25x25 mm)

6. Frame

7. Nut

8. Lockwasher

9. Plain washer

10. Steering wrm

11. Cover

12. "O" ring

13. Bushing (29x38 mm)

14. Axle main member 1

15. Ball bearing (6205)

16. Washer (42x51.8x1 mm)

17. Seal

18. Spindle

28. Tie rod

29. Pivot bracket

SHOP MANUAL

Paragraphs 4-11

Center pivot pin

diameter 34.95-34.975 mm

(1.3760-1.3770 in.)

^Center pivot to bushing clearance.

Desired 0.025-0.089 mm

(0.0010-0.0035 in.)

Wear limit 0.4 mm

(0.0157 in.)

Axle end play on center pin.

Desired 0.1-0.3 mm

(0.0039-0.0118 in.)

Maximum limit 0.5 mm

(0.0197 in.)

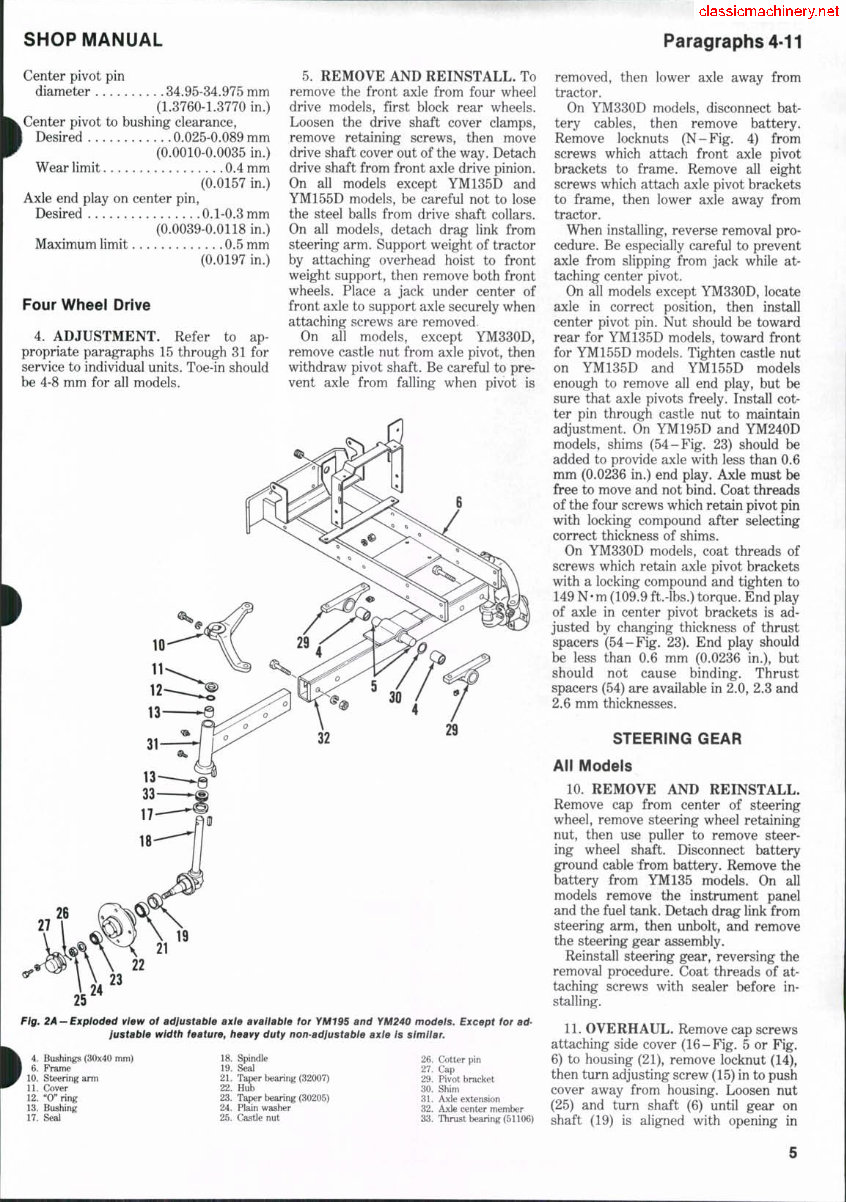

Four Wheel Drive

4. ADJUSTMENT. Refer to ap-

propriate paragraphs 15 through 31 for

service to individual units. Toe-in should

be 4-8 mm for all models.

5. REMOVE AND REINSTALL. To

remove the front axle from four wheel

drive models, first block rear wheels.

Loosen the drive shaft cover clamps,

remove retaining screws, then move

drive shaft cover out of the way. Detach

drive shaft from front axle drive pinion.

On all models except YM135D and

YM155D models, be careful not to lose

the steel balls from drive shaft collars.

On all models, detach drag link from

steering arm. Support weight of tractor

by attaching overhead hoist to front

weight support, then remove both front

wheels. Place a jack under center of

front axle to support axle securely when

attaching screws are removed.

On all models, except YM330D,

remove castle nut from axle pivot, then

withdraw pivot shaft. Be careful to pre-

vent axle from falling when pivot is

Fig, 2A-Exploded vfew of adfustabtB axle awalfable for YMIBS and YfAZAO models. Except for ad-

lustable width feature, heavy duty non-adjustable axle is similar.

26. Cotter pin

27. Cap

29. Pivot bracket

30. Shim

31. Axle extension

32. Axle center member

33. Thrust bearing (51106)

4. Bushings (30x40 mm)

6. Frame

10. Steering arm

11. Cover

12. "0" ring

13. Bushing

17. Seal

18. Spindle

19. Seal

21. Taper bearing (32007)

22. Hub

23. Taper bearing (30205)

24. Plain washer

25. Castle nut

removed, then lower axle away from

tractor.

On YM330D models, disconnect bat-

tery cables, then remove battery.

Remove locknuts (N-Fig. 4) from

screws which attach front axle pivot

brackets to frame. Remove all eight

screws which attach axle pivot brackets

to frame, then lower axle away from

tractor.

When installing, reverse removal pro-

cedure. Be especially careful to prevent

axle from slipping from jack while at-

taching center pivot.

On all models except YM330D, locate

axle in correct position, then install

center pivot pin. Nut should be toward

rear for YM135D models, toward front

for YM155D models. Tighten castle nut

on YM135D and YM155D models

enough to remove all end play, but be

sure that axle pivots freely. Install cot-

ter pin through castle nut to maintain

adjustment. On YM195D and YM240D

models, shims (54-Fig. 23) should be

added to provide axle with less than 0.6

mm (0.0236 in.) end play. Axle must be

free to move and not bind. Coat threads

of the four screws which retain pivot pin

with locking compound after selecting

correct thickness of shims.

On YM330D models, coat threads of

screws which retain axle pivot brackets

with a locking compound and tighten to

149 N-m (109.9 ft.-lbs.) torque. End play

of axle in center pivot brackets is ad-

justed by changing thickness of thrust

spacers (54-Fig. 23). End play should

be less than 0.6 mm (0.0236 in.), but

should not cause binding. Thrust

spacers (54) are available in 2.0, 2.3 and

2.6 mm thicknesses.

STEERiNG GEAR

All Models

10. REMOVE AND REINSTALL.

Remove cap from center of steering

wheel, remove steering wheel retaining

nut, then use puller to remove steer-

ing wheel shaft. Disconnect battery

ground cable from battery. Remove the

battery from YM135 models. On all

models remove the instrument panel

and the fuel tank. Detach drag link from

steering arm, then unbolt, and remove

the steering gear assembly.

Reinstall steering gear, reversing the

removal procedure. Coat threads of at-

taching screws with sealer before in-

stalling.

11. OVERHAUL. Remove cap screws

attaching side cover (16-Fig. 5 or Fig.

6) to housing (21), remove locknut (14),

then turn adjusting screw (15) in to push

cover away from housing. Loosen nut

(25) and turn shaft (6) until gear on

shaft (19) is aligned with opening in

Paragraph 11 Cont.

YANMAR

housing. Remove adjusting screw (15),

then bump end of shaft (19) out toward

right. After steering arm (24) is released

from end of shaft, remove nut (25) and

steering arm, then withdraw shaft (19)

from housing. Unbolt steering column

(12), then withdraw shaft (6) and ball nut

(8).

Bushings (22) are available only as an

assembly with housing (21). Seal (23)

should be flush with housing. Inner race

for ball bearings (7) is integral with shaft

(6) and disassembly is not recommended.

Clean ball nut (8) without disassembling

and check for smoothness. Ball nut is

available only as an assembly with shaft

(6). Apply grease liberally to shaft and

ball nut. Grease lower bearing (7) and

position in bearing race located in hous-

ing. Grease upper bearing (7) and locate

on shaft (6). Position shaft (6) with ball

nut (8) and upper bearing in housing

(21). Position column (12) over shaft and

select thickness of shims (13) which will

permit free movement of shaft in bear-

ings (7) with no end play of shaft. Install

column (12) with sealing "0" ring (9)

after selecting correct thickness of

shims (13).

Turn shaft (6) until ball nut (8) is in

center of travel. Coat cross shaft (19)

with grease, then install with center

tooth in center valley of ball nut. Posi-

tion adjustment screw (15) and shim (18)

in end of shaft and gasket (20) on hous-

ing, then install cover (16). Turn ad-

justing screw (15) out through cover (16)

while installing, then tighten the cover

attaching screws to 23-30 N-m

(16.96-22.13 ft.-lbs.) torque. Be sure that

adjusting screw (15) remains loose while

tightening the cover attaching screws.

Install steering arm (24) over shaft

splines with index marks aligned. Some

models have a missing spline to assist

alignment of steering arm. Adjust screw

(15) to provide 30-50 mm (1 3/16-2 in.)

free play at rim of steering wheel, then

lock adjustment with nut (4). Initial ad-

justment can be accomplished by turn-

ing screw clockwise as far as possible,

then backing screw up V4-turn and lock

with nut (14). Wear is indicated if play at

rim exceeds 50 mm (2 in.) with correct

adjustment of screw (15) and correct

thickness of shims (13).

Steering gear should be filled with

SAE 90 gear lubricant. Capacity is 20

mL for YM135, YM135D, YM155 and

YM155D. Capacity is 26 mL for other

models.

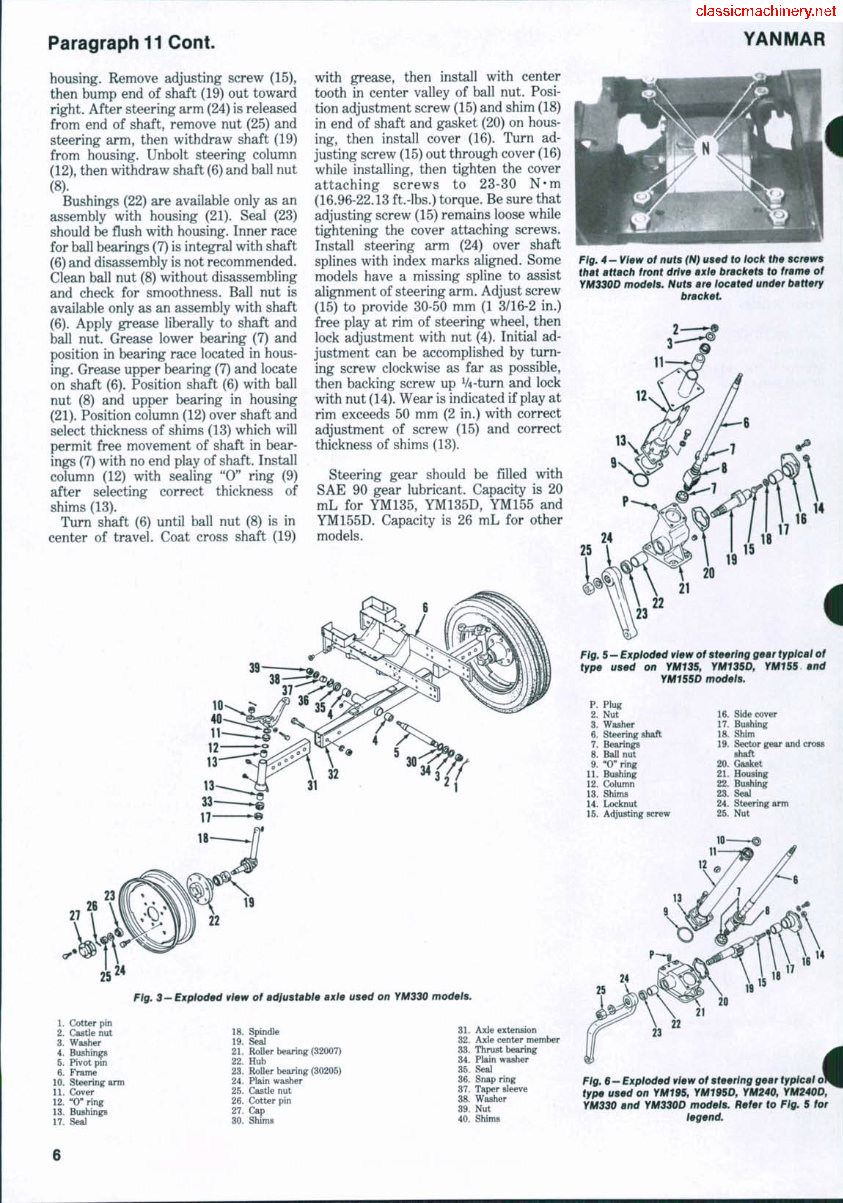

Fig. $- Exploded view of adfustable axle used on rM330 models.

1. Cotter pin

2. Castle nut

3. Washer

4. Bushings

5. Pivot pin

6. Frame

10. Steering arm

11. Cover

12. "0" ring

13. Bushings

17. Seal

18. Spindle

19. Seal

21. RoUer bearing (32007)

22. Hub

23. Roller bearing (30205)

24. Plain washer

25. Castle nut

26. Cotter pin

27. Cap

30. Shims

31. Axle extension

32. Axle center member

33. Thrust bearing

34. Plain washer

35. Seal

36. Snap ring

37. Taper sleeve

38. Washer

39. Nut

40. Shims

Fig. 4 "View of nuts {Hi used to iock tbe screws

tbat attacb front drive axle brackets to frame of

yM330O modeis. Nuts are located under battery

bracket

Fig. 5 — Expioded view of steering gear typlcai of

type used on YM135, YM135D, rM155 and

YM155D models.

P. Plug

2. Nut

3. Washer

6. Steering shaft

7. Bearings

8. Ball nut

9. "0" ring

11. Bushing

12. Column

13. Shims

14. Locknut

15. Adjusting screw

16. Side cover

17. Bushing

18. Shim

19. Sector gear and cross

shaft

20. Gasket

21. Housing

22. Bushing

23. Seal

24. Steering arm

25. Nut

10 ^

25

Fig. 6—Exploded view of steering gear typical ol

type used on YM195, YM195D, YM240, YM240D,

YM330 and YM330D modeis. Refer to Fig. 5 for

iegend.

SHOP MANUAL

FRONT WHEEL

DRIVE

OUTER DRIVE HOUSING

YM135D and YM155D Models

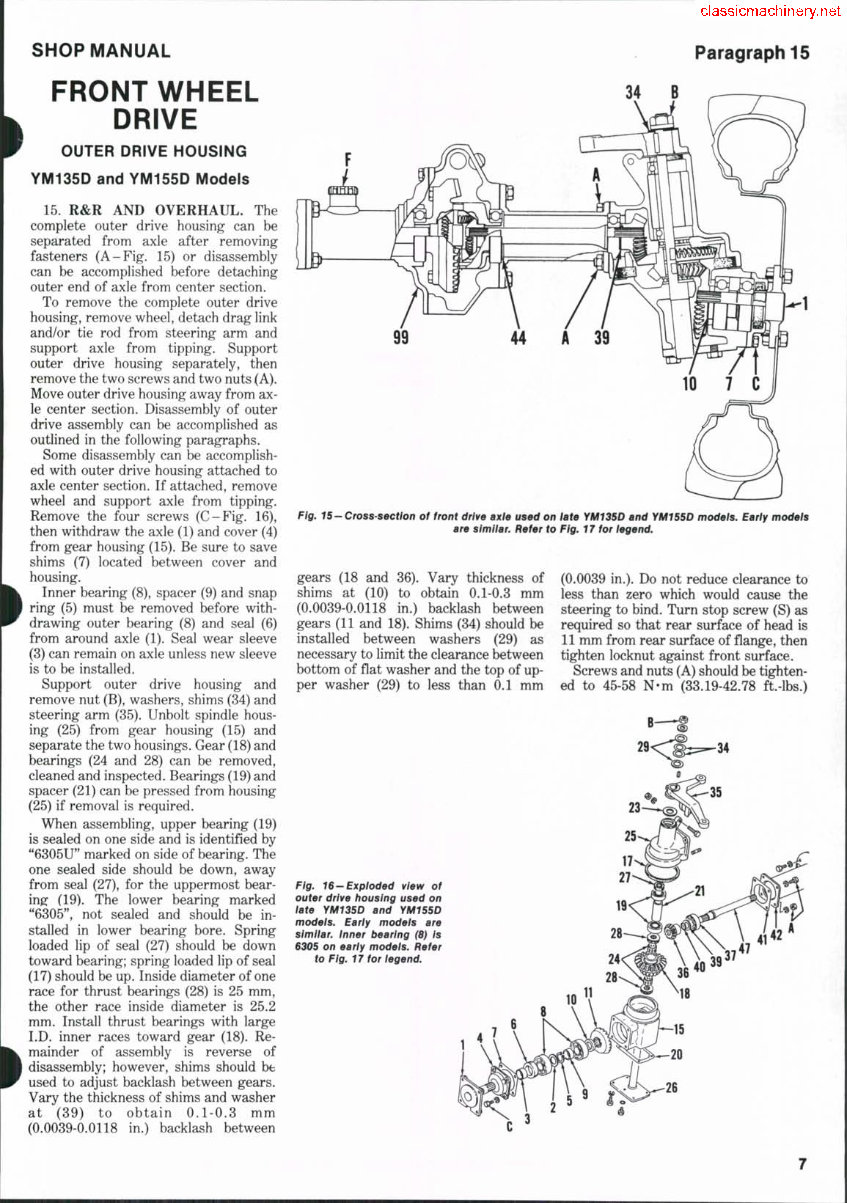

15. R&R AND OVERHAUL. The

complete outer drive housing can be

separated from axle after removing

fasteners (A-Fig, 15) or disassembly

can be accomplished before detaching

outer end of axle from center section.

To remove the complete outer drive

housing, remove wheel, detach drag link

and/or tie rod from steering arm and

support axle from tipping. Support

outer drive housing separately, then

remove the two screws and two nuts (A).

Move outer drive housing away from ax-

le center section. Disassembly of outer

drive assembly can be accomplished as

outlined in the following paragraphs.

Some disassembly can be accomplish-

ed with outer drive housing attached to

axle center section. If attached, remove

wheel and support axle from tipping.

Remove the four screws (C-Fig. 16),

then withdraw the axle (1) and cover (4)

from gear housing (15). Be sure to save

shims (7) located between cover and

housing.

Inner bearing (8), spacer (9) and snap

ring (5) must be removed before with-

drawing outer bearing (8) and seal (6)

from around axle (1). Seal wear sleeve

(3) can remain on axle unless new sleeve

is to be installed.

Support outer drive housing and

remove nut (B), washers, shims (34) and

steering arm (35). Unbolt spindle hous-

ing (25) from gear housing (15) and

separate the two housings. Gear (18) and

bearings (24 and 28) can be removed,

cleaned and inspected. Bearings (19) and

spacer (21) can be pressed from housing

(25) if removal is required.

When assembling, upper bearing (19)

is sealed on one side and is identified by

"6305U" marked on side of bearing. The

one sealed side should be down, away

from seal (27), for the uppermost bear-

ing: (19). The lower bearing marked

"6305", not sealed and should be in-

stalled in lower bearing bore. Spring

loaded lip of seal (27) should be down

toward bearing; spring loaded lip of seal

(17) should be up. Inside diameter of one

race for thrust bearings (28) is 25 mm,

the other race inside diameter is 25.2

mm. Install thrust bearings with large

I.D. inner races toward gear (18). Re-

mainder of assembly is reverse of

disassembly; however, shims should be

used to adjust backlash between gears.

Vary the thickness of shims and washer

at (89) to obtain 0.1-0.3 mm

(0.0039-0.0118 in.) backlash between

Paragraph 15

99

Fig, 15-Crosss0ctlon of front drive axie used on late rMY35D and YM1SSD models. Early models

are similar. Refer to Fig, 17 tor legend.

gears (18 and 36). Vary thickness of

shims at (10) to obtain 0.1-0.3 mm

(0.0039-0.0118 in.) backlash between

gears (11 and 18). Shims (34) should be

installed between washers (29) as

necessary to limit the clearance between

bottom of flat washer and the top of up-

per washer (29) to less than 0.1 mm

(0.0039 in.). Do not reduce clearance to

less than zero which would cause the

steering to bind. Turn stop screw (S) as

required so that rear surface of head is

11 mm from rear surface of flange, then

tighten locknut against front surface.

Screws and nuts (A) should be tighten-

ed to 45-58 N-m (33.19-42.78 ft.-lbs.)

Fig. 16—Exploded view of

outer drive housing used on

late YM135D and YMiSSD

models. Early models are

similar, inner bearing (8) Is

S305 on early models. Refer

to Fig. 17 for legend.

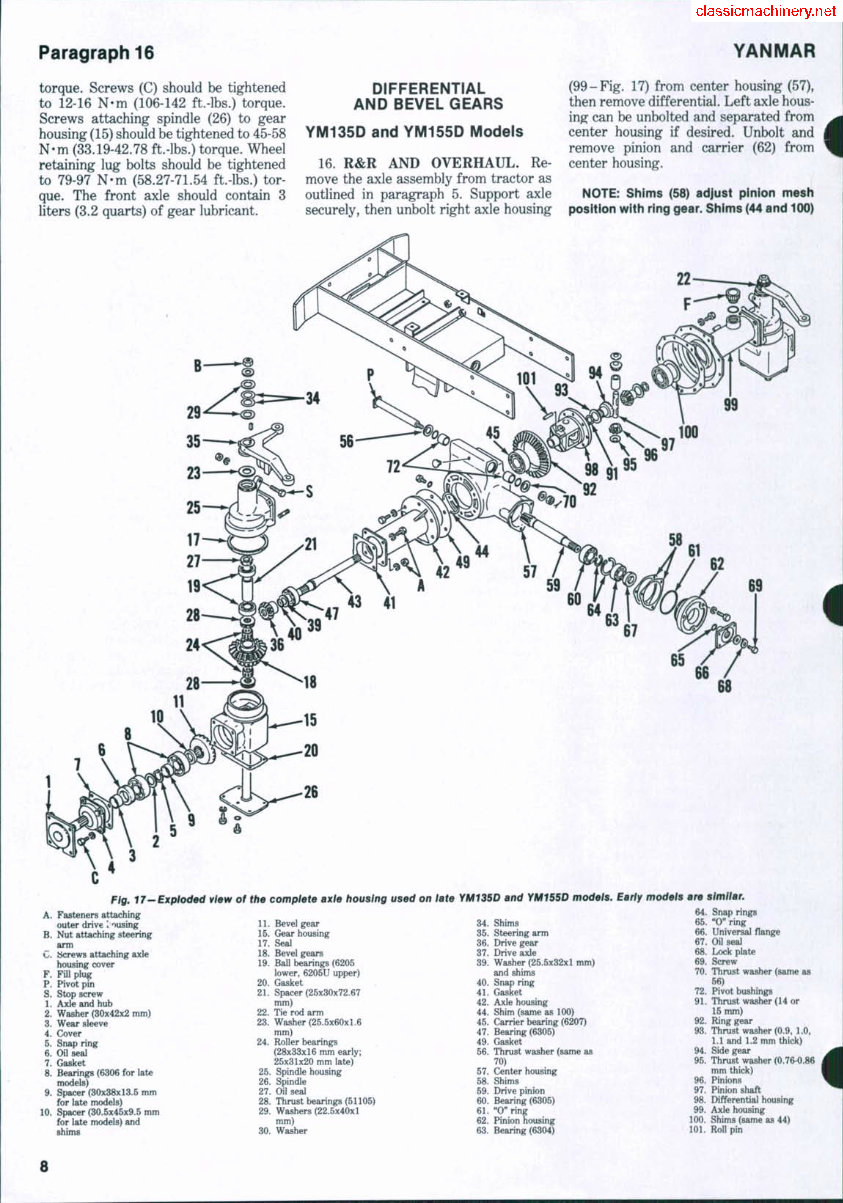

Paragraph 16 YANMAR

torque. Screws (C) should be tightened

to 12-16 N-m (106-142 ft.-lbs.) torque.

Screws attaching spindle (26) to gear

housing (15) should be tightened to 45-58

N-m (33.19-42.78 ft.-lbs.) torque. Wheel

retaining lug bolts should be tightened

to 79-97 N-m (58.27-71.54 ft.-lbs.) tor-

que. The front axle should contain 3

liters (3.2 quarts) of gear lubricant.

DIFFERENTIAL

AND BEVEL GEARS

YM135D and YM155D Models

16. R&R AND OVERHAUL. Re-

move the axle assembly from tractor as

outlined in paragraph 5. Support axle

securely, then unbolt right axle housing

(99-Fig. 17) from center housing (57),

then remove differential. Left axle hous-

ing can be unbolted and separated from

center housing if desired. Unbolt and

remove pinion and carrier (62) from

center housing.

NOTE: Shims (58) adjust pinion mesh

position with ring gear. Shims (44 and 100)

Fig. IT—Exptaded ¥i0w of the complete axle housing used on late

YM1350 and YMiSSD models. Early models are similar.

10.

Fasteners attaching

outer drive I 'msing

Nut attaching steering

arm

tScrews attaching axle

housing cover

Fill plug

Pivot pin

Stop screw

Axle and hub

Washer (30x42x2 mnn)

Wear sleeve

Cover

Snap ring

Oil seal

Gasket

Bearings (6306 for late

models)

Spacer (30x38x13.5 nun

for late models)

Spacer (30.5x45x9.5 mm

for late models) and

shims

11. Bevel gear

15. Gear housing

17. Seal

18. Bevel gears

19. Ball bearing (6205

lower, 6205U upper)

20. Gasket

21. Spacer (25x30x72.67

mm)

22. Tie rod arm

23. Washer (25.5x60x1.6

mm)

24. Roller bearings

(28x33x16 mm early;

25x31x20 mni late)

25. Spindle housing

26. Spindle

27. Oil seal

28. Thrust bearings (51105)

29. Washers (22.5x40x1

mm)

30. Washer

34. Shims

35. Steering arm

36. Drive gear

37. Drive axle

39. Washer (25.5x32x1 mm)

and shims

40. Snap ring

41. Gasket

42. Axle housing

44. Shim (same as 100)

45. Carrier bearing (6207)

47. Bearing (6305)

49. Gasket

56. Thrust washer (same as

70)

57. Center housing

58. Shims

59. Drive pinion

60. Bearing (6305)

61. "O"ring

62. Pinion housing

63. Bearing (6304)

64. Snap rings

65. "0" ring

66. Universal flange

67. OU seal

68. Lock plate

69. Screw

70. Thrust washer (same as

56)

72. Pivot bushings

91. Thrust washer (14 or

15 mm)

92. Ring gear

93. Thrust washer (0.9, 1.0,

1.1 and 1.2 mm thick)

94. Side gear

95. Thrust washer (0.76-0.86

mm thick)

96. Pinions

97. Pinion shaft

98. Differential housing

99. Axle housing

100. Shims (same as 44)

101. Roll pin

8

SHOP MANUAL

Paragraph 20

adjust carrier bearings (45). Moving shims

(44 and 100) from one side to the other

moves the differentiai and therefore ad-

justs bevei gear backiash. Be carefui not

to iose or damage shims when dis-

assembiing.

The pinion bearings (60 and 63), car-

rier (62) and related parts can be

assembled on the pinion shaft (59) before

assembling into center housing. The

mesh position can be checked using a

mandrel manufactured to the dimen-

sions shown in Fig. 18. Distance (A)

should be 15.95-16.05 mm (0.6280-

0.6319 in.) if checked with mandrel. If

mandrel is not available and thickness of

shims (58-Fig. 17) is not correct, mesh

position can be checked by coating teeth

of ring gear with mechanics blueing,

then installing differential in center

Fig. 18—A mandrel can be

used to determine correct

t/ifc/rness of sbims (58) to In-

staii, by measuring distance

iA}. Diameter of mandrei at

(B) sbouid be 71.9972.00

mm, length at (C) sliouid be

60 mm and radius (D) of boit

cirde sbouid be 58 mm.

housing (57) with left carrier bearing

(45) and axle housing (42) installed. The

toe of the pinion gear should be aligned

with center edge of ring gear teeth and

mesh pattern should be approximately

centered on teeth. Change thickness of

shims (58) to set correct pinion position.

Change the thickness of shims (44)

under left carrier bearing to provide

0.1-0.3 mm (0.0039-0.0118 in.) backlash

between pinion and ring gear teeth. Be

sure that left axle housing is securely at-

tached to the center housing and that

differential and left carrier bearing are

firmly seated when measuring backlash.

Shims should be provided at (100) to

remove all play from carrier bearings,

but should not cause bearings to bind

when axle housing is assembled. Screws

attaching left axle housing (42) to center

housing (57) should be tightened to

38 36 B 28 B

59

Fig. 20 - Cross section of front drive axle used on YM195D modeis. The wheei dxle (U S^^r (11) and

related parts are different than used on YM240D models shovi/n in Fig. 21. Refer to Fig. 22 for legend.

44.7-58.3 N-m (33-43 ft.-lbs.) torque.

Screws attaching pinion housing (62) to

center housing (57) should be tightened

to 12.2-16.3 N-m (108-144 in.lbs.) tor-

que. Screw (69) should be tightened to

23.0-29.8 N-m (203.6-263.8 in.-lbs.) tor-

que, then locked with plate (68). Screws

attaching right axle housing (99) to

center housing (57) should be tightened

to 23.0-29.8 N-m (203.6-263.8 in.-lbs.)

torque.

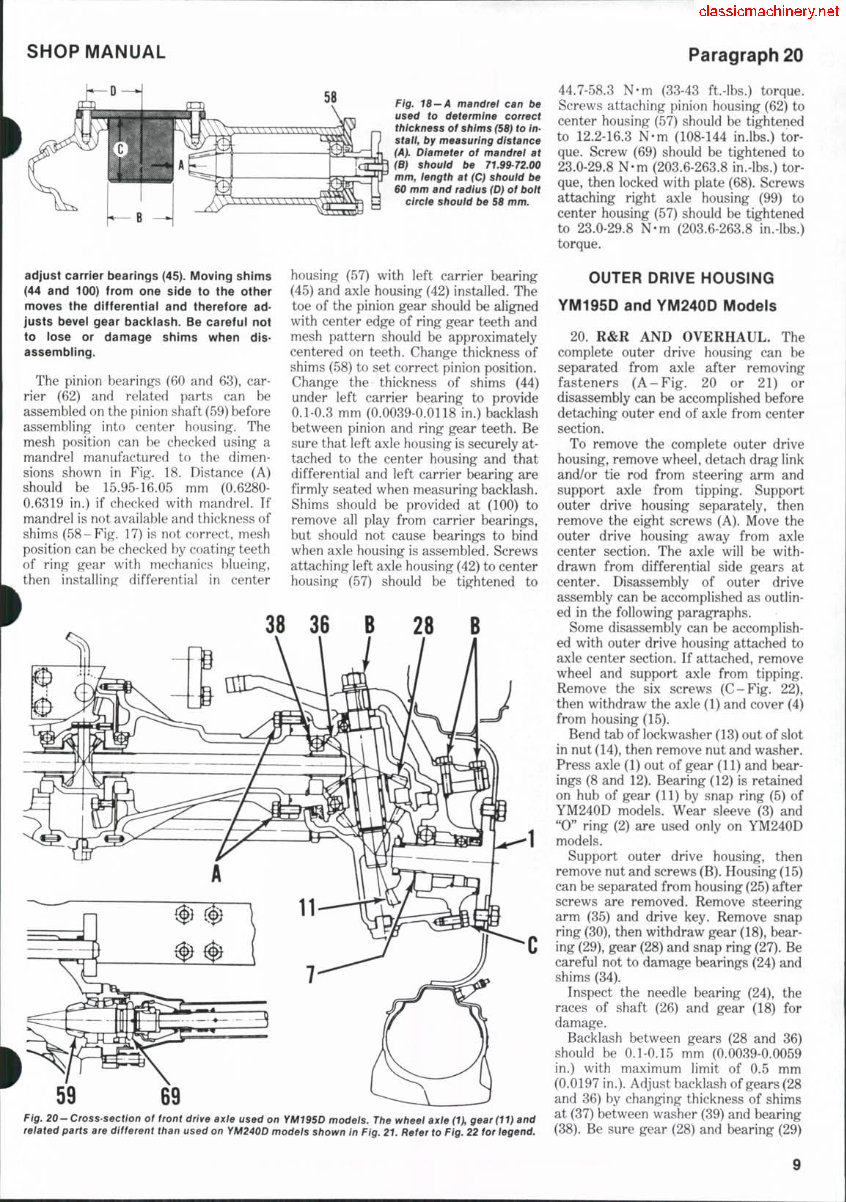

OUTER DRIVE HOUSING

YM195D and YM240D Models

20. R&R AND OVERHAUL. The

complete outer drive housing can be

separated from axle after removing

fasteners (A-Fig. 20 or 21) or

disassembly can be accomplished before

detaching outer end of axle from center

section.

To remove the complete outer drive

housing, remove wheel, detach drag link

and/or tie rod from steering arm and

support axle from tipping. Support

outer drive housing separately, then

remove the eight screws (A). Move the

outer drive housing away from axle

center section. The axle will be with-

drawn from differential side gears at

center. Disassembly of outer drive

assembly can be accomplished as outlin-

ed in the following paragraphs.

Some disassembly can be accomplish-

ed with outer drive housing attached to

axle center section. If attached, remove

wheel and support axle from tipping.

Remove the six screws (C-Fig. 22),

then withdraw the axle (1) and cover (4)

from housing (15).

Bend tab of lockwasher (13) out of slot

in nut (14), then remove nut and washer.

Press axle (1) out of gear (11) and bear-

ings (8 and 12). Bearing (12) is retained

on hub of gear (11) by snap ring (5) of

YM240D models. Wear sleeve (3) and

"0" ring (2) are used only on YM240D

models.

Support outer drive housing, then

remove nut and screws (B). Housing (15)

can be separated from housing (25) after

screws are removed. Remove steering

arm (35) and drive key. Remove snap

ring (30), then withdraw gear (18), bear-

ing (29), gear (28) and snap ring (27). Be

careful not to damage bearings (24) and

shims (34).

Inspect the needle bearing (24), the

races of shaft (26) and gear (18) for

damage.

Backlash between gears (28 and 36)

should be 0.1-0.15 mm (0.0039-0.0059

in.) with maximum limit of 0.5 mm

(0.0197 in.). Adjust backlash of gears (28

and 36) by changing thickness of shims

at (37) between washer (39) and bearing

(38). Be sure gear (28) and bearing (29)

9

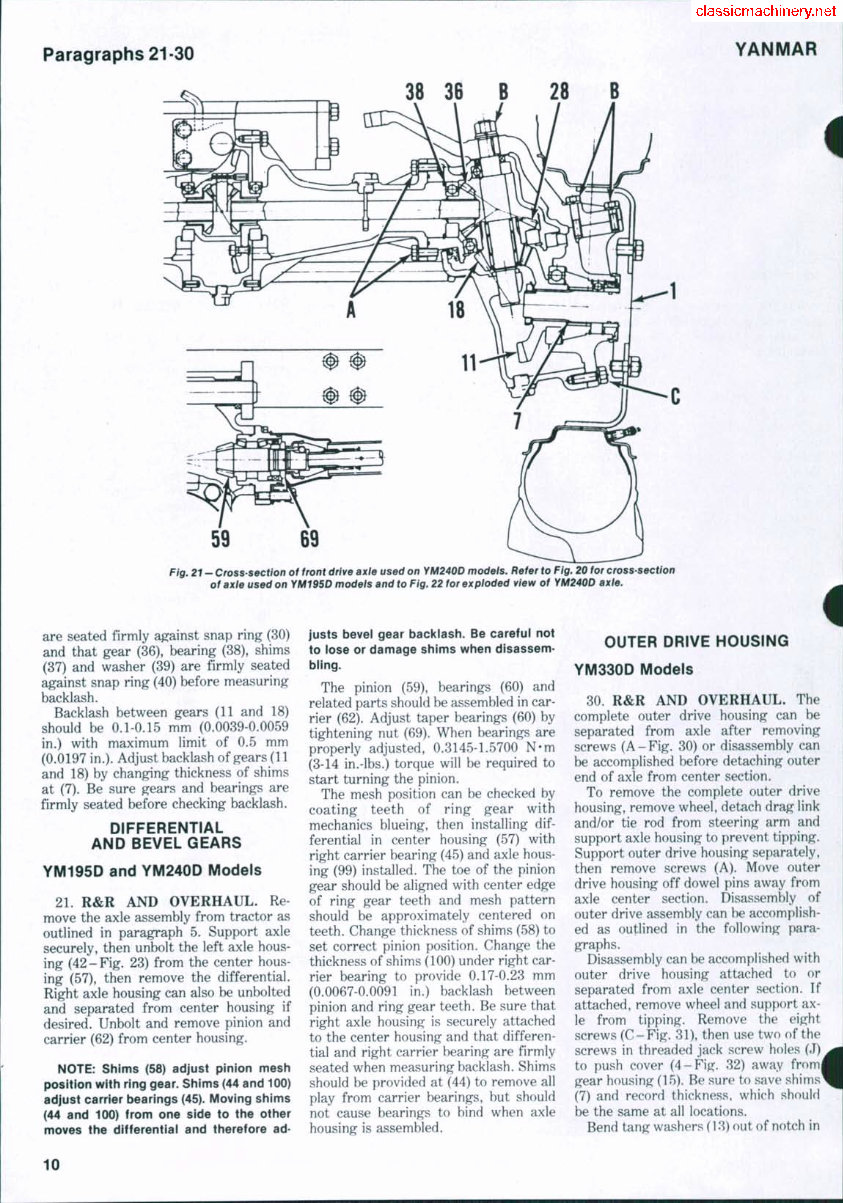

Paragraphs 21-30

YANMAR

38 36 B 28 B

59 69

Fig, 21 - Cross-section of front drive axle used on fM240D models. Refer to Fig. 20 for cross-section

of axle used on YM195D models and to Fig, 22 for exploded view of YM240D axle.

are seated firmly against snap ring (30)

and that gear (36), bearing (38), shims

(37) and washer (39) are firmly seated

against snap ring (40) before measuring

backlash.

Backlash between gears (11 and 18)

should be 0.1-0.15 mm (0.0039-0.0059

in.) with maximum limit of 0.5 mm

(0.0197 in.). Adjust backlash of gears (11

and 18) by changing thickness of shims

at (7). Be sure gears and bearings are

firmly seated before checking backlash.

DIFFERENTIAL

AND BEVEL GEARS

YM195D and YM240D Models

21. R&R AND OVERHAUL. Re

move the axle assembly from tractor as

outlined in paragraph 5. Support axle

securely, then unbolt the left axle hous-

ing (42-Fig. 23) from the center hous-

ing (57), then remove the differential.

Right axle housing can also be unbolted

and separated from center housing if

desired. Unbolt and remove pinion and

carrier (62) from center housing.

NOTE: Shims (58) adjust pinion mesh

position with ring gear. Shims (44 and 100)

adjust carrier bearings (45). Moving shims

(44 and 100) from one side to the other

moves the differentiai and therefore ad-

justs bevel gear bacidash. Be careful not

to lose or damage shims when disassem-

bling.

The pinion (59), bearings (60) and

related parts should be assembled in car-

rier (62). Adjust taper bearings (60) by

tightening nut (69). When bearings are

properly adjusted, 0.3145-1.5700 N-m

(3-14 in.-lbs.) torque will be required to

start turning the pinion.

The mesh position can be checked by

coating teeth of ring gear with

mechanics blueing, then installing dif-

ferential in center housing (57) with

right carrier bearing (45) and axle hous-

ing (99) installed. The toe of the pinion

gear should be aligned with center edge

of ring gear teeth and mesh pattern

should be approximately centered on

teeth. Change thickness of shims (58) to

set correct pinion position. Change the

thickness of shims (100) under right car-

rier bearing to provide 0.17-0.23 mm

(0.0067-0.0091 in.) backlash between

pinion and ring gear teeth. Be sure that

right axle housing is securely attached

to the center housing and that differen-

tial and right carrier bearing are firmly

seated when measuring backlash. Shims

should be provided at (44) to remove all

play from carrier bearings, but should

not cause bearings to bind when axle

housing is assembled.

OUTER DRIVE HOUSING

YM330D Models

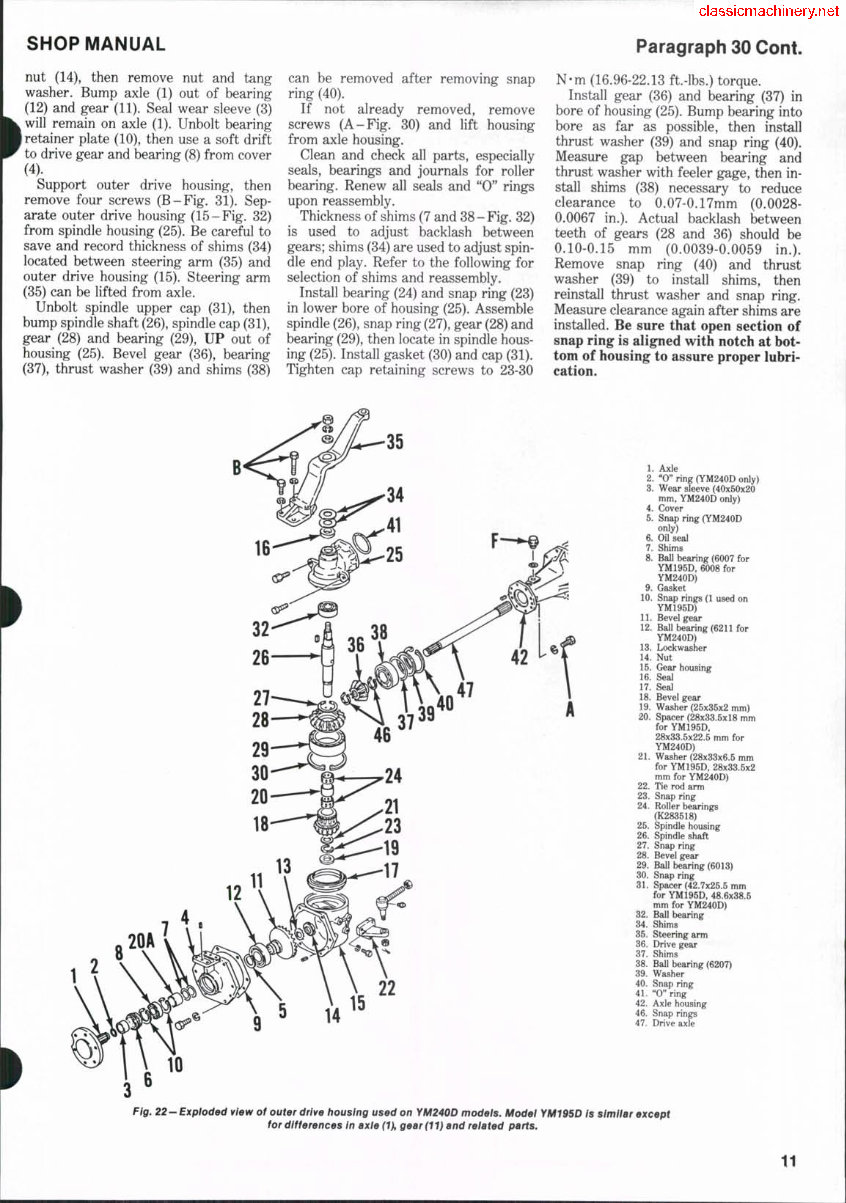

30. R&R AND OVERHAUL. The

complete outer drive housing can be

separated from axle after removing

screws (A-Fig. 30) or disassembly can

be accomplished before detaching outer

end of axle from center section.

To remove the complete outer drive

housing, remove wheel, detach drag link

and/or tie rod from steering arm and

support axle housing to prevent tipping.

Support outer drive housing separately,

then remove screws (A). Move outer

drive housing off dowel pins away from

axle center section. Disassembly of

outer drive assembly can be accomplish-

ed as outlined in the following para-

graphs.

Disassembly can be accomplished with

outer drive housing attached to or

separated from axle center section. If

attached, remove wheel and support ax-

le from tipping. Remove the eight

screws (C-Fig. 31), then use two of the

screws in threaded jack screw holes (J)

to push cover (4-Fig. 32) away fromi

gear housing (15). Be sure to save shims"

(7) and record thickness, which should

be the same at all locations.

Bend tang washers (13) out of notch in

10

SHOP MANUAL

Paragraph 30 Cont.

nut (14), then remove nut and tang

washer. Bump axle (1) out of bearing

(12) and gear (11). Seal wear sleeve (3)

will remain on axle (1). Unbolt bearing

[retainer plate (10), then use a soft drift

to drive gear and bearing (8) from cover

(4).

Support outer drive housing, then

remove four screws (B-Fig. 31). Sep-

arate outer drive housing (15-Fig. 32)

from spindle housing (25). Be careful to

save and record thickness of shims (34)

located between steering arm (35) and

outer drive housing (15). Steering arm

(35) can be lifted from axle.

Unbolt spindle upper cap (31), then

bump spindle shaft (26), spindle cap (31),

gear (28) and bearing (29), UP out of

housing (25). Bevel gear (36), bearing

(37), thrust washer (39) and shims (38)

can be removed after removing snap

ring (40).

If not already removed, remove

screws (A-Fig. 30) and lift housing

from axle housing.

Clean and check all parts, especially

seals, bearings and journals for roller

bearing. Renew all seals and "0" rings

upon reassembly.

Thickness of shims (7 and 38-Fig. 32)

is used to adjust backlash between

gears; shims (34) are used to adjust spin-

dle end play. Refer to the following for

selection of shims and reassembly.

Install bearing (24) and snap ring (23)

in lower bore of housing (25), Assemble

spindle (26), snap ring (27), gear (28) and

bearing (29), then locate in spindle hous-

ing (25). Install gasket (30) and cap (31).

Tighten cap retaining screws to 23-30

N-m (16.96-22.13 ft.-lbs.) torque.

Install gear (36) and bearing (37) in

bore of housing (25). Bump bearing into

bore as far as possible, then install

thrust washer (39) and snap ring (40).

Measure gap between bearing and

thrust washer with feeler gage, then in-

stall shims (38) necessary to reduce

clearance to 0.07-0.17mm (0.0028-

0.0067 in.). Actual backlash between

teeth of gears (28 and 36) should be

0.10-0.15 mm (0.0039-0.0059 in.).

Remove snap ring (40) and thrust

washer (39) to install shims, then

reinstall thrust washer and snap ring.

Measure clearance again after shims are

installed. Be sure that open section of

snap ring is alig^ned with notch at bot-

tom of housing to assure proper luhri-

cation.

22

1. Axle

2. "0" ring (YM240D only)

3. Wear sleeve (40x50x20

mm, YM240D only)

4. Cover

5. Snap ring (YM240D

only)

6. Oil seal

7. Shims

8. Ball bearing (6007 for

YM195D, 6008 for

YM240D)

9. Gasket

10. Snap rings (1 used on

YM195D)

11. Bevel gear

12. Ball bearing (6211 for

YM240D)

13. Lockwasher

14. Nut

15. Gear housing

16. Seal

17. Seal

18. Bevel gear

19. Washer (25x35x2 mm)

20. Spacer (28x33.5x18 mm

for YM195D,

28x33.5x22.5 mm for

YM240D)

21. Washer (28x33x6.5 mm

for YM195D, 28x33.5x2

mm for YM240D)

22. Tie rod arm

23. Snap ring

24. Roller bearings

(K283518)

25. Spindle houBing

26. Spindle shaft

27. Snap ring

28. Bevel gear

29. Ball bearing (6013)

30. Snap ring

31. Spacer (42.7x25.5 mm

for YM195D, 48.6x38.5

mm for YM240D)

32. Ball bearing

34. Shims

35. Steering arm

36. Drive gear

37. Shims

38. Ball bearing (6207)

39. Washer

40. Snap ring

41. "0" ring

42. Axle housing

46. Snap rings

47. Drive axle

Fig. 22-Exploded view of outer drive housing used on YM240D models. Model YM195D Is simitar except

for differences in axle (1), gear (11) and related parts.

11

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

$54.99

Viewed 96 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

$54.99

This manual is suitable for both first-time owners and amateur enthusiasts, as well as professional technicians. It is designed in an easy-to-read format and provides all the necessary information to perform procedures accurately. Keeping this service manual accessible and referring to it regularly is highly recommended. Regular and preventive maintenance outlined in the manual can effectively save time and money by preventing premature failure and unnecessary repairs.

- BRAKES

- CLUTCH

- COOLING SYSTEM

- DIESEL FUEL SYSTEM

- DIFFERENTIAL

- DIFFERENTIAL LOCK

- ELECTRICAL SYSTEM

- ENGINE

- FINAL DRIVE

- FRONT SYSTEM

- HYDRAULIC SYSTEM

- POWER TAKE-OFF

- TRANSMISSION

File Format: PDF

Compatibility: All Versions of Windows & Mac

Language: English

Requirements: Adobe Reader