MASSEY FERGUSON MF-50 MF-202 MF-204 F-40 Repair Service MANU

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

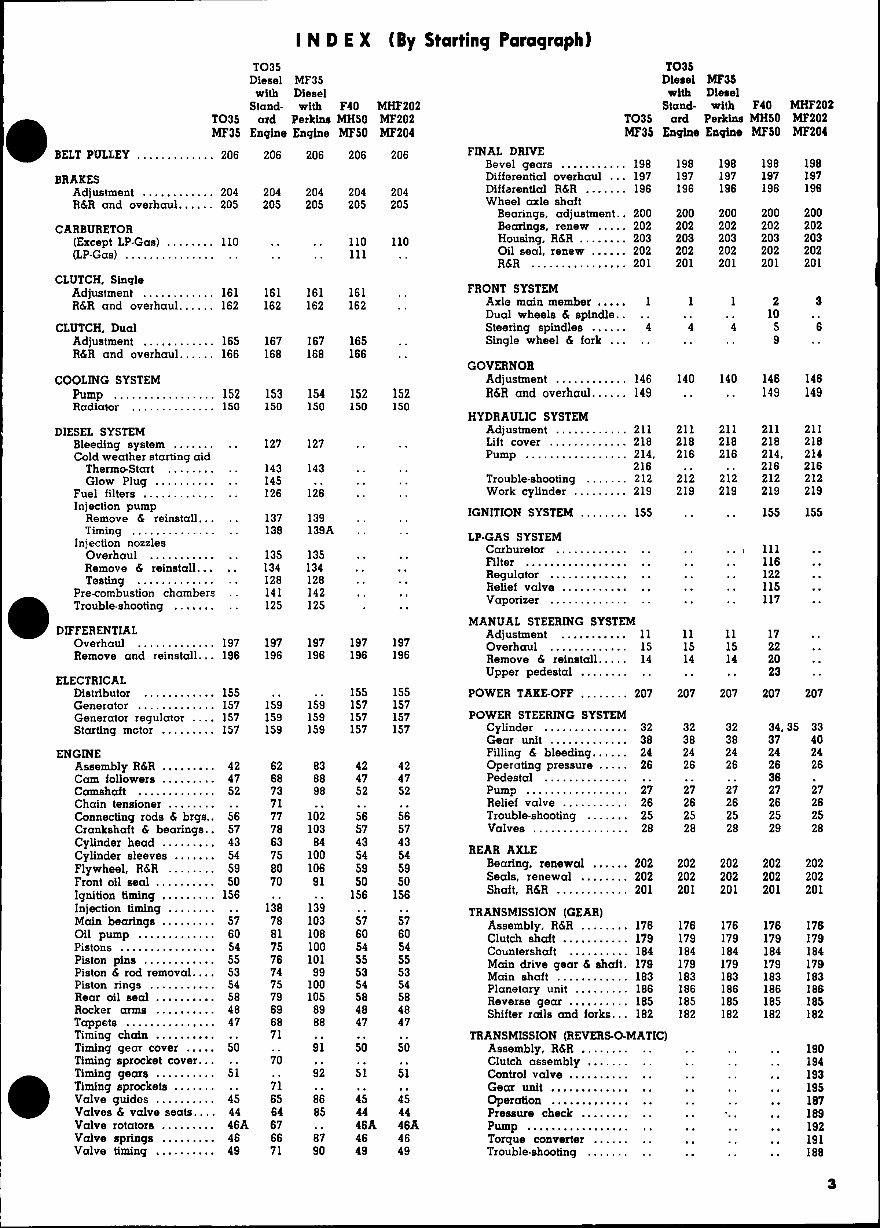

INDEX (By Starting Paragraph)

TO35

Diesel MF35

with Diesel

Stand- with F40 MHF202

TO35 aid Petkins MH50 MF202

MF35 Engine Engine MF50 MF204

BELT POUEY 206 206

BRAKES

Adjustment 204

R&R and overhaul 205

206 206 206

CARBURETOR

(Except LP-Gas) UO

(LP-Gcs)

CLUTCH, Single

Adjustment 161

R&R and overhaul 162

CLUTCH, Dual

Adjustment 165

R&R and overhaul 166

COOLING SYSTEM

Pump 152

Radicrtor 150

DIESEL SYSTEM

Bleeding system

Cold weather starting aid

Thermo-Start

Glow Plug

Fuel filters

Injection pump

Remove & reinstall

Timing

Injection nozzles

Overhaul

Remove & reinstall

Testing

Pre-combustion chambers . .

Trouble-shooting

DIFFERENTIAL

Overhaul 197

Remove and reinstall... 196

ELECTRICAL

Distributor

Generator

Generator regulator . ...

Starting motor

ENGINE

Assembly R&H

Cam followers

Camshait

Chain tensioner

Connecting rods & brgs..

Crankshaft & bearings..

Cylinder head

Cylinder sleeves

Flywheel, R&H

Front oil seal

Igrution timing

Injection timing

Main bearings

Oil pump

Pistons

Piston pins

Piston & rod removal ....

Piston rings

Rear oil seal

Rocker arms

Tappets

Timing chain

Timing gear cover

Timing sprocket cover...

Timing gears

Timing sprockets

Valve guides

Valves & valve seats...,

Valve rotators

Valve springs

Valve timing

42

47

52

56

57

43

54

59

50

156

57

60

54

55

53

54

58

48

47

50

51

45

44

46A

46

49

204

205

161

162

167

168

153

150

204

205

161

162

167

168

154

150

204

205

110

111

161

162

165

166

152

150

204

205

no

152

150

127

143

145

126

137

138

135

134

128

141

125

197

196

155

157 159

157 159

157 159

62

68

73

71

77

78

63

75

80

70

138

78

81

75

76

74

75

79

69

68

71

70

71

65

64

67

66

71

127

143

126

139

139 A

135

134

128

142

125

197

196

159

159

159

83

88

98

102

103

84

100

106

91

139

103

108

100

101

99

100

105

89

88

91

92

86

85

87

90

197

196

155

157

157

157

42

47

52

56

57

43

54

59

50

156

57

60

54

55

53

54

58

48

47

SO

51

45

44

46A

46

49

197

196

155

157

157

157

42

47

52

56

57

43

54

59

50

156

57

60

54

55

53

54

58

48

47

50

51

45

44

46A

46

49

TO35

MF35

FINAL DRIVE

Bevel gears 198

Differential overhaul . . . 197

Diffarenttal R&R 196

Wheel axle shaft

Bearings, adjustment.. 200

Bearings, renew 202

Housing, R&R 203

Oil seal, renew 202

R&R 201

FRONT SYSTEM

Axle main member 1

Dual wheels & spindle..

Steering spindles 4

Single wheel & fork

GOVERNOR

Adjustment 146

R&R and overhaul 149

HYDRAULIC SYSTEM

Adjustment 211

Lift cover 218

Pump 214,

216

Trouble-shooting 212

Work cylinder 219

IGNITION SYSTEM 155

LP-GAS SYSTEM

Carburetor

Filter

Regulator

Relief valve

Vaporizer

TO35

Dietel MF35

with Dieiel

Stand- with F40 MHF202

ard Perkins MH50 MF202

Engine Engine MF50 MF204

198 198 198 198

197 197 197 197

196 196 196 196

200

202

203

202

201

200

202

203

202

201

140 140

211

218

216

212

219

211

218

216

212

219

MANUAL STEERING SYSTEM

Adjustment II 11 11

Overhaul 15 15 15

Remove & reinstail 14 14 14

Upper pedestal

200

202

203

202

201

2

10

5

9

146

149

211

218

214,

216

212

219

155

111

116

122

115

117

17

22

20

23

200

202

203

202

201

146

149

211

218

214

216

212

219

155

POWER TAKE-OFF 207 207 207 207 207

POWER STEERING SYSTEM

CyUnder 32 32 32 34,35 33

Gear unit 38 38 38 37 40

Filling & bleeding 24 24 24 24 24

Operating pressure 26 26 26 26 26

Pedestal .. .. 36

Pump 27 27 27 27 27

Relief valve 26 26 26 26 26

Trouble-shooting 25 25 25 25 25

Valves 28 28 28 29 28

REAR AXLE

Bearing, renewal 202 202 202 202 202

Seals, renewal 202 202 202 202 202

Shaft, R&R 201 201 201 201 201

TRANSMISSION (GEAR)

Assembly, R&R 176 176 176 178

Clutch shait 179 179 179 179

Countershaft 184 184 184 184

Main drive gear & shaft. 179 179 179 179

Main shaft 183 183 183 183

Planetary unit 186 186 186 186

Reverse gear 185 185 185 185

Shifter rails and forks... 182 182 182 182

TRANSMISSION (REVERS-O-MATIC)

Assembly, R&R

Clutch assembly

Control valve

Gear tinit

Operation

Pressure check

Pump .. .. . ,

Torque converter

Trouble-shooting

17S

179

184

179

183

186

185

182

190

194

193

195

187

189

182

191

188

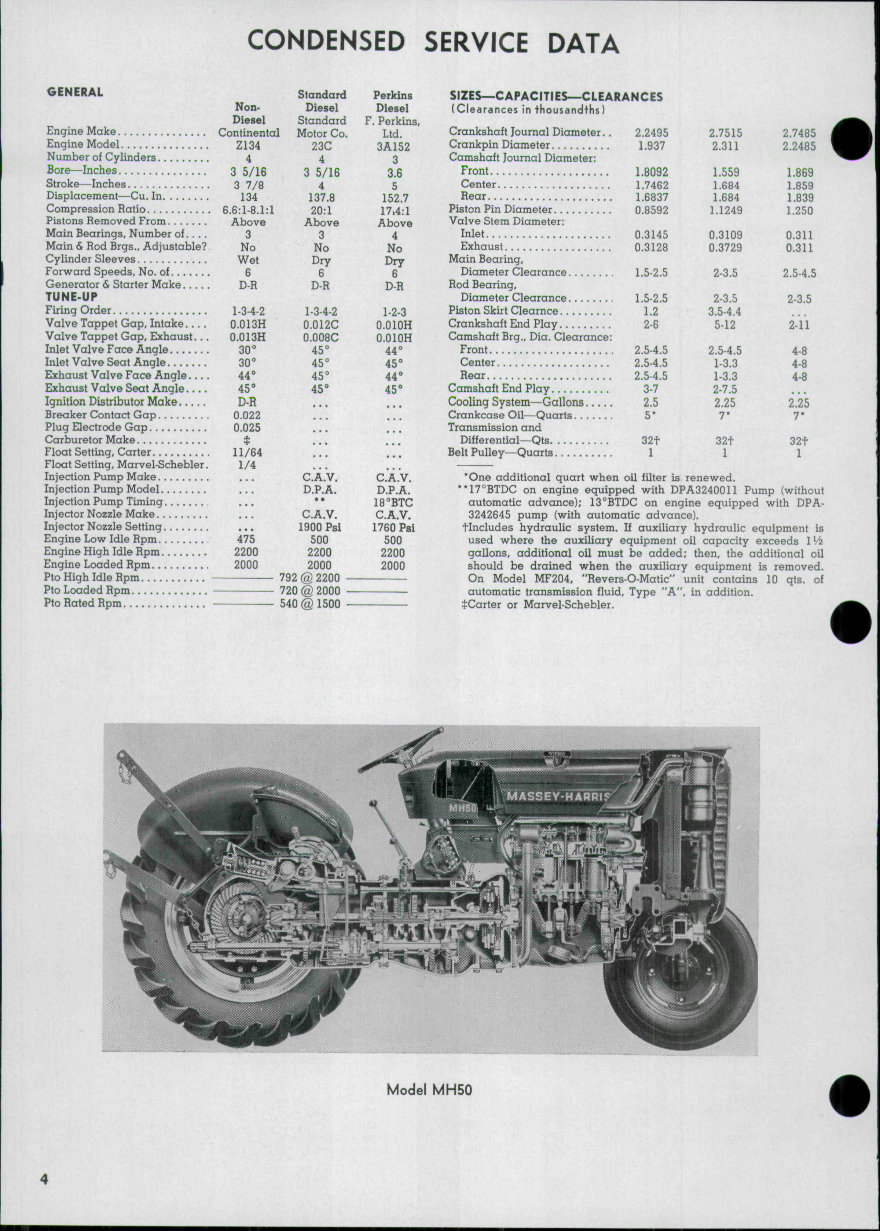

CONDENSED SERVICE DATA

GENERAL

Engine Make

Engine Model

Number of Cylinders

Bore—Inches

Stroke—Inches

Displacement—Cu. In

Compression Ratio

Pistons Removed From

Main Bearings, Number of ....

Main & Rod Brgs., Adjustable?

Cylinder Sleeves

Forward Speeds, No. of

Generator & Starter Make

TUNE-UP

Firing Order

Valve Tappet Gap, Intake ....

Valve Tappet Gap, Exhaust...

Inlet Valve Face Angle

Inlet Valve Seat Angle

Exhaust Valve Face Angle ....

Exhaust Valve Seat Angle ....

Ignition Distributor Make

Breaker Contact Gap

Plug Electrode Gap

Carburetor Make

Float Setting, Carter

Float Setting, Marvel-Schebler.

Injection Pump Make

Injection Pump Model

Injection Pump Timing

Injector Nozzle Make

Injector Nozzle Setting

Engine Low Idle Rpm

Engine High Idle Rpm

Engine Loaded Rpm

Pto High Idle Rpm

Pto Loaded Rpm

Pto Rated Hpm

Non-

Diesel

Continental

Z134

4

3 5/16

3 7/8

134

6.6:1-8.1:1

Above

3

No

Wet

6

D-R

1-3-4-2

0.013H

0.013H

30°

30°

44°

45°

Standard

Diesel

Standard

Motor Co.

23C

4

3 5/16

4

137.8

20:1

Above

3

No

Dry

6

D-H

1-3-4-2

0.012C

0.008C

45°

45°

45°

45°

Perkins

Diesel

F. Perkins

Ltd.

3A152

3

3.6

5

152.7

17.4:1

Above

4

No

Dry

6

D-R

1-2-3

O.OIOH

O.OIOH

44°

45°

44°

45°

D-R

0.022

0.025

t

11/64

1/4

475

2200

2000

C.A.V.

D.P.A.

• *

C.A.V.

1900 Psi

500

2200

2000

792 @ 2200

720 @ 2000

540 @ 1500

C.A.V.

D.P.A.

18°BTC

C.A.V.

1780 Pai

500

2200

2000

SIZES—CAPACITIES—CLEARANCES

(Clearances In thousandths)

Crankshaft Journal Diameter.. 2.2495 2.7515 2,7485

Crankpin Diameter 1.937 2.311 2.2485

Camshaft Journal Diameter:

Front 1,8092 1.559 1.869

Center 1.7462 1.684 1.859

Rear 1.6837 1.684 1.839

Piston Pin Diameter 0.8592 1.1249 1.250

Valve Stem Diameter:

Inlet 0.3145 0.3109 0.311

Exhaust 0.3128 0.3729 0.311

Main Bearing,

Diameter Clearance 1.5-2.5 2-3.5 2.5-4.5

Rod Bearing,

Diameter Clearance 1.5-2.5 2-3.5 2-3.5

Piston Skirt Clearnce 1.2 3.5-4.4

Crankshaft End Play 2-6 5-12 2-11

Camshaft Brg., Dia. Clearance:

Front 2.5-4.5 2.5-4.5 4-8

Center 2.5-4.5 1-3.3 4-8

Rear 2.5-4.5 1-3.3 4-8

Camshaft End Play 3-7 2-7.5

Cooling System—Gallons 2.5 2.25 2.25

Crankcase Oil—Quarts 5* 7* 7*

Transmission and

Differential—Qts 32t 32t 32t

Belt Pulley—Quarts 1 1 1

"One additional quart when oil filter is renewed.

**17°BTDC on engine equipped with DPA3240011 Pump (without

automatic advance); 13°BTDC on engine equipped with DPA-

3242645 pump (with automatic advance).

tincludes hydraulic system. If auxiliary hydraulic equipment is

used where the auxiliary equipment oil capacity exceeds l'/2

gallons, additional oil must be added; then, the additional oil

should be drained when the auxiliary equipment is removed.

On Model MF204, "Revers-O-Matic" unit contains 10 qts. of

automatic transmission fluid. Type "A", in addition.

:i:Carter or Marvel-Schebler.

Model MH50

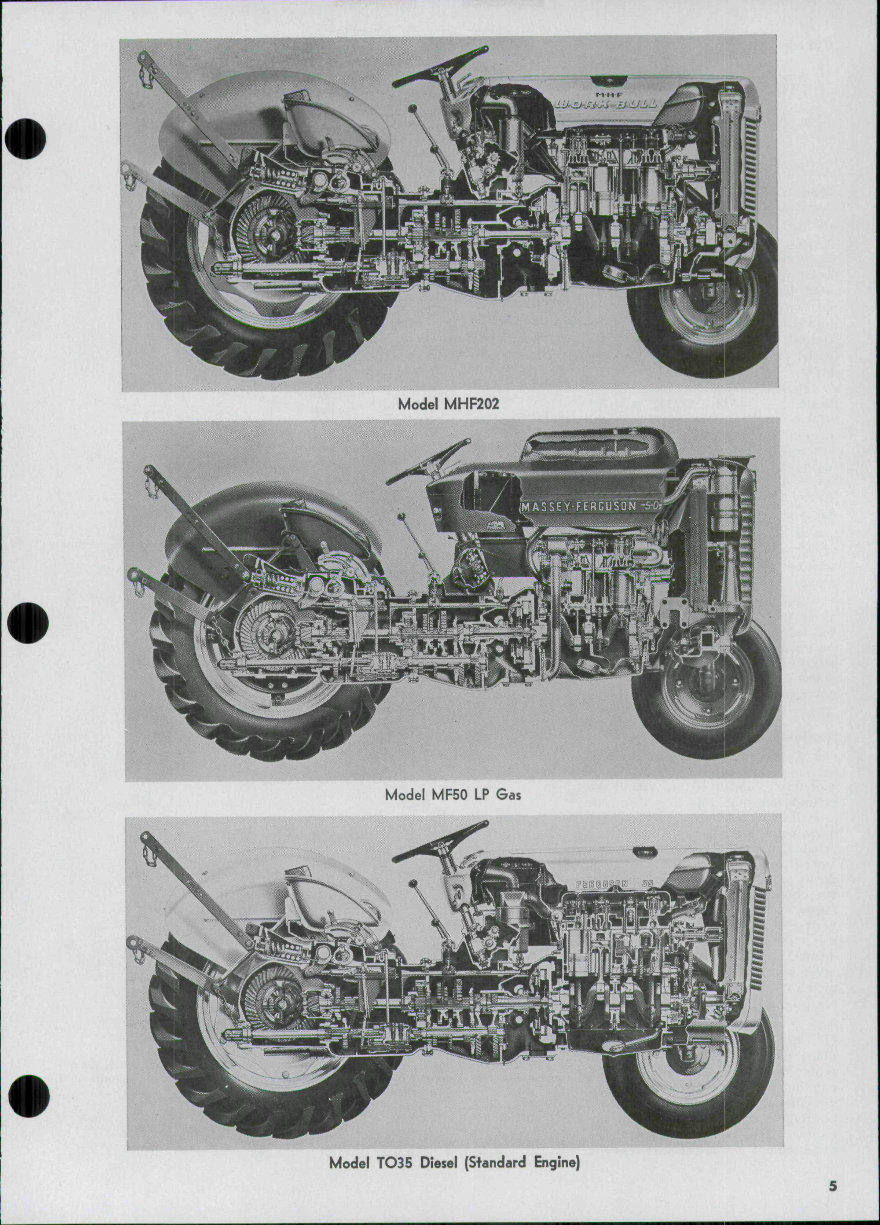

Model MHF202

Model MF50 LP Gas

Model TO35 Diesel (Standard Engine)

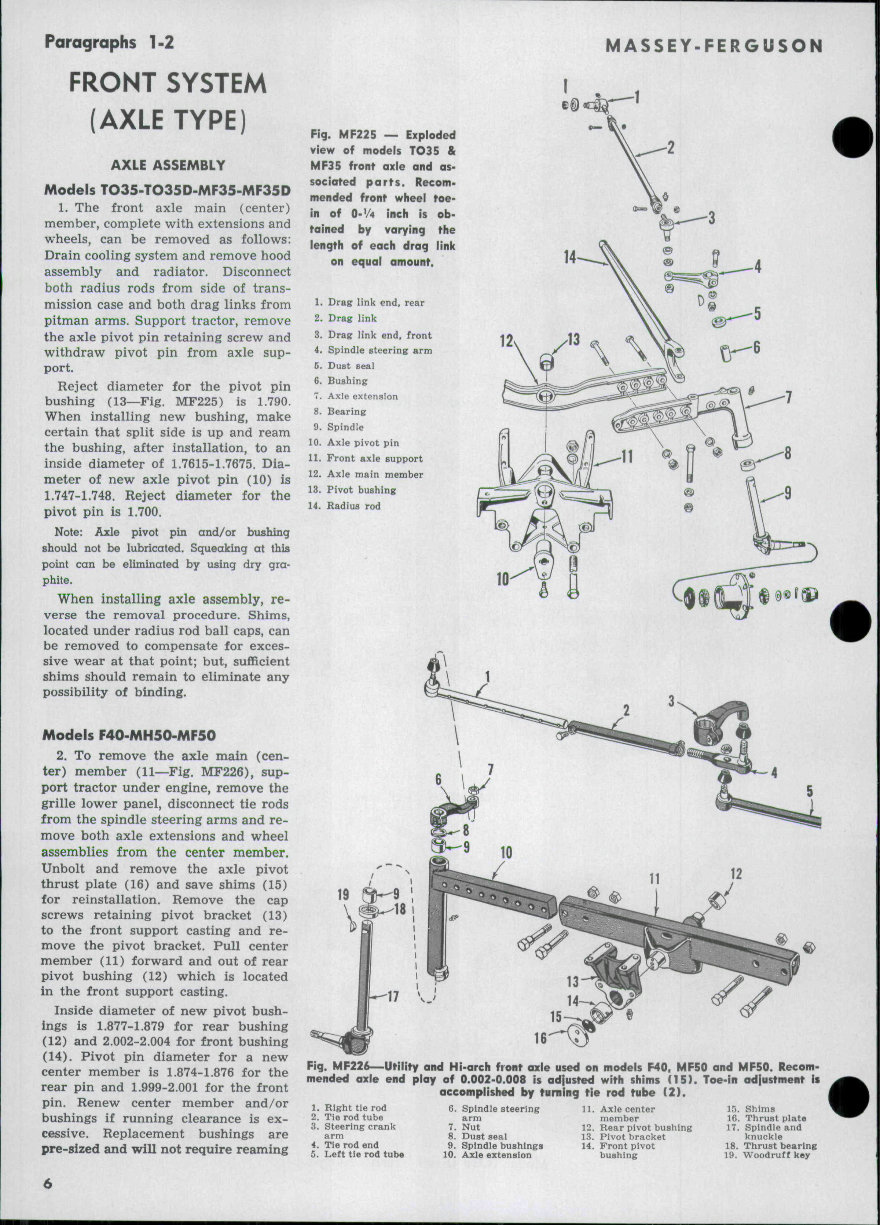

Paragraphs 1-2

FRONT SYSTEM

(AXLE TYPE)

AXLE ASSEMBLY

Models TO35-TO35D-MF35-MF35D

1. The front axle main (center)

member, complete with extensions and

wheels, can be removed as follows:

Drain cooling system and remove hood

assembly and radiator. Disconnect

both radius rods from side of trans-

mission case and both drag links from

pitman arms. Support tractor, remove

the axle pivot pin retaining screw and

withdraw pivot pin from axle sup-

port.

Reject diameter for the pivot pin

bushing (13—Fig. MF225) is 1.790.

When installing new bushing, make

certain that split side is up and ream

the bushing, after installation, to an

inside diameter of 1.7615-1.7675. Dia-

meter of new axle pivot pin (10) is

1.747-1.748. Reject diameter for the

pivot pin is 1.700.

Note: Axle pivot pin and/or bushing

should not be lubricated. Squeaking at this

point can be eliminated by using dry gra-

phite.

When installing axle assembly, re-

verse the removal procedure. Shims,

located under radius rod ball caps, can

be removed to compensate for exces-

sive wear at that point; but, sufficient

shims should remain to eliminate any

possibility of binding.

Models F40-MH50-MF50

2. To remove the axle main (cen-

ter) member (11—Fig. MF226), sup-

port tractor under engine, remove the

grille lower panel, disconnect tie rods

from the spindle steering arms and re-

move both axle extensions and wheel

assemblies from the center member.

Unbolt and remove the axle pivot

thrust plate (16) and save shims (15)

for reinstallation. Remove the cap

screws retaining pivot bracket (13)

to the front support casting and re-

move the pivot bracket. Pull center

member (11) forward and out of rear

pivot bushing (12) which is located

in the front support casting.

Inside diameter of new pivot bush-

ings is 1.877-1.879 for rear bushing

(12) and 2.002-2.004 for front bushing

(14). Pivot pin diameter for a new

center member is 1.874-1.876 for the

rear pin and 1.999-2.001 for the front

pin. Renew center member and/or

bushings if running clearance is ex-

cessive. Replacement bushings are

pre-8ized and will not require reaming

MASSEY-FERGUSON

Fig. MF225 — Exploded

view of models TO35 &

MF35 front axle and as-

sociated parts. Recom-

mended front wheel toe-

in of O-V4 inch is ob-

tained by varying the

length of each drag link

on equal amount.

1.

2.

3.

4.

6.

6.

7_

8.

9.

10.

11.

12.

13.

14.

Drag hnk end, rear

Drag link

Drag link end, front

Spindle steering arm

Dust Beal

Bushing

Axle extension

Bearing

Spindle

Axle pivot pin

Front axle support

Axle main member

Pivot bushing

Radius rod

10

19

Fig. MF226—Utility and Hi-arch front axle used on models F40, MF50 and MF50. Recom-

mended axle end play of 0.002-0.008 is adjusted with shims (15). Toe-in adjustment if

accomplished by turning tie rod tube ( 2 ) .

1. Right tie rod

2. Tie rod tube

3. Steering crank

arm

4. Tie rod end

5. Left tie rod tube

6. Spindle steering

arm

7. Nut

8. Dust seal

9. Spindle bushings

10. Axle extension

11. Axle center

member

12. Rear pivot bushing

13. Pivot bracket

14. Front pivot

bushing

15. Shims

16. Thrust plate

17. Spindle and

knuckle

18. Thrust bearing

19. Woodruff key

TO35-TO35D-F40<MH50-MF35-MF35D-MF50-MHF202'MF202-MF204 Paragraphs 3-5

if carefully installed with a suitable

arbor. Make certain, however, that

lubrication holes in bushings are in

register with similar holes in pivot

bracket and front support.

When installing the axle center

member, reverse the removal proce-

dure and vary the number of shims

(15) to obtain a center member end

play of 0.002-0.008 when checked be-

tween rear face of pivot bracket (13)

and front face of center member (11).

Shims are available in thicknesses of

0.002, 0.005 and 0.010.

Moders MHF202-MF202-MF204

3. The front axle main member

complete with spindles and wheels

can be removed as follows: Drain cool-

ing system and remove hood assembly

and radiator. On Model MF204 it will

first be necessary to remove oil cool-

ing radiator and oil lines. Disconnect

both drag links and both power steer-

ing cylinders from the spindle steer-

ing arms. Disconnect both power

steering cylinders from the axle main

member and, without disconnecting

the oil lines, lay the cylinders rear-

w ard and out of way. Unbolt and re-

move thrust plate from axle support

and withdraw spacer (S—Fig. MF228)

and shims. Remove bolt (B) retaining

axle to pivot pin.

Support tractor under oil pan, un-

bolt front support casting from engine

and roll axle and support assembly

away from tractor. Bump the axle

pivot pin forward and out of axle and

support casting.

Inside diameter of new pivot bush-

ings is 1.8765-1.8795. Diameter of new

pivot pin is 1.8745-1.8750. Renew pivot

pin and/or bushings if clearance is ex-

cessive. Replacement bushings are pre-

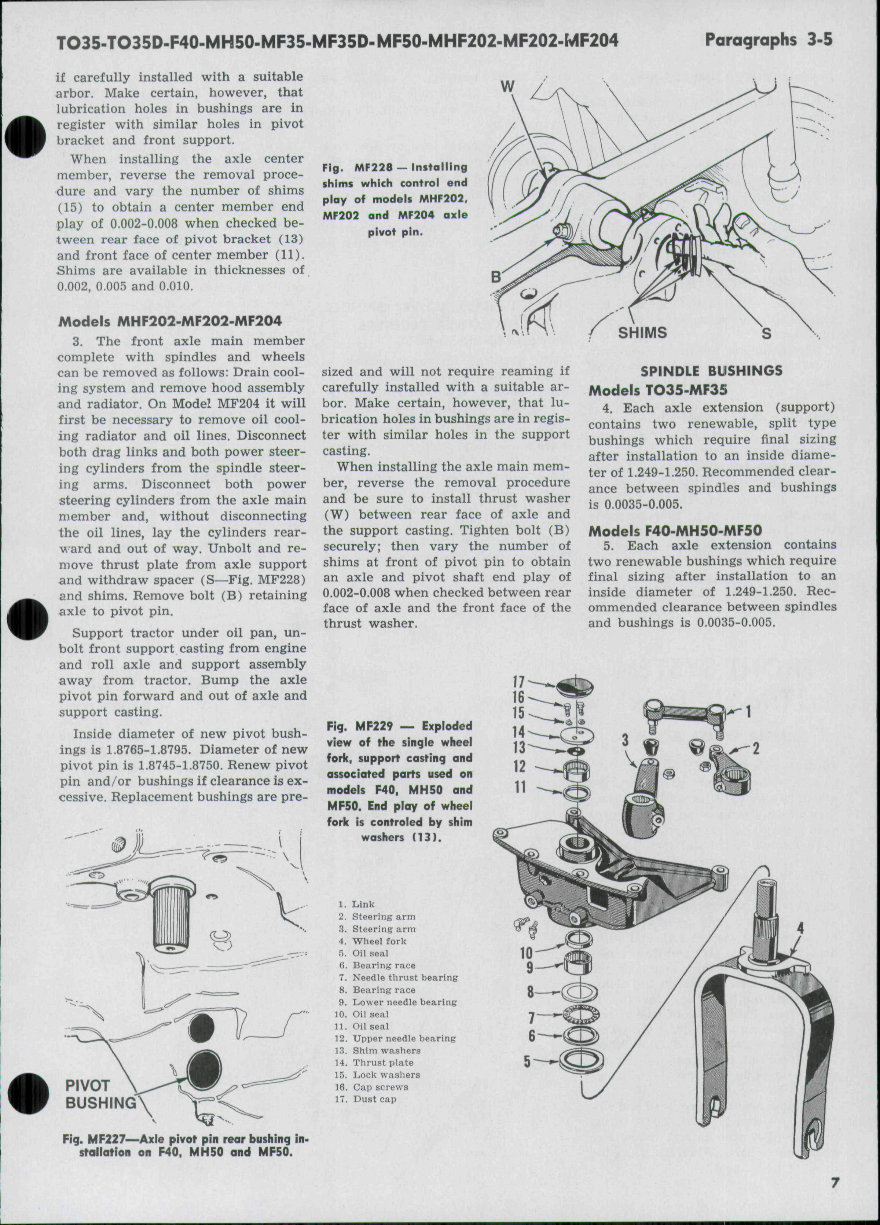

w

Fig. MF228 — Installing

shims which control end

play of models MHF202.

MF202 and MF204 axle

pivot pin.

sized and will not require reaming if

carefully installed with a suitable ar-

bor. Make certain, however, that lu-

brication holes in bushings are in regis-

ter with similar holes in the support

casting.

When installing the axle main mem-

ber, reverse the removal procedure

and be sure to install thrust washer

(W) between rear face of axle and

the support casting. Tighten bolt (B)

securely; then vary the number of

shims at front of pivot pin to obtain

an axle and pivot shaft end play of

0.002-0.008 when checked between rear

face of axle and the front face of the

thrust washer.

SPINDLE BUSHINGS

Models TO35-MF35

4. Each axle extension (support)

contains two renewable, split type

bushings which require final sizing

after installation to an inside diame-

ter of 1.249-1.250. Recommended clear-

ance between spindles and bushings

is 0.0035-0.005.

Models F40-MH50-MF50

5. Each axle extension contains

two renewable bushings which require

final sizing after installation to an

inside diameter of 1.249-1.250. Rec-

ommended clearance between spindles

and bushings is 0.0035-0.005.

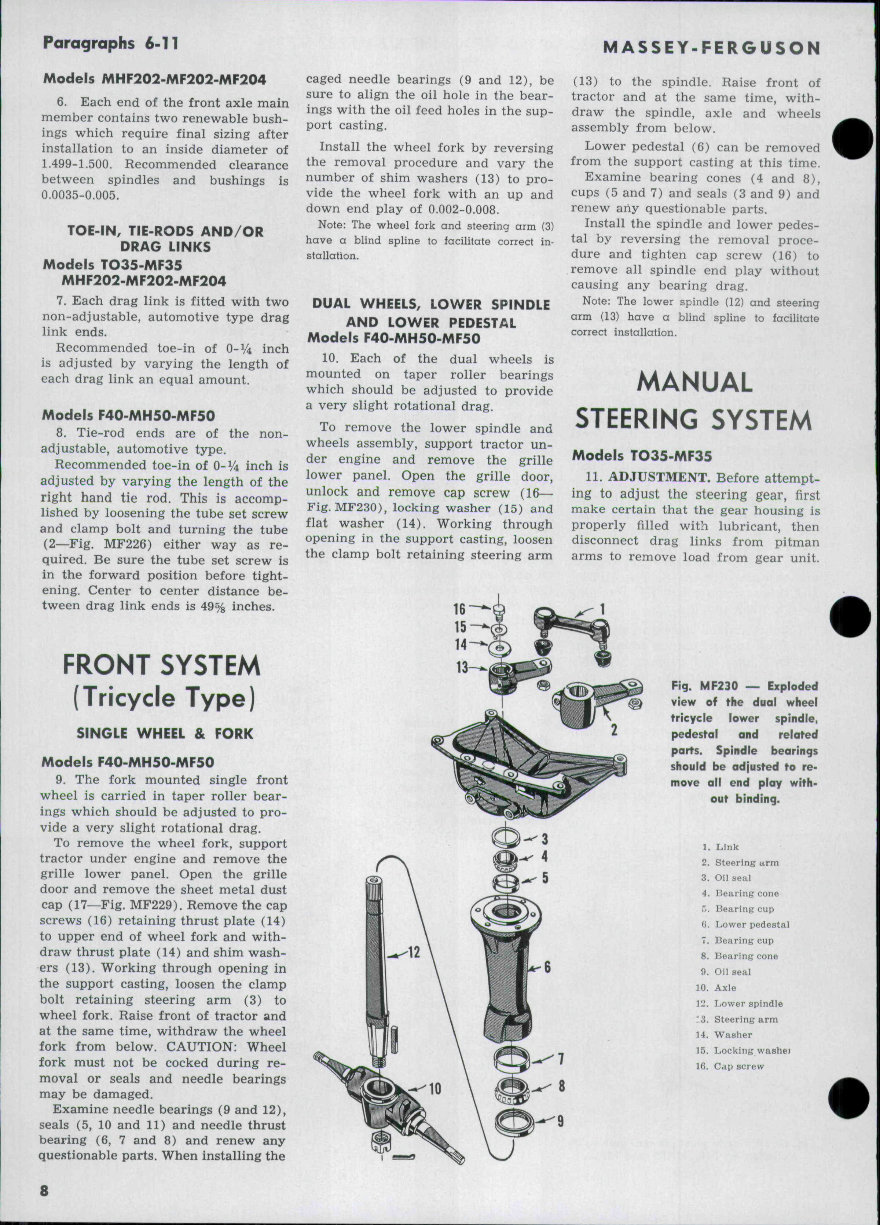

Fig. MF229 — Exploded

view of the single wheel

fork, support casting and

associated parts used on

models F40, MH50 and

MF50. End play of wheel

foric is controled by shim

washers (13).

1.

2.

3.

4.

5,

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

Link

Steering arm

Steering arm

Wheel fork

Oil seal

Bearing race

Needle thrust bearing

Bearing race

Lower needle bearing

Oil seal

Oil seal

Upper needle bearing

Shim washers

Thrust plate

Lock washers

Cap screws

Dust cap

Fig. MF227—Axle pivot pin rear bushing in-

stallation on F40. MH50 and MF50.

Paragraphs 6-11

MASSEY'FERGUSON

Models MHF202-MF202-MF204

6. Each end of the front axle main

member contains two renewable bush-

ings which require final sizing after

installation to an inside diameter of

1.499-1.500. Recommended clearance

between spindles and bushings is

0.0035-0.005.

TOE-IN, TIE-RODS AND/OR

DRAG LINKS

Models TO35-MF35

MHF202-MF202-MF204

7. Each drag link is fitted with two

non-adjustable, automotive type drag

link ends.

Recommended toe-in of 0-y4 inch

is adjusted by varying the length of

each drag link an equal amount.

Models F40-MH50-MF50

8. Tie-rod ends are of the non-

adjustable, automotive type.

Recommended toe-in of O-Vi inch is

adjusted by varying the length of the

right hand tie rod. This is accomp-

lished by loosening the tube set screw

and clamp bolt and turning the tube

(2—Fig. MF226) either way as re-

quired. Be sure the tube set screw is

in the forward position before tight-

ening. Center to center distance be-

tween drag link ends is 49% inches.

FRONT SYSTEM

(Tricycle Type)

SINGLE WHEEL & FORK

Models F40-MH50-MF50

9. The fork mounted single front

wheel is carried in taper roller bear-

ings which should be adjusted to pro-

vide a very slight rotational drag.

To remove the wheel fork, support

tractor under engine and remove the

grille lower panel. Open the grille

door and remove the sheet metal dust

cap (17—Fig. MF229). Remove the cap

screws (16) retaining thrust plate (14)

to upper end of wheel fork and with-

draw thrust plate (14) and shim wash-

ers (13). Working through opening in

the support casting, loosen the clamp

bolt retaining steering arm (3) to

wheel fork. Raise front of tractor and

at the same time, withdraw the wheel

fork from below. CAUTION: Wheel

fork must not be cocked during re-

moval or seals and needle bearings

may be damaged.

Examine needle bearings (9 and 12),

seals (5, 10 and 11) and needle thrust

bearing (6, 7 and 8) and renew any

questionable parts. When installing the

caged needle bearings (9 and 12), be

sure to align the oil hole in the bear-

ings with the oil feed holes in the sup-

port casting.

Install the wheel fork by reversing

the removal procedure and vary the

number of shim washers (13) to pro-

vide the wheel fork with an up and

down end play of 0.002-0.008.

Note: The wheel fork and steering arm (3)

have a blind spline to facilitate correct in-

stallation.

DUAL WHEELS, LOWER SPINDLE

AND LOWER PEDESTAL

Models F40-MH50-MF50

10. Each of the dual wheels is

mounted on taper roller bearings

which should be adjusted to provide

a very slight rotational drag.

To remove the lower spindle and

wheels assembly, support tractor un-

der engine and remove the grille

lower panel. Open the grille door,

unlock and remove cap screw (16—

Fig. MF230), locking washer (15) and

flat washer (14). Working through

opening in the support casting, loosen

the clamp bolt retaining steering arm

(13) to the spindle. Raise front of

tractor and at the same time, with-

draw the spindle, axle and wheels

assembly from below.

Lower pedestal (6) can be removed

from the support casting at this time.

Examine bearing cones (4 and 8),

cups (5 and 7) and seals (3 and 9) and

renew any questionable parts.

Install the spindle and lower pedes-

tal by reversing the removal proce-

dure and tighten cap screw (16) to

remove all spindle end play without

causing any bearing drag.

Note: The lower spindle (12) and steering

arm (13) have a blind spline to facilitate

correct installation.

MANUAL

STEERING SYSTEM

Models TO35-MF35

11. ADJUSTMENT. Before attempt-

ing to adjust the steering gear, first

make certain that the gear housing is

properly filled with lubricant, then

disconnect drag links from pitman

arms to remove load from gear unit.

Fig. MF230 — Expioded

view of the dual wlieei

tricycie iower spindie,

pedestai and related

parts. Spindle bearings

siiouid be adjusted to re-

move all end play with-

out binding.

1. Link

2. Steering urni

3. Oil seal

4. Bearing cone

r*. Bearing cup

6. Lower pedestal

7. Bearing cup

8. Bearing cone

9. Oil seal

10. Axle

12. Lower spindle

!3. Steering arm

14. Washer

15. Locking wa8hei

16. Cap screw

8

TO35-TO35D-F40-MH50-MF35-MF35D-MF50-MHF202-MF202-MF204 Paragraphs 12-15A

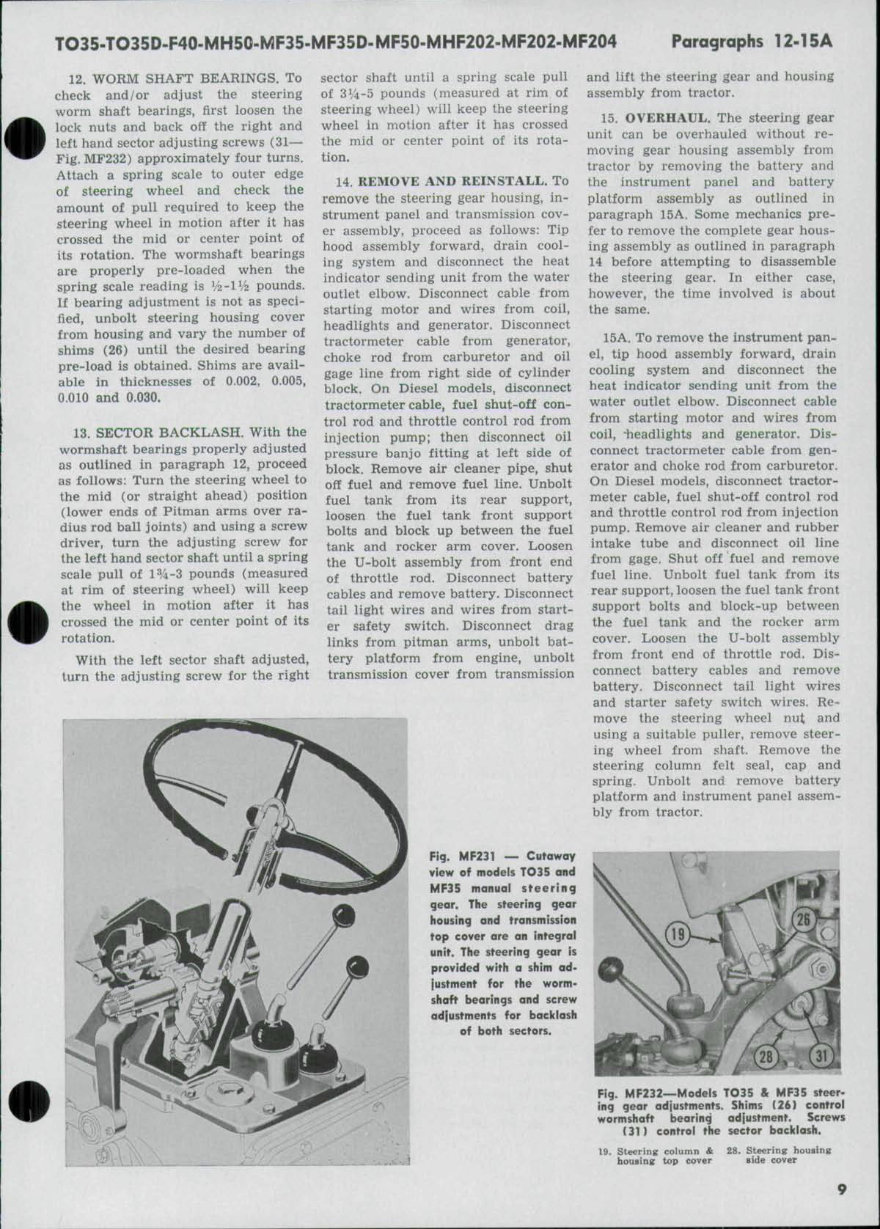

12. WORM SHAFT BEARINGS. To

check and/or adjust the steering

worm shaft bearings, first loosen the

lock nuts and back off the right and

left hand sector adjusting screws (31—

Fig. MF232) approximately four turns.

Attach a spring scale to outer edge

of steering wheel and check the

amount of pull required to keep the

steering wheel in motion after it has

crossed the mid or center point of

its rotation. The wormshaft bearings

are properly pre-loaded when the

spring scale reading is Va-l^/^ pounds.

If bearing adjustment is not as speci-

fied, unbolt steering housing cover

from housing and vary the number of

shims (26) until the desired bearing

pre-load is obtained. Shims are avail-

able in thicknesses of 0.002, 0.005,

0.010 and 0.030.

13. SECTOR BACKLASH. With the

wormshaft bearings properly adjusted

as outlined in paragraph 12, proceed

as follows: Turn the steering wheel to

the mid (or straight ahead) position

(lower ends of Pitman arms over ra-

dius rod ball joints) and using a screw

driver, turn the adjusting screw for

the left hand sector shaft until a spring

scale pull of l%-3 pounds (measured

at rim of steering wheel) will keep

the wheel in motion after it has

crossed the mid or center point of its

rotation.

With the left sector shaft adjusted,

turn the adjusting screw for the right

sector shaft until a spring scale pull

of 3'74-5 pounds (measured at rim of

steering wheel) will keep the steering

wheel in motion after it has crossed

the mid or center point of its rota-

tion.

14. REMOVE AND REINSTALL. To

remove the steering gear housing, in-

strument panel and transmission cov-

er assembly, proceed as follows: Tip

hood assembly forward, drain cool-

ing system and disconnect the heat

indicator sending unit from the water

outlet elbow. Disconnect cable from

starting motor and wires from coil,

headlights and generator. Disconnect

tractormeter cable from generator,

choke rod from carburetor and oil

gage line from right side of cylinder

block. On Diesel models, disconnect

tractormeter cable, fuel shut-off con-

trol rod and throttle control rod from

injection pump; then disconnect oil

pressure banjo fitting at left side of

block. Remove air cleaner pipe, shut

off fuel and remove fuel line. Unbolt

fuel tank from its rear support,

loosen the fuel tank front support

bolts and block up between the fuel

tank and rocker arm cover. Loosen

the U-bolt assembly from front end

of throttle rod. Disconnect battery

cables and remove battery. Disconnect

tail light wires and wires from start-

er safety switch. Disconnect drag

links from pitman arms, unbolt bat-

tery platform from engine, unbolt

transmission cover from transmission

and lift the steering gear and housing

assembly from tractor.

15. OVERHAUL. The steering gear

unit can be overhauled without re-

moving gear housing assembly from

tractor by removing the battery and

the instrument panel and battery

platform assembly as outlined in

paragraph 15A. Some mechanics pre-

fer to remove the complete gear hous-

ing assembly as outlined in paragraph

14 before attempting to disassemble

the steering gear. In either case,

however, the time involved is about

the same.

15A. To remove the instrument pan-

el, tip hood assembly forward, drain

cooling system and disconnect the

heat indicator sending unit from the

water outlet elbow. Disconnect cable

from starting motor and wires from

coil, -headlights and generator. Dis-

connect tractormeter cable from gen-

erator and choke rod from carburetor.

On Diesel models, disconnect tractor-

meter cable, fuel shut-off control rod

and throttle control rod from injection

pump. Remove air cleaner and rubber

intake tube and disconnect oil line

from gage. Shut off fuel and remove

fuel line. Unbolt fuel tank from its

rear support, loosen the fuel tank front

support bolts and block-up between

the fuel tank and the rocker arm

cover. Loosen the U-bolt assembly

from front end of throttle rod. Dis-

connect battery cables and remove

battery. Disconnect tail light wires

and starter safety switch wires. Re-

move the steering wheel nut and

using a suitable puller, remove steer-

ing wheel from shaft. Remove the

steering column felt seal, cap and

spring. Unbolt and remove battery

platform and instrument panel assem-

bly from tractor.

Fig. MF231 — Cutaway

view of models TO35 and

MF35 manual steering

gear. The steering gear

housing and transmission

top cover are an integral

unit. The steering gear is

provided with a shim ad-

justment for the worm-

shaft bearings and screw

adjustments for backlash

of both sectors.

Fig. MF232—Models TO35 & MF35 steer-

ing gear adjustments. Shims (26) control

wormshaft bearing adjustment. Screws

(31) control the sector backlash.

19. Steering coiumn & 28. Steering housing

housins top cover side cover

Paragraph 16

MASSEY-FERGUSON

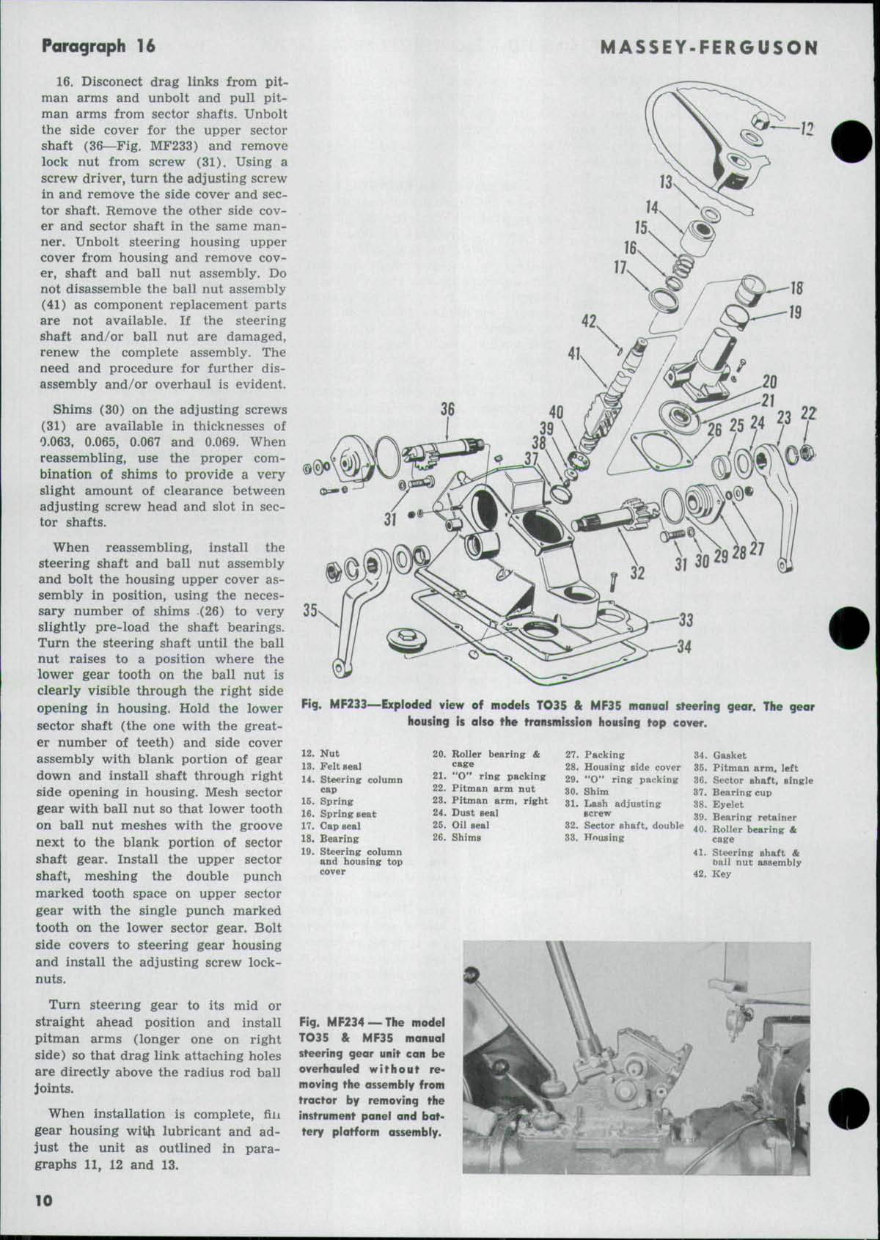

16. Disconect drag links from pit-

man arms and unbolt and pull pit-

man arms from sector shafts. Unbolt

the side cover for the upper sector

shaft (36—Fig. MF233) and remove

lock nut from screw (31). Using a

screw driver, turn the adjusting screw

in and remove the side cover and sec-

tor shaft. Remove the other side cov-

er and sector shaft in the same man-

ner. Unbolt steering housing upper

cover from housing and remove cov-

er, shaft and ball nut assembly. Do

not disassemble the ball nut assembly

(41) as component replacement parts

are not available. If the steering

shaft and/or ball nut are damaged,

renew the complete assembly. The

need and procedure for further dis-

assembly and/or overhaul is evident.

Shims (30) on the adjusting screws

(31) are available in thicknesses of

0.063, 0.065, 0.067 and 0.069. When

reassembling, use the proper com-

bination of shims to provide a very

slight amount of clearance between

adjusting screw head and slot in sec-

tor shafts.

When reassembling, install the

steering shaft and ball nut assembly

and bolt the housing upper cover as-

sembly in position, using the neces-

sary number of shims (26) to very

slightly pre-load the shaft bearings.

Turn the steering shaft until the ball

nut raises to a position where the

lower gear tooth on the ball nut is

clearly visible through the right side

opening in housing. Hold the lower

sector shaft (the one with the great-

er number of teeth) and side cover

assembly with blank portion of gear

down and install shaft through right

side opening in housing. Mesh sector

gear with ball nut so that lower tooth

on ball nut meshes with the groove

next to the blank portion of sector

shaft gear. Install the upper sector

shaft, meshing the double punch

marked tooth space on upper sector

gear with the single punch marked

tooth on the lower sector gear. Bolt

side covers to steering gear housing

and install the adjusting screw lock-

nuts.

Turn steering gear to its mid or

straight ahead position and install

pitman arms (longer one on right

side) so that drag link attaching holes

are directly above the radius rod ball

joints.

When installation is complete, fin

gear housing with lubricant and ad-

just the unit as outlined in para-

graphs 11, 12 and 13.

35

Fig. MF233—Exploded view of modeis TO35 & MF35 manuai steering gear. The gear

housing is aiso the transmission housing top cover.

12. Nut

13. Felt seal

14. Steering column

cap

15. Spring

16. Spring Beat

17. Cap seal

18. Bearing

19. Steering column

and housing top

cover

20. Roller bearing &

cage

21. "O" ring packing

22. Pitman arm nut

23. Pitman arm, right

24. Dust Beal

2b. Oil Beal

26. ShimB

27. Packing

28. HouBing Bide cover

29. "O" ring packing

30. Shim

31. Lash adjUBting

Bcrew

32. Sector Bhaft, double

33.

34. Gasket

36. Pitman arm, left

36. Sector Bhaft, Bingle

37. Bearing cup

38. Eyelet

39. Bearing retainer

40. Roller bearing A

cage

41. Steering shaft A

bail nut aBBembiy

42. Key

Fig. MF234 —The model

TO35 & MF35 manuol

steering geor unit can be

overhauled without re-

moving the assembly from

tractor by removing the

instrument panel and bat-

tery platform assembly.

10

TO35-TO35D-F40-MH50-MF35.MF35D-MF50-MHF202-MF202-MF204 Paragraphs 17-20

UPPER PEDESTAL

IDRAG LINK

STEERING

COLUMN

SHIMS

\.

0

|CAMSHAFT|

W'

FRONT SUPPORT

Fig. MF235—Cut-away view of the cam and iever type steering gear unit used on F40. MH50 and MF50. Pedestal

unit shown in this iilustratlon is used on models with manual steering oniy. The gear unit, however, it the tame

on models with or without power steering.

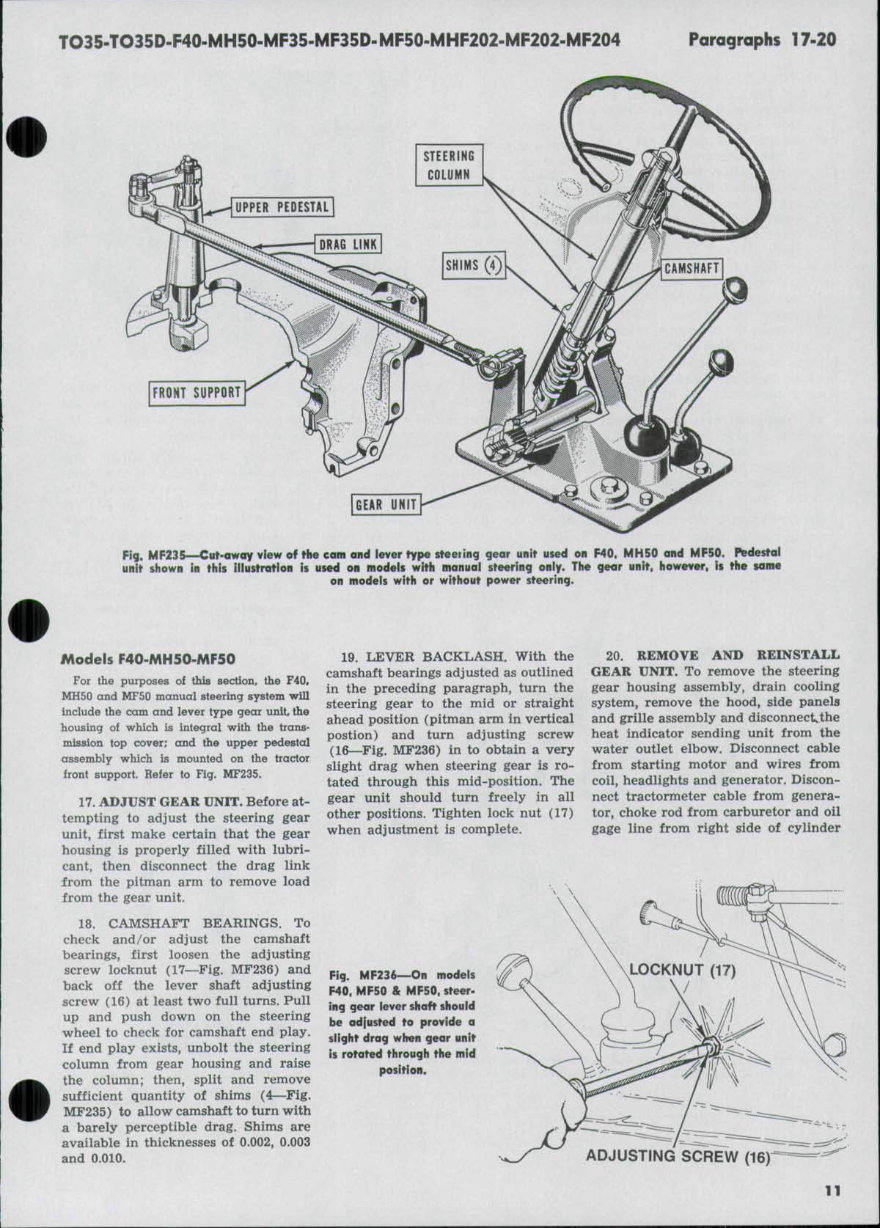

Models F40-MH50-MF50

For the purposes of this section, the F40.

MH50 and MF50 manual steering system will

include the cam and lever type gear unit, the

housing oi which is integral with the trans-

mission top cover; and the upper pedestal

assembly which is mounted on the tractor

front support. Refer to Fig. MF235.

17. ADJUST GEAR UNIT. Before at-

tempting to adjust the steering gear

unit, first make certain that the gear

housing is properly filled with lubri-

cant, then disconnect the drag link

from the pitman arm to remove load

from the gear unit.

18. CAMSHAFT BEARINGS. To

check and/or adjust the camshaft

bearings, first loosen the adjusting

screw locknut (17—Fig. MF236) and

back off the lever shaft adjusting

screw (16) at least two full turns. Pull

up and push down on the steering

wheel to check for camshaft end play.

If end play exists, unbolt the steering

column from gear housing and raise

the column; then, split and remove

sufficient quantity of shims (4—Fig.

MF235) to allow camshaft to turn with

a barely perceptible drag. Shims are

available in thicknesses of 0.002, 0.003

and 0.010.

19. LEVER BACKLASH. With the

camshaft bearings adjusted as outlined

in the preceding paragraph, turn the

steering gear to the mid or straight

ahead position (pitman arm in vertical

postion) and turn adjusting screw

(16—Fig. MF236) in to obtain a very

slight drag when steering gear is ro-

tated through this mid-position. The

gear unit should turn freely in all

other positions. Tighten lock nut (17)

when adjustment is complete.

20. REMOVE AND REINSTALL

GEAR UNIT. To remove the steering

gear housing assembly, drain cooling

system, remove the hood, side panels

and grille assembly and disconnect the

heat indicator sending unit from the

water outlet elbow. Disconnect cable

from starting motor and wires from

coil, headlights and generator. Discon-

nect tractormeter cable from genera-

tor, choke rod from carburetor and oil

gage line from right side of cylinder

Fig. MF236—On modeis

F40. MF50 & MF50. steer-

ing gear iever shaft should

be adjusted to provide a

slight drag when gear unit

is rotated through the mid

position.

ADJUSTING SCREW {^6y

11

Paragraphs 21-22

MASSEY-FERGUSON

block. Shut off the fuel and remove

the fuel line. Unbolt the fuel tank

from its rear support, loosen the fuel

tank front support bolts and block up

between fuel tank and rocker cover.

Note: Some mechanics prefer to com-

pletely remove the fuel tank. Loosen

the U-bolt assembly from front end of

throttle rod. Disconnect battery cables

and remove battery. Disconnect tail

light wires and wires from starter saf-

ety switch. Unbolt battery platform

from engine and remove steering

wheel, steering wheel Woodruff key,

felt washer (25—Fig. MF237), spring

(22), chrome cap (24) and rubber seal

(23). Remove the cap screws retaining

the instrument panel and battery plat-

form to steering gear housing and lift

the instrument panel and battery plat-

form assembly from tractor.

21. Disconnect drag link from pit-

man arm, remove the cap screws re-

taining the transmission cover to

transmission housing and lift the

steering gear and transmission cover

unit from tractor.

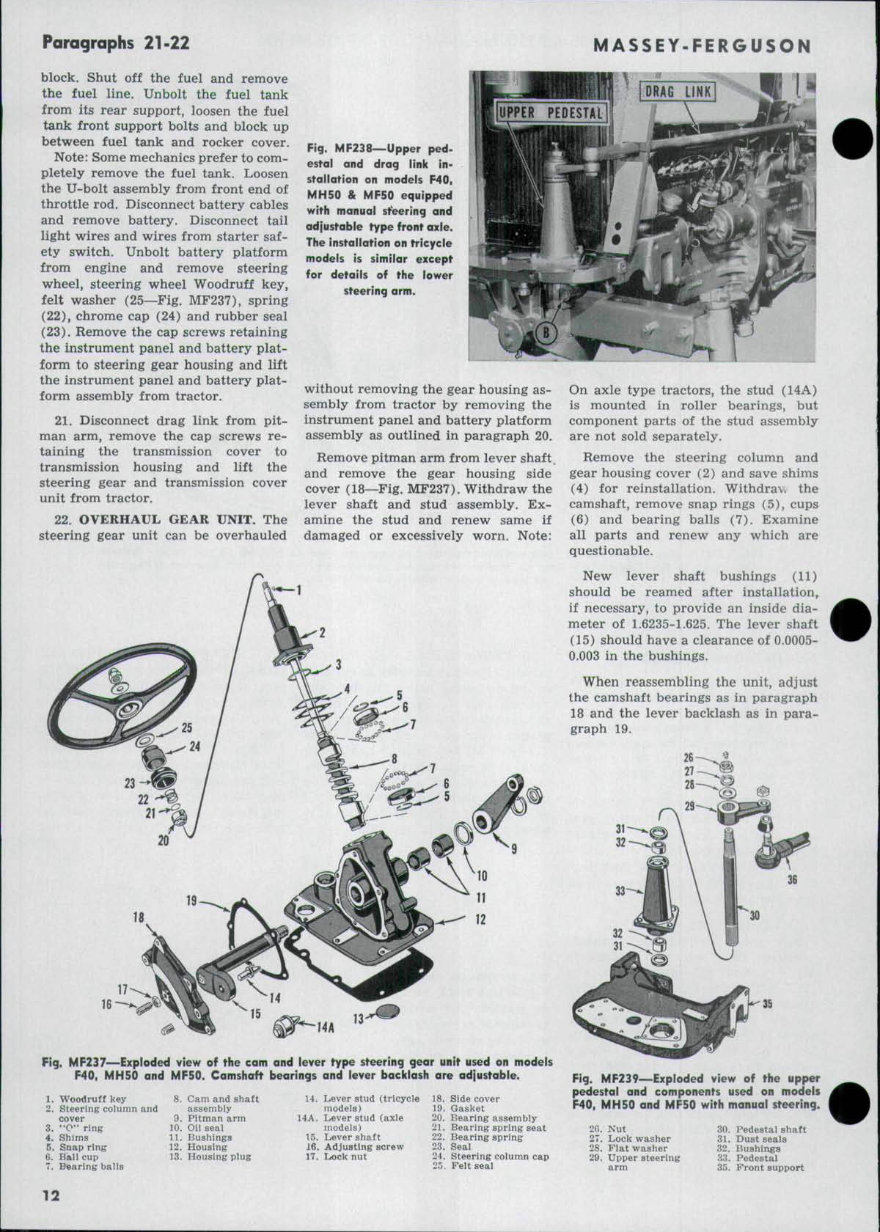

22. OVERHAUL GEAR UNIT. The

steering gear unit can be overhauled

Fig. MF238—Upper ped-

estal and drag linli in-

stallation on models F40.

MH50 & MF50 equipped

with manual steering and

adjustable type front axle.

The installation on tricycle

models is similar except

for details of the lower

steering arm.

without removing the gear housing as-

sembly from tractor by removing the

instrument panel and battery platform

assembly as outlined in paragraph 20.

Remove pitman arm from lever shaft,

and remove the gear housing side

cover (18—Fig. MF237). Withdraw the

lever shaft and stud assembly. Ex-

amine the stud and renew same if

damaged or excessively worn. Note:

On axle type tractors, the stud (14A)

is mounted in roller bearings, but

component parts of the stud assembly

are not sold separately.

Remove the steering column and

gear housing cover (2) and save shims

(4) for reinstallation. Withdra\, the

camshaft, remove snap rings (5), cups

(6) and bearing balls (7). Examine

all parts and renew any which are

questionable.

16

Fig. MF237—Exploded view of the cam and lever type steering gear unit used on models

F40, MH50 and MF50. Camshaft bearings and iever baciclash are adjustabie.

1. Woodruff key

2. Steering column and

cover

3. ••C" ring

4. Shims

5. Snap ring

(i. Ball cup

7. Bearing balls

8. Cam and shaft

assembly

9. Pitman arm

10. Oil seal

11. Bushings

12. Housing

13. Housing plug

14. Lever stud (tricycle 18. Side cover

models)

14A. Lever stud (axle

models)

13. Lever shaft

16. Adjusting screw

17. Lock nut

19. Gasket

20. Bearing assembiy

21. Bearing spring seat

22. Bearing spring

23. Seal

24. Steering column cap

23. Felt seal

New lever shaft bushings (11)

should be rean:ied after installation,

if necessary, to provide an inside dia-

meter of 1.6235-1.625. The lever shaft

(15) should have a clearance of 0.0005-

0.003 in the bushings.

When reassembling the unit, adjust

the camshaft bearings as in paragraph

18 and the lever backlash as in para-

graph 19.

Fig. MF239—Exploded view of the upper

pedestal and components used on models

F40, MH50 and MF50 with manual steering.

20. Nut

27. Lock washer

28. Flat washer

29. Upper steering

arm

30. Pedestal shaft

31. Dust seals

32. Bushings

Xi. Pedestal

3.">. Front support

12

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$33.99

Viewed 97 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$33.99

This repair manual is essential for anyone who needs to repair or service Massey-Ferguson models TO35, TO35 Diesel, MF35, MF35 Diesel, MH50, MHF202, MF50, MF202, MF204, and F40. It is a valuable resource for both professional mechanics and DIY enthusiasts.

- Detailed illustrations and exploded views

- Troubleshooting sections covering most models

- Brakes

- Cab

- Cooling system

- Differential

- Electrical system

- Engine

- Final drive

- Axles

- Hydraulics

- Transmission

- Condensed service data information

- Detailed index