1948-1952 Ford 8N Tractor Service Repair Factory Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

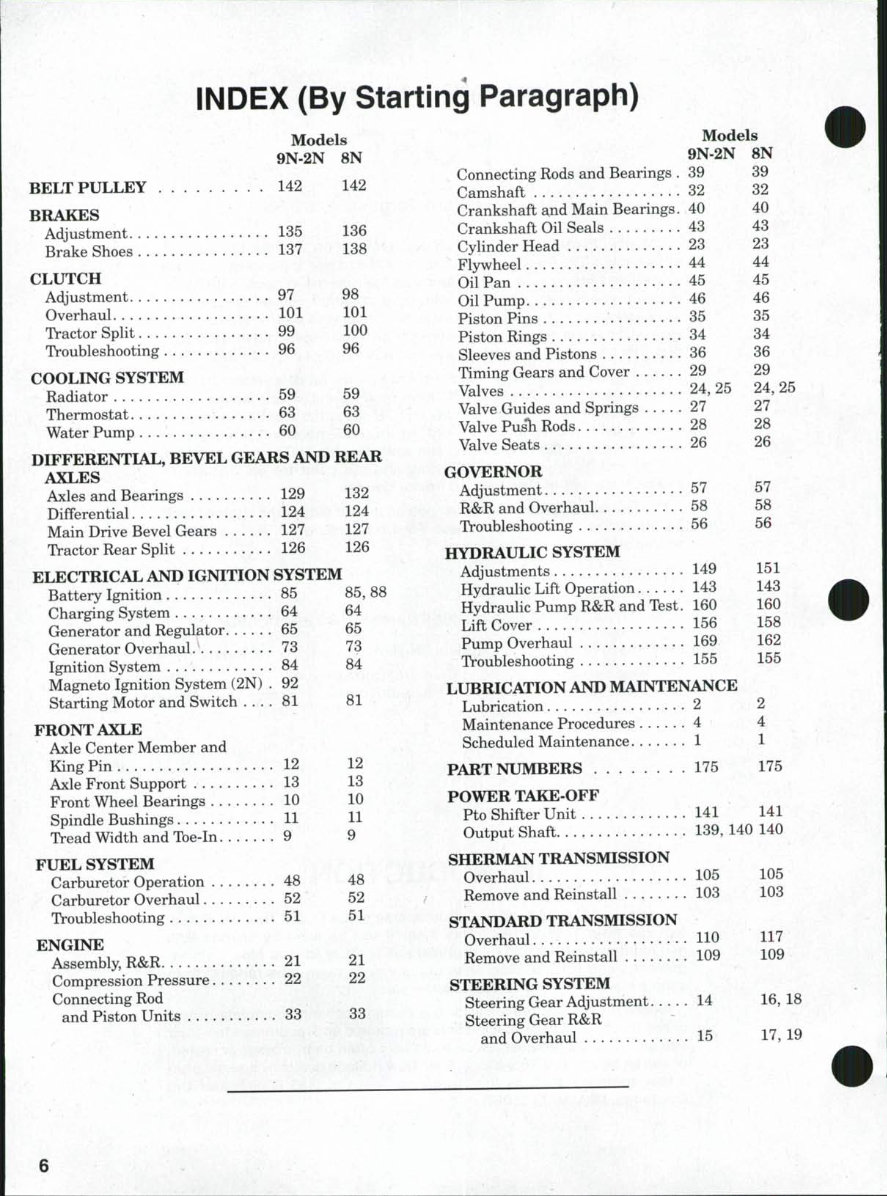

INDEX (By Starting Paragraph)

Models

9N-2N 8N

BELT PULLEY 142 142

BRAKES

Adjustment 135 136

Brake Shoes 137 138

CLUTCH

Adjustment 97 98

Overhaul 101 101

Tractor Split 99 100

Troubleshooting 96 96

COOLING SYSTEM

Radiator 59 59

Thermostat 63 63

Water Pump 60 60

DIFFERENTL\L, BEVEL GEARS AND REAR

AXLES

Axles and Bearings 129 132

Differential 124 124

Main Drive Bevel Gears 127 127

Tractor Rear Split 126 126

ELECTRICAL AND IGNITION SYSTEM

Battery Ignition 85 85, 88

Charging System 64 64

Generator and Regulator 65 65

Generator Overhaul. 73 73

Ignition System 84 84

Magneto Ignition System (2N) . 92

Starting Motor and Switch .... 81 81

FRONT AXLE

Axle Center Member and

King Pin 12 12

Axle Front Support 13 13

Front Wheel Bearings 10 10

Spindle Bushings 11 H

Tread Width and Toe-In 9 9

FUEL SYSTEM

Carburetor Operation 48 48

Carburetor Overhaul 52 52

Troubleshooting 51 51

ENGINE

Assembly, R&R 21 21

Compression Pressure 22 22

Connecting Rod

and Piston Units 33 33

Models

9N-2N 8N

Connecting Rods and Bearings . 39

Camshaft 32

Crankshaft and Main Bearings. 40

Crankshaft Oil Seals 43

Cyhnder Head 23

Flywheel 44

Oil Pan 45

Oil Pump 46

Piston Pins 35

Piston Rings 34

Sleeves and Pistons 36

Timing Gears and Cover 29

Valves 24, 25

Valve Guides and Springs ..... 27

Valve PusTi Rods. . 28

Valve Seats 26

GOVERNOR

Adjustment 57

R&R and Overhaul 58

Troubleshooting 56

HYDRAULIC SYSTEM

Adjustments 149

Hydraulic Lift Operation 143

Hydraulic Pump R&R and Test. 160

Lift Cover 156

Pump Overhaul 169

Troubleshooting 155

LUBRICATION AND MAINTENANCE

Lubrication 2 2

Maintenance Procedures 4 4

Scheduled Maintenance 1 1

39

32

40

43

23

44

45

46

35

34

36

29

24,25

27

28

26

57

58

56

151

143

160

158

162

155

PART NUMBERS 175 175

POWER TAKE-OFF

Pto Shifter Unit 141 141

Output Shaft 139, 140 140

SHERMAN TRANSMISSION

Overhaul 105 105

Remove and Reinstall 103 103

STANDARD TRANSMISSION

Overhaul HO 117

Remove and Reinstall 109 109

STEERING SYSTEM

Steering Gear Adjustment 14 16,18

Steering Gear R&R

and Overhaul 15 17, 19

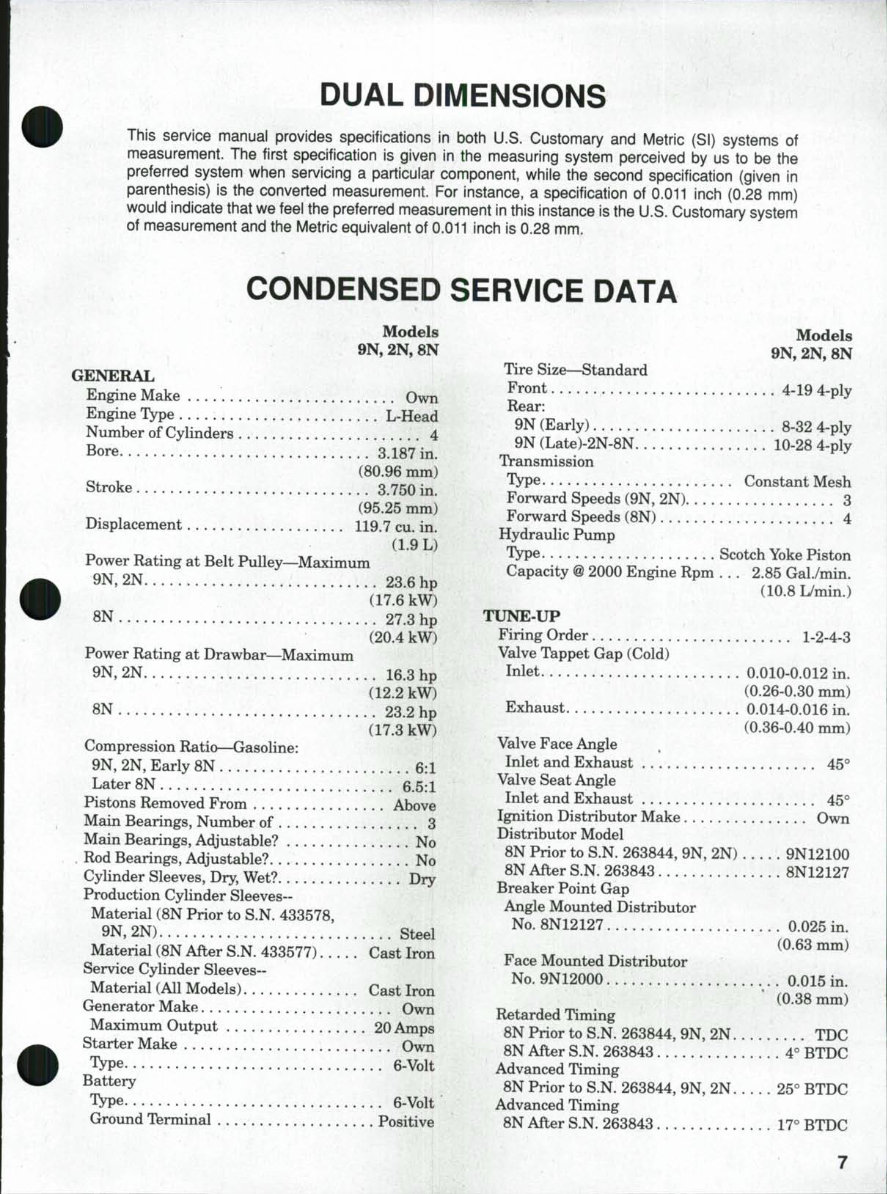

DUAL DIMENSIONS

This service manual provides specifications in both U.S. Customary and Metric (SI) systems of

measurement. The first specification is given in the measuring system perceived by us to be the

preferred system when servicing a particular component, whiie the second specification (given in

parenthesis) is the converted measurement. For instance, a specification of 0.011 inch (0.28 mm)

wouid indicate that we feel the preferred measurement in this instance is the U.S. Customary system

of measurement and the Metric equivalent of 0.011 inch is 0.28 mm.

CONDENSED SERVICE DATA

Models

9N,2N,8N

GENERAL

Engine Make Own

Engine Type L-Head

Number of Cylinders 4

Bore 3.187 in.

(80.96 mm)

Stroke 3.750 in.

(95.25 mm)

Displacement 119.7 cu. in.

(1.9 L)

Power Rating at Belt Pulley—Maximum

9N, 2N 23.6 hp

(17.6 kW)

8N 27.3 hp

(20.4 kW)

Power Rating at Drawbar—Maximum

9N, 2N 16.3 hp

(12.2 kW)

8N 23.2 hp

(17.3 kW)

Compression Ratio—Gasoline:

9N, 2N, Early 8N 6:1

Later 8N 6.5:1

Pistons Removed From Above

Main Bearings, Number of 3

Main Bearings, Adjustable? No

. Rod Bearings, Adjustable? No

Cylinder Sleeves, Dry, Wet? Dry

Production Cylinder Sleeves-

Material (8N Prior to S.N. 433578,

9N,2N) Steel

Material (8N After S.N. 433577) Cast Iron

Service Cylinder Sleeves-

Material (All Models) Cast Iron

Generator Make Own

Maximum Output 20 Amps

Starter Make Own

Type 6-Volt

Battery ^

Type 6-Volt

Ground Terminal . Positive

Models

. 9N,2N,8N

Tire Size^—Standard

Front 4-19 4-ply

Rear:

9N (Early) 8-32 4-ply

9N (Late)-2N-8N 10-28 4-ply

Transmission

Type Constant Mesh

Forward Speeds (9N, 2N) 3

Forward Speeds (8N) 4

Hydraulic Pump

Type Scotch Yoke Piston

Capacity @ 2000 Engine Rpm . . . 2.85 Gal./min.

(10.8L/min.)

TUNE-UP

Firing Order 1-2-4-3

Valve Tappet Gap (Cold)

Inlet. 0.010-0.012 in.

(0.26-0.30 mm)

Exhaust 0.014-0.016 in.

(0.36-0.40 mm)

Valve Face Angle

Inlet and Exhaust 45°

Valve Seat Angle

Inlet and Exhaust 45°

Ignition Distributor Make Own

Distributor Model

8N Prior to S.N. 263844, 9N, 2N) 9N12100

8N After S.N. 263843 8N12127

Breaker Point Gap

Angle Mounted Distributor

No. 8N12127 0.025 in.

(0.63 mm)

Face Mounted Distributor

No. 9N12000 0.015 in.

(0.38 mm)

Retarded Timing

8N Prior to S.N. 263844, 9N, 2N TDC

8N After S.N. 263843 4° BTDC

Advanced Timing

8N Prior to S.N. 263844, 9N, 2N 25° BTDC

Advanced Timing

8N After S.N. 263843 ........ .. ! . . . 17° BTDC

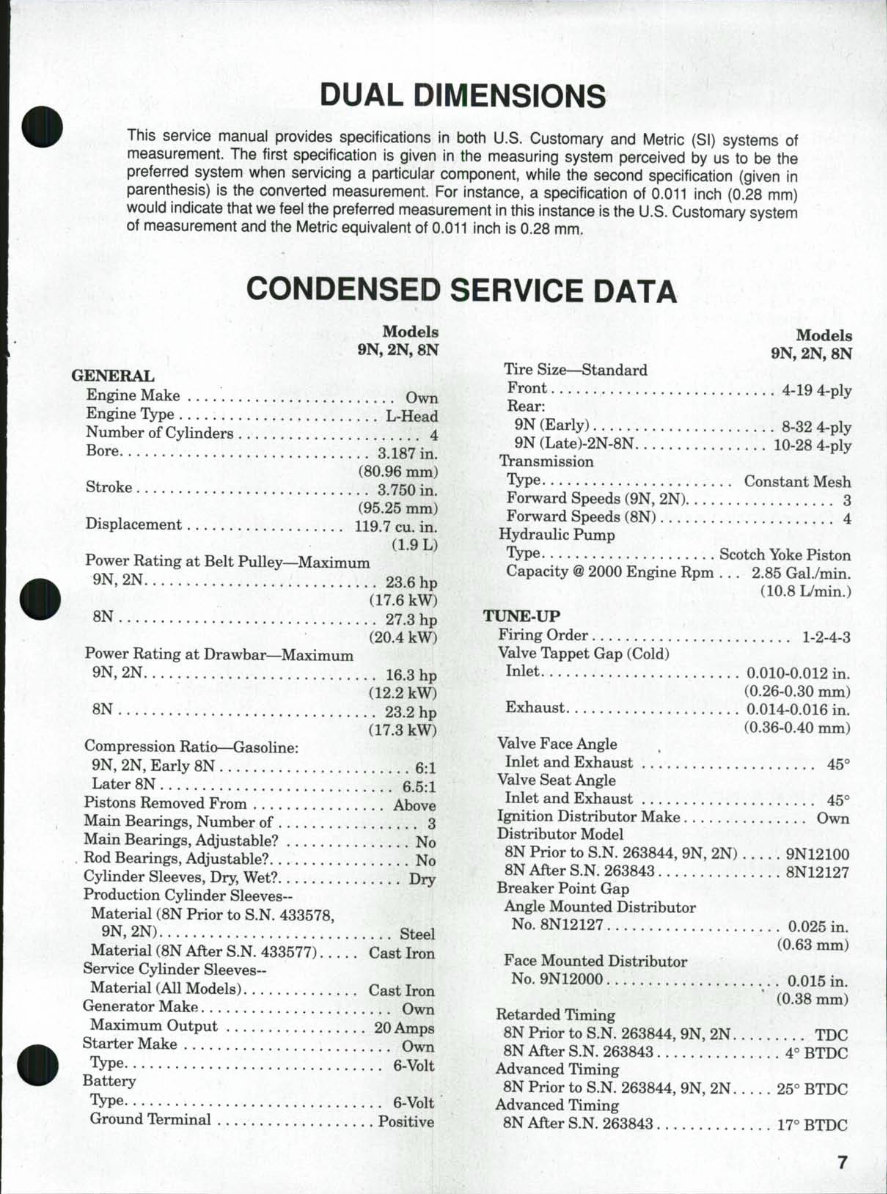

DUAL DIMENSIONS

This service manual provides specifications in both U.S. Customary and Metric (SI) systems of

measurement. The first specification is given in the measuring system perceived by us to be the

preferred system when servicing a particular component, whiie the second specification (given in

parenthesis) is the converted measurement. For instance, a specification of 0.011 inch (0.28 mm)

wouid indicate that we feel the preferred measurement in this instance is the U.S. Customary system

of measurement and the Metric equivalent of 0.011 inch is 0.28 mm.

CONDENSED SERVICE DATA

Models

9N,2N,8N

GENERAL

Engine Make Own

Engine Type L-Head

Number of Cylinders 4

Bore 3.187 in.

(80.96 mm)

Stroke 3.750 in.

(95.25 mm)

Displacement 119.7 cu. in.

(1.9 L)

Power Rating at Belt Pulley—Maximum

9N, 2N 23.6 hp

(17.6 kW)

8N 27.3 hp

(20.4 kW)

Power Rating at Drawbar—Maximum

9N, 2N 16.3 hp

(12.2 kW)

8N 23.2 hp

(17.3 kW)

Compression Ratio—Gasoline:

9N, 2N, Early 8N 6:1

Later 8N 6.5:1

Pistons Removed From Above

Main Bearings, Number of 3

Main Bearings, Adjustable? No

. Rod Bearings, Adjustable? No

Cylinder Sleeves, Dry, Wet? Dry

Production Cylinder Sleeves-

Material (8N Prior to S.N. 433578,

9N,2N) Steel

Material (8N After S.N. 433577) Cast Iron

Service Cylinder Sleeves-

Material (All Models) Cast Iron

Generator Make Own

Maximum Output 20 Amps

Starter Make Own

Type 6-Volt

Battery ^

Type 6-Volt

Ground Terminal . Positive

Models

. 9N,2N,8N

Tire Size^—Standard

Front 4-19 4-ply

Rear:

9N (Early) 8-32 4-ply

9N (Late)-2N-8N 10-28 4-ply

Transmission

Type Constant Mesh

Forward Speeds (9N, 2N) 3

Forward Speeds (8N) 4

Hydraulic Pump

Type Scotch Yoke Piston

Capacity @ 2000 Engine Rpm . . . 2.85 Gal./min.

(10.8L/min.)

TUNE-UP

Firing Order 1-2-4-3

Valve Tappet Gap (Cold)

Inlet. 0.010-0.012 in.

(0.26-0.30 mm)

Exhaust 0.014-0.016 in.

(0.36-0.40 mm)

Valve Face Angle

Inlet and Exhaust 45°

Valve Seat Angle

Inlet and Exhaust 45°

Ignition Distributor Make Own

Distributor Model

8N Prior to S.N. 263844, 9N, 2N) 9N12100

8N After S.N. 263843 8N12127

Breaker Point Gap

Angle Mounted Distributor

No. 8N12127 0.025 in.

(0.63 mm)

Face Mounted Distributor

No. 9N12000 0.015 in.

(0.38 mm)

Retarded Timing

8N Prior to S.N. 263844, 9N, 2N TDC

8N After S.N. 263843 4° BTDC

Advanced Timing

8N Prior to S.N. 263844, 9N, 2N 25° BTDC

Advanced Timing

8N After S.N. 263843 ........ .. ! . . . 17° BTDC

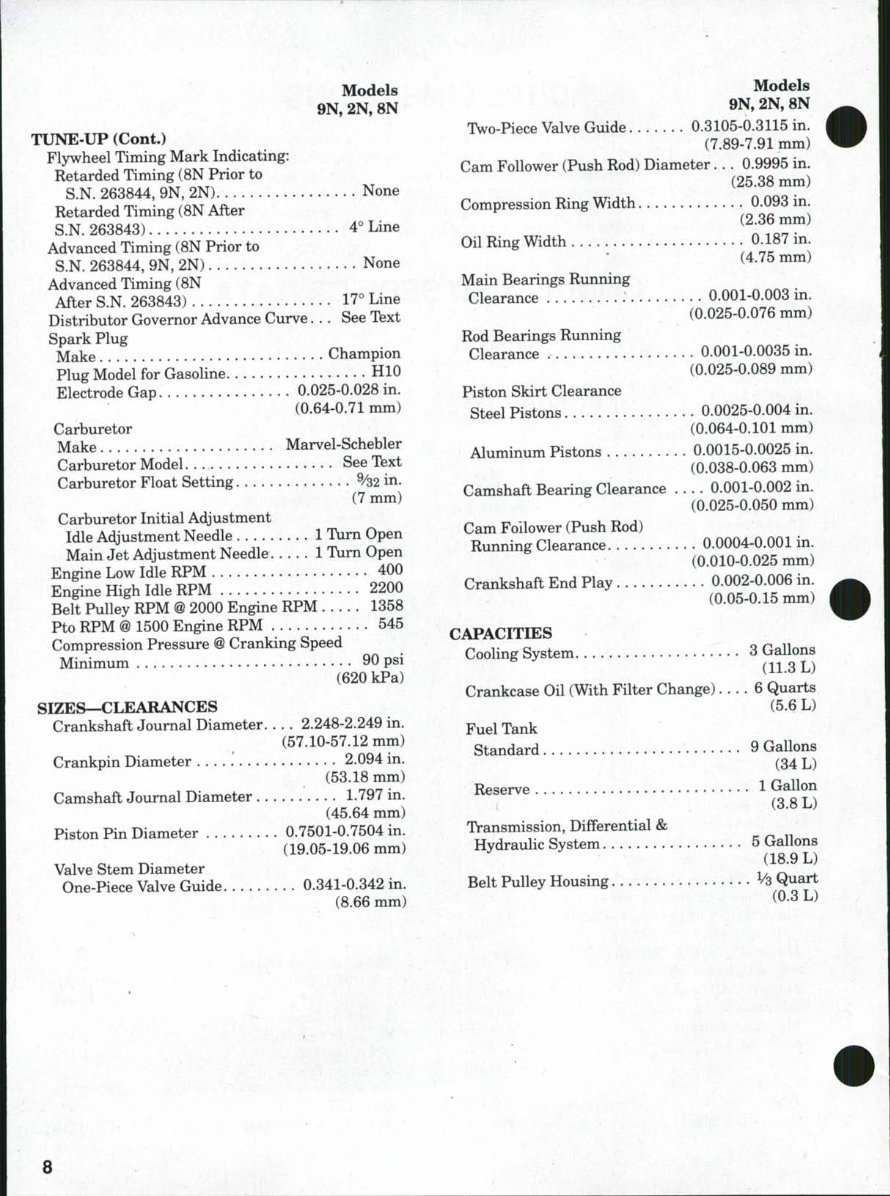

V / Models

V.:' • : 9N,2N,8N

TUNE-UP (Cont.)

Flywheel Timing Mark Indicating:

Retarded Timing (8N Prior to

S.N. 263844, 9N, 2N) None

Retarded Timing (8N After

S.N. 263843) 4° Line

Advanced Timing (8N Prior to

S.N. 263844, 9N, 2N) None

Advanced Timing (8N

After S.N. 263843) 17° Line

Distributor Governor Advance Curve. . . See Text

Spark Plug

Make Champion

Plug Model for Gasoline HIO

Electrode Gap 0.025-0.028 in.

(0.64-0.71 mm)

Carburetor

Make Marvel-Schebler

Carburetor Model See Text

Carburetor Float Setting %2 in.

(7 mm)

Carburetor Initial Adjustment

Idle Adjustment Needle 1 Turn Open

Main Jet Adjustment Needle 1 Tum Open

Engine Low Idle RPM 400

Engine High Idle RPM 2200

Belt Pulley RPM @ 2000 Engine RPM 1358

Pto RPM @ 1500 Engine RPM 545

Compression Pressure @ Cranking Speed

Minimum 90 psi

(620 kPa)

SIZES—CLEARANCES

Crankshaft Joumal Diameter 2.248-2.249 in.

(57.10-57.12 mm)

Crankpin Diameter .' 2.094 in.

(53.18 mm)

Camshaft Joumal Diameter 1.797 in.

(45.64 mm)

Piston Pin Diameter 0.7501-0.7504 in.

(19.05-19.06 mm)

Valve Stem Diameter

One-Piece Valve Guide 0.341-0.342 in.

(8.66 mm)

Models

9N,2N,8N

Two-Piece Valve Guide 0.3105-0.3115 in.

(7.89-7.91 mm)

Cam Follower (Push Rod) Diameter... 0.9995 in.

(25.38 mm)

Compression Ring Width 0.093 in.

(2.36 mm)

Oil Ring Width 0.187 in.

(4.75 mm)

Main Bearings Running

Clearance 0.001-0.003 in.

(0.025-0.076 mm)

Rod Bearings Running

Clearance 0.001-0.0035 in.

(0.025-0.089 mm)

Piston Skirt Clearance

Steel Pistons 0.0025-0.004 in.

(0.064-0.101 mm)

Aluminum Pistons 0.0015-0.0025 in.

(0.038-0.063 mm)

Camshaft Bearing Clearance 0.001-0.002 in.

(0.025-0.050 mm)

Cam Follower (Push Rod)

Running Clearance 0.0004-0.001 in.

(0.010-0.025 mm)

Crankshaft End Play 0.002-0.006 in.

(0.05-0.15 mm)

CAPACITIES

Coohng System 3 Gallons

(11.3 L)

Crankcase Oil (With Filter Change) 6 Quarts

(5.6 L)

Fuel Tank

Standard 9 Gallons

(34 L)

Reserve 1 Gallon

(3.8 L)

Transmission, Differential &

Hydraulic System 5 Gallons

(18.9 L)

Belt Pulley Housing V3 Quart

(0.3 L)

8

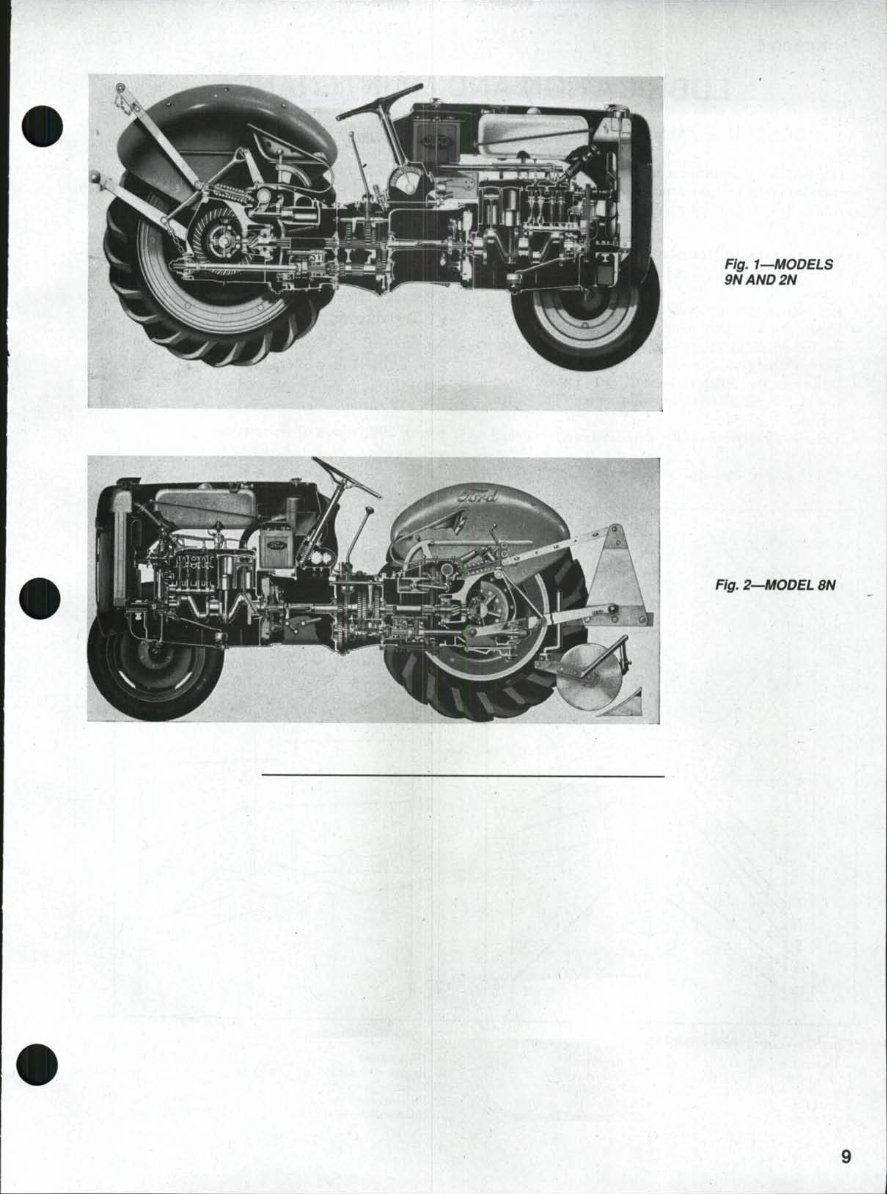

Fig, 1—MODELS

9NAND2N

Fig. 2—MODEL 8N

Paragraph 1

FORD

LUBRICATION AND MAINTENANCE

SCHEDULED MAINTENANCE

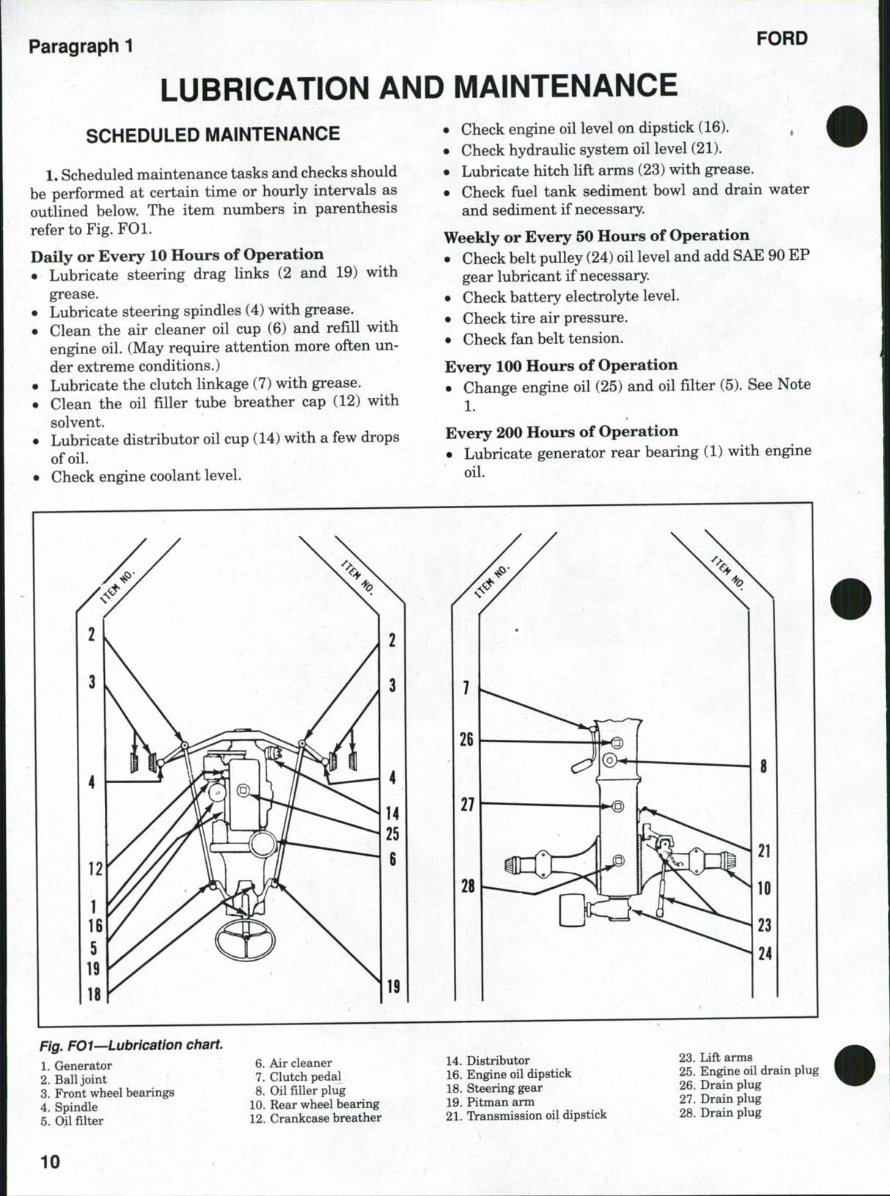

1. Scheduled maintenance tasks and checks should

be performed at certain time or hourly intervals as

outlined below. The item numbers in parenthesis

refer to Fig. FOl.

Daily or Every 10 Hours of Operation

• Lubricate steering drag links (2 and 19) with

grease.

• Lubricate steering spindles (4) with grease.

• Clean the air cleaner oil cup (6) and refill with

engine oil. (May require attention more often un-

der extreme conditions.)

• Lubricate the clutch linkage (7) with grease.

• Clean the oil filler tube breather cap (12) with

solvent.

• Lubricate distributor oil cup (14) with a few drops

of oil.

• Check engine coolant level.

• Check engine oil level on dipstick (16). ,

• Check hydraulic system oil level (21).

• Lubricate hitch lift arms (23) Mdth grease.

• Check fuel tank sediment bowl and drain water

and sediment if necessary.

Weekly or Every 50 Hours of Operation

• Check belt pulley (24) oil level and add SAE 90 EP

gear lubricant if necessary.

• Check battery electrolyte level.

• Check tire air pressure.

• Check fan belt tension.

Every 100 Hours of Operation

• Change engine oil (25) and oil filter (5). See Note

1.

Every 200 Hours of Operation

• Lubricate generator rear bearing (1) with engine

oil.

Fig. FOl—Lubrication chart.

1. Grenerator

2. Ball joint

3. Front wheel bearings

4. Spindle

5. Oil filter ;

6. Air cleaner

7. Clutch pedal

8. Oil filler plug

10. Rear wheel bearing

12. Crankcase breather

14. Distributor

16. Engine oil dipstick

18. Steering gear

19. Pitman arm

21. Transmission oil dipstick

23. Lift arms

25. Engine oil drain plug

26. Drain plug

27. Drain plug

28. Drain plug

10

MODELS 9N, 2N & 8N ^^^ h

• Clean distributor cam (14) and apply new lubri-

cant to cam.

• Check steering gear (18) oil level and add SAE 90

EP gear lubricant if necessary. Fill to top of filler

plug opening in side of steering gear housing.

Yearly or Every 600 Hours of Operation

• Tune-up the engine.

• Clean and repack front wheel bearings (3).

• Remove and clean carburetor air cleaner housing

and filter element (6). See Note 2.

• Drain transmission, differential and hydraulic

system oil and refill with new oil.

• Drain and flush cooling system. Refill with new

coolant.

Every 1800 Hours of Operation

• Clean and repack rear wheel bearings (10).

NOTE 1 - If tractor is operated under any of the

following conditions, change the engine oii and oii

fiiter more frequently:

a. Extremeiy hot or coid temperatures

b. Sustained heavy loads

c. Extended low speed operation

d. Extremely dusty conditions

NOTE 2 - Under severe dust condition, remove

and ciean the carburetor air cieaner assembiy every

100 hours of operation.

LUBRICATION

Engine Oil Change Periods

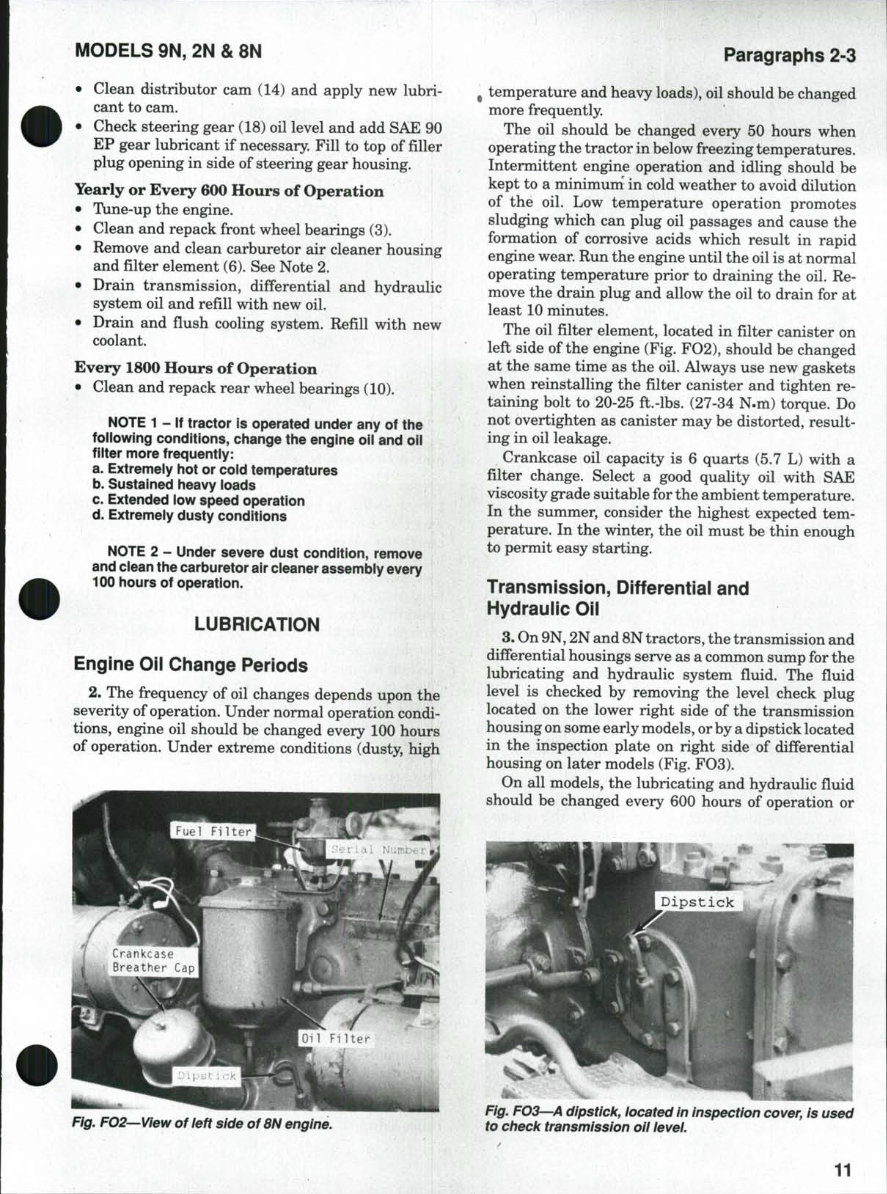

2. The frequency of oil changes depends upon the

severity of operation. Under normal operation condi-

tions, engine oil should be changed every 100 hours

of operation. Under extreme conditions (dusty, high

Paragraphs 2-3

^ temperature and heavy loads), oil should be changed

more frequently.

The oil should be changed every 50 hours when

operating the tractor in below freezing temperatures.

Intermittent engine operation and idling should be

kept to a minimum' in cold weather to avoid dilution

of the oil. Low temperature operation promotes

sludging which can plug oil passages and cause the

formation of corrosive acids which result in rapid

engine wear. Run the engine until the oil is at normal

operating temperature prior to draining the oil. Re-

move the drain plug and allow the oil to drain for at

least 10 minutes.

The oil filter element, located in filter canister on

left side of the engine (Fig. F02), should be changed

at the same time as the oil. Always use new gaskets

when reinstalling the filter canister and tighten re-

taining bolt to 20-25 ft.-lbs. (27-34 N.m) torque. Do

not overtighten as canister may be distorted, result-

ing in oil leakage.

Crankcase oil capacity is 6 quarts (5.7 L) with a

filter change. Select a good quality oil with SAE

viscosity grade suitable for the ambient temperature.

In the summer, consider the highest expected tem-

perature. In the winter, the oil must be thin enough

to permit easy starting.

Transmission, Differentiai and

Hydraulic Oii

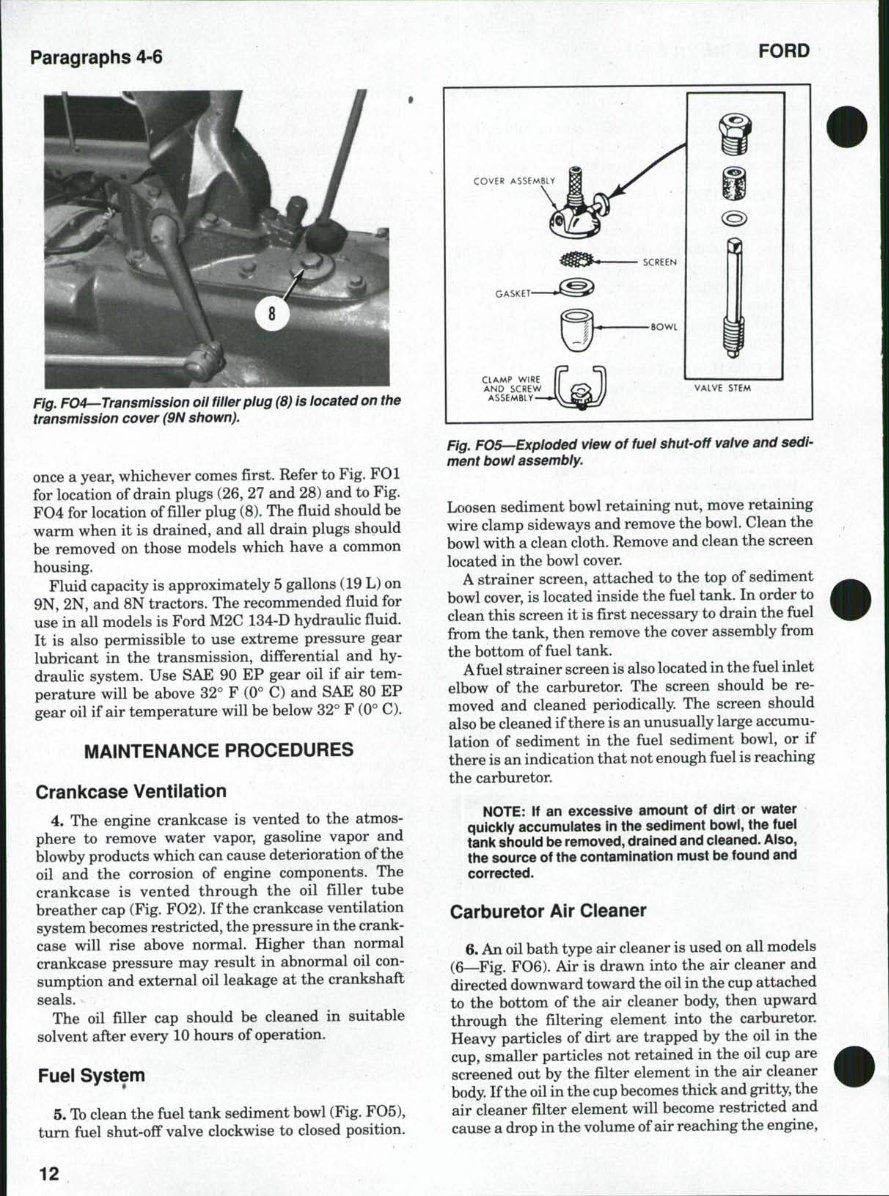

3. On 9N, 2N and 8N tractors, the transmission and

differential housings serve as a common sump for the

lubricating and hydraulic system fiuid. The fiuid

level is checked by removing the level check plug

located on the lower right side of the transmission

housing on some early models, or by a dipstick located

in the inspection plate on right side of differential

housing on later models (Fig. F03).

On all models, the lubricating and hydraulic fiuid

should be changed every 600 hours of operation or

Fig. FO2—View of ieft side of 8N engine.

Fig. FO3—A dipstick, iocated in inspection cover, is used

to checii transmission oii ievei.

11

Paragraphs 4-6

FORD

Fig. F04—Transmission oil filler piug (8) is located on the

transmission cover (9N shown).

once a year, whichever comes first. Refer to Fig. FOl

for location of drain plugs (26, 27 and 28) and to Fig.

F04 for location offillerplug (8). The fiuid should be

warm when it is drained, and all drain plugs should

be removed on those models which have a common

housing.

Fluid capacity is approximately 5 gallons (19 L) on

9N, 2N, and 8N tractors. The recommended fiuid for

use in all models is Ford M2C 134-D hydraulic fiuid.

It is also permissible to use extreme pressure gear

lubricant in the transmission, differential and hy-

draulic system. Use SAE 90 EP gear oil if air tem-

perature will be above 32° F (0° C) and SAE 80 EP

gear oil if air temperature will be below 32° F (0° C).

MAINTENANCE PROCEDURES

Crankcase Ventilation

4. The engine crankcase is vented to the atmos-

phere to remove water vapor, gasoline vapor and

blowby products which can cause deterioration of the

oil and the corrosion of engine components. The

crankcase is vented through the oil filler tube

breather cap (Fig. F02). If the crankcase ventilation

system becomes restricted, the pressure in the crank-

case will rise above normal. Higher than normal

crankcase pressure may result in abnormal oil con-

sumption and external oil leakage at the crankshaft

seals.

The oil filler cap should be cleaned in suitable

solvent after every 10 hours of operation.

Fuei System

5. To clean the fuel tank sediment bowl (Fig. F05),

tum fuel shut-off valve clockwise to closed position.

COVER ASSEMBLY

SCREEN

GASKET-

CLAMP WIRE

AND SCREW

ASSEMBLY

VALVE STEM

Fig. F05—Exploded view of fuei shut-off vaive and sedi-

ment bowl assembly.

Loosen sediment bowl retaining nut, move retaining

wire clamp sideways and remove the bowl. Clean the

bowl with a clean cloth. Remove and clean the screen

located in the bowl cover.

A strainer screen, attached to the top of sediment

bowl cover, is located inside the fuel tank. In order to

clean this screen it is first necessary to drain the fiiel

from the tank, then remove the cover assembly from

the bottom of fuel tank.

Afuel strainer screen is also located in the fuel inlet

elbow of the carburetor. The screen should be re-

moved and cleaned periodically. The screen should

also be cleaned if there is an unusually large accumu-

lation of sediment in the fuel sediment bowl, or if

there is an indication that not enough fuel is reaching

the carburetor.

NOTE: If an excessive amount of dirt or water

quickly accumulates in the sediment bowl, the fuei

tank shouid be removed, drained and cleaned. Also,

the source of the contamination must be found and

corrected.

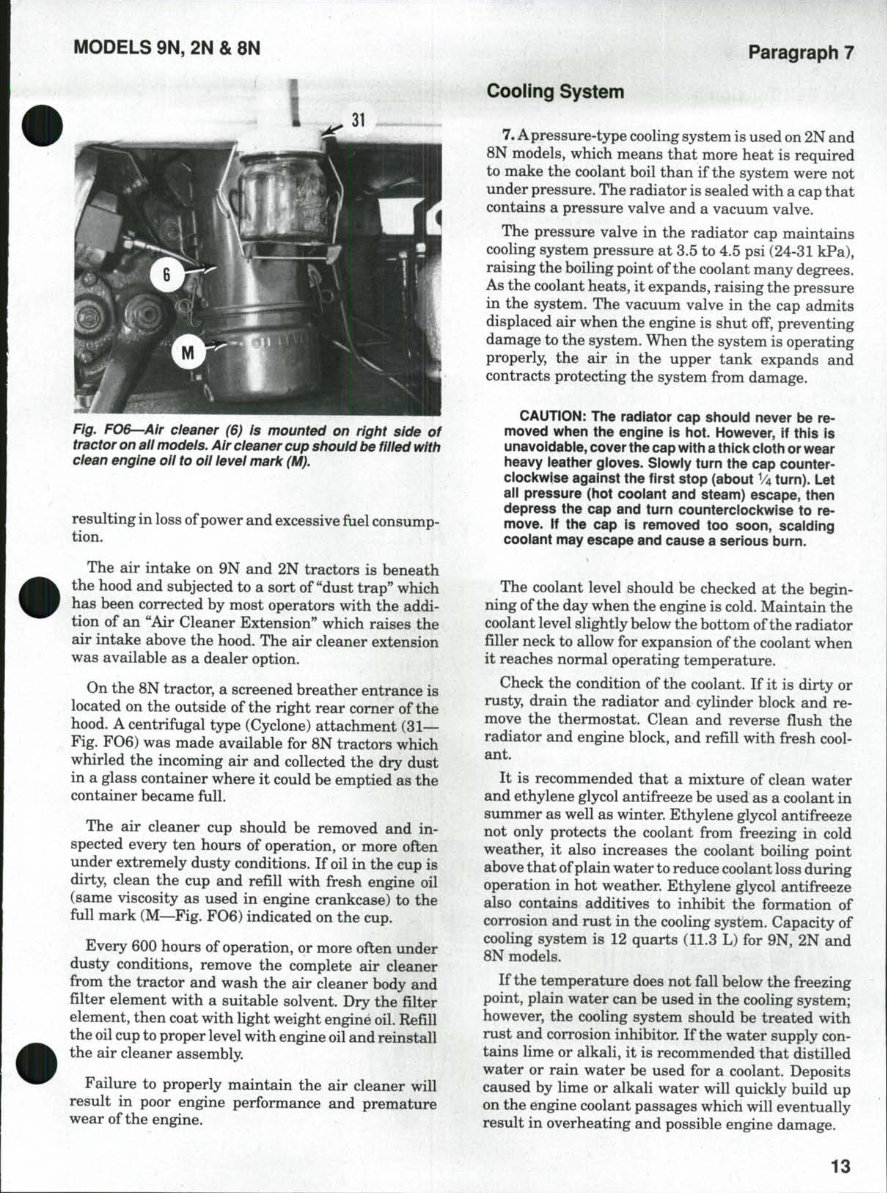

Carburetor Air Cieaner

6. An oil bath type air cleaner is used on all models

(6—Fig. F06). Air is drawn into the air cleaner and

directed downward toward the oil in the cup attached

to the bottom of the air cleaner body, then upward

through the filtering element into the carburetor.

Heavy particles of dirt are trapped by the oil in the

cup, smaller particles not retained in the oil cup are

screened out by the filter element in the air cleaner

body. If the oil in the cup becomes thick and gritty, the

air cleaner filter element will become restricted and

cause a drop in the volume of air reaching the engine.

12

iViODELS 9N, 2N & 8N

Paragraph 7

Fig. FO&-~Air cleaner (6) is mounted on right side of

tractor on ail models. Air cleaner cup shouid be fiiied with

ciean engine oil to oii level marii (M).

resulting in loss of power and excessive fuel consump-

tion.

The air intake on 9N and 2N tractors is beneath

the hood and subjected to a sort of "dust trap" which

has been corrected by most operators with the addi-

tion of an "Air Cleaner Extension" which raises the

air intake above the hood. The air cleaner extension

was available as a dealer option.

On the 8N tractor, a screened breather entrance is

located on the outside of the right rear comer of the

hood. A centrifugal type (Cyclone) attachment (31—

Fig. F06) was made available for 8N tractors which

whirled the incoming air and collected the dry dust

in a glass container where it could be emptied as the

container became full.

The air cleaner cup should be removed and in-

spected every ten hours of operation, or more often

under extremely dusty conditions. If oil in the cup is

dirty, clean the cup and refill with fresh engine oil

(same viscosity as used in engine crankcase) to the

full mark (M—Fig. F06) indicated on the cup.

Every 600 hours of operation, or more often under

dusty conditions, remove the complete air cleaner

from the tractor and wash the air cleaner body and

filter element with a suitable solvent. Dry the filter

element, then coat with light weight engine oil. Refill

the oil cup to proper level with engine oil and reinstall

the air cleaner assembly.

Failure to properly maintain the air cleaner will

result in poor engine performance and premature

wear of the engine.

Cooiing System

7. A pressure-type cooling system is used on 2N and

8N models, which means that more heat is required

to make the coolant boil than if the system were not

under pressure. The radiator is sealed with a cap that

contains a pressure valve and a vacuum valve.

The pressure valve in the radiator cap maintains

cooHng system pressure at 3.5 to 4.5 psi (24-31 kPa),

raising the boiling point of the coolant many degrees.

As the coolant heats, it expands, raising the pressure

in the system. The vacuum valve in the cap admits

displaced air when the engine is shut off, preventing

damage to the system. When the system is operating

properly, the air in the upper tank expands and

contracts protecting the system from damage.

CAUTiON: The radiator cap shouid never be re-

moved when the engine is hot. However, if this is

unavoidabie, cover the cap with a thick cioth or wear

heavy ieather gioves. Siowiy turn the cap counter-

ciockwise against the first stop (about V4 turn). Let

ail pressure (hot coolant and steam) escape, then

depress the cap and turn counterciockwise to re-

move. If the cap is removed too soon, scalding

coolant may escape and cause a serious burn.

The coolant level should be checked at the begin-

ning of the day when the engine is cold. Maintain the

coolant level slightly below the bottom of the radiator

filler neck to allow for expansion of the coolant when

it reaches normal operating temperature.

Check the condition of the coolant. If it is dirty or

rusty, drain the radiator and cylinder block and re-

move the thermostat. Clean and reverse fiush the

radiator and engine block, and refill with fresh cool-

ant.

It is recommended that a mixture of clean water

and ethylene glycol antifreeze be used as a coolant in

summer as well as winter. Ethylene glycol antifreeze

not only protects the coolant from freezing in cold

weather, it also increases the coolant boiling point

above that of plain water to reduce coolant loss during

operation in hot weather. Ethylene glycol antifreeze

also contains additives to inhibit the formation of

corrosion and rust in the cooling system. Capacity of

cooling system is 12 quarts (11.3 L) for 9N, 2N and

8N models.

If the temperature does not fall below the freezing

point, plain water can be used in the cooling system;

however, the cooling system should be treated with

rust and corrosion inhibitor. If the water supply con-

tains lime or alkali, it is recommended that distilled

water or rain water be used for a coolant. Deposits

caused by lime or alkali water will quickly build up

on the engine coolant passages which will eventually

result in overheating and possible engine damage.

13

Paragraphs 8-9

FORD

Fan Beit Tension

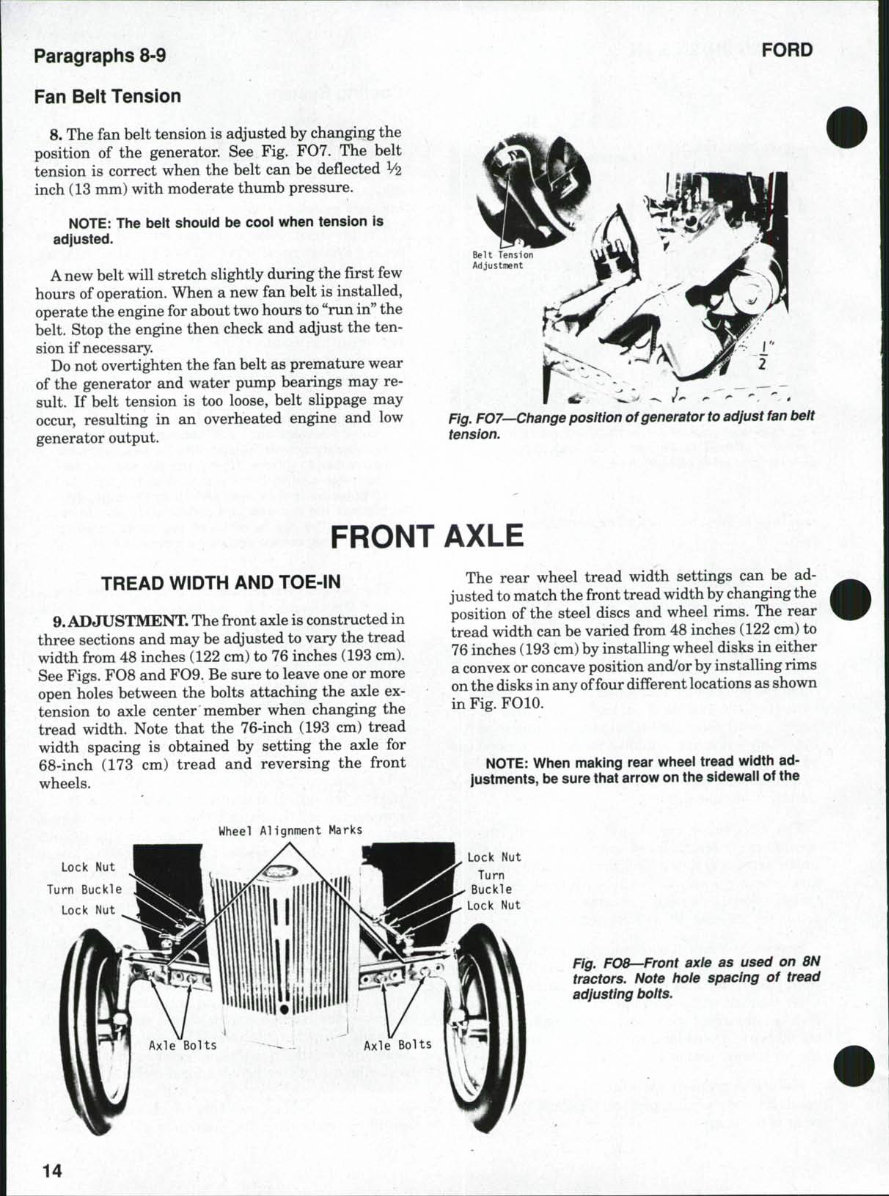

8. The fan belt tension is adjusted by changing the

position of the generator. See Fig. F07. The belt

tension is correct when the belt can be defiected V2

inch (13 mm) with moderate thumb pressure.

NOTE: The belt should be cool when tension is

adjusted.

A new belt will stretch slightly during the first few

hours of operation. When a new fan belt is installed,

operate the engine for about two hours to "run in" the

belt. Stop the engine then check and adjust the ten-

sion if necessary.

Do not overtighten the fan belt as premature wear

of the generator and water pump bearings may re-

sult. If belt tension is too loose, belt slippage may

occur, resulting in an overheated engine and low

generator output.

Fig. FOl—Change position of generator to adjust fan belt

tension.

FRONT AXLE

TREAD WiDTH AND TOE-iN

9. ADJUSTMENT. The front axle is constructed in

three sections and may be adjusted to vary the tread

width from 48 inches (122 cm) to 76 inches (193 cm).

See Figs. F08 and F09. Be sure to leave one or more

open holes between the bolts attaching the axle ex-

tension to axle center member when changing the

tread width. Note that the 76-inch (193 cm) tread

width spacing is obtained by setting the axle for

68-inch (173 cm) tread and reversing the front

wheels. ••?-•..

The rear wheel tread width settings can be ad-

justed to match the front tread width by changing the

position of the steel discs and wheel rims. The rear

tread width can be varied from 48 inches (122 cm) to

76 inches (193 cm) by installing wheel disks in either

a convex or concave position and/or by installing rims

on the disks in any of four different locations as shown

in Fig. FOIO.

NOTE: When making rear wheel tread width ad-

justments, be sure that arrow on the sidewail of the

Wheel Alignment Marks

Lock Nut

Turn Buckle

Lock Nut

Lock Nut

Turn

Buckle

Lock Nut

flg^ FO8—Front axle as used on 8N

tractors. Note hole spacing of tread

adjusting boits.

14

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 18 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

This Service Manual is an essential resource for anyone in need of immediate repair for the 1948-1952 Ford 8N Tractor. It contains comprehensive technical data, diagrams, and a complete list of parts, making it indispensable for professional mechanics and DIY enthusiasts alike.

- Description and Specifications

- Steering Gear

- Transmission

- Hydraulic System

- Rear Axle

- Power Take-off

- Belt Pulley

The manual is available in PDF format, compatible with all versions of Windows and Mac, and is presented in English. It can be easily accessed using Adobe Reader. Whether you take it into the garage or use it for cost-saving DIY repairs, this manual provides step-by-step instructions suitable for all skill levels.