Oliver 1755, 1855, 1955 Tractor Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

SHOP MANUAL

OLIVER & COCKSHUTT

SERIES 1755, 1855, 1955

Also Covers MINNEAPOLIS-MOLINE

SERIES G-850, G-940

NOTE: Servicing the MInneapolis-Moline Series G-850 can be accomplished

by using the information contained in this manuai for Series 1755. To

service Minneapolis-Moiine Series G-940, use information for Series 1855.

SERiAL NUIVIBER LOCATION

Tractor serial number plate is located on the rear side of the instrument

panel support. Engine serial number is stamped on right flange of engine

directly below the alternator.

BUILT IN THESE VERSIONS

Rowcrop Tricycle, Rowcrop Adjustable Front Axle, Rowcrop Utility,

Wheatland and Four-Wheel Drive. Wheatland models are available with

non-adjustable front axles only.

INDEX (By Starting Paragraph)

Series Series Series

1755 1855 1955

BRAKES 205 205 205

CARBURETOR 86 86

CLUTCH

Engine clutch adjustment .. 133 133 133

Engine clutch R&R 134 134 134

Engine clutch overhaul . 135 135 135

COOLING SYSTEM

Water pump 125 125 125

Radiator 124 124 124

Thermostat 127 127 127

DIESEL SYSTEM

Fuel supply pump , 115 115 115

Fuel system bleeding 96 96 96

Governor adjust 114 114 114

Nozzies. testing 102 102 102

Nozzles, R&R 101 101 101

Nozzles, overhaul 107 107 107

Injection pump, R&R 110 110 110

Injection pump, timing 109 109 109

Troubleshooting 93 93 93

DIFFERENTIAL

Overhaul 198 198 198

Remove and reinstall 195 195 195

ELECTRICAL

Distributor 129 129

Alternator 131 131 131

Regulator 131 131 131

Starting motor 132 132 132

ENGINE

Assembly, R&R 55 55 55

Cam followers 61 61 61

Camshaft 66 66 66

Connecting rod and

bearings 73 73 73

ENGINE CONT,

Crankshaft and bearings

Cylinder head

Cylinder sleeves

Flywheel

Front oil seal

Idler gear

Main bearings

Oil cooler ,.,

Oil pump

Pistons

Piston pins

Piston and rod removal .,

Piston rings

Rear oil seal

Relief valve, oil pressure ,

Rocker arms

Tappets

Timing gear cover

Timing gears

Valve guides

Valve rotators

Valve springs

Valve timing

Valves and valve seats . . .

FINAL DRIVE

Bevel gears

Bull gears

Bull pinions

Differential

Wheel axle shaft

FRONT SYSTEM

Four-wheel drive

Front axle member

Series

1755

74

56

68

77

75

65

74

82

78

68

72

67

71

76

81

62

61

64

65

58

59

60

63

58

199

203

204

195

201

13

1

Series

1855

74

56

68

77

75

65

74

82

78

68

72

67

71

76

81

62

61

64

65

58

59

60

63

58

199

203

204

195

201

13

1

Series

1955

74

56

68

11

75

65

74

82

78

68

72

67

71

76

81

62

61

64

65

58

59

60

63

58

199

203

204

195

201

13

1

Series Series Series

FRONT SYSTEM CONT. 1755 1855 1955

Front boister 4 4 4

Pivot pin 1 1 t

Spindle (knuckle) 6 6 6

Tie rods & toe-in 5 5 5

GOVERNOR

Adjustment, non-diesel 119 119

Adjustment, diesel 114 114 114

Overhaul, non-diesel 123 123

R&R, non-diesel 123 123

HYDRA-POWER 145 145 145

HYDRAUL SHIFT 162 162 162

LIFT SYSTEM, HYDRAULIC

Draft control spring,

adjust 245 245 245

Draft input shaft 266 266 266

Drain and refill 240 240 240

External lift cylinders 271 271 271

Hitch control lever 265 265 265

Hydraulic housing 262 262 262

Lubrication and

maintenance 239 239 239

Cylinder and piston 269 269 269

Manifold 267 267 267

Oil filter 241 241 241

Pump 256 256 256

Series Series Series

LIFT SYSTEM CONT. 1755 1855 1955

Pressure relief valve 249 249 249

Ouick check 237 237 237

Remote cylinders 288 288 288

Remote valves 280 280 280

Rockshaft 263 263 263

Servo valve 267 267 267

System adjustments 243 243 243

Troubleshooting 225 225 225

POWER STEERING 40 40 40

POWER TAKE-OFF

Control valve 219 219 219

Clutch overhaul 217 217 217

Drive shaft,R&R 215 215 215

PTOunit,R&R 216 216 216

TRANSFER DRIVE 32 32 32

TRANSMISSION

Bevel pinion shaft 191 191 191

Countershaft 190 190 190

Input shaft 188 188 188

Lubrication system 176 176 176

Reverse idler 194 194 194

Shifter rails & forks 184 184 184

Top cover 183 183 183

TURBOCHARGER . 117 117

CONDENSED SERVICE DATA

•

Series Series Series

GENERAL 1755 1855 1955

Engine Make Own Own Own

Cylinders, No. of 6 6 6

Cylinder Bore—(nches 37/3 37/8 37/0

Stroke—Inches

Non-Diesel 4 4

Diesel 4% 4% 4%

Displacement—Cubic

Inches

Non-Diesel 283 283

Diesel 310 310 310

Compression Ratio:

Gasoline 8.5:1 8.5-1

Diesel 16.0:1 16.5:1 16.0:1

Main Bearings No. of 7 7 7

Cylinder sleeves Type Wet Wet Wet

Forward Speeds, No. of 6 6 6

Battery Terminal Grounded .. Negative

TUNE-UP

Firing Order 1-5-3-6-2-4

Valve Tappet Gap Inlet:

Non-Diesel : 0.020 0.020 ....

Diesel 0.030 0.030 0.030

Valve Tappet Gap,

Exhaust:

Non-Diesel 0.030 0.030 ....

Diesel 0.030 0.030 0.030

Valve Face Angle, Degrees .. See Par. 58

Valve Seat Angle, Degrees .. See Par. 58

Ignition Distributor Make Holley

Ignition Distributor Model ... —D-2563AA

Generator and Regulator

Make Delco-Remy

Generator Model 1100808

Regulator Model 1119511

Starting Motor Make Delco-Remy

Starting Motor Model:

Non-Diesel 1108431 1108431 ....

Diesel 1113139 1113656 1113656

Ignition Distributor Contact

Gap 0.025 0.025 ....

Ignition Distributor Timing

(Static):

Gasoline 0.025 0.025

Injection Pump Make Roosa-Master

Injection Pump Timing

(Static) 4° 4° T

Carburetor Make -Marvel Schebler- ....

TUNE.UP(Cont.,

Carburetor Model USX-44 USX-37

Engine Low Idle RPM aoo 800

Engine High Idle RPM 2640 2640

Engine Rated RPM ... 2400 2400

PTO RPM @ Engine Rated

RPM:

540 rpm pto 549 549

1000 rpm pto 984 984

SIZES—CLEARANCES—CAPACITIES

Crankshaft Journal Dia 2.624-2 625 —

Crankpin Diameter 2 4365-2 4375

Rod Length 6.749-6.750-

Camshaft Journal Diameter:

Front 1.749-1.750—

Others 1.7485-1.7495

Piston Pin Diameter 1.2494-1.2497

Valve Stem Diameter:

Inlet 0.372-0.373-

Exhaust 0.371-0.372 —

Piston Ring Side

Clearance See Par. 71 —

Main Bearing Clearance 0.0015-0.0045

Rod Bearings Clearance 0.0005-0.0015

Piston Skirt Clearance See Par. 70—

Crankshaft End Play 0.0045-0.0095

Camshaft Bearing

Clearance See Par. 66 —

Cooling System—Gallons 5 5

Engine Crankease

w/filter—Ots 9 9

Fuel Tank, Gasoline—Gals. .. 35 35

Fuel Tank Diesel—Gallons ... 35 35

Transmission and Final

Drive—Ots 43 43

Transfer Case—Quarts 1 1

Hydra-Power Drive—Quarts .. 6 6

Hydraulic Lift—Quarts 27 27

Diff. Housing (4WD)—

Quarts 8 8

Planetary Drive (4WD)—Qts .. 2.5 2.5

TIGHTENING TORQUES—Ft.-Lbs.

Cylinder Head:

Non-Diesel 129-133

Diesel —See Par. 57 —

Main Bearings 129-133

Connecting Rods 44-46

Flywheel 67-69

Series

1955

' 800

2640

2400

549

984

9

35

35

43

1

6

27

8

2.5

Paragraphs 1-2

OLIVER

FRONT SYSTEM (AXLE TYPE)

AXLE MAIN MEMBER AND

PIVOT PIN

Rowcrop Models

1. Rowcrop tractors may be equipped

with an adjustable front axle as shown

in Fig. 1. The center main member

(16) is carried on a pivot pin which is

retained in front support (carrier) by a

pin.

To remove the front axle, stay rod

(26) and wheels as an assembly, sup-

port front of tractor, then unbolt stay

rod support (32) from front main

frame. Disconnect inner ends of tie

rods from center steering arm. Remove

pivot pin from front support (Fig. 3)

and axle, raise front of tractor and roll

front axle and wheels assembly from

under tractor.

Remove nut from rear of stay rod

and remove stay rod support (32—Fig.

1). Bushings (31) and (17) should be

reamed, if necessary, to provide 0.001-

0.002 diametral clearance on pins.

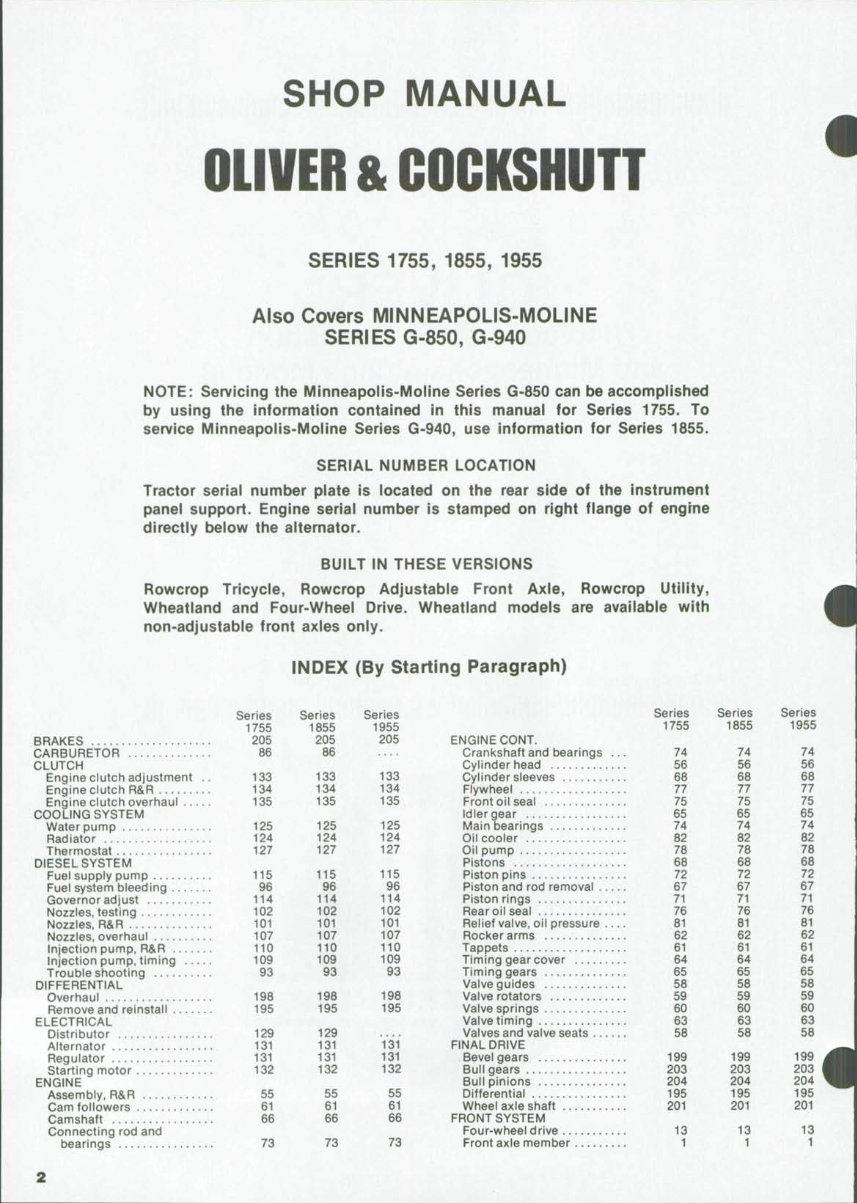

Fig. 1-Exploded view of

Rowcrop adjustable front

axie assembiy used on Se-

ries 7755, t855 and t955.

1. Steering knuckle

2. Thrust washer

3. Bushing

4. Axle extension

6. Felt washer

7. Steering arm

8. Nut

10 Washer

11. "IT'bolt

14. Lock pin

16. Center member

17. Pivot hushing

26. Stay rod

27. Nut

31. Bushing

32. Support

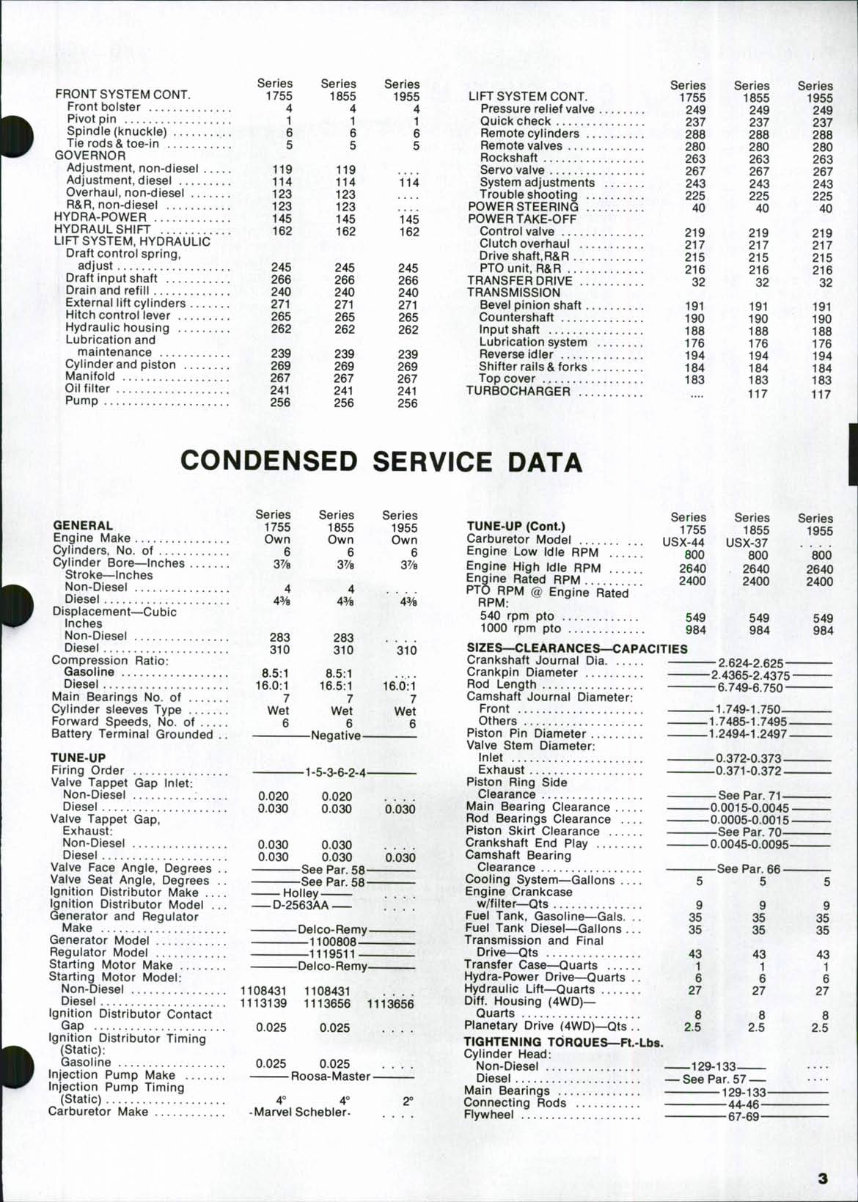

Ftg. 2-Expioded view of

Short Wheei Base (Utility)

front axle assembiy.

1. Steering knuckle

2. Thrust washer

3. Bushing

4. Axle extension

6. Felt washer

7. Steering arm

8. Nut

10. Washer

11. "IT'holt

14. Lock pin

15. Thrust washer

16. Center memher

31. Bushing

32. Support

33. Pivot pin

34. Washer (shim)

Short Wheel Base Models

2, Short wheel base model tractors

are equipped with the axle shown in

Fig. 2. Axle rear pivot pin (33) is sepa-

rate and is retained in rear support

(32) by a set screw. The axle front

pivot pin is integral with axle center

member and is carried in a bushing

(11—Fig. 4) fitted in axle carrier (3).

Bushings for pivot pins are presized

and should not require reaming if

carefully installed.

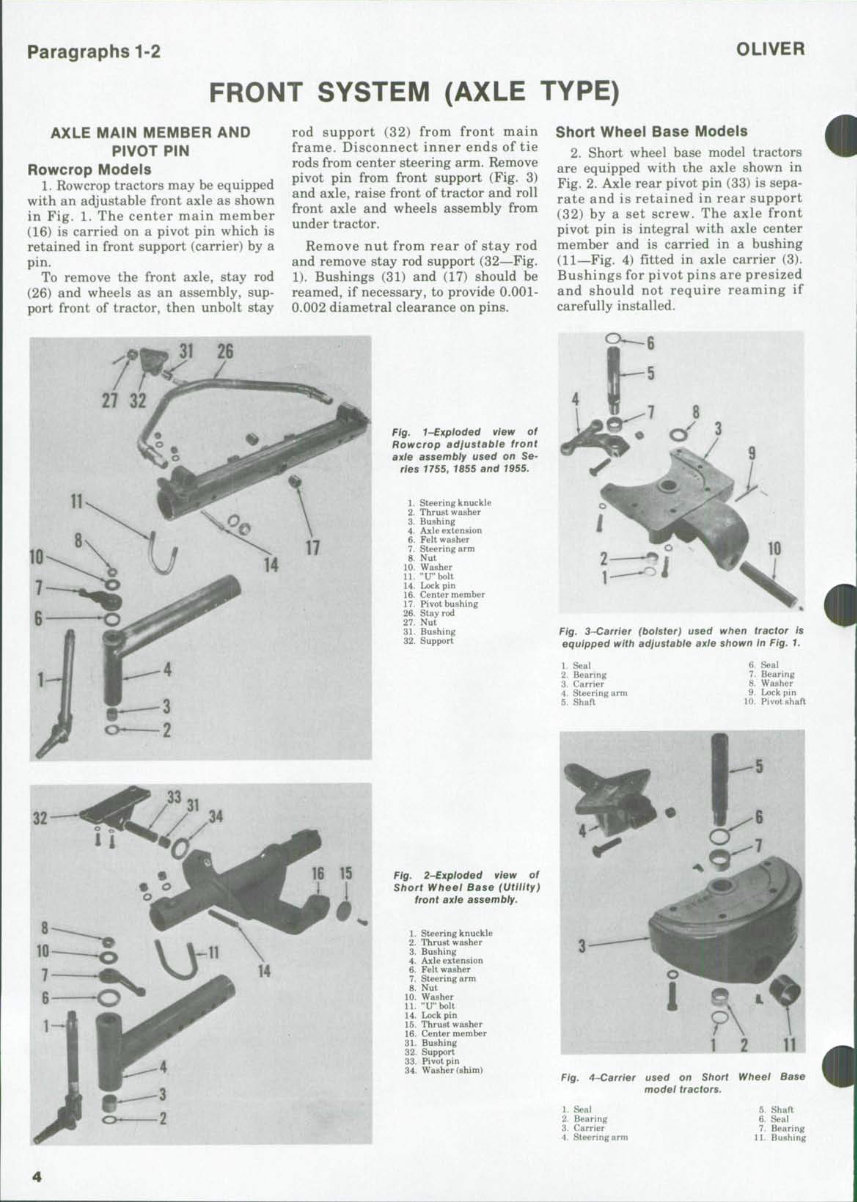

O_6

Fig. 3~Carrier (boister) used when tractor is

equipped with adjustable axie shown in Fig. 1.

1. Seal

2. Bearing

3. Carrier

4. Steering arm

5. Shaft

6. Seal

7. Bearing

8. Washer

9. Lock pin

10. Pivot shaft

Fig. 4~Carrier used on Short Wheel Base

modei tractors.

1. Seal

2. Bearing

3. Carrier

4. Steering arm

5. Shaft

6. Seal

7. Bearing

11. Bushing

SERIES 1755-1855-1955

Paragraphs 3-8

To remove front axle and wheels as

an assembly, support front end of

tractor and disconnect tie rods from

center steering arm (4). Remove rear

support (32—Fig. 2) and thrust washer

(15) and slide axle rearward out of

front support (3—Fig. 4). Bushings (11

and 31—Fig. 2) can now be renewed.

When installing bushings, be sure

grease holes in bushings are aligned

with grease fittings.

Be sure to install shim washer (34)

during reassembly.

Wheatland Models

3. Wheatland model tractors have a

non-adjustable front axle which is

fitted with rotating spindles as shown

in Fig. 5.

To remove axle, stay rod (19) and

wheels as an assembly, support front

end of tractor, remove stay rod support

(17) or stay rod nut (22), and discon-

nect tie rods from center steering arm

(4—Fig. 6). Remove cap screw which

retains pivot pin (10) in front support

(3), drive pivot pin from front support

and axle, then raise front of tractor

and roll front axle and wheels as-

sembly from under tractor.

Stay rod bushing and pivot pin

bushing can be renewed and should be

reamed, if necessary, to provide 0.001-

0.002 diametral clearance.

FRONT AXLE CARRIER

Series 1755-1855-1955.

4. Front axle carriers (bolsters) are

shown in Figs. 3, 4 and 6.

To remove front carrier, remove

front axle as outlined in paragraph 1,

2 or 3 and the power steering cylinder

as outlined in paragraph 48, then

unbolt carrier from tractor main

frame.

Remove clamp bolt from steering

arm, then remove steering shaft and

thrust washer (when used) from car-

rier. Remove oil seals, then note loca-

tion of bearings prior to driving them

out. When installing new bearings,

drive or press on lettered end of

bearing cage only and be sure oil holes

in bearing cages are aligned with lu-

brication fittings when bearings are

installed. Seals are installed with lips

toward ends of steering shaft (out-

ward).

TIE RODS and TOE-IN

All Axle Models

5. Tie rod ends are the non-adjust-

able type and are serviced either by

renewing the end assembly or the

complete tie rod assembly.

Toe-in for all axle type models is

3/16-inch. Obtain correct toe-in by

adjusting each tie rod an equal

amount.

STEERING KNUCKLES AND

BUSHINGS

Rowcrop and Short Wheel Base

Models

6. To remove steering knuckles and

renew bushings (3—Fig. 1 or Fig. 2),

support front end of tractor and re-

move tire and wheel assembly.

Straighten tab of washer (10) and

remove nut (8). Remove steering arm

(7) from knuckle and withdraw

knuckle from axle extension (4).

Fig. S~Expioded view of

front axle assembly used on

Wheatiand model tractors.

1. Spindle

2. Wear cup

3. Seal

4. Outer bearing

5. Spindle carrier

6. Plug

7. Bearing

8. Seal

9. Thrust washer

10. Thrust bearing

11. Inner bearing

12. Nut

13. Cotter pin

14. Cap

15. Pivot pin

16. Grease rating

17. Support

18. Bushing

19. Stay rod

20. Main member

21. Bushing

22. Nut

Drive bushings (3) from axle exten-

sion and install new bushings flush

with bore. Bushings are presized and

reaming should not be necessary if

bearings are installed with a suitable

driver.

Thrust washer (2) can be installed

either side up. Insert knuckle into axle

extension, install new felt (6), then on

Rowcrop models, install steering arm

(7) extending to rear and at approxi-

mately 90 degrees to wheel spindle.

On Short Wheel Base models, install

steering arm (7) extending to front at

approximately 90 degrees to wheel

spindle.

LIVE SPINDLES AND SPINDLE

CARRIERS

Wheatland Models

7. SPINDLES. Front wheels on

Wheatland models are attached to live

(rotating) spindles (1—Fig. 5) which

are carried in tapered roller bearings

mounted in the spindle carriers (5).

Spindles can be removed by removing

the cap (14) from inner side of spindle

carrier and removing the cotter pin

(13) and slotted nut (12) from inner

end of spindle. Refer to paragraph 9

for bearing and seal service informa-

tion.

8. SPINDLE CARRIERS. To

renew the spindle carrier pivot pin (15

—Fig. 5) and/or pivot pin needle bear-

ings (7), first remove wheel and dis-

connect tie rod outer end from carrier.

Remove nut from bottom end of pivot

pin and drive the pin up out of axle

(20) and carrier. Drive bearings (7)

from carrier and install new bearings

by driving or pressing on lettered end

of cage only. To renew carrier, remove

O—^8

S~View of carrier used on Wheatland

model tractors.

1. Seal

2. Bearing

3. Carrier

4. Steering arm

5. Shaft

6. Seal

7. Bearing

8. Washer

10. Pivot pin

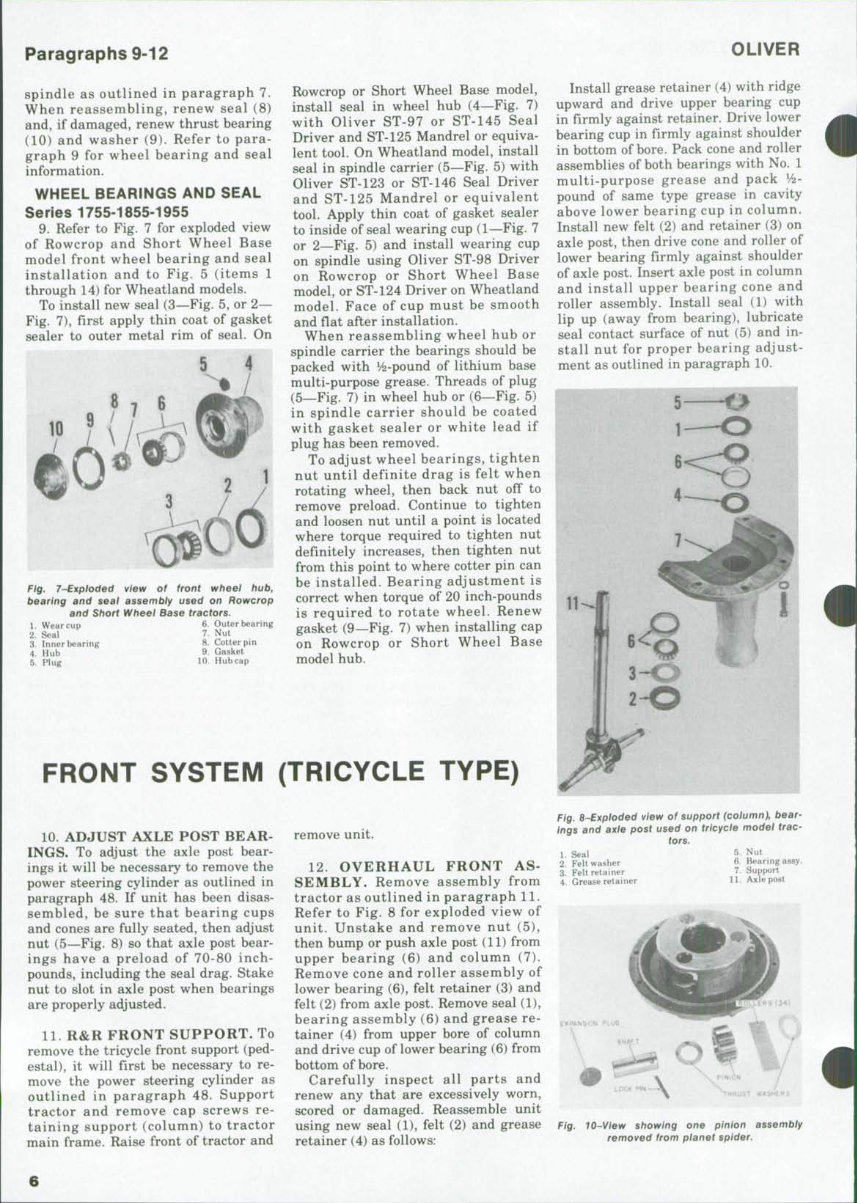

Paragraphs 9-12

OLIVER

spindle as outlined in paragraph 7.

When reassembling, renew seal (8)

and, if damaged, renew thrust bearing

(10) and washer (9). Refer to para-

graph 9 for wheel bearing and seal

information,

WHEEL BEARINGS AND SEAL

Series 1755-1855-1955

9. Refer to Fig. 7 for exploded view

of Rowcrop and Short Wheel Base

model front wheel bearing and seal

installation and to Fig. 5 (items 1

through 14) for Wheatland models.

To install new seal (3—Fig. 5, or 2—

Fig. 7), first apply thin coat of gasket

sealer to outer metal rim of seal. On

Fig. 7~Expioded view of front wheei hub,

bearing and seat assembly used on Rowcrop

and Short Wheel Base tractors.

1. Wear cup 6. Outer bearing

2. Seal 7. Nut

3. Inner bearing 8. Cotter pin

4. Huh 9- Gasket

5 Plug 10. Hubcap

Rowcrop or Short Wheel Base model,

install seal in wheel hub (4—Fig. 7)

with Oliver ST-97 or ST-145 Seal

Driver and ST-125 Mandrel or equiva-

lent tool. On Wheatland model, install

seal in spindle carrier (5—Fig. 5) with

Oliver ST-123 or ST-146 Seal Driver

and ST-125 Mandrel or equivalent

tool. Apply thin coat of gasket sealer

to inside of seal wearing cup (1—Fig. 7

or 2—Fig. 5) and install wearing cup

on spindle using Oliver ST-98 Driver

on Rowcrop or Short Wheel Base

model, or ST-124 Driver on Wheatland

model. Face of cup must be smooth

and Oat after installation.

When reassembling wheel hub or

spindle carrier the bearings should be

packed with y2-pound of lithium base

multi-purpose grease. Threads of plug

(5—Fig. 7) in wheel bub or (6—Fig. 5)

in spindle carrier should be coated

with gasket sealer or white lead if

plug has been removed.

To adjust wheel bearings, tighten

nut until definite drag is felt when

rotating wheel, then back nut off to

remove preload. Continue to tighten

and loosen nut until a point is located

where torque required to tighten nut

definitely increases, then tighten nut

from this point to where cotter pin can

be installed. Bearing adjustment is

correct when torque of 20 inch-pounds

is required to rotate wheel. Renew

gasket (9—Fig. 7) when installing cap

on Rowcrop or Short Wheel Base

model hub.

Install grease retainer (4) with ridge

upward and drive upper bearing cup

in firmly against retainer. Drive lower

bearing cup in firmly against shoulder

in bottom of bore. Pack cone and roller

assemblies of both bearings with No. 1

multi-purpose grease and pack V2-

pound of same type grease in cavity

above lower bearing cup in column.

Install new felt (2) and retainer (3) on

axle post, then drive cone and roller of

lower bearing firmly against shoulder

of axle post. Insert axle post in column

and install upper bearing cone and

roller assembly. Install seal (1) with

lip up (away from bearing), lubricate

seal contact surface of nut (5) and in-

stall nut for proper bearing adjust-

ment as outlined in paragraph 10.

FRONT SYSTEM (TRICYCLE TYPE)

10. ADJUST AXLE POST BEAR-

INGS. To adjust the axle post bear-

ings it will be necessary to remove tbe

power steering cylinder as outlined in

paragraph 48. If unit has been disas-

sembled, be sure that bearing cups

and cones are fully seated, then adjust

nut (5—Fig. 8) so that axle post bear-

ings have a preload of 70-80 inch-

pounds, including the seal drag. Stake

nut to slot in axle post when bearings

are properly adjusted.

11. R&R FRONT SUPPORT. To

remove tbe tricycle front support (ped-

estal), it will first be necessary to re-

move the power steering cylinder as

outlined in paragraph 48. Support

tractor and remove cap screws re-

taining support (column) to tractor

main frame. Raise front of tractor and

remove unit.

12. OVERHAUL FRONT AS-

SEMBLY. Remove assembly from

tractor as outlined in paragraph 11.

Refer to Fig. 8 for exploded view of

unit, Unstake and remove nut (5),

then bump or push axle post (11) from

upper bearing (6) and column (7).

Remove cone and roller assembly of

lower bearing (6), felt retainer (3) and

felt (2) from axle post. Remove seal (1),

bearing assembly (6) and grease re-

tainer (4) from upper bore of column

and drive cup of lower bearing (6) from

bottom of bore.

Carefully inspect all parts and

renew any that are excessively worn,

scored or damaged. Reassemble unit

using new seal (1), felt (2) and grease

retainer (4) as follows:

4

i

Fig. 8-Expioded view of support (column), bear-

ings and axle post used on tricycle model trac-

tors.

1. Seal

2. Felt washer

3. Felt retainer

4. Grease retainer

5. Nut

6. Bearing assy.

7. Support

11, Axle post

Fig. tO-View showing one pinion assembiy

removed from planet spider.

6

SERIES 1755-1855-1955 Paragraphs 13-16

FRONT SYSTEiVI

(Front-Wheel Drive Axie)

Series 1755,1855 and 1955 tractors are

avaifabie with a front drive axie which is

driven from the transmission bevel pinion

shaft via a transfer case and a drive shaft

fitted with two universal joints. A shifting

mechanism in the transfer case allows

connecting or disconnecting power to the

front drive axie.

Ail four-wheel drive tractors are

equipped with power steering. Aii models

are equipped with a Saginaw Hydramotor

steering unit. Refer to POWER STEERiNG

section for information on the Saginaw

Hydramotor and the two steering cyiin-

ders.

FRONT AXLE AND CARRIER

All Models So Equipped

13. R&R AXLE ASSEMBLY. The

complete front axle assembly can be

removed from tractor as follows: Re-

move drive shaft shield and shield

front support. Disconnect drive shaft

from companion flange of differential

pinion shaft. Disconnect both power

steering cylinders from axle and

spindle supports and lay cylinders on

top of axle carrier. Remove bolts re-

taining axle to axle carrier, then raise

tractor and roll the complete axle and

wheels unit forward and away from

tractor.

Note: A rolling floor jack can be

placed under differential pinion shaft

to keep axle from rotating as tractor is

lifted from axle.

If necessary, wheels and tie-rod can

now be removed and procedure for

doing so is obvious.

Reinstall axle by reversing the re-

moval procedure and be sure piston

rod ends of steering cylinders are at-

tached to steering spindle supports.

Tighten the cylinder attaching bolt

lock nuts until they just contact the

mounting flanges. Further tightening

may distort mounting flanges and

cause cylinder to bind.

14. R&R AXLE CARRIER. To

remove axle carrier, first remove the

front axle as outlined in paragraph 13,

then, secure steering cylinders to

tractor frame. Place a rollingfloorjack

under axle carrier and take weight of

carrier. Remove pivot pin retaining

cap screws, slide pivot pins from pivot

supports and lower the axle carrier

from tractor. If necessary, pivot sup-

ports can be removed from tractor

frame.

Bushings in axle carrier can now be

renewed. Bushings are pre-sized and

should not require reaming if carefully

installed.

15. OVERHAUL FRONT AXLE.

Overhaul of the front drive axle as-

sembly will be discussed as four opera-

tions; the planet spider assembly, the

hub assembly, the spindle support as-

sembly and the differential and carrier

assembly. All operations except the

differential and carrier overhaul can

be accomplished without removing the

front drive axle from tractor. Both

outer ends of axle are identical, hence,

only one outer end will be discussed.

16. PLANET SPIDER. To overhaul

the planet spider assembly, support

outer end of axle and remove the tire

and rim. Remove relief valve from

center of planet spider, remove plug

from wheel hub and drain oil from

planet spider. Remove capscrews that

retain planet spider to wheel hub and

the two puller hole cap screws. Use

two of the removed retaining cap

screws in the puller holes to remove

planet spider assembly from wheel

hub.

With unit removed, remove the

three pinion shaft lock pins by driving

them toward center of unit. Remove

pinion shafts and expansion plugs by

driving pinion shafts toward outside of

planet spider. Remove planet pinions,

rollers (34 in each pinion) and thrust

washers. Discard the expansion plugs.

Refer to Fig. 10.

14

15

Fig. 11-Cross-sectional view

tion axles have a one-p/ecc

1. Internal gear hub

2. Thrust washer

3. Pinion shaft lock pin

6. Wheel hub

7. Hub inner bearing

8. Dirt shield

9. Spindle

10. Spindle support

11. LTp per trunnion

12. Grease fitting

13. Shims

14. Universal joint

15. Upper trunnion bearing

29

showing components of front drive axle outer end. Current produc-

' internal gear and hub instead of the two-piece assembly shown

above.

16. Grease retainer

17. Thrust washer

18. Oil seal

19. Axle shaft (inner)

20. Washer

21. Axle housing

22. Lower trunnion bearing

23. Dust seal retainer

24. Dust seal

25. Spring

26. Felt seal

27. Retainer ring

28. Seal retainer

29. Gasket

30. Shims

31. Lower trunnion

32. Thrust washer

33. Oil seal

34. Oil seal

35. Bushing

36. Axle shaft (outer)

37. Hub outer bearing

38. Thrust washer

39. Innernut

40. Lock washer

41. Outer nut

42. Filler hole plug

43. Planet spider

44. Snap ring

45. Relief valve

46. Sun gear

47. Pinion

48. Pinion rollers

50. Expansion plug

51. Thrust washer

52. Internal gear

Paragraphs 17-21

OLIVER

Clean and inspect all parts and

renew as necessary. Pay particular

attention to the pinion rollers and

thrust washers.

17. When reassembling, use heavy

grease to hold rollers in inner bore of

pinions. Be sure tangs of thrust

washers are in the slots provided for

them and that holes in pinion shaft

and mounting boss are aligned before

pinion shafts are final positioned. Coat

mating surfaces of planet spider and

wheel hub with No, 2 Permatex or

equivalent sealer and install planet

spider in wheel hub. Tighten retaining

cap screws to a torque of 52-57 ft.-lbs.

18. HUB ASSEMBLY, To overhaul

the wheel hub assembly, first remove

planet spider assembly as outlined in

paragraph 16. With planet spider

removed, remove snap ring and sun

gear from outer end of axle shaft.

Straighten tabs of spindle nut lock-

washer, then use OTC tool JD-4 or

equivalent and remove spindle outer

nut and lockwasher. Now loosen but

do not remove the spindle inner nut.

Unbolt spindle from spindle support

and remove wheel hub assembly.

Place hub assembly on bench with

spindle nut on top side and block up

assembly so spindle will be free to

drop several inches. Remove the

spindle inner nut, then place a wood

block over end of spindle and bump

spindle from internal gear hub. Lift

internal gear hub and bearing from

wheel hub and be careful not to allow

bearing to drop from bub of internal

gear bub. Complete removal of spindle

from wheel hub. All bearings and

seals, thrust washers and dirt shield

can now be removed and renewed if

necessary. Bushing and oil seal in

mer bore of spindle (items 33 and 35

"%. 11) can also be renewed at this

Use Fig. 11 as a reference and

ible wheel hub unit as follows:

rearing cups (7 and 37) in hub

allest diameters toward inside

inner bearing in inner

bearing cup, then install oil seal (34)

with lip facing bearing. Bump seal

into bore until it bottoms. Place dirt

shield (8) on hub so flat side is toward

flange of spindle, then using caution

not to damage seal, install spindle in

wheel hub. Hold spindle in that posi-

tion and turn unit over so threaded

end of spindle shaft is on top. Place

outer bearing over end of spindle and

push bearing down into cup. Start

bearing hub of internal gear (1) into

outer bearing cone and, if necessary,

tap gear lightly with a soft faced

hammer to position. Install thrust

washer (38) and spindle inner nut (39)

and tighten nut finger tight. Coat

mating surfaces of spindle and spindle

support with No, 2 Permatex or equiv-

alent sealer and install dirt shield and

spindle on spindle support. Tighten

retaining capscrews to a torque of 80-

88 ft.-lbs.

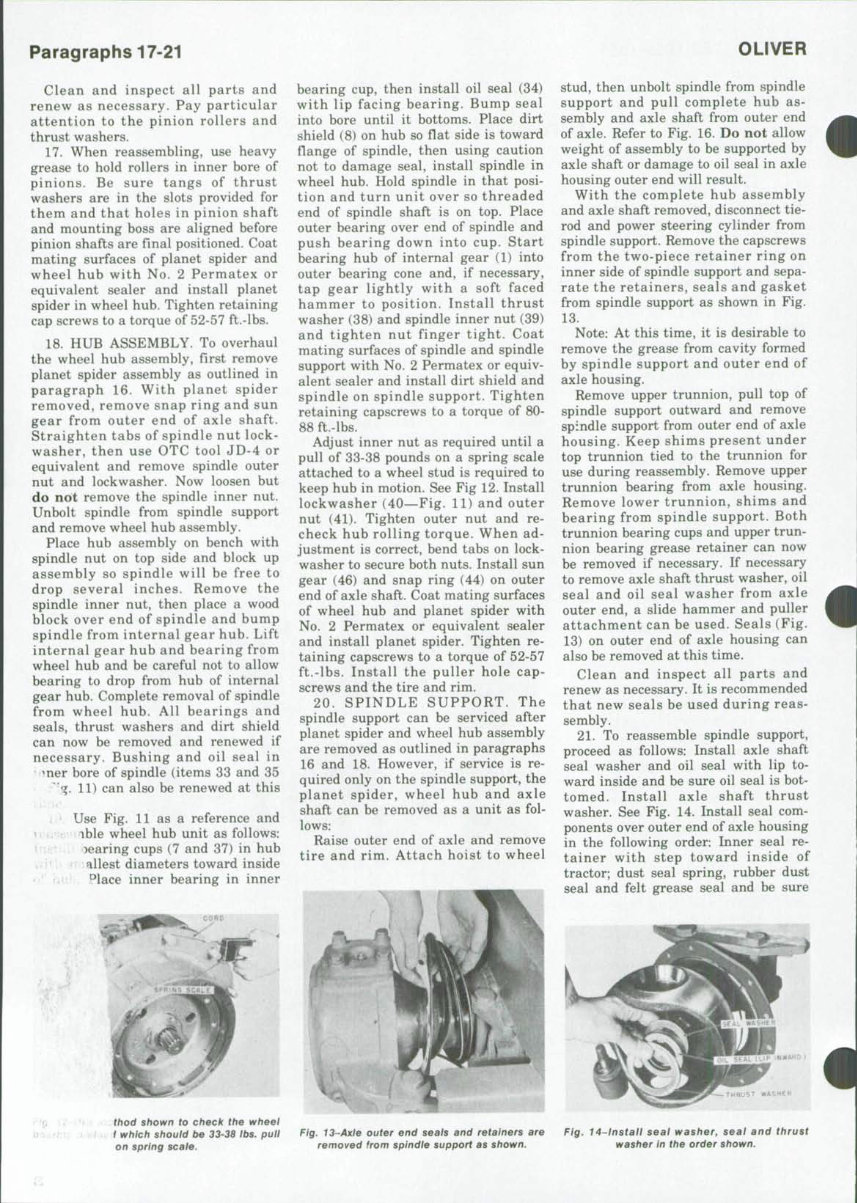

Adjust inner nut as required until a

pull of 33-38 pounds on a spring scale

attached to a wheel stud is required to

keep hub in motion. See Fig 12. Install

lockwasher (40—Fig, 11) and outer

nut (41), Tighten outer nut and re-

check hub rolling torque. When ad-

justment is correct, bend tabs on lock-

washer to secure both nuts. Install sun

gear (46) and snap ring (44) on outer

end of axle shaft. Coat mating surfaces

of wheel hub and planet spider with

No. 2 Permatex or equivalent sealer

and install planet spider. Tighten re-

taining capscrews to a torque of 52-57

ft.-lbs. Install the puller hole cap-

screws and the tire and rim.

20, SPINDLE SUPPORT, The

spindle support can be serviced after

planet spider and wheel hub assembly

are removed as outlined in paragraphs

16 and 18, However, if service is re-

quired only on the spindle support, the

planet spider, wheel hub and axle

shaft can be removed as a unit as fol-

lows:

Raise outer end of axle and remove

tire and rim. Attach hoist to wheel

stud, then unbolt spindle from spindle

support and pull complete hub as-

sembly and axle shaft from outer end

of axle. Refer to Fig. 16. Do not allow

weight of assembly to be supported by

axle shaft or damage to oil seal in axle

housing outer end will result.

With the complete hub assembly

and axle shaft removed, disconnect tie-

rod and power steering cylinder from

spindle support. Remove the capscrews

from the two-piece retainer ring on

inner side of spindle support and sepa-

rate the retainers, seals and gasket

from spindle support as shown in Fig,

13,

Note: At this time, it is desirable to

remove the grease from cavity formed

by spindle support and outer end of

axle housing.

Remove upper trunnion, pull top of

spindle support outward and remove

spindle support from outer end of axle

housing. Keep shims present under

top trunnion tied to the trunnion for

use during reassembly. Remove upper

trunnion bearing from axle housing.

Remove lower trunnion, shims and

bearing from spindle support. Both

trunnion bearing cups and upper trun-

nion bearing grease retainer can now

be removed if necessary. If necessary

to remove axle shaft thrust washer, oil

seal and oil seal washer from axle

outer end, a slide hammer and puller

attachment can be used. Seals (Fig,

13) on outer end of axle housing can

also be removed at this time.

Clean and inspect all parts and

renew as necessary. It is recommended

that new seals be used during reas-

sembly,

21, To reassemble spindle support,

proceed as follows: Install axle shaft

seal washer and oil seal with lip to-

ward inside and be sure oil seal is bot-

tomed. Install axle shaft thrust

washer. See Fig. 14. Install seal com-

ponents over outer end of axle housing

in the following order: Inner seal re-

tainer with step toward inside of

tractor; dust seal spring, rubber dust

seal and felt grease seal and be sure

thod shown to check the wheel

1 which should be 33-38 ibs. puii

on spring scale.

Fig. 13~Axle outer end seais and retainers are

removed from spindie support as shown.

Fig. 14~lnstatt seat washer, seat and thrust

washer in the order shown.

SERIES 1755-1855-1955

Paragraphs 22-23

bevel in inside diameter of both seals

is toward bell of axle outer end; outer

seal retainer with step toward outside

of tractor and gasket. Install grease

retainer (cup side up) and upper

bearing cup (smallest LD. down) in the

upper trunnion bearing bore. Bolt

lower trunnion to spindle support

using original shims and tighten cap

screws to a torque of 80-88 ft.-lbs.

Place lower trunnion bearing over

lower trunnion. Install lower trunnion

bearing cup in outer end of axle

housing with smallest LD. of cup up.

Place upper trunnion bearing in the

upper trunnion bearing cup, then

while tipping upper side of spindle

support slightly outward, position

spindle support over outer end of axie

housing and install upper trunnion

with original shim pack. Tighten trun-

nion retaining cap screws to a torque

of 80-88 ft.-lbs.

Before attaching tie-rod, power

steering cylinder or seal assembly to

spindle support, check adjustment of

trunnion bearings as follows: Connect

a spring pull scale to tie-rod hole of

spindle support and check pull re-

quired to rotate the spindle support.

Refer to Fig. 15. Adjustment is correct

when 12 to 18 pounds pull is required.

To adjust bearings, vary number of

shims located under the trunnions as

required to obtain proper adjustment

keeping the total thickness of shims

under the top trunnion and lower

trunnion as equal as possible. Shims

are available in thicknesses of 0.003,

0.005 and 0.010.

Use grease to hold seal retainer

gasket in place, then install seal as-

sembly on spindle support, being sure

that the split ends of outer seal as-

sembly do not align. Attach tie-rod

and tighten tie-rod stud nut to a

torque of 200 ft.-lbs. Attach power

steering cylinder and tighten at-

taching bolt lock nut until it just con-

tacts mounting flange.

Place approximately four pounds of

grease in the cavity of spindle support

and pack universal joint of axle shaft.

Coat mating surfaces of spindle and

spindle support with No. 2 Permatex

or equivalent sealer and install the

planet spider, wheel hub and axle as-

sembly on the spindle support.

Tighten attaching capscrews to a

torque of 80-88 ft.-lbs. Then, install

tire and rim.

DIFFERENTIAL AND CARRIER

The Four Wheei Drive front axie can be

equipped with either a conventionai dif-

ferentiai assembiy or a "No-Spin" differ-

entiai assembiy. Removai procedure wili

be the same for both types. For service

Information, refer to paragraphs 23 and

27.

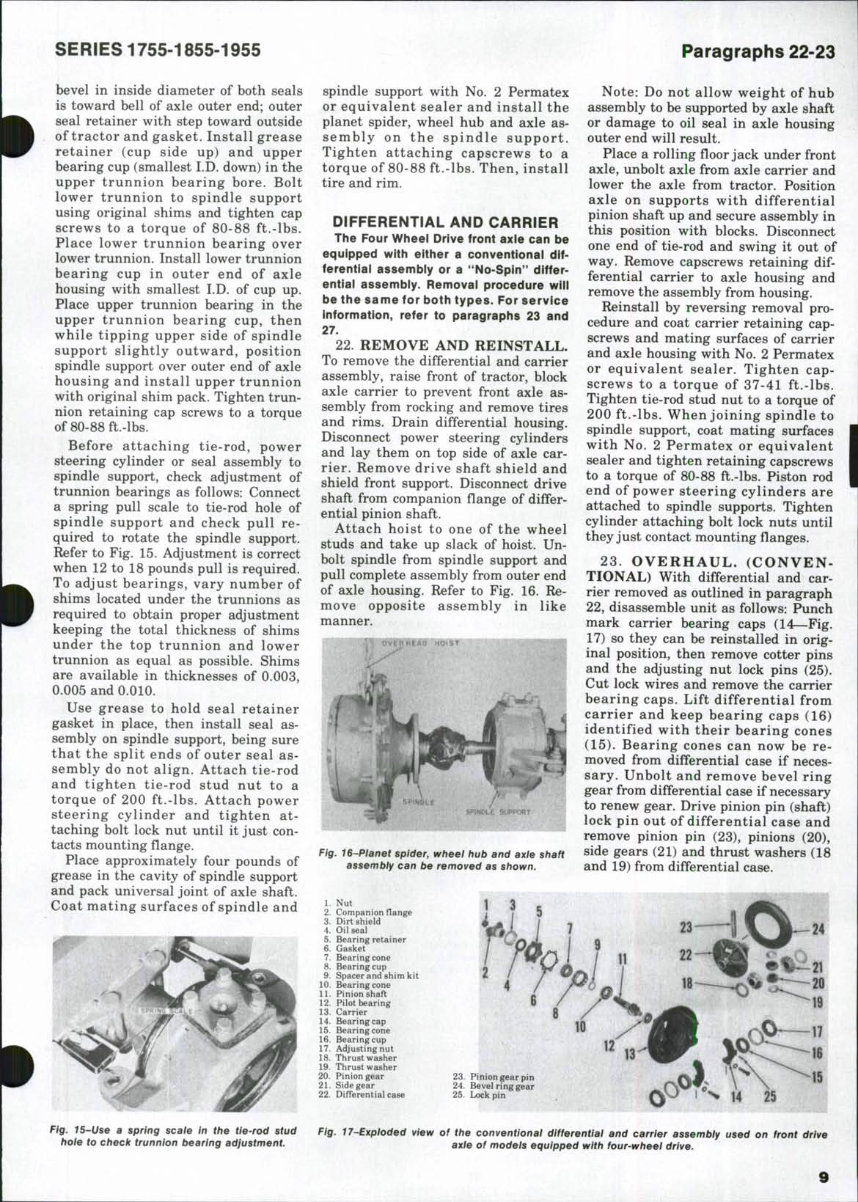

22. REMOVE AND REINSTALL.

To remove the differential and carrier

assembly, raise front of tractor, block

axle carrier to prevent front axle as-

sembly from rocking and remove tires

and rims. Drain differential housing.

Disconnect power steering cylinders

and lay them on top side of axle car-

rier. Remove drive shaft shield and

shield front support. Disconnect drive

shaft from companion flange of differ-

ential pinion shaft.

Attach hoist to one of the wheel

studs and take up slack of hoist. Un-

bolt spindle from spindle support and

pull complete assembly from outer end

of axle housing. Refer to Fig. 16. Re-

move opposite assembly in like

manner.

Fig. 16~Pianet spider, wheei hub and axie shaft

assembly can be removed as shown.

1. Nut

2. Companion flange

3. Dirt shield

4. Oil seal

5. Bearing retainer

6. Gasket

7. Bearing cone

8. Bearing cup

9. Spacer and shim kit

10. Bearing cone

11. Pinion shaft

12. Pilot bearing

13. Carrier

14. Bearing cap

15. Bearing cone

16. Bearing cup

17. Adjusting nut

18. Thrust washer

19. Thrust washer

20. Pinion gear

21. Side gear

22. Differential case

Note: Do not allow weight of hub

assembly to be supported by axle shaft

or damage to oil seal in axle housing

outer end will result.

Place a rolling floor jack under front

axle, unbolt axle from axle carrier and

lower the axle from tractor. Position

axle on supports with differential

pinion shaft up and secure assembly in

this position with blocks. Disconnect

one end of tie-rod and swing it out of

way. Remove capscrews retaining dif-

ferential carrier to axle housing and

remove the assembly from housing.

Reinstall by reversing removal pro-

cedure and coat carrier retaining cap-

screws and mating surfaces of carrier

and axle housing with No. 2 Permatex

or equivalent sealer. Tighten cap-

screws to a torque of 37-41 ft.-lbs.

Tighten tie-rod stud nut to a torque of

200 ft.-lbs. When joining spindle to

spindle support, coat mating surfaces

with No. 2 Permatex or equivalent

sealer and tighten retaining capscrews

to a torque of 80-88 ft.-lbs. Piston rod

end of power steering cylinders are

attached to spindle supports. Tighten

cylinder attaching bolt lock nuts until

they just contact mounting flanges.

23. OVERHAUL. (CONVEN-

TIONAL) With differential and car-

rier removed as outlined in paragraph

22, disassemble unit as follows: Punch

mark carrier bearing caps (14—Fig.

17) so they can be reinstalled in orig-

inal position, then remove cotter pins

and the adjusting nut lock pins (25).

Cut lock wires and remove the carrier

bearing caps. Lift differential from

carrier and keep bearing caps (16)

identified with their bearing cones

(15). Bearing cones can now be re-

moved from differential case if neces-

sary. Unbolt and remove bevel ring

gear from differential case if necessary

to renew gear. Drive pinion pin (shaft)

lock pin out of differential case and

remove pinion pin (23), pinions (20),

side gears (21) and thrust washers (18

and 19) from differential case.

23. Pinion gear pin

24. Bevel ringgear

25. Lock pin

25

Fig. 15-Use a spring scaie In the tie-rod stud

hole to check trunnion bearing adjustment.

Fig. 17-Exploded view of the conventionai differential and carrier assembiy used on front drive

axie of models equipped with four-wheei drive.

9

Paragraphs 24-28

OLIVER

Remove cotter pin and nut (1) from

pinion shaft (11), then using a puller,

remove the companion flange (2) and

dust shield. Remove pinion shaft

bearing retainer (5) and press pinion

shaft and bearing from carrier. Use a

split bearing puller to support pinion

bearing cup (8) on edge nearest pinion

shaft gear and press pinion shaft from

rear bearing and bearing cup. Remove

spacer (9) and any shims which may

be present from pinion shaft. Remove

front bearing and inner (pilot) bearing

(12) in a similar manner.

Clean and inspect all parts. Pay par-

ticular attention to bearings, bearing

cups and thrust washers. If any of the

differential side gears or pinions are

damaged or excessively worn, renew

all gears and thrust washers. Pinion

shaft and bevel ring gear are available

in a matched set only.

24, The differential and carrier unit

is assembled as follows: Place inner

(pilot) bearing on inner end of pinion

shaft and stake in four places. Use a

piece of pipe the size of inner pinion

shaft bearing race to press forward

bearing cone (10) onto shaft with taper

facing threaded end of pinion shaft.

Place bearing spacer and any shims

which were present during disas-

sembly over pinion shaft, then position

the bearing cup over forward bearing.

Press the rear pinion shaft bearing (7)

on shaft with taper away from

threaded end of pinion shaft. Check

and, if necessary, renew the dust

shield (3) on companion flange. Posi-

tion companion flange so it will not

obstruct cotter pin hole in end of

pinion shaft, slide bearing retainer oil

seal on its land on companion flange,

then press companion flange on pinion

shaft. Install retaining nut, clamp

companion flange in a vise and tighten

nut to a torque of 300 ft.-lbs.

Note: Pressure of oil seal will gener-

ally hold bearing retainer away from

bearing. If it does not do so, tie re-

tainer to companion flange.

25, With pinion shaft assembled as

outlined above, clamp the bearing cup

in a soft jawed vise just tight enough

to prevent rotation, then using an

inch-pound torque wrench on com-

panion flange retaining nut, check

torque required to rotate pinion shaft.

Pinion shaft bearing adjustment is

correct if 13 to 23 inch-pounds is re-

quired to rotate shaft. If rolling torque

is not as specified, disassemble the

pinion shaft assembly and vary thick-

ness of spacer and/or shims as re-

quired to obtain proper rolling torque,

A spacer and shim kit is available

under Oliver part number 155 342-A.

With pinion shaft assembled and

correct rolling torque (bearing adjust-

ment) obtained, press pinion shaft as-

sembly into carrier, install bearing

retainer and tighten capscrews to a

torque of 25 ft,-lbs. Install cotter pin to

lock the nut in place,

26, Reassemble differential case

assembly as follows: Place side gears,

pinions and thrust washers in differ-

ential case and install pinion pin

(shaft). Secure pinion pin with lock pin

and, if lock pin is straight type, stake

pin in position. It is not necessary to

stake the spring type lock pin. If bevel

ring gear was removed, reinstall with

bolt heads on ring gear side of as-

sembly and tighten the nuts to a

torque of 78-86 ft,-lbs. Press bearings

on differential case with tapers facing

away from case. Place bearing cups

over differential bearings and place

differential assembly in carrier. Posi-

tion bearing adjusting nuts in carrier

and install the carrier bearing caps.

Tighten the bearing cap screws until

caps are snug but be sure threads of

caps and adjusting nuts are in reg-

ister. Maintain some clearance be-

tween gear teeth and tighten ad-

justing nuts until bearing cups are

seated and all end play of differential

is eliminated. Mount a dial indicator

and shift differential assembly as re-

quired to obtain a backlash of 0,008-

0,011 between bevel pinion shaft and

bevel ring gear. Differential is shifted

by loosening one adjusting nut and

tightening the opposite nut an equal

amount. Note: Mesh position of the

bevel pinion shaft is not adjustable.

With gear backlash adjusted,

tighten the bearing cap retaining cap-

screws to a torque of 65 ft,-lbs, and

secure with lock wire. Install ad-

justing nut lock pins and cotter pins.

Note: If lock pins will not enter slots

of adjusting nuts after backlash ad-

justment has been made, tighten

rather than loosen the adjusting nut,

or nuts. Recheck gear backlash.

Fig. 18~Exptoded view of

the 'nO'Spin" differentiat

case assembiy a v ait able for

the four-wheel drive front

axle.

1. Case half

2. Side gear

3. Spring

4. Spring retainer

5. Driven center

6. Hold-out ring

7. Central driver & center cam

8. Case half

If used, install thrust screw and

turn screw in until it contacts back

side of bevel ring gear, then back

screw out ^^ to y2-turn. Apply sealer to

threads of thrust screw at surface of

carrier, then while holding screw from

turning, install locking washer and

nut. Secure nut by bending one tang of

locking washer over nut and another

tang over boss of carrier,

27. OVERHAUL (NO-SPIN). With

differential and carrier removed as

outlined in paragraph 22, unit is dis-

assembled as follows: Punch mark the

carrier bearing caps (14—Fig, 17) so

they can be reinstalled in their orig-

inal positions, then remove cotter pins

and the adjusting nut lock pins (25),

Cut lock wires and remove the carrier

bearing caps. Lift differential from

carrier and keep bearing cups (16)

identified with their bearing cones

(15), Bearing cones can now be re-

moved from differential case, if neces-

sary.

Remove cotter pin and nut (1) from

pinion shaft (11), then using a puller,

remove the companion flange (2) and

dust shield. Remove pinion shaft

bearing retainer (5) and press shaft

and bearings from carrier. Use a split

bearing puller to support pinion

bearing cup (8) on edge nearest pinion

shaft gear and press pinion shaft from

rear bearing (7) and bearing cup.

Remove spacer (9) and any shims

which may be present from pinion

shaft. Remove front bearing (10) and

inner (pilot) bearing (12) in a similar

manner.

Unbolt and remove bevel ring gear

from differential, if necessary. Remove

differential case bolts and hold case

together as last bolt is removed to

keep assembly from flying apart due

to the internal spring pressure. See

Fig. 18, Hold out rings (6) can be re-

moved with snap ring spreaders,

28, Clean and inspect all parts.

Check splines on side gears and clutch

members and remove any burrs or

4

•

10

SERIES 1755-1855-1955 Paragraphs 29-31

chipped edges with a stone or burr

grinder. Renew any parts which have

sections of splines broken away. In-

spect springs (3) for fractures, or other

damage, and renew springs which do

not have a free height of 2V4-2^

inches. Center cam in central driver

(7) must be free to rotate within the

limits of keys in central driver. Check

the weld between driven clutch (5) and

cam ring on clutch by tapping lightly

on cams of cam ring. If cam ring ro-

tates in driven clutch, weld is defec-

tive (failed). Inspect teeth on central

driver and driven clutches. Small de-

fects can be dressed with a stone. If

central driver or driven clutch is re-

newed, also renew the part it mates

with. A smooth wear pattern up to 50

percent of face width is acceptable for

the cams on center cam and driven

clutch.

29. The differential and carrier unit

is assembled as follows: Place the

inner (pilot) bearing on inner end of

pinion shaft and stake in four places.

Use a piece of pipe the size of inner

race of pinion shaft bearing and press

the forward pinion shaft bearing (10—

Fig. 17) on shaft with taper facing

threaded end of pinion shaft. Place

bearing spacer, and any shims which

were present during disassembly over

pinion shaft, then position the bearing

cup over forward bearing. Press the

rear pinion shaft bearing (7) on shaft

with taper away from threaded end of

pinion shaft. Check, and renew if nec-

essary, the oil seal (4) in pinion shaft

bearing retainer (5). Seal is installed

with lip toward inside. Place gasket

and bearing retainer over pinion shaft.

Check, and renew if necessary, the

dust shield (3) on companion flange.

Position companion flange so it will

not obstruct cotter pin hole in end of

pinion shaft, slide bearing retainer oil

seal on its land on companion flange,

then press companion flange on pinion

shaft. Install retaining nut, clamp

companion flange in a vise and tighten

nut to a torque of 300 ft.-lbs.

NOTE: Pressure of oil seal will gen-

erally hold bearing retainer away

from bearing. If it does not, tie re-

tainer to companion flange.

30. With pinion shaft assembled as

outlined above, clamp the bearing cup

in a soft jawed vise only tight enough

to prevent rotation, then using an

inch-pound torque wrench attached to

companion flange retaining nut, check

the rolling torque (bearing preload) of

the pinion shaft. This rolling torque

should be 13-23 in.-lbs.

If rolling torque is not as specified,

it will be necessary to disassemble the

shaft assembly and vary the spacer

and/or shims as required. A spacer and

shim kit is available under Oliver part

number 155 342-A.

With pinion shaft assembled and the

rolling torque of shaft determined,

press pinion shaft assembly into car-

rier, install bearing retainer and

tighten cap screws to a torque of 25 ft.-

lbs. Install cotter pin to lock nut (1) in

place.

31. Lubricate all parts and reas-

semble no-spin differential by re-

versing disassembly procedure. Be

sure to position spring retainers so

that spring seats inside cupped section

of retainer. Be sure key in central

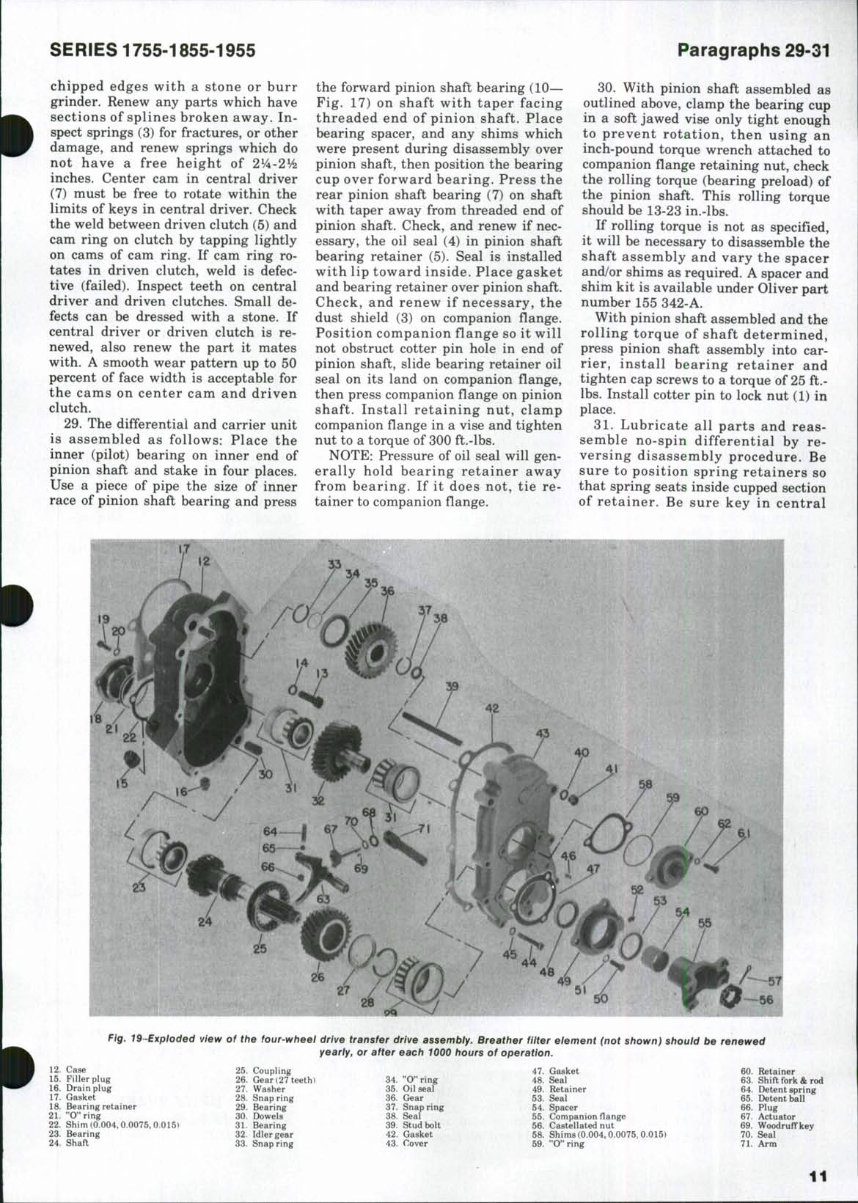

Fig. 19~Exploded view of the four-wheei drive transfer drive assembiy. Breather filter eiement (not shown) should be renewed

yearly, or after each 1000 hours of operation.

12. Case

15. Filler plug

16. Drain plug

17. Gasket

18. Bearing retainer

21. "O"ring

22. Shim (0.004, 0.0075, 0.015)

23. Bearing

24. Shaft

25. Coupling

26. Gear (27 teeth)

27. Washer

28. Snap ring

29. Bearing

30. I>owels

31. Bearing

32. Idler gear

33. Snap ring

34. "O"ring

35. Oil seal

36. Gear

37. Snap ring

38. Seal

39. Stud bolt

42. Gasket

43. Cover

47. Gasket

48. Seal

49. Retainer

53. Seal

54. Spacer

55. Companion flange

56. Castellated nut

58. Shims (0.004,0.0075, 0.015)

59. "O"ring

60. Retainer

63. Shift fork & rod

64. Detent spring

65. Detent ball

66. Plug

67. Actuator

69. Woodruffkey

70. Seal

71. Arm

11

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

Viewed 96 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

- Complete Factory Service Repair Workshop Manual

- Available for instant access on your computer, tablet, or smartphone

- Professional Manual covering all repairs, servicing, and troubleshooting procedures

- Contains detailed photos & diagrams

- Used by professional Mechanics and Technicians

- Can be printed out in full or in part

- Can be used on multiple computers

- Full Manual without any limitations or trial periods

- No expiration or renewal fees

- Fully compatible with Windows & MAC computers

Thanks for looking at this item, please click on the Button.