IH 3088 3288 3488 Hydro 3688 Shop Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

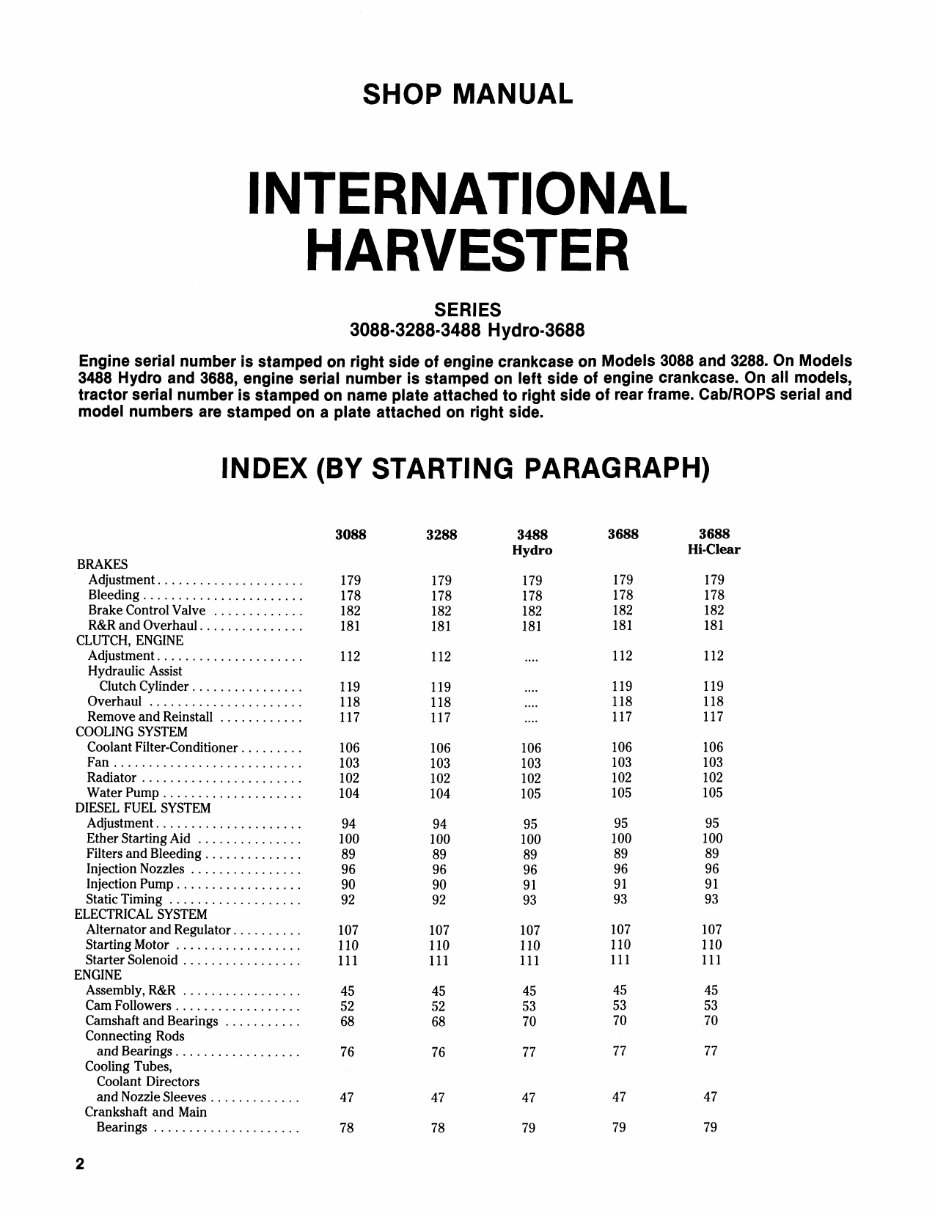

SHOP MANUAL

INTERNATIONAL

HARVESTER

SERIES

3088·3288·3488 Hydro·3688

Engine serial number is stamped on right side of engine crankcase on Models 3088 and 3288. On Models

3488 Hydro and 3688, engine serial number is stamped on left side of engine crankcase. On a" models,

tractor serial number is stamped on name plate attached to right side of rear frame. Cab/ROPS serial and

model numbers are stamped on a plate attached on right side.

INDEX (BY STARTING PARAGRAPH)

BRAKES

Adjustment. ................... .

Bleeding ...................... .

Brake Control Valve ............ .

R&R and Overhaul. ............. .

CLUTCH, ENGINE

Adjustment. ................... .

Hydraulic Assist

Clutch Cylinder ............... .

Overhaul ..................... .

Remove and Reinstall ........... .

COOLING SYSTEM

Coolant Filter-Conditioner ........ .

Fan .......................... .

Radiator ...................... .

Water Pump ................... .

DIESEL FUEL SYSTEM

Adjustment. ................... .

Ether Starting Aid .............. .

Filters and Bleeding ............. .

Injection Nozzles ............... .

Injection Pump ................. .

Static Timing .................. .

ELECTRICAL SYSTEM

Alternator and Regulator ......... .

Starting Motor ................. .

Starter Solenoid ................ .

ENGINE

2

Assembly, R&R ................ .

Cam Followers ................. .

Camshaft and Bearings .......... .

Connecting Rods

and Bearings ................. .

Cooling Tubes,

Coolant Directors

and Nozzle Sleeves ............ .

Crankshaft and Main

Bearings .................... .

3088

179

178

182

181

112

11.9

118

117

106

103

102

104

94

100

89

96

90

92

107

110

111

45

52

68

76

47

78

3288

179

178

182

181

112

119

118

117

106

103

102

104

94

100

89

96

90

92

107

110

111

45

52

68

76

47

78

3488

Hydro

179

178

182

181

106

103

102

105

95

100

89

96

91

93

107

110

III

45

53

70

77

47

79

3688

179

178

182

181

112

119

118

117

106

103

102

105

95

100

89

96

91

93

107

110

111

45

53

70

77

47

79

3688

Hi·Clear

179

178

182

181

112

119

118

117

106

103

102

105

95

100

89

96

91

93

107

110

III

45

53

70

77

47

79

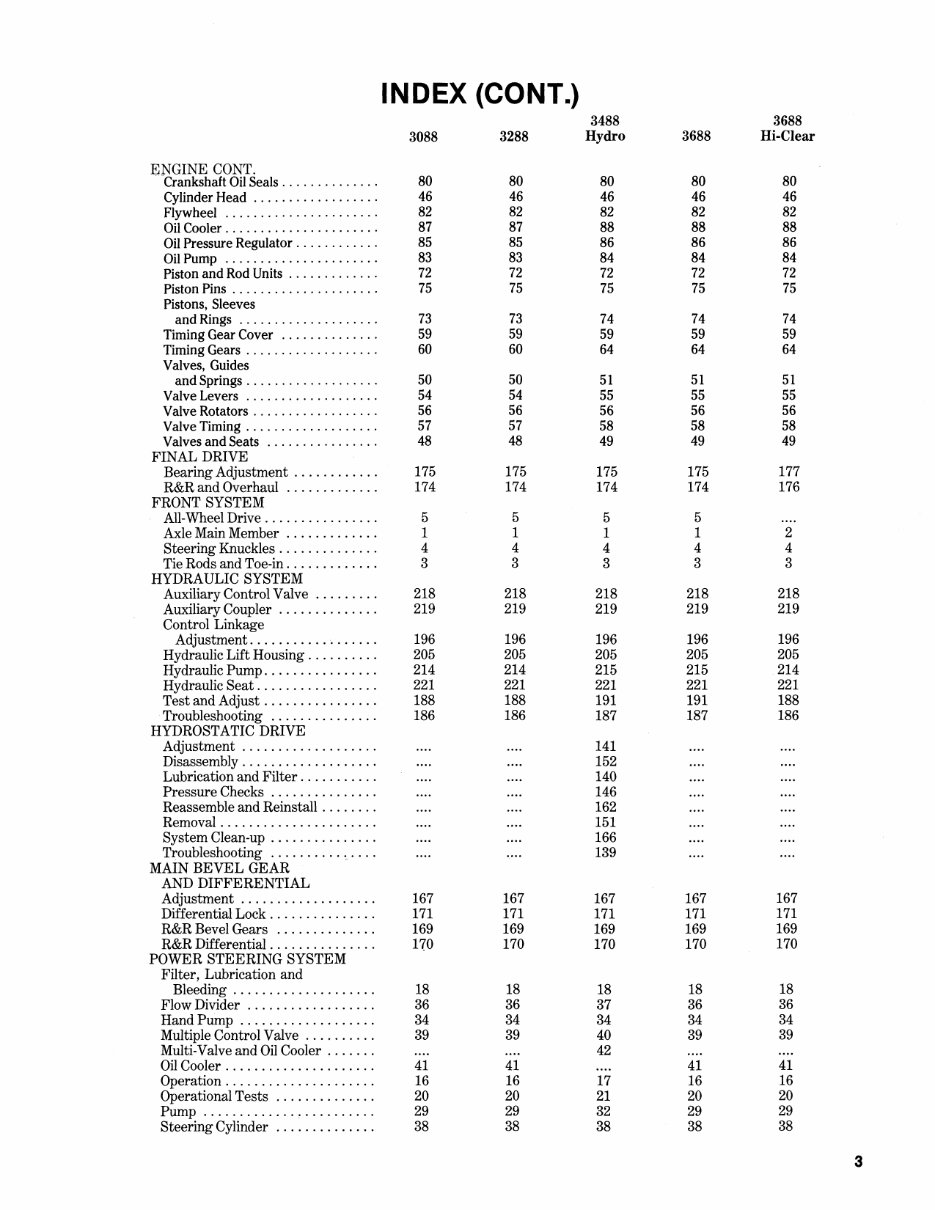

INDEX (CONT.)

3488 3688

3088 3288 Hydro 3688 Hi-Clear

ENGINE CONT.

Crankshaft Oil Seals .............. 80 80 80 80 80

Cylinder Head .................. 46 46 46 46 46

Flywheel ...................... 82 82 82 82 82

Oil Cooler ...................... 87 87 88 88 88

Oil Pressure Regulator ............ 85 85 86 86 86

OilPump ...................... 83 83 84 84 84

Piston and Rod Units ............. 72 72 72 72 72

Piston Pins ..................... 75 75 75 75 75

Pistons, Sleeves

and Rings .................... 73 73 74 74 74

Timing Gear Cover .............. 59 59 59 59 59

Timing Gears ................... 60 60 64 64 64

Valves, Guides

and Springs ................... 50 50 51 51 51

Valve Levers ................... 54 54 55 55 55

Valve Rotators .................. 56 56 56 56 56

Valve Timing ................... 57 57 58 58 58

Valves and Seats ................ 48 48 49 49 49

FINAL DRIVE

Bearing Adjustment ............ 175 175 175 175 177

R&R and Overhaul ............. 174 174 174 174 176

FRONT SYSTEM

All-Wheel Drive ................ 5 5 5 5

Axle Main Member ............. 1 1 1 1 2

Steering Knuckles .............. 4 4 4 4 4

Tie Rods and Toe-in ............. 3 3 3 3 3

HYDRAULIC SYSTEM

Auxiliary Control Valve ......... 218 218 218 218 218

Auxiliary Coupler .............. 219 219 219 219 219

Control Linkage

Adjustment ........... • ...... 196 196 196 196 196

Hydraulic Lift Housing .......... 205 205 205 205 205

Hydraulic Pump ................ 214 214 215 215 214

Hydraulic Seat ................. 221 221 221 221 221

Test and Adjust ................ 188 188 191 191 188

Troubleshooting ............... 186 186 187 187 186

HYDROSTATIC DRIVE

Adjustment ................... 141

Disassembly ................... 152

Lubrication and Filter ........... 140

Pressure Checks ............... 146

Reassemble and Reinstall ........ 162

Removal ...................... 151

System Clean-up ............... 166

Troubleshooting ............... 139

MAIN BEVEL GEAR

AND DIFFERENTIAL

Adjustment ................... 167 167 167 167 167

Differential Lock ............... 171 171 171 171 171

R&R Bevel Gears .............. 169 169 169 169 169

R&R Differential ............... 1(0 170 170 170 170

POWER STEERING SYSTEM

Filter, Lubrication and

Bleeding .................... 18 18 18 18 18

Flow Divider .................. 36 36 37 36 36

HandPump ................... 34 34 34 34 34

Multiple Control Valve .......... 39 39 40 39 39

Multi-Valve and Oil Cooler ....... 42

Oil Cooler ..................... 41 41 41 41

Operation ..................... 16 16 17 16 16

Operational Tests .............. 20 20 21 20 20

Pump ............. • .......... 29 29 32 29 29

Steering Cylinder .............. 38 38 38 38 38

3

INDEX (CONT.)

3488 3688

3088 3288 Hydro 3688 Hi-Clear

POWER STEERING CONT.

Telescoping Steering

Column ..................... 44 44 44 44 44

Tilt Steering Wheel ............. 43 43 43 43 43

Troubleshooting ............... 19 19 19 19 19

POWER TAKE-OFF

Control Cable Adjustment ....... 185 185 185 185 185

Pressure Check and

. Adjustment .................. 183 183 183 183 183

R&R and Overhaul ............. 184 184 184 184 184

RANGE TRANSMISSION

Linkage Adjustment ............ 137 137 137 137 137

Overhaul ...................... 126 126 126 126 126

Remove and Reinstall ........... 125 125 125 125 125

TORQUE AMPLIFIER AND

SPEED TRANSMISSION

Adjustment ................... 120 120 120 120

Overhaul ...................... 124 124 124 124

Remove and Reinstall ........... 123 123 123 123

Torque Amplifier

Shift Solenoid ................. 121 121 121 121

Transmission Brake ............ 122 122 122 122

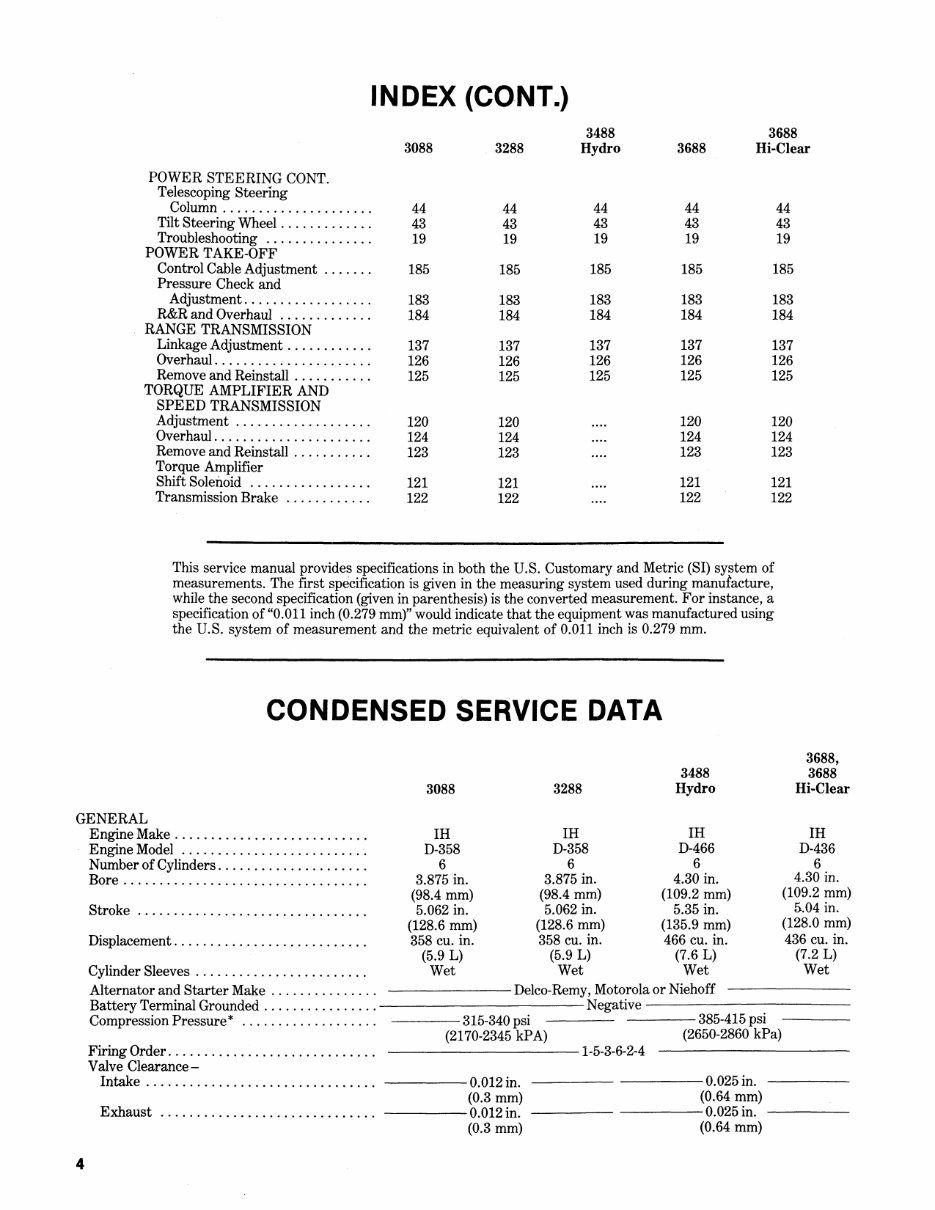

This service manual provides specifications in both the U.S. Customary and Metric (SI) system of

measurements. The first specification is given in the measuring system used during manufacture,

while the second specification (given in parenthesis) is the converted measurement. For instance, a

specification of "0.011 inch (0.279 mm)" would indicate that the equipment was manufactured using

the U.S. system of measurement and the metric equivalent of 0.011 inch is 0.279 mm.

CONDENSED SERVICE DATA

3488

3088 3288 Hydro

3688,

3688

Hi-Clear

GENERAL

Engine Make .......................... . IH IH IH IH

Engine Model ......................... . D-358 D-358 D-466 D-436

Number of Cylinders .................... .

Bore ................................. .

6 6 6 6

3.875 in. 3.875 in. 4.30 in.

4.30 in.

Stroke ............................... .

(98.4 mm) (98.4 mm) (109.2 mm)

(109.2 mm)

5.062 in. 5.062 in. 5.35 in.

5.04 in.

(128.6 mm) (128.6 mm) (135.9 mm)

(128.0 mm)

Displacement .......................... . 358 cu. in. 358 cu. in. 466 cu. in. 436 cu. in.

(5.9 L) (5.9 L) (7.6 L) (7.2 L)

Cylinder Sleeves ....................... . Wet Wet Wet Wet

Alternator and Starter Make . . . . . . . . . . . . . . . Delco-Remy, Motorola or Niehoff

Battery Terminal Grounded ................ -----------Negative -----------

CompressionPressure* ................... ----315-340 psi ----385-415 psi

(2170-2345 kPA) (2650-2860 kPa)

Firing Order ............................ . ----------1-5-3-6-2-4

Valve Clearance-

Intake ............................... . -----0.012 in. ----- -----0.025 in.

Exhaust ............................. .

(0.3 mm) (0.64 mm)

-----0.012 in. ----- -----0.025in. -----

(0.3 mm) (0.64 mm)

4

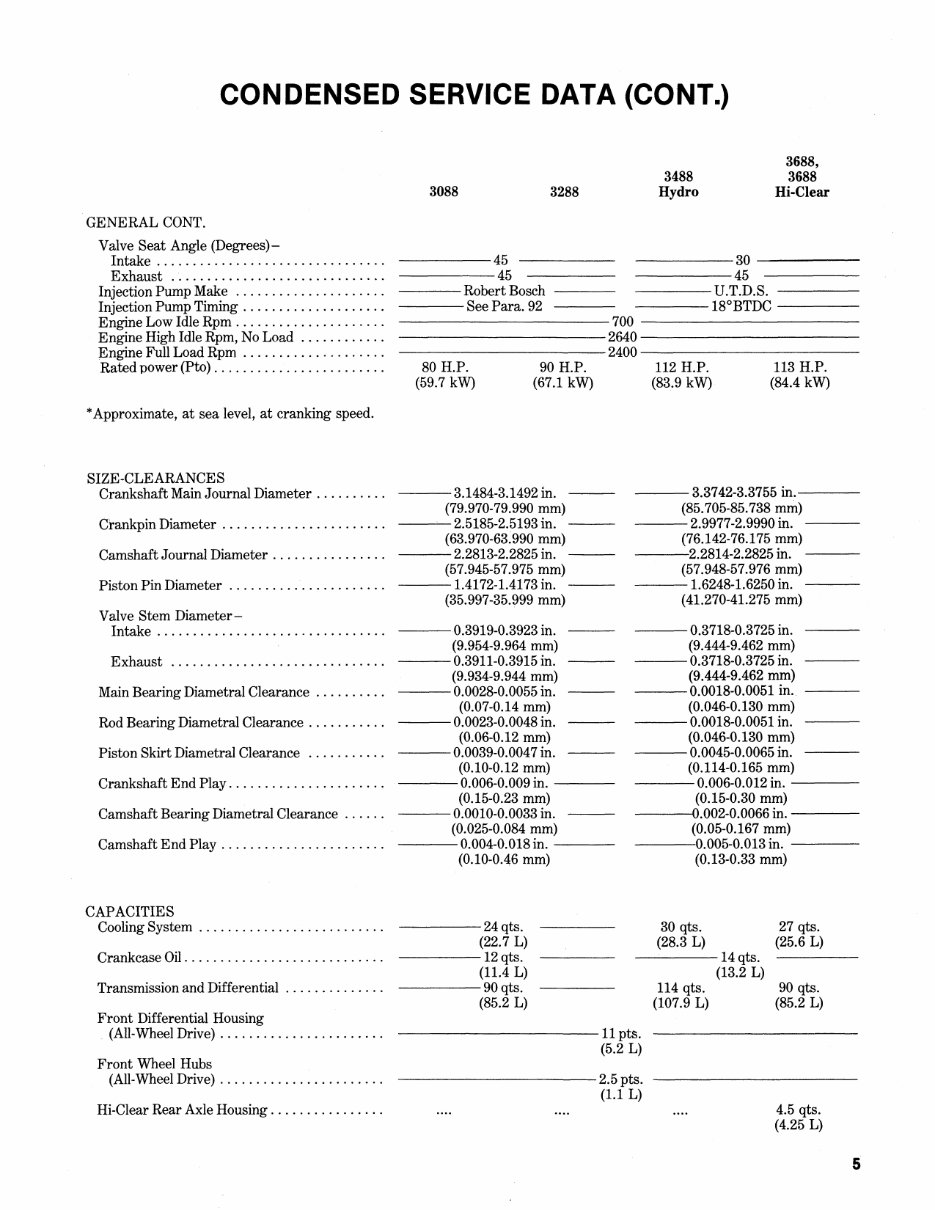

CONDENSED SERVICE DATA (CONT.)

GENERAL CaNT.

Valve Seat Angle (Degrees)-

Intake ............................... .

Exhaust.· ............................ .

Injection Pump Make .................... .

Injection Pump Timing .................. ..

Engine Low Idle Rpm .................... .

Engine High Idle Rpm, No Load ........... .

Engine Full Load Rpm ................... .

Rated power (Pto) ...................... ..

* Approximate, at sea level, at cranking speed.

SIZE-CLEARANCES

Crankshaft Main Journal Diameter ......... .

Crankpin Diameter ...................... .

Camshaft Journal Diameter ............... .

Piston Pin Diameter ..................... .

Valve Stem Diameter-

Intake ............................... .

Exhaust ............................. .

Main Bearing Diametral Clearance ......... .

Rod Bearing Diametral Clearance .......... .

Piston Skirt Diametral Clearance .......... .

Crankshaft End Play ..................... .

Camshaft Bearing Diametral Clearance ..... .

Camshaft End Play ...................... .

CAPACITIES

Cooling System ......................... .

Crankcase Oil ........................... .

Transmission and Differential ............. .

Front Differential Housing

. (All-Wheel Drive) ...................... .

Front Wheel Hubs

(All-Wheel Drive) ...................... .

Hi-Clear Rear Axle Housing ............... .

3088 3288

-----45

-----45

---Robert Bosch ---

---- See Para. 92

3488

Hydro

3688,

3688

Hi·Clear

------30--------

-----45

----U.T.D.S. -----

-----18°BTDC -----

-----------700 --------------------

---------------------2MO----------------------

---------------------2400------------

80H.P.

(59.7 kW)

90 H.P.

(67.1 kW)

----3.1484-3.1492 in. --

(79.970-79.990 mm)

--~- 2.5185-2.5193 in. --

(63.970-63.990 mm)

---- 2.2813-2.2825 in. --

(57.945-57.975 mm)

---1.4172-1.4173in. --

(35.997-35.999 mm)

---0.3919-0.3923 in.

(9.954-9.964 mm)

---0.3911-0.3915 in.

(9.934-9.944 mm)

---0.0028-0.0055 in.

(0.07-0.14 mm)

---0.0023-0.0048 in.

(0.06-0.12 mm)

--- 0.0039-0.0047 in.

(0.10-0.12 mm)

---0.006-0.009 in. ---

(0.15-0.23 mm)

--- 0.0010-0.0033 in.

(0.025-0.084 mm)

---- 0.004-0.018 in. ----

(0.10-0.46 mm)

----24qts.

(22.7 L)

-----12 qts.

(11.4 L)

----90qts.

(85.2 L)

112 H.P. 113 H.P.

(83.9 kW) (84.4 kW)

--- 3.3742-3.3755 in.---

(85.705-85.738 mm)

--- 2.9977-2.9990 in. ----

(76.142-76.175 mm)

----2.2814-2.2825 in. ---

(57.948-57.976 mm)

---1.6248-1.6250in. ---

(41.270-41.275 mm)

--- 0.3718-0.3725 in.

(9.444-9.462 mm)

---0.3718-0.3725 in. -----

(9.444-9.462 mm)

---0.0018-0.0051 in. -----

(0.046-0.130 mm)

--- 0.0018-0.0051 in. -----

(0.046-0.130 mm)

--- 0.0045-0.0065 in. ---

(0.114-0.165 mm)

--- 0.006-0.012 in. -----

(0.15-0.30 mm)

---0.002-0.0066 in. -----

(0.05-0.167 mm)

----0.005-0.013 in. ----

(0.13-0.33 mm)

30 qts. 27 qts.

(28.3 L) (25.6 L)

--'----14 qts.

(13.2 L)

114 qts. 90 qts.

(107.9 L) (85.2 L)

--------------llpts.

(5.2 L)

-------------2.5 pts. ------------

(1.1 L)

4.5 qts.

(4.25 L)

5

Paragraphs 1·4

INTERNATIONAL HARVESTER

FRONT SYSTEM AXLE TYPE

AXLE MAIN MEMBER

All Models Except 3688 Hi·Clear

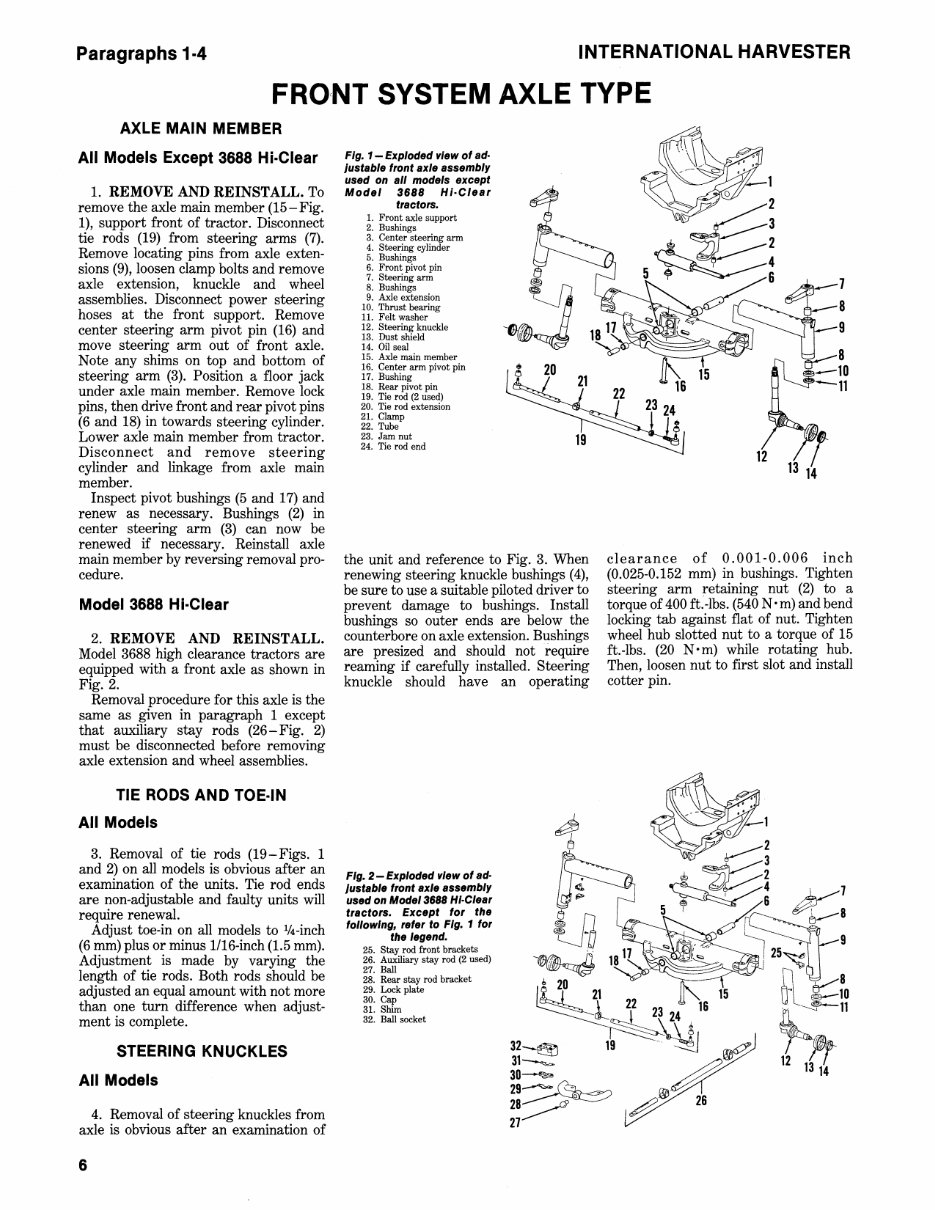

1. REMOVE AND REINSTALL. To

remove the axle main member (15-Fig.

1), support front of tractor. Disconnect

tie rods (19) from steering arms (7).

Remove locating pins from axle exten-

sions (9), loosen clamp bolts and remove

axle extension, knuckle and wheel

assemblies. Disconnect power steering

hoses at the front support. Remove

center steering arm pivot pin (16) and

move steering arm out of front axle.

Note any shims on top and bottom of

steering arm (3). Position a floor jack

under axle main member. Remove lock

pins, then drive front and rear pivot pins

(6 and 18) in towards steering cylinder.

Lower axle main member from tractor.

Disconnect and remove steering

cylinder and linkage from axle main

member.

Inspect pivot bushings (5 and 17) and

renew as necessary. Bushings (2) in

center steering arm (3) can now be

renewed if necessary. Reinstall axle

main member by reversing removal pro-

cedure.

Model 3688 Hi·Clear

2. REMOVE AND REINSTALL.

Model 3688 high clearance tractors are

equipped with a front axle as shown in

Fig. 2.

Removal procedure for this axle is the

same as given in paragraph 1 except

that auxiliary stay rods (26-Fig. 2)

must be disconnected before removing

axle extension and wheel assemblies.

TIE RODS AND TOE·IN

All Models

3. Removal of tie rods (19-Figs. 1

and 2) on all models is obvious after an

examination of the units. Tie rod ends

are non-adjustable and faulty units will

require renewal.

Adjust toe-in on all models to 1/4-inch

(6 mm) plus or minus 1I16-inch (1.5 mm).

Adjustment is made by varying the

length of tie rods. Both rods should be

adjusted an equal amount with not more

than one turn difference when adjust-

ment is complete.

STEERING KNUCKLES

All Models

4. Removal of steering knuckles from

axle is obvious after an examination of

6

Fig. 1- Exploded view of ad·

Justable front axle assembly

used on all models except

Model 3688 Hi·C/ear

tractors.

1. Front axle support

2. Bushings

3. Center steering arm

4. Steering cylinder

5. Bushings

6. Front pivot pin

7. Steering arm

8. Bushings

9. Axle extension

10. Thrust bearing

11. Felt washer

12. Steering knuckle

13. Dust shield

14. Oil seal

15. Axle main member

16. Center arm pivot pin

17. Bushing

18. Rear pivot pin

19. Tie rod (2 used)

20. Tie rod extension

21. Clamp

22. Tube

23. Jam nut

24. Tie rod end

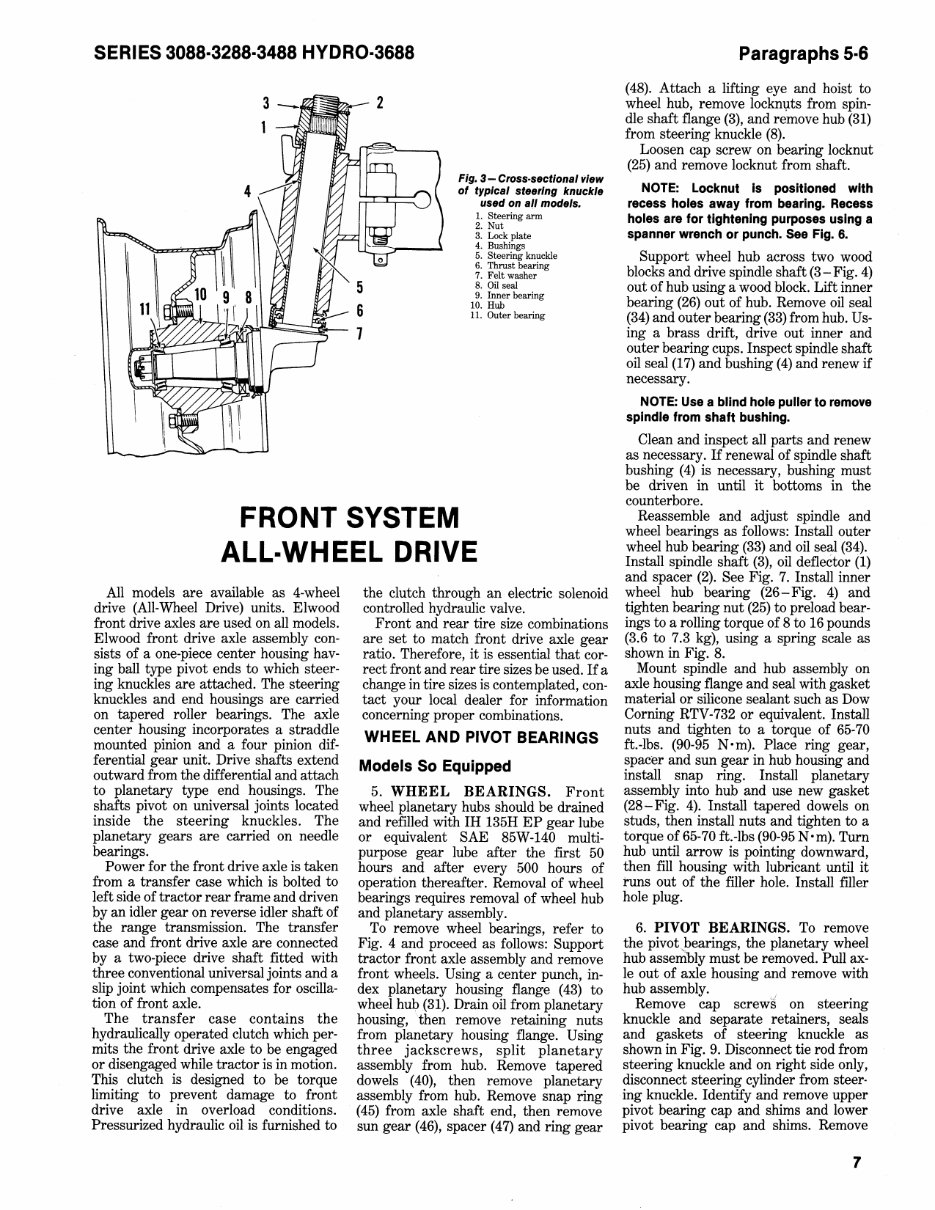

the unit and reference to Fig. 3. When

renewing steering knuckle bushings (4),

be sure to use a suitable piloted driver to

prevent damage to bushings. Install

bushings so outer ends are below the

counterbore on axle extension. Bushings

are presized and should not require

reaming if carefully installed. Steering

knuckle should have an operating

Fig. 2-Exploded view of ad·

Justable front axle assembly

used on Model 3688 HI·C/ear

tractors. Except for the

following, refer to Fig. 1 for

the legend.

25. Stay rod front brackets

26. Auxiliary stay rod (2 used)

27. Ball

28. Rear stay rod bracket

29. Lock plate

30. Cap

31. Shim

32. Ball socket

clearance of 0.001-0.006 inch

(0.025-0.152 mm) in bushings. Tighten

steering arm retaining nut (2) to a

torque of 400 ft. -lbs. (540 N' m) and bend

locking tab against flat of nut. Tighten

wheel hub slotted nut to a torque of 15

ft.-Ibs. (20 N· m) while rotating hub.

Then, loosen nut to first slot and install

cotter pin.

SERIES 3088·3288·3488 HYDRO·3688

Fig. 3 - Closs·sectlonal view

of typical steeling knuckle

used on all models.

1. Steering arm

2. Nut

3. Lock plate

4. Bushings

5. Steering knuckle

6. Thrust bearing

7. Felt washer

8. Oil seal

9. Inner bearing

10. Hub

11. Outer bearing

FRONT SYSTEM

ALL-WHEEL DRIVE

All models are available as 4-wheel

drive (All-Wheel Drive) units. Elwood

front drive axles are used on all models.

Elwood front drive axle assembly con-

sists of a one-piece center housing hav-

ing ball type pivot ends to which steer-

ing knuckles are attached. The. steering

knuckles and end housings are carried

on tapered roller bearings. The axle

center housing incorporates a straddle

mounted pinion and a four pinion dif-

ferential gear unit. Drive shafts extend

outward from the differential and attach

to planetary type end housings. The

shafts pivot on universal joints located

inside the steering knuckles. The

planetary gears are carried on needle

bearings.

Power for the front drive axle is taken

from a transfer case which is bolted to

left side of tractor rear frame and driven

by an idler gear on reverse idler shaft of

the range transmission. The transfer

case and front drive axle are connected

by a two-piece drive shaft fitted with

three conventional universal joints and a

slip joint which compensates for oscilla-

tion of front axle.

The transfer case contains the

hydraulically operated clutch which per-

mits the front drive axle to be engaged

or disengaged while tractor is in motion.

This clutch is designed to be torque

limiting to prevent damage to front

drive axle in overload conditions.

Pressurized hydraulic oil is furnished to

the clutch through an electric solenoid

controlled hydraulic valve.

Front and rear tire size combinations

are set to match front drive axle gear

ratio. Therefore, it is essential that cor-

rect front and rear tire sizes be used. If a

change in tire sizes is contemplated, con-

tact your local dealer for information

concerning proper combinations.

WHEEL AND PIVOT BEARINGS

Models So Equipped

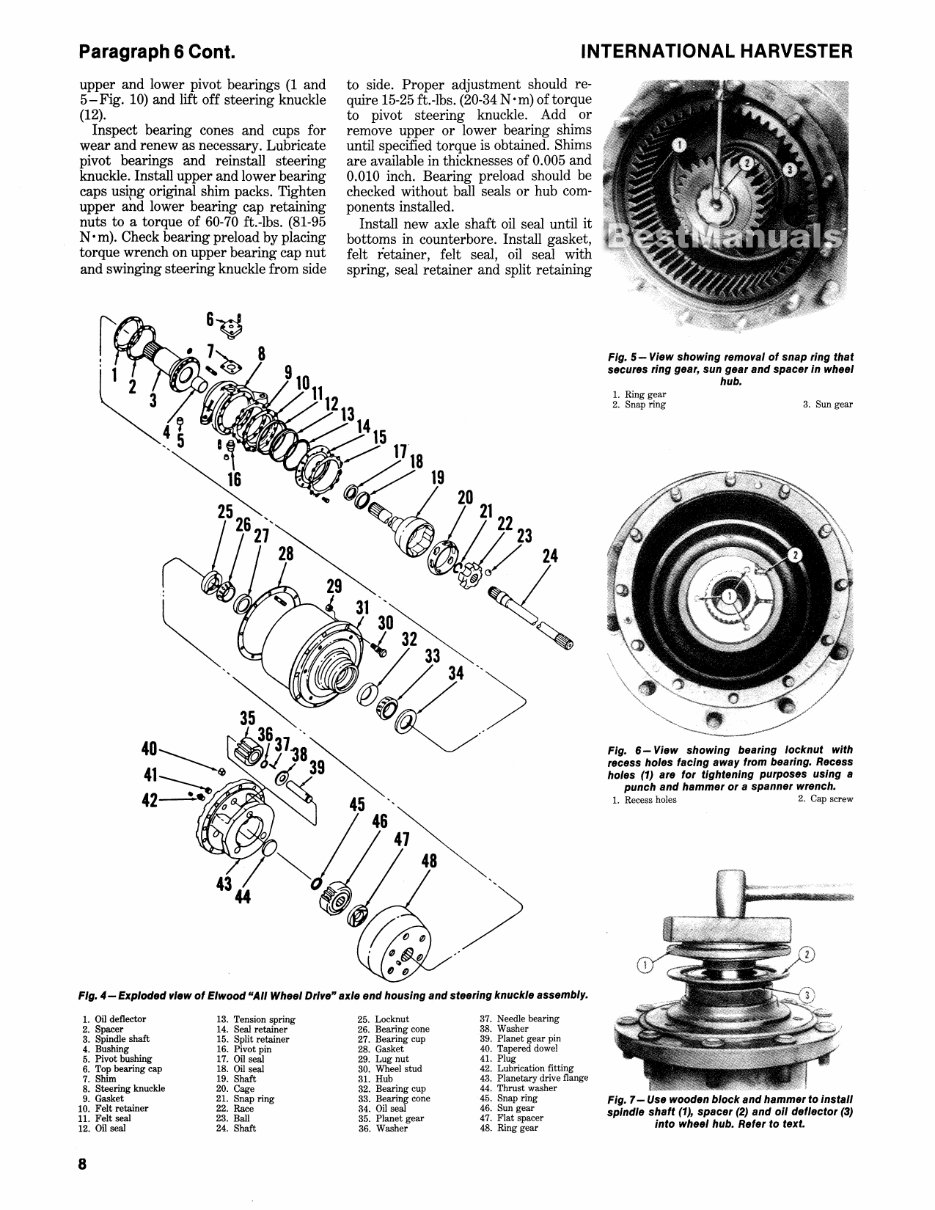

5. WHEEL BEARINGS. Front

wheel planetary hubs should be drained

and refIlled with IH 135H EP gear lube

or equivalent SAE 85W-140 multi-

purpose gear lube after the first 50

hours and after every 500 hours of

operation thereafter. Removal of wheel

bearings requires removal of wheel hub

and planetary assembly.

To remove wheel bearings, refer to

Fig. 4 and proceed as follows: Support

tractor front axle assembly and remove

front wheels. Using a center punch, in-

dex planetary housing flange (43) to

wheel hub (31). Drain oil from planetary

housing, then remove retaining nuts

from planetary housing flange. Using

three jackscrews, split planetary

assembly from hub. Remove tapered

dowels (40), then remove planetary

assembly from hub. Remove snap ring

(45) from axle shaft end, then remove

sun gear (46), spacer (47) and ring gear

Paragraphs 5·6

(48). Attach a lifting eye and hoist to

wheel hub, remove lockm.zts from spin-

dle shaft flange (3), and remove hub (31)

from steering knuckle (8).

Loosen cap screw on bearing locknut

(25) and remove locknut from shaft.

NOTE: Locknut Is pOSitioned with

recess holes away from bearing. Recess

holes are for tightening purposes using a

spanner wrench or punch. See Fig. 6.

Support wheel hub across two wood

blocks and drive spindle shaft (3 - Fig. 4)

out of hub using a wood block. Lift inner

bearing (26) out of hub. Remove oil seal

(34) and outer bearing (33) from hub. Us-

ing a brass drift, drive out inner and

outer bearing cups. Inspect spindle shaft

oil seal (17) and bushing (4) and renew if

necessary.

NOTE: Use a blind hole puller to remove

spindle from shaft bushing.

Clean and inspect all parts and renew

as necessary. If renewal of spindle shaft

bushing (4) is necessary, bushing must

be driven in until it bottoms in the

counterbore.

Reassemble and adjust spindle and

wheel bearings as follows: Install outer

wheel hub bearing (33) and oil seal (34).

Install spindle shaft (3), oil deflector (1)

and spacer (2). See Fig. 7. Install inner

wheel hub bearing (26-Fig. 4) and

tighten bearing nut (25) to preload bear-

ings to a rolling torque of 8 to 16 pounds

(3.6 to 7.3 kg), using a spring scale as

shown in Fig. 8.

Mount spindle and hub assembly on

axle housing flange and seal with gasket

material or silicone sealant such as Dow

Corning RTV-732 or equivalent. Install

nuts and tighten to a torque of 65-70

ft.-Ibs. (90-95 N ·m). Place ring gear,

spacer and sun gear in hub housing and

install snap ring. Install planetary

assembly into hub and use new gasket

(28-Fig. 4). Install tapered dowels on

studs, then install nuts and tighten to a

torque of 65-70 ft.-Ibs (90-95 N ·m). Turn

hub until arrow is pointing downward,

then fUl housing with lubricant until it

runs out of the fIller hole. Install fIller

hole plug.

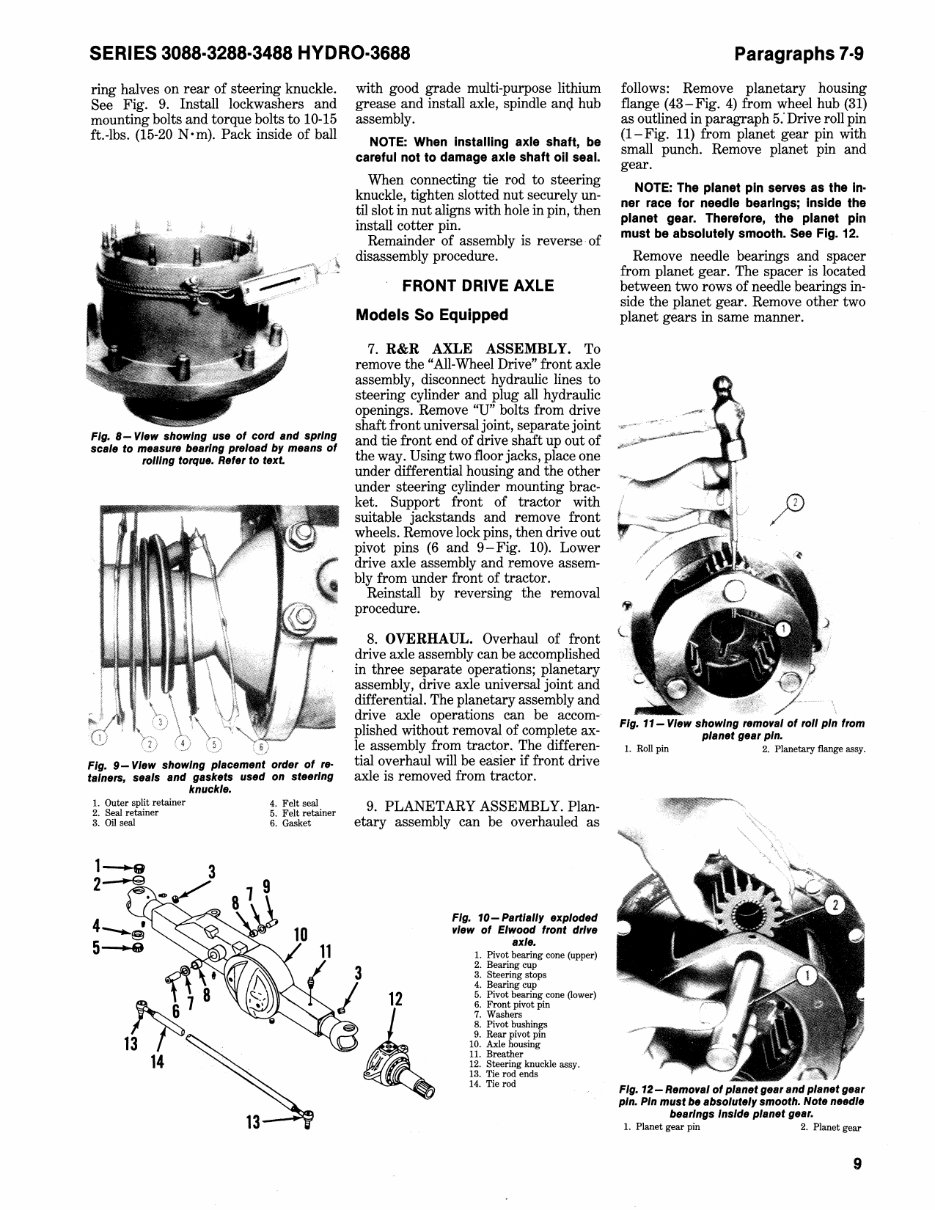

6. PIVOT BEARINGS. To remove

the pivot bearings, the planetary wheel

hub asse~ly must be removed. Pull ax-

le out of axle housing and remove with

hub assembly.

Remove cap screwi on steering

knuckle and separate retainers, seals

and gaskets of steering knuckle as

shown in Fig. 9. Disconnect tie rod from

steering knuckle and on right side only,

disconnect steering cylinder from steer-

ing knuckle. Identify and remove upper

pivot bearing cap and shims and lower

pivot bearing cap and shims. Remove

7

Paragraph 6 Cont.

upper and lower pivot bearings (1 and

5-Fig. 10) and lift off steering knuckle

(12).

Inspect bearing cones and cups for

wear and renew as necessary. Lubricate

pivot bearings and reinstall steering

knuckle. Install upper and lower bearing

caps usipg original shim packs. Tighten

upper and lower bearing cap retaining

nuts to a torque of 60-70 ft.-lbs. (81-95

N· m). Check bearing preload by placing

torque wrench on upper bearing cap nut

and swinging steering knuckle from side

INTERNATIONAL HARVESTER

to side. Proper adjustment should re-

quire 15-25 ft.-lbs. (20-34 N • m) of torque

to pivot steering knuckle. Add or

remove upper or lower bearing shims

until specified torque is obtained. Shims

are available in thicknesses of 0.005 and

0.010 inch. Bearing preload should be

checked without ball seals or hub com-

ponents installed.

Install new axle shaft oil seal until it

bottoms in counterbore. Install gasket,

felt retainer, felt seal, oil seal with

spring, seal retainer and split retaining

Fig. 5 - View showing remo"al of snap ring that

secures ring gear, sun gear and spacer In wheel

hub.

1. Ring gear

2. Snap ring 3. Sun gear

Fig. 6 - View showing bearing locknut with

recess holes facing away from bearing. Recess

holes (1) are for tightening purposes using a

punch and hammer or a spanner wrench.

1. Recess holes 2. Cap screw

Fig. 4 - Exploded ,,'ew of Elwood "All Wheel DrI"e" axle end housing and steering knuckle assembly.

1. Oil deflector 13. Tension spring

2. Spacer 14. Seal retainer

3. Spindle shaft 15. Split retainer

4. Bushing

5. Pivot bushing

16. Pivot pin

17. Oil seal

6. Top bearing cap 18. Oil seal

7. Shim 19. Shaft

8. Steering knuckle 20. Cage

9. Gasket 21. Snap ring

10. Felt retainer 22. Race

11. Felt seal 23. Ball

12. Oil seal 24. Shaft

8

25. Locknut

26. Bearing cone

27. Bearing cup

28. Gasket

29. Lug nut

30. Wheel stud

31. Hub

32. Bearing cup

33. Bearing cone

34. Oil seal

35. Planet gear

36. Washer

37. Needle bearing

38. Washer

39. Planet gear pin

40. Tapered dowel

41. Plug

42. Lubrication fitting

43. Planetary drive flange

44. Thrust washer

45. Snap ring

46. Sun gear

47. FIat spacer

48. Ring gear

Fig. 7 - Use wooden block and hammer to install

spindle shaft (1), spacer (2) and 011 deflector (3)

into wheel hub. Refer to text.

SERIES 3088·3288·3488 HYDRO·3688

ring halves on rear of steering knuckle.

See Fig. 9. Install lockwashers and

mounting bolts and torque bolts to 10-15

ft.-lbs. (15-20 N ·m). Pack inside of ball

Fig. 8- View showing use of cord and spring

scale to measure bearing preload by means of

roiling torque. Refer to text

Fig. 9- View showing placement order of re·

talners, seals and gaskets used on steering

knuckle.

1. Outer split retainer

2. Seal retainer

3. Oil seal

1-&

2~

4. Felt seal

5. Felt retainer

6. Gasket

with good grade multi-purpose lithium

grease and install axle, spindle anQ. hub

assembly.

NOTE: When Installing axle shaft, be

careful not to damage axle shaft 011 seal.

When connecting tie rod to steering

knuckle, tighten slotted nut securely un-

til slot in nut aligns with hole in pin, then

install cotter pin.

Remainder of assembly is reverse· of

disassembly procedure.

FRONT DRIVE AXLE

Models So Equipped

7. R&R AXLE ASSEMBLY. To

remove the "All-Wheel Drive" front axle

assembly, disconnect hydraulic lines to

steering cylinder and plug all hydraulic

openings. Remove "U" bolts from drive

shaft front universal joint, separate joint

and tie front end of drive shaft up out of

the way. Using two floor jacks, place one

under differential housing and the other

under steering cylinder mounting brac-

ket. Support front of tractor with

suitable jackstands and remove front

wheels. Remove lock pins, then drive out

pivot pins (6 and 9-Fig. 10). Lower

drive axle assembly and remove assem-

bly from under front of tractor.

Reinstall by reversing the removal

procedure.

8. OVERHAUL. Overhaul of front

drive axle assembly can be accomplished

in three separate operations; planetary

assembly, drive axle universal joint and

differential. The planetary assembly and

drive axle operations can be accom-

plished without removal of complete ax-

le assembly from tractor. The differen-

tial overhaul will be easier if front drive

axle is removed from tractor.

9. PLANETARY ASSEMBLY. Plan-

etary assembly can be overhauled as

Fig. 10- Partially exploded

view of Elwood front drive

axle.

1. Pivot bearing cone (upper)

3

I 12

~

2. Bearing cup

3. Steering stops

4. Bearing cup

5. Pivot bearing cone (lower)

6. Front pivot pin

7. Washers

8. Pivot bushings

9. Rear pivot pin

10. Axle housing

11. Breather

12. Steering knuckle assy.

13. Tie rod ends

14. Tie rod

Paragraphs 7·9

follows: Remove planetary housing

flange (43-Fig. 4) from wheel hub (31)

as outlined in paragraph 5: Drive roll pin

(I-Fig. 11) from planet gear pin with

small punch. Remove planet pin and

gear.

NOTE: The planet pin serves as the In·

ner race for needle bearings; Inside the

planet gear. Therefore, the planet pin

must be absolutely smooth. See Fig. 12.

Remove needle bearings and spacer

from planet gear. The spacer is located

between two rows of needle bearings in-

side the planet gear. Remove other two

planet gears in same manner.

Fig. 11- View showing removal of roll pin from

planet gear pin.

1. Roll pin 2. Planetary flange assy.

Fig. 12 - Removal of planet gear and planet gear

pin. Pin must be absolutely smooth. Note needle

bearings Inside planet gear.

1. Planet gear pin 2. Planet gear

9

Paragraphs 10·11

Clean and inspect all parts and renew

any showing excessive wear or other

damage. Assembly is the reverse of

disassembly. Tighten planetary housing

flange retaining nuts to a torque of

65-70 ft.~lbs. (90-95 Nom).

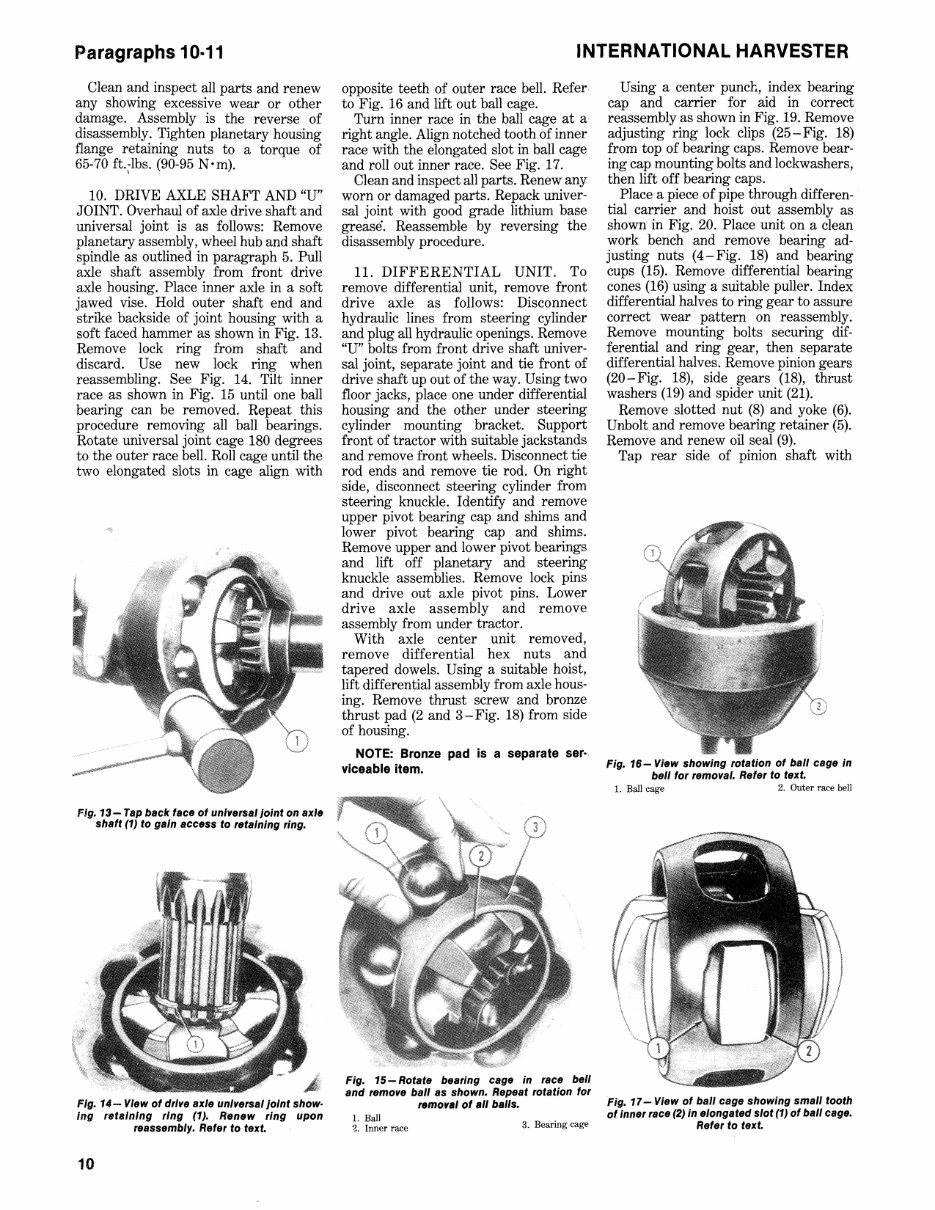

10. DRIVE AXLE SHAFT AND "U"

JOINT. Overhaul of axle drive shaft and

universal joint is as follows: Remove

planetary assembly, wheel hub and shaft

spindle as outlined in paragraph 5. Pull

axle shaft assembly from front drive

axle housing. Place inner axle in a soft

jawed vise. Hold outer shaft end and

strike backside of joint housing with it

soft faced hammer as shown in Fig. 13.

Remove lock ring from shaft and

discard. Use new lock ring when

reassembling. See Fig. 14. Tilt inner

race as shown in Fig. 15 until one ball

bearing can be removed. Repeat this

procedure removing all ball bearings.

Rotate universal joint cage 180 degrees

to the outer race bell. Roll cage until the

two elongated slots in cage align with

Fig. 13- Tap back face of universal Joint on axle

shaft (1) to gain access to letalnlng ling.

Fig. 14- View of dll"e axle universal Joint show·

Ing retaining ling (1). Renew ling upon

leassembly. Refer to text

10

INTERNATIONAL HARVESTER

opposite teeth of outer race bell. Refer·

to Fig. 16 and lift out ball cage.

Turn inner race in the ball cage at a

right angle. Align notched tooth of inner

race with the elongated slot in ball cage

and roll out inner race. See Fig. 17.

Clean and inspect all parts. Renew any

worn or damaged parts. Repack univer-

sal joint with good grade lithium base

grease'. Reassemble by reversing the

disassembly procedure.

11. DIFFERENTIAL UNIT. To

remove differential unit, remove front

drive axle as follows: Disconnect

hydraulic lines from steering cylinder

and plug all hydraulic openings. Remove

"U" bolts from front drive shaft univer-

sal joint, separate joint and tie front of

drive shaft up out of the way. Using two

floor jacks, place one under differential

housing and the other under steering

cylinder mounting bracket. Support

front of tractor with suitable jackstands

and remove front wheels. Disconnect tie

rod ends and remove tie rod. On right

side, disconnect steering cylinder from

steering knuckle. Identify and remove

upper pivot bearing cap and shims and

lower pivot bearing cap and shims.

Remove upper and lower pivot bearings

and lift off planetary and steering

knuckle assemblies. Remove lock pins

and drive out axle pivot pins. Lower

drive axle assembly and remove

assembly from under tractor.

With axle center unit removed,

remove differential hex nuts and

tapered dowels. Using a suitable hoist,

lift differential assembly from axle hous-

ing. Remove thrust screw and bronze

thrust pad (2 and 3 - Fig. 18) from side

of housing.

NOTE: Bronze pad is a separate ser-

viceable item.

Fig. 15 - Rotate bealing cage in lace bell

and remove ball as shown. Repeat rotation fOl

removal of all balls.

1. Ball

3. Bearing cage

2. Inner race

Using a center punch, index bearing

cap and carrier for aid in correct

reassembly as shown in Fig. 19. Remove

adjusting ring lock clips (25-Fig. 18)

from top of bearing caps. Remove bear-

ing cap mounting bolts and lockwashers,

then lift off bearing caps.

Place a piece of pipe through differen-

tial carrier and hoist out assembly as

shown in Fig. 20. Place unit on a clean

work bench and remove bearing ad-

justing nuts (4-Fig. 18) and bearing

cups (15). Remove differential bearing

cones (16) using a suitable puller. Index

differential halves to ring gear to assure

correct wear pattern on reassembly.

Remove mounting bolts securing dif-

ferential and ring gear, then separate

differential halves. Remove pinion gears

(20-Fig. 18), side gears (18), thrust

washers (19) and spider unit (21).

Remove slotted nut (8) and yoke (6).

Unbolt and remove bearing retainer (5).

Remove and renew oil seal (9).

Tap rear side of pinion shaft with

Fig. 16- View showing rotation of ball cage In

bell fOl removal. Refel to text.

1. Ball cage 2. Outer race bell

Fig. 17- View of ball cage showing small tooth

of innel lace (2) In elongated slot (1) of ball cage.

Refel to text.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$52.99

$68.99

Viewed 92 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$52.99

$68.99

This service manual is an essential resource for DIY repair enthusiasts, from first-time owners to experienced technicians. It is designed in an easy-to-read format and provides comprehensive instructions necessary for accurate procedure execution. Keeping this manual accessible and referring to it regularly ensures that routine and preventive maintenance is performed efficiently, saving both time and cost by preventing premature failure and unnecessary repairs.

- BRAKES

- CLUTCH, ENGINE

- COOLING SYSTEM

- DIESEL FUEL SYSTEM

- ELECTRICAL SYSTEM

- ENGINE

- FINAL DRIVE

- FRONT SYSTEM

- HYDRAULIC SYSTEM

- HYDROSTATIC DRIVE

- MAIN BEVEL GEAR

- POWER STEERING SYSTEM

- POWER TAKE-OFF

- RANGE TRANSMISSION

- TORQUE

- SERVICE DATA

Language: English