Massey Ferguson MF GC2300 Series GC-2300 Tractor Complete Workshop Service Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

INTRODUCTION

79023519

01-1

INTRODUCTION

Contents

INDEXING ....................................................................................................... 01- 2

SPECIAL TOOLS ............................................................................................. 01- 2

REPAIRS & REPLACEMENTS ........................................................................ 01- 2

REPAIR TIME SCHEDULE .............................................................................. 01- 2

AMENDMENTS ............................................................................................... 01- 2

SAFETY PRECAUTIONS ................................................................................ 01- 3

GENERAL INFORMATION .............................................................................. 01- 4

Model Name and Identification Numbers ........................................................................... 01- 4

Chasis ............................................................................................................................... 01- 5

Engine Model and Serial Number ...................................................................................... 01- 5

Specifications .................................................................................................................... 01- 6

TRANSMISSION & RELATED PARTS

AGRI TIRE (REVOLUTION OF SHAFTS) ....................................................... 01- 9

Drive System ..................................................................................................................... 01- 9

PTO System ...................................................................................................................... 01- 9

Gear Pump System ........................................................................................................... 01- 9

TURF TIRE (REVOLUTION OF SHAFTS) .................................................... 01- 10

Drive System ................................................................................................................... 01- 10

PTO System .................................................................................................................... 01- 10

Gear Pump System ......................................................................................................... 01- 10

LUBRICATION & PERIODIC MAINTENANCE .............................................. 01- 12

SPECIFICATIONS & CAPACITIES

ENGINE OIL .................................................................................................. 01- 12

Engine Coolant ................................................................................................................ 01- 12

Fuel Tank ......................................................................................................................... 01- 12

Transmission & Differential Housing (Including Hydraulic System) ................................. 01- 12

Front Axle (4-WD Only) ................................................................................................... 01- 12

Grease Fittings ................................................................................................................ 01- 12

PERIODIC MAINTENANCE SCHEDULE ...................................................... 01- 12

MAINTENANCE SCHEDULE ........................................................................ 01- 13

LUBRICATION AND FILL POINTS ................................................................ 01- 14

STANDARD TORQUE CHART ...................................................................... 01- 15

SEALANT & ADHESIVES .............................................................................. 01- 16

CONVERSION TABLES ................................................................................ 01- 17

INTRODUCTION

01-2 79023519

INTRODUCTION

The purpose of this manual is to assist dealers and

distribute in the efficient repair and maintenance of

Massey Ferguson and AGCO machinery. Carrying out

the procedures as detailed, together with the use of

special tools where appropriate will enable the operations

to be completed within the time stated in the repair time

schedule.

NOTE: To assist with locating information, each division

of the manual is preceded by a contents page

listing the operations in numerical order.

Each operation is given in sequential order. To

complete the operation in the minimum time it is

essential that these instructions are preformed

in given order unless otherwise stated. When

applicable, the callout numbers in the text

reference components in the appropriate

illustration. Where performance of an operation

requires the use of a special tool, the tool is called

out in that operation.

INDEXING

For convenience, the manual is divided into parts sections

with each page number bearing the part and section

number. Page numbers are located at top outside of each

page. Beneath the page number is written title of manual

division.

Page Number Example: 7A-15

Part 7 Section A, Page 15

This simplifies cross-referencing and enables the subject

to be found easily.

NOTE: Page numbers will be consecutive within each

sub-section. A void of page numbers may be

used between these sub-sections in order to

provide space for future amendments and also

to indicate the beginning/end of adjacent sub-

sections.

SPECIAL TOOLS

Where the use of a special tool is specified in an operation,

the tool number will be shown under the operation.

The use of the special tools mentioned in the text

contributes to a safe, efficient and profitable repair. Some

operations are impracticable without their use.

Make certain proper tools are available when starting the

job.

REPAIRS & REPLACEMENTS

When service parts are required, it is essential that only

genuine Massey Ferguson and AGCO replacements are

used. Attention is particularly drawn to the following points

concerning repairs and the fitting of replacement parts

accessories:

Safety features embodied in the tractor may be impaired

if other than genuine parts are fitted.

In certain territories, legislation prohibits the fitting of parts

not to the tractor manufacturer’s specification.

Torque wrench setting figures given in the Workshop

Manual must be strictly adhered to.

Locking devices where specified must be fitted. If the

efficiency of a locking device is impaired during removal

it must be renewed.

The tractor warranty may be invalidated by the fitting of

other than genuine Massey Ferguson, AGCO, and

Challenger parts. All Massey Ferguson and AGCO

replacements have the full backing of the manufacturer’s

warranty. Massey Ferguson and AGCO Distributors and

Dealers are obliged to supply only genuine service parts.

REPAIR TIME SCHEDULE

The operations listed in the Repair Time Schedule refer

to those described in this manual. The time set against

each operation in the schedule is established by

performing the actual operations on standard machines

using special tools where applicable. The Repair Time

Schedule for use with this manual is issued as a separate

publication.

NOTE: Repair Time Schedules are issued to Massey

Ferguson and AGCO Distributors and Dealers

only and are not for general publication.

AMENDMENTS

Under normal conditions, revised pages issued carry the

same number as the existing pages requiring

amendment. The new pages are inserted in place of the

existing ones. The old pages should then be discarded.

In some cases additional pages or completely new

sections may be issued. These pages are to be inserted

immediately following the page carrying the next lowest

page number, or section number as appropriate. Where

new pages are required to be positioned between existing

pages, the new page numbers will contain a suffix letter:

Example New Page Number: 7A-16a.

This page is inserted after existing page number 7A-16

and before page number 7A-17. Correspondingly a further

new page numbered 7A-16b would be positioned after

7A-16a but before 7A-17.

NOTE: Service Bulletins and Amendment Sheets are

issued to the Massey Ferguson and AGCO

Distributors and Dealers only and are not for

general publication.

INTRODUCTION

79023519

01-3

SAFETY PRECAUTIONS

• Make sure that all personnel are in a safe position

before starting the engine, or operating ANY of the

controls.

• Always stop the engine before leaving the operator’s

platform.

• Wait for all moving parts to stop COMPLETELY

before starting any work on the tractor.

• Before starting service procedures, attached

equipment should be resting on the ground and all

hydraulic control levers operated back and forth

several times with the engine stopped.

• If it becomes necessary to go under raised

attachment (i.e: to perform adjustments, etc.), safety

standards must be used to support the attachment.

• Make sure the battery ground cable is disconnected

before working on or near the electrical system or

electrical system components.

• Keep hands, feet and clothing a safe distance away

from moving belts, pulleys and other moving parts.

Make sure all safety shields are installed.

• Be extra careful when performing any checks,

inspections, adjustments or tests that require

operating the engine, the hydraulic controls, OR with

the machine in motion.

• Make sure dependable jacks of adequate lifting

capacity AND suitable stands (or wooden blocking)

are used to securely block up the machine when

removing any of the wheels or axles.

CAUTION: PERSONAL INJURY MAY RESULT

IF THESE PRECAUTIONS ARE NOT

FOLLOWED.

Look for this symbol to point out important

safety precautions. It means - ATTENTION!

BECOME ALERT! YOUR SAFETY IS

INVOLVED.

• Before any attempt is made to disconnect or remove

any hydraulic component, make sure the hydraulic

pressure within the system is relieved and the engine

is stopped.

• Carry out the repair procedures in a “common sense”

manner. Safety procedures cannot be over-

emphasized when working on, or around machinery,

especially when working on engine driven and/or

hydraulically actuated equipment.

• Safety also depends upon the skill of the service man

in the use of tools and other shop equipment while

performing the recommended service procedures.

• Exercise extreme caution when testing hydraulic or

fuel system components as fluid ejected under high

pressure can easily penetrate skin causing serious

infection.

• When it is necessary to remove hoods, shields,

ROPS, etc. to conduct repair operation, all items must

be reinstalled to unit and secured in original fashion.

• Modification of ROPS is not permissible. Do not weld,

drill or modify ROPS in any manner. Damaged or

modified ROPS must be replaced.

INTRODUCTION

01-4 79023519

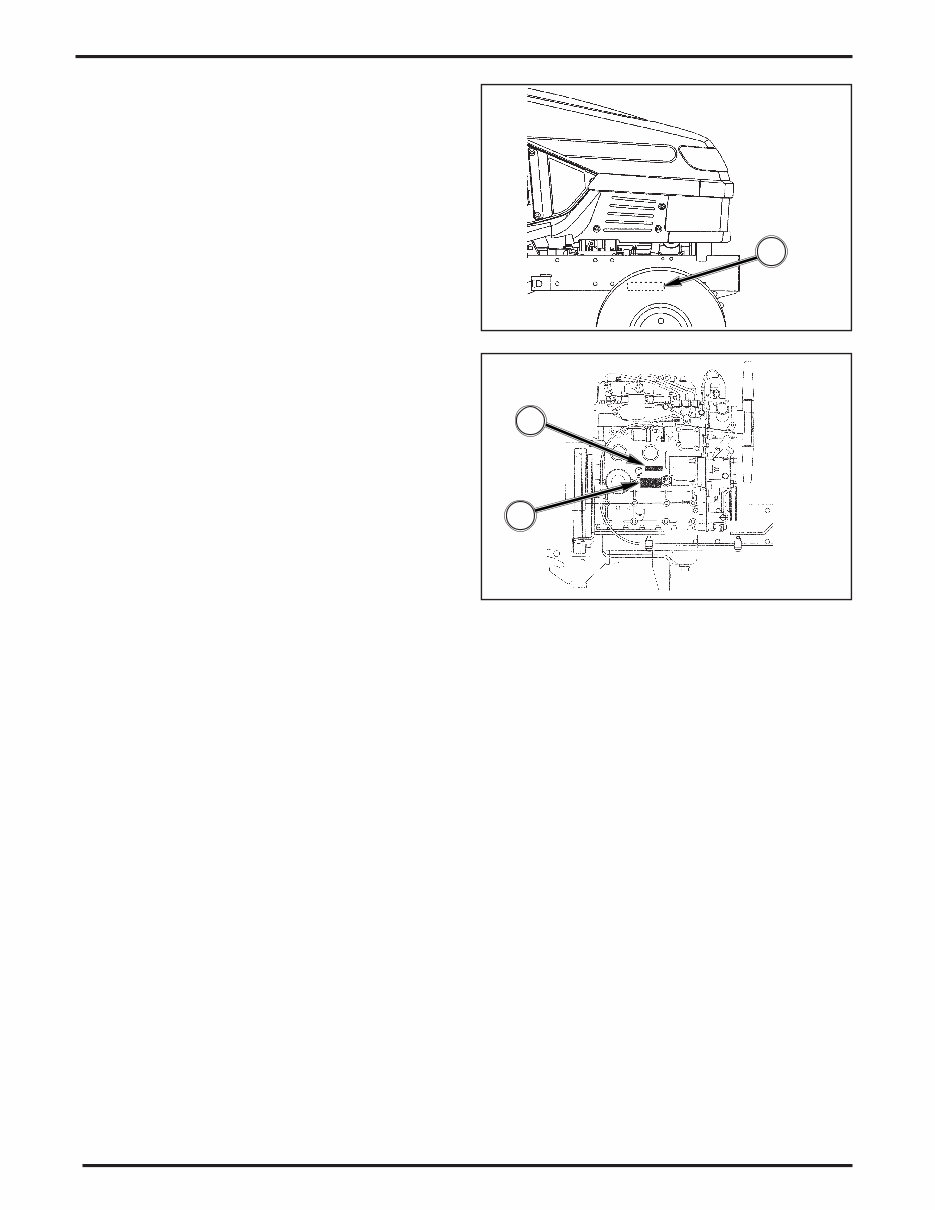

FIG. 1

I-6006

FIG. 2

I-6090

1

GENERAL INFORMATION

Model Name and Identification Numbers

FIGS. 1, 2 & 2a: The name plate (1) which gives the

model name, type, production serial number, and

production year of the machine, is located on the left-

hand side of the rear fender (2).

FIG. 2a

I-7196

2

1

INTRODUCTION

79023519

01-5

FIG. 4

I-7197

FIG. 3

I-7198

1

1

2

Engine Model and Serial Number

FIG. 4: The engine model name (1) is cast into the left-

hand side wall of the cylinder block.

The serial number (2) is punched into the left-hand side

wall of the cylinder block.

Chasis

FIG. 3: The chassis number is punched on the plate

provided on the right-hand side of the chassis (1).

INTRODUCTION

01-6 79023519

ENGINE

Make Iseki Diesel

Model E3112-B12

Type Indirect injection, overhead valve

Aspiration Natural

Displacement 68.5 cu. in. (1123 cc)

Number of Cylinders 3

Bore 3.08” (78.2 mm)

Stroke 3.07” (78.2 mm)

Engine Horsepower (Gross) 22.5 HP (16.5kW) @ 2600 rpm

Net 21.6 PS (15.9 kW) @ 2600 rpm

PTO Horsepower (Estimate) 17.5 @ PTO rpm

Firing Order 1-3-2

Compression Ratio 22.5 to 1

Low Idle Speed 1250 to 1300 rpm

High Idle Speed 2760 to 2860 rpm

Valve Clearance (Cold):

Intake 0.010” (0.25 mm)

Exhaust 0.010” (0.25 mm)

Air Cleaner Single stage, dry element

Engine cooling Liquid, forced circulation

Cold Starting Aid Glow plugs (3)

TRANSMISSION

Primary Hydrostatic

Range 2 speed constant mesh (2 forward, 2 reverse)

Clutch None

Brakes Mechanically actuated sealed wet disk

Specifications

INTRODUCTION

79023519

01-7

POWER TAKE-OFF (PTO)

Type Independent, engine driven

Control Hydraulic control

Clutch Mechanically engaged, multi-plate wet disk

Rear PTO; Shaft 1.375” (35mm) diameter, six spline

Output Clockwise rotation

Engine Speed @ 540 PTO

rpm

2532 rpm

Mid PTO; Shaft 1.000” (25.4) diameter, fifteen spline

Output Clockwise rotation

Engine Speed @ 2100 PTO

rpm

2476 rpm

HYDRAULICS

Steering System Hydrostatic (power)

Pump Transmission-mounted gear pump with flow divider

Maximum

Output

2.0 U.S. gals./min. (7.5 I/min.)

Pressure Relief valve setting 1209 psi (8335 kPa)

Main Hydraulic System Transmission-mounted gear pump

Maximum Output 6.1 U.S. gals./min. (23.1 I/min.)

Pressure Relief valve setting 1920 psi (13244 kPa)

Rear Linkage; Type Three-point hitch

Size Category 1

Control Position control

Lift Capacity 1191 lbs. (540 kg) measured at ball ends

ELECTRICAL SYSTEM

System Voltage 12 volt, negative (-) ground

Battery cca @ 0F (-18) 390 cca

Charging 40 amp alternator with internal regulator/rectifier

INTRODUCTION

01-8 79023519

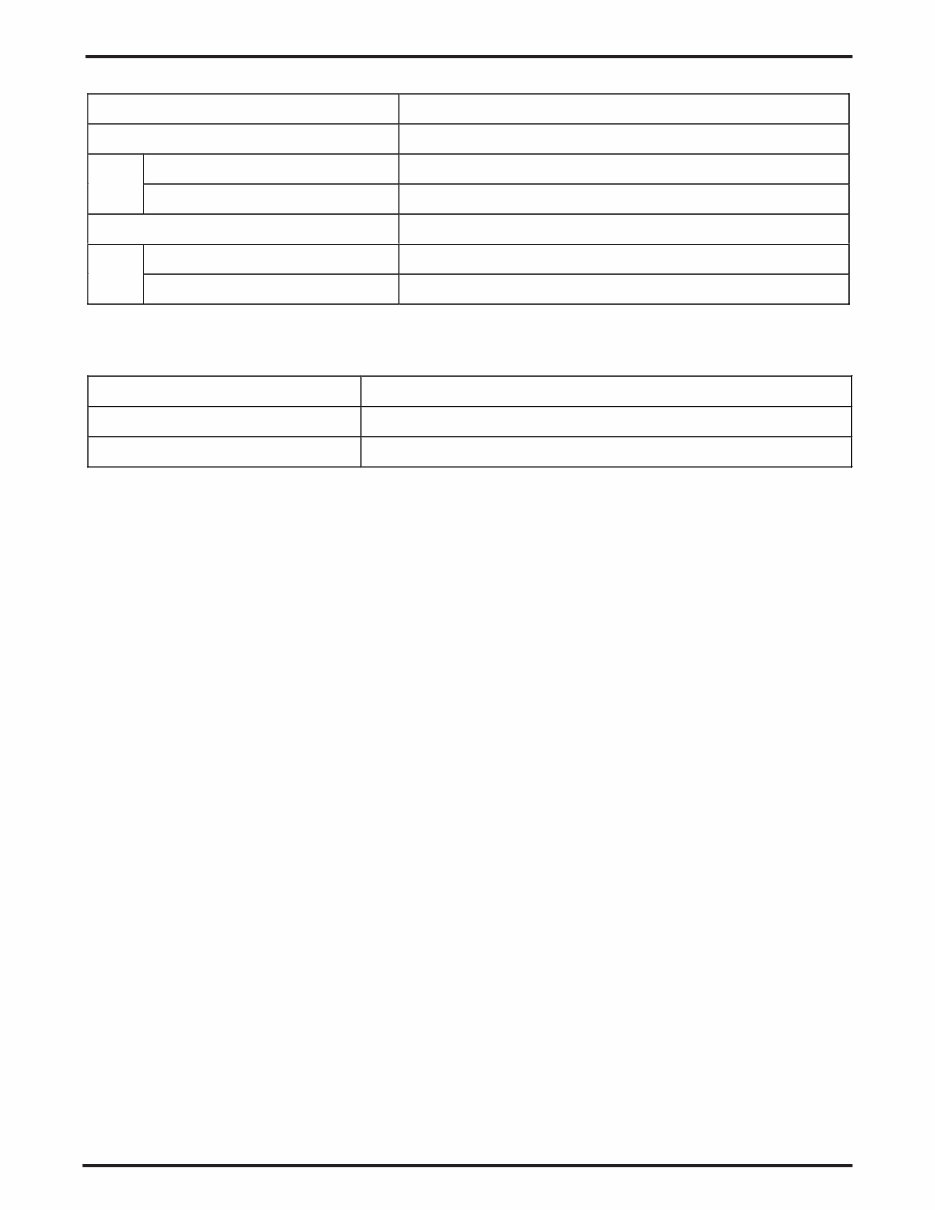

TREAD WIDTH SETTINGS

Front 4WD

Ag. Tires (“Dished In” Only) 36.6” (930 mm)

Turf Tires (“Dished In” Only) 36.6” (930 mm)

Rear 4WD

Ag. Tires (“Dished In “ Only) 33.1” (840 mm)

Turf Tires (“Dished In” Only) 33.1” (840 mm)

MAXIMUM AXLE LOADING

Front 4WD 1940 lbs (880 kg)

Rear Axle 2094 lbs. (950 kg)

INTRODUCTION

79023519

01-9

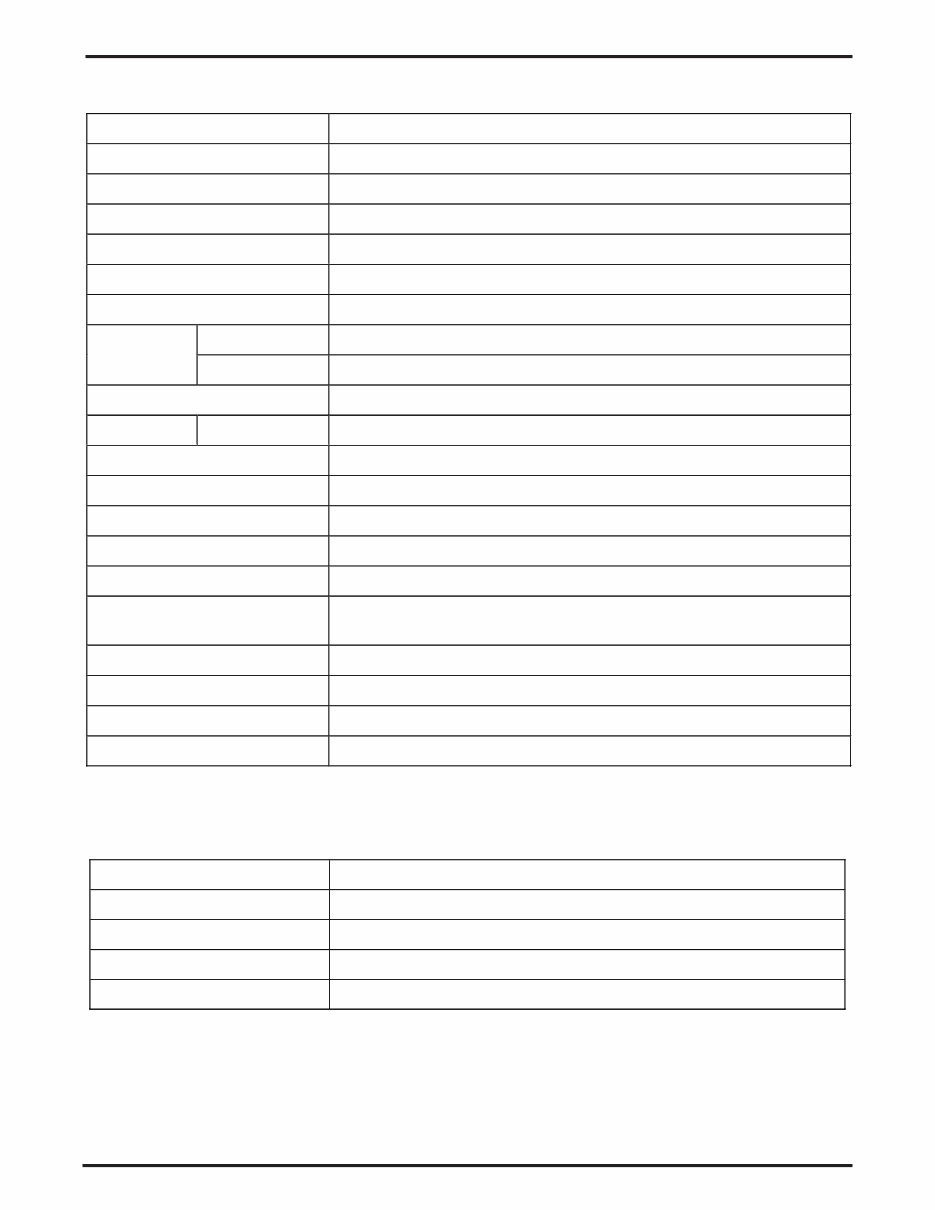

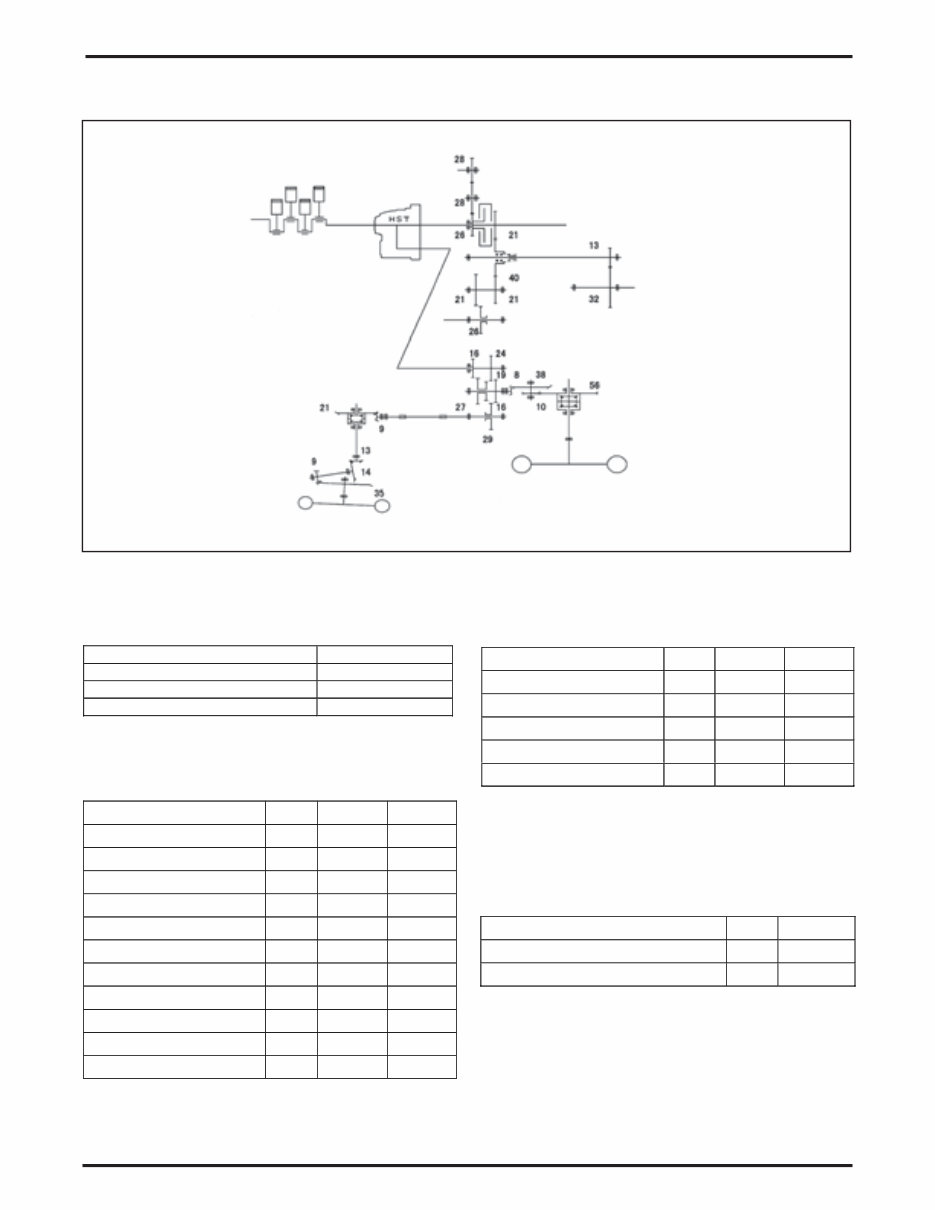

FIG. 5

I-9273

Diameter of front wheel 457 [mm]

Diameter of rear wheel 665 [mm]

Engine Speed [RPM] 2600

HST Pump Capacity (cc) 21.0

HST Motor Capacity (cc) 21.0

HST Volumetric Efficiency 95%

L H

Input Shaft RPM 2600 2600

HST Output Shaft RPM 2470 2470

Drive Pinion RPM 1463.70 3120

Wheel Pinion RPM 308.15 656.84

Rear Wheel Shaft RPM 55.03 117.29

Rear Wheel Speed Km/h 6.90 14.70

Front Drive Shaft RPM 807.56 1721.38

Front Ring Gear RPM 346.10 737.73

Front Kingpin RPM 321.38 685.04

Front Wheel Shaft RPM 82.64 176.15

Front Wheel Speed Km/h 7.12 15.17

Rear Mid

Input Shaft RPM 2600 2600

PTO Counter Shaft RPM 1365 1365

Rear PTO Shaft RPM 554.53

Mid PTO Idle Gear RPM 2600

Mid PTO Shaft RPM 2100

Input Shaft RPM 2600

Counter Gear RPM 2414.29

Input SHaft RPM 2414.29

TRANSMISSION & RELATED PARTS

AGRI TIRE (REVOLUTION OF SHAFTS)

FIG. 5: Drive Train Diagram shown.

Drive System

PTO System

Gear Pump System

NOTE: Front axle lead ratio is 3.12%.

INTRODUCTION

01-10 79023519

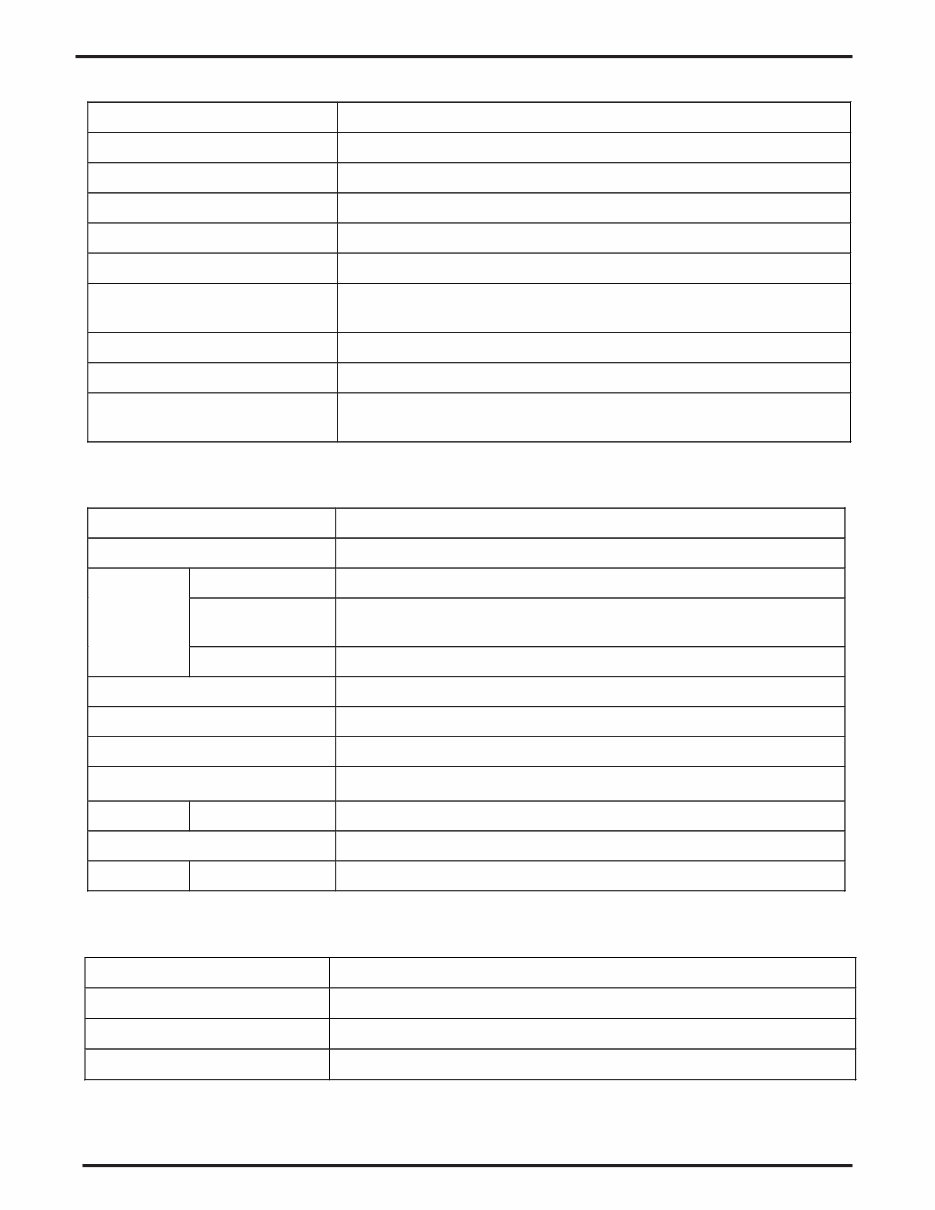

FIG. 6

I-9273

Diameter of front wheel 450 [mm]

Diameter of rear wheel 648 [mm]

Engine Speed [RPM] 2600

HST Pump Capacity (cc) 21.0

HST Motor Capacity (cc) 21.0

HST Volumetric Efficiency ( - ) 0.95

L H

Input Shaft RPM 2600 2600

HST Output Shaft RPM 2470 2470

Drive Pinion RPM 1463.70 3120

Wheel Pinion RPM 308.15 656.84

Rear Wheel Shaft RPM 55.03 117.29

Rear Wheel Speed Km/h 6.72 14.33

Front Drive Shaft RPM 807.56 1721.38

Front Ring Gear RPM 346.10 737.73

Front Kingpin RPM 321.38 685.04

Front Wheel Shaft RPM 82.64 176.15

Front Wheel Speed Km/h 7.01 14.94

Rear Mid

Input Shaft RPM 2600 2600

PTO Counter Shaft RPM 1365 1365

Rear PTO Shaft RPM 554.53

Mid PTO Idle Gear RPM 2600

Mid PTO Shaft RPM 2100

Input Shaft RPM 2600

Counter Gear RPM 2414.29

Input SHaft RPM 2414.29

TURF TIRE (REVOLUTION OF SHAFTS)

FIG. 6 &7: Drive Train Diagram shown.

Drive System

PTO System

Gear Pump System

NOTE: Front axle Lead Ratio is 4.29 (%).

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

Viewed 66 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

Thank you for considering the Complete Service Repair Workshop Manual for the Massey Ferguson MF GC2300 Series GC-2300 Tractor.

This comprehensive manual covers every Service & Repair Procedure necessary, enabling you to save money by performing your own repairs. It provides easy-to-follow step-by-step instructions and detailed pictures for all servicing and repairs, making any service or repair job effortless.

Upon obtaining this manual, it becomes your permanent resource. You have the flexibility to print out specific pages, chapters, or the entire manual. Additionally, you can save it to your tablet or smartphone for easy access.

MODELS COVERED:

- All Models/Engines/Trim/Transmissions Types Are Covered.

CONTENTS:

- This high-quality Service Repair Workshop Manual encompasses all repair procedures from A to Z, ensuring that every repair and service procedure is comprehensively covered.

COMPUTER REQUIREMENTS:

- This downloadable Manual is compatible with All PC & MAC Computers, tablets, and mobile phones. The only software required is Adobe Reader, which is typically pre-installed on your computer. If not, it can be downloaded for free.

INSTANT DELIVERY:

- Upon payment by Visa, MasterCard, or PayPal, the manual will be instantly emailed to the address used during checkout.

Customer Satisfaction Guaranteed.