David Brown 885 Tractor Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

dl CASE

BROWN)

MODELS: 885·885N·995-1210·1212·141o.1412

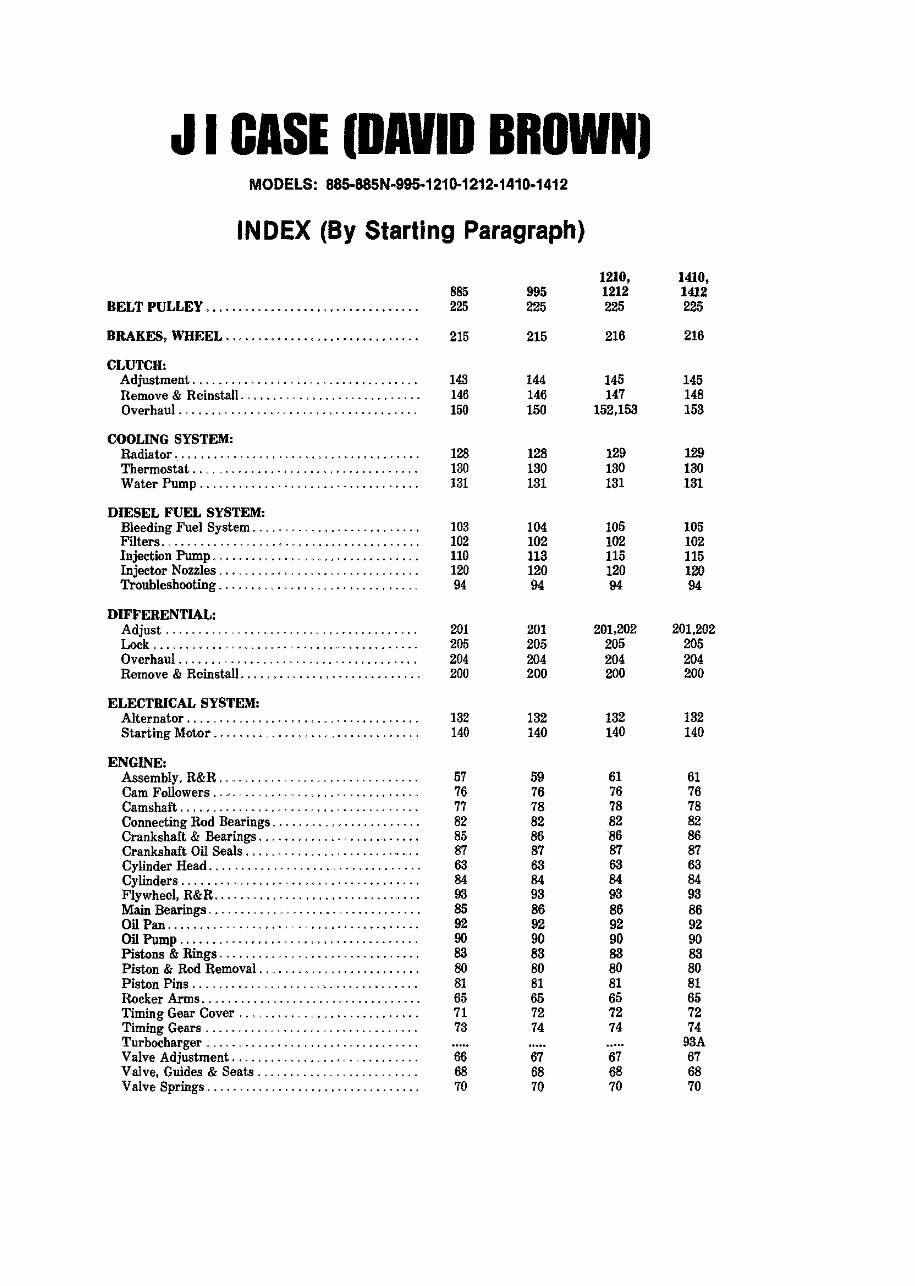

INDEX (By Starting Paragraph)

BELT PULLEY ....................... • .........

BRAKES, WHEEL ............................ ..

CLUTCH:

Adjustment., ..... " ...... ". 0' ••••••••••••••••

Remove & Reinstall . ...... > , •• , ••••••••••••••••

Overhaul . .... , . > ••••••• > •••• < ••••••••••••••••

COOLING SYSTEM:

Radiator ............... , ..... ,., ..... , ... , ... .

Thermostat . ..... " ...... , .................... .

Water Pump . ............ " . > •••••••••••••••••

DIESEL FUEL SYSTEM:

Bleeding Fuel System ......................... .

Filters . ........... , ... , ., .. 0 ••••••••••••••••••

Injection Pump ............................... .

Injector Nozzles. .. ., .. 0 , • ' ••• , • , ••••••••••••

Troubleshooting ............................. .

DIFFERENTIAL:

Adjust ...................................... .

Lock ........................................ .

Overhaul. ................................... .

Remove & Reinstall. > ••••• , " •••• , ••••••••••••••

ELECTRICAL SYSTEM:

Alternator . .... , ...... , ... , , .... , ............ .

Starting Motor .......................... .

ENGINE:

Assemhly. R&R ......................... .

Cam Followers . .. " ........ ", .... " ....... , ..... .

Camshaft .................................... .

Connecting Rod Bearings . ..................... .

Crankshaft & Bearings ........................ .

Crankshaft Oil Seals ...................... '" ..

Cylinder Head ................................ .

Cylinders .................................... .

Flywheel. R&R ............................... .

Main Bearings ................................ .

Oil Pan ...................................... .

Oil Pump .................................... .

Piatons & Rings .............................. .

Piston & Rod Removal. ....................... .

Piston Pins . ....... _ . . .. . ... _ ............... .

Rocker Arms ................................. .

Timing Gear Cover ..... , ....... , ............. .

Timing Gears ......................... " ... " .. .

Turbocharger . ............................ " .. .

Valve Adjustment ............................ .

Valve. Guides & Seats ........................ .

Valve Springs ................................ .

885

225

215

143

146

150

128

130

131

103

102

110

120

94

201

205

204

200

132

140

57

76

77

82

85

87

63

84

93

85

92

90

83

80

81

65

71

73

66

66

70

995

225

215

144

146

150

128

130

131

104

102

113

120

94

201

205

204

200

132

140

59

76

78

82

86

87

63

84

93

86

92

90

63

80

81

65

72

74

67

68

70

1210,

1212

225

216

145

147

152.153

129

130

131

105

102

115

120

94

201.202

205

204

200

132

140

61

76

78

82

86

87

63

84

93

86

92

90

83

80

81

65

72

74

67

68

70

1410,

1412

225

216

145

148

153

129

130

131

105

102

115

120

94

201.202

205

204

200

132

140

61

76

78

82

86

87

63

84

93

86

92

90

83

80

81

65

72

74

93A

67

68

70

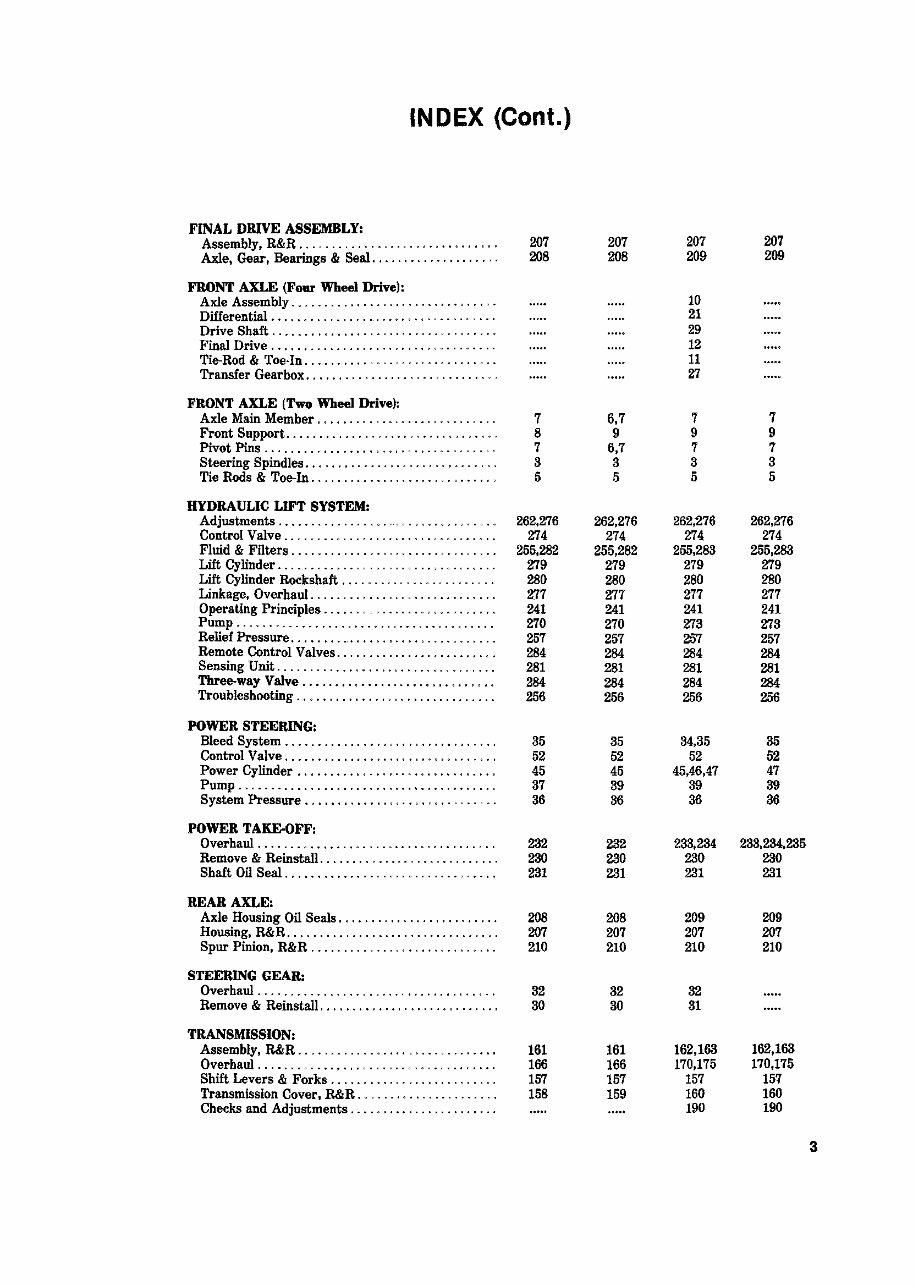

INDEX (Cont.)

FINAL DRIVE ASSEMBLY:

Assembly, R&R .............. . . . . . .. , ......... 207 207 207 207

Axle. Gear, Bearings & Seal .................... 208 208 209 209

FRONT AXLE (Four Wheel Drive):

Axle Assembly ................................ 10

Differential ...................................

21

Drive Shaft ................................... 29

Final Drive . .................... , ... , ......... 12

Tie-Rod & Toe·In .............................. 11

Transfer Gearbox . .... , ... , .... , ............. ' 27

FRONT AXLE (Two Wheel Drive):

Axle Main Member ............................ 7 6,7 7 7

Front Support ................................. 8 9 9 9

Pivot Pins .. , ................. , ... , .......... , 7 6,7 7 7

Steering Spindles . .. , .......................... 3 3 3 3

Tie Rods & Toe-In .................... ........ , 5 5 5 5

HYDRAULIC LIFT SYSTEM:

Adjustments .................................. 262,276 262,276 262,276 262,276

Control Valve ................................. 274 274 274 274

Fluid & Filters ................................ 255,282 255,282 255,283 255,283

Lift Cylinder .................................. 279 279 279 279

Lift Cylinder Rockshaft ........................ 280 280 280 280

Linkage, Overhaul ............................. 277 277 277 277

Operating Principles . ...... , ........ , ........ , . 241 241 241 241

Pump ........................................ 270 270 273 273

Relief Pressure . . , .................... < ••••••••• 257 257 257 257

Remote Control Valves . ........................ 284 284 284 284

Sensing Unit .................................. 281 281 281 281

Three-way Valve .............................. 284 284 284 284

Troubleshooting ............................... 256 256 256 256

POWER STEERING:

Bleed System ................................. 35 35 34,35 35

Control Valve . ..... , ............. , .. 0 ••••• , •• , 52 52 52 52

Power Cylinder . .............................. 45 45 45,46.47 47

Pump ........................................ 37 39 39 39

System Pressure . ................ , . , ...... " ... 36 36 36 36

POWER TAKE-OFF:

Overhaul ..................................... 282 232 233,284 283,234,285

Remove & Reinstall . ........................... 230 230 230 280

Shaft Oil Seal ................................. 231 231 231 231

REAR AXLE:

Axle Housing Oil Seals ......................... 203 208 209 209

Housing, R&R ................................. 207 207 207 207

Spur Pinion, R&R ............. 0 ••••••••••••••• 210 210 210 210

STEERING GEAR:

Overhaul . .............................. , ..... 32 32 32

Remove & Reinstall. ........................... 30 30 31

TRANSMISSION:

Assembly, R&R ............................... 161 161 162,183 162,163

Overhaul ..................................... 166 166 170,175 170,175

Shift Levers & Forks .......................... 157 157 157 157

Transmission Cover. R&R .. .................... 158 159 160 160

Checks and Adjustments ....................... 190 190

3

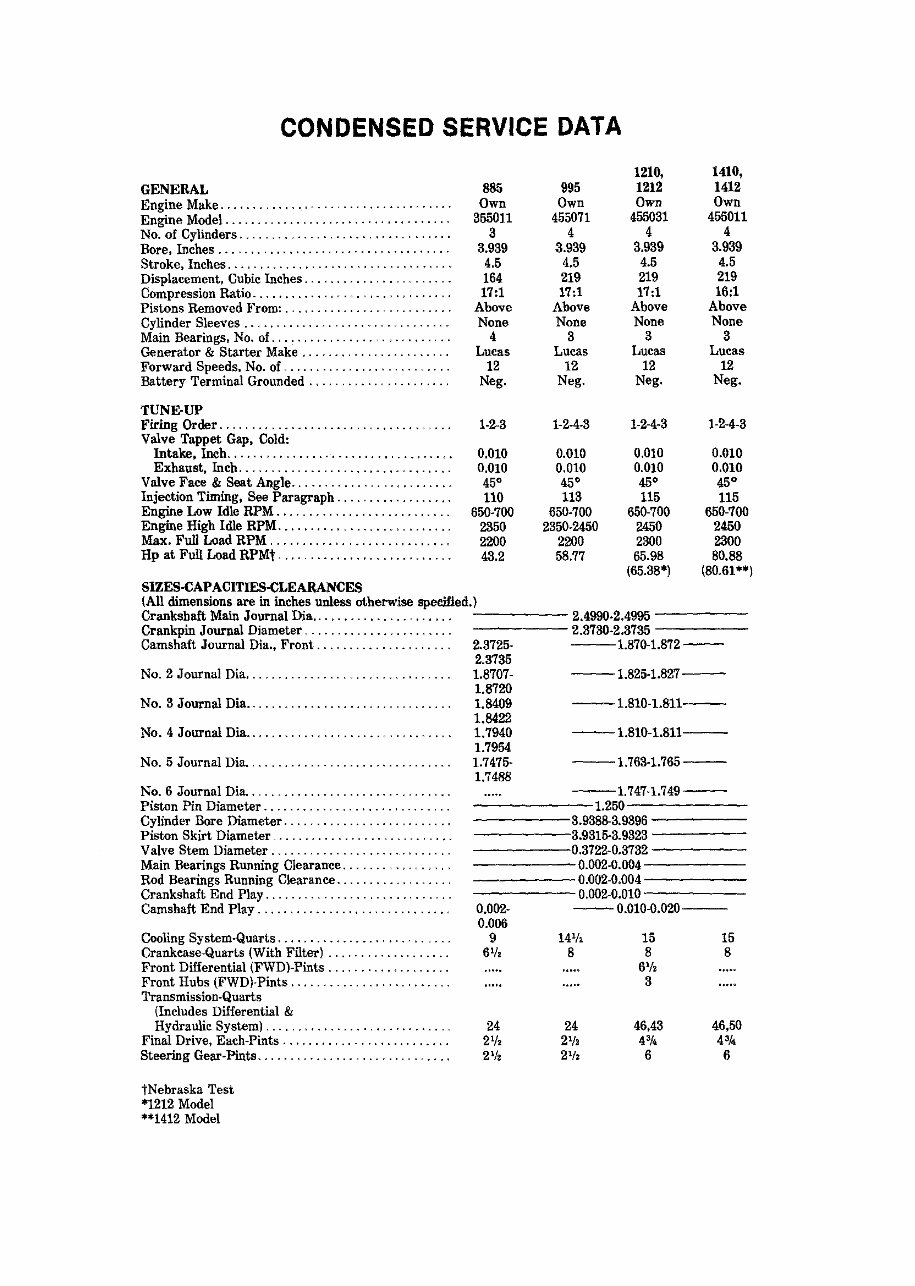

CONDENSED SERVICE DATA

GENERAL

Engine Make .................................. ..

Engine Model. ................................. .

No. of Cylinders .......................... .

Bore, Inches ................................... .

Stroke. Inches .. ... , ............................ .

Displacement. Cubic Inches . ..................... .

Compression Ratio . ................. , ..... , . , ... .

Pistons Removed From: . . . . . . . . . . . . . .. . ........ .

Cylinder Sleeves ............................... .

Main Bearings, No. of . .......................... .

Generator & Starter Make . ......... , ........... .

Forward Speeds, No. of ......................... .

Battery Terminal Grounded. , ............... , ... ,

TUNE-UP

Firing Order ................................... .

Valve Tappet Gap, Cold:

Intake, Inch ................................. ..

Exhaust, Inch ......... ' ...................... .

Valve Face & Seat Angle ....................... ..

Injection Timing, See Paragraph ................. .

Engine Low Idle RPM .......................... .

Engine High Idle RPM .......................... .

Max. Full Load RPM ........................... .

Hp at Full Load RPMt ......................... ..

SIZES-CAPACITIES·CLEARANCES

885

Own

355011

3

3.939

4.5

164

17:1

Above

None

4

Lucas

12

Neg.

1·2-3

0.010

0.010

45·

110

650·700

2350

2200

43.2

995

Own

455071

4

3.939

4.5

219

17:1

Above

None

3

Lucas

12

Neg.

1-2·4-3

0.010

0.010

45·

113

650·700

2350·2450

2200

58.77

1210,

1212

Own

455031

4

3.939

4.5

219

17:1

Above

None

3

Lucas

12

Neg.

1·2·4·3

0.010

0.010

45·

115

650·700

2450

2300

65.98

(65.38*)

1410,

1412

Own

455011

4

3.939

4.5

219

16:1

Above

None

3

Lucas

12

Neg.

1·2·4·3

0.010

0.010

45·

115

650·700

2450

2300

80.88

(80.61'*)

(All dimensions are in inches unless otherwise specified.)

Crankshaft Main Journal Dia ................... ... ------2.4990·2.4995 ------

Crankpin Journal Diameter ........... " . . ... . .. . . 2.3730·2.3735 -----

Camshaft Journal Dia., Front ........... .......... 2.3725· ---1.870·1.872--

No.2 Journal Dia . ..... , ........ , .... , ...... .

No.3 Journal Dia ............................... .

No.4 Journal Dia ............................... .

No. 5 Journal Dia .. .... , ....................... _ ,

No.6 Journal Dia .. ... _ ................. _

Piston Pin Diameter .......... ... ' . , ....... , . _ .. .

Cylinder Bore Diameter .. ....................... .

Piston Skirt Diameter _ ...................... .

Valve Stem Diameter . ................. , ........ .

Main Bearings Running Clearance . ...... , .. .

Rod Bearings Running Clearance . ................ ,

Crankshaft End Play ............................ .

Camshaft End Play ............................ ..

Cooling System-Quarts . ......................... .

Crankcase-Quarts (With Filter) .................. .

Front Differential (FWD)·Pints .................. .

Front Hubs (FWD)·Pints .... '" ......... " ...... .

Transmission-Quarts

(Includes Differential &

Hydraulic System) ............................ .

Final Drive, Each-Pints . ........................ .

Steering Gear· Pints ....................... .

tNebraska Test

'1212 Model

**1412 Model

2.3735

1.8707· --1.825-1.827--

1.8720

1.8409

1.8422

1.7940

1.7954

1.7475-

1.7488

--1.810·1.811--

--1.810·1.811--

--1.763·1.765--

--1.747·1.749--

------1.250

-----3.93883.9396 -----

-----:3.9315-3.9323 -----

-----10.3722-0.3732 -----

-----0.002·0.004-----

=====0.002-0.004-----

0.002·0.010 -----

-- 0.010·0.020-- 0.002·

0.006

9

6

1

1z

46,43

4'1<

6

15

8

885-995-1210-1212-1410-1412

Paragraphs 1-4

FRONT AXLE (TWO WHEEL DRIVE)

FRONT WHEEL BEARINGS

All Models Except 88SN

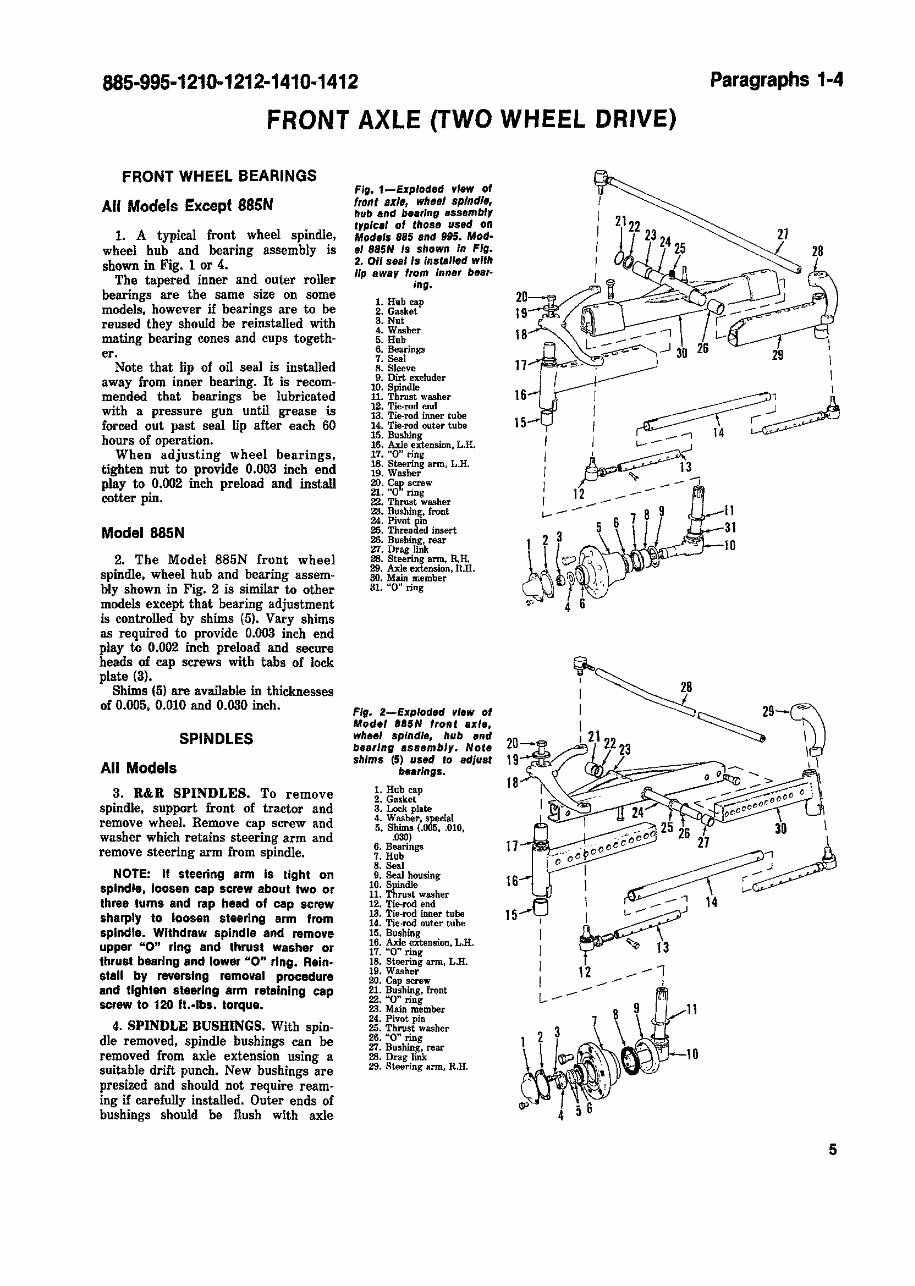

1. A typical front wheel spindle,

wheel hub and bearing assembly is

shown in Fig. 1 or 4.

The tapered inner and outer roller

bearings are the same size on some

models. however if bearings are to be

reused they should be reinstalled with

mating bearing cones and cups togeth-

er.

Note that lip of oil seal is installed

away from inner bearing. It is recom-

mended that bearings be lubricated

with a pressure gun until grease is

forced out past seal lip after each 60

hours of operation.

When adjusting wheel bearings.

tighten nut to provide 0.003 inch end

play to 0.002 inch preload and install

cotter pin.

Model8S5N

2. The Model 885N front wheel

spindle. wheel hub and bearing assem-

bly shown in Fig. 2 is similar to other

models except that bearing adjustment

is controlled by shims (5). Vary shims

as required to provide 0.003 inch end

play to 0.002 inch preload and secore

heads of cap screws with tabs of leek

plate (3).

Shims (5) are available in thicknesses

of 0.005, 0.010 and 0.030 inch.

SPINDLES

All Models

3. R&R SPINDLES. To remove

spindle. support front of tractor and

remove wheel. Remove cap screw and

washer which retains steering arm and

remove steering arm from spindle.

NOTE: If steering arm Is tight on

spindle, loosen cap screw about two or

three turns and rap head of cap screw

sharply to loosen steering arm from

spindle. Withdraw spindle and remove

upper "0" ring and thrust washer or

thrust bearing and lower "0" ring. Reinm

stall by reversing removal procedure

and tighten steering arm retaining cap

screw to 120 ft.-Ibs. torque.

4. SPINDLE BUSIIINGS. With spin-

dle removed, spindle bushings can be

removed from axle extension using a

suitable drift punch. New bushings are

presized and should not require ream-

ing if carefully installed. Outer ends of

bushings should be flush with axle

Fig. 1-Exploded ,"lew of

front axlll wheel spIn dis.

hub and bearing assembl,

typlca' of those used on

Models 885 and 995. Mod·

e' ,85H 'S shown In Fig.

2. Oil sea' Is installed with

lip away from Inner blte,-

ing.

1. Hub cap

2. Gasket

3. Nut

4. Washer

5. Hub

6. Bearingll

7. Seal

8. Sleeve

9. Dirt excluder

i~: ~h:~ washer

12. Tie·rod end

13. Tie·rod inner tube

14. Tie·rod outer tube

15. Bushing

16. Axle extension, L.R.

17. "0" ring

18. Steering ann, L.H.

19. Washer

20. ~ screw

21. "'0' ring

22. Thrust washer

23. Bushin~. front

~: ~v:!S!d insert

26. Busbing, rear

Zl. Drag link

28. Steering arm, R.R.

29. Axle enension. R.H.

30. Main member

31. "0" ring

Fig. 2-Exploded vIew of

Model ,aSH 'ront axle,

WhH' spindle, hub end

bea"ng assembly. Note

shims (5) used to adjust

beallngs.

1. Hub cap

2. Gasket

3. Lock plate

4. Washer. special

5. Shima (.005, .010,

.030)

6. Bearings

7. Hub

8. Sea]

9. Seal housing

10. Spindle

11. Thrust washer

12. Tie-rod end

13. Tie-rod inner tube

14. Tie·rod outer tube

15. Bushing

16. Axle extension, L.R.

17. "0" ring

18. Steering arm, LB.

19. Washer

20. Cap screw

21. Bushing, front

22. "'0" ring

23. Main member

24. Pivot pin

25. Thrust washer

26. ''0'' ring

27. Bushing, rear

28. Drag link

29. Steering arm, R.H.

I

I 2122

I J.J 23

24

I 25

I I

20~1~

19

18 _-"'

L-:-=- ..J 30

17 - ~- ,

21

29

I

I

I

16

15

I

~' I

I ~4 =:~

I I c.---

, ~

I

I

I

I

~~ 13

IF ,. ---"'

c.---

6

789 11

5 31

1 2 3 ~~~::::'J-IO

~~l~~.

~. 4 6

20

19-"'''/

18

I . " . 25 26 30 I

(:-;0

00

' 27 \

::ooro~~

IV? l~J 14

I r-"" 1'3

I 12 _-1

I _ ,

l----

8 9 11

7

1 2 3

<lP 4 56

5

Paragraphs 5-6

extension. Bushings are alike for 8

series and 9 series (with 52·76 inch

width axle) tractors but upper bushing

has a smaller I.D. for 9 series (with

56-80 inch width axle), 12 series and 14

series tractors.

TIE-RODS AND TOE-IN

All Models

5. Toe-in of front wheels should be

l/16-l/S-inch and can be adjusted by

lengthening or shortening the tie-rod.

Adjust tie-rod ends an equal amount.

Tie-rod ends are available as a unit

only.

AXLE MAIN MEMBER AND

PIVOT PIN

All Models

6. On early 995 (prior ser. no.

934315) \.ractors it is necessary to split

tractor between front support and main

frame using the following procedure:

Remove hood and drain cooling system.

Disconnect radiator hoses. battery

cable and air cleaner hose at rear side

of radiator. Disconnect drag link

(manual steering) or steering ram

(power steering) from steering arm.

Support traetor under main frame and

attach a hoist to Iront unit. Unbolt

Iront support Irom main frame and roll

assembly away from tractor.

Loosen the pivot pin retaining cap

screw about five turns, rap on head of

cap screw to dislodge threaded insert,

then remove cap screw and threaded

insert. Attach a slide hammer, pull

pivot pin rearward from front support

and front axle. then raise front support

until it clears axle assembly. Remove

the thrust washers and sealing "0"

rings.

The two rear bushings (B-Fig. 5) may

be removed with suitable driver. To

remove the two front bushings from

blind hole. use a cape chisel and pliers.

Drive new forward front bushing into

blind hole until it bottoms or is forward

of lubrication hole. then drive second

front bushing in flush with support

casting. Drive rear bushings into sup·

port from each side until bushings are

flush with support casting. Bushings

are pre·sized and should not require

reaming if carefully installed. Be sure

pivot pin is a free fit in bushings before

reinstalling front axle to front support.

The axle front to rear float in front

support should be 0.002-0.014 inch.

Renew pivot thrust washers if front to

rear float is excessive.

When rejoining front support to main

frame, tighten bolts to 45 ft.-lbs.

torque.

6

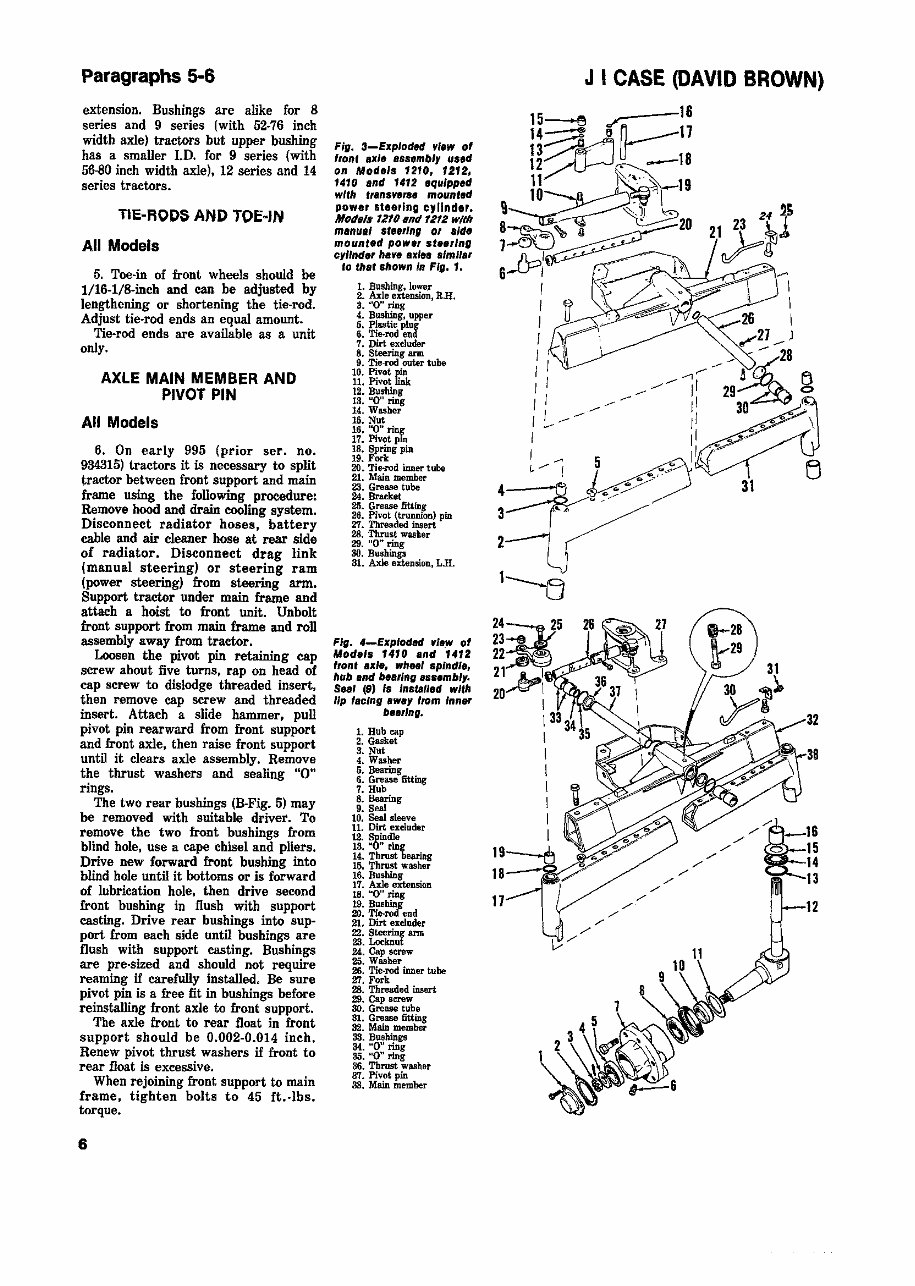

Fig. 3-Exploded ~,.w of

front Ix'e 8ssemb'y used

on Models 1210. 1212,

1410 and 1412 equipped

with transverse mounted

powe, Iteerlng cylinder.

Mqd.'9 1210 and 1212 with

manua' st •• rlng 01 .,de

mounted powel steelInG

cylinder ha~e alde• • Imllar

10 that shown In FIG. 1.

1. Bushing, lower

2. Axle extension, RH.

a. "0" ring

4.. Bushing, upper

6. Plastic plug

6. Tie-rod end

7. Dirt excluder

8. Steering ann

9. Tie-.rod outer tube

10. Pivot pin

11. Pivot link

12. Bushing

13. uO" ring

14.. Washer

15. Nut

16. "0" ~

17. Pivot pm

18. ~ring pin

19. Fork

20. Tie-rod inner tube

21. Main member

23. Grease tube

24. Bracket

25. Grease fitting

26. Pivot (trunnion) pin

27. Threaded insert

28. Thrust washer

29. "0" ring

30. Bushings

31. Axle extension, LlI.

Fig. 4-Exploded ~I._w of

Models 1410 and 1412

fronfaxle, wheel spindle,

hub and bearing assembly.

Sea' (9) #s Insfalled with

lip 'acIng awey 110m Inner

be.,lng.

1. Hub cap

2. Gasket

3. Nut

4. Washer

5. Bearing

6. Grease fitting

7. Hub

8. Bearing

9. Seal

10. Seal sleeve

11. Dirt excluder

12. Spindle

13. "0" rin

14.. Thrust tearing

15, Thrust washer

16. Bushing

17. Axle extension

18. "0" ring

19. B~hin.

20. Tie-rod end

21. Dirt excluder

22. Steering ann

23. Loeimut

24.. Cap serew

25. Washer

26. Tie-rod inner tube

2:1. Fork

28. Threaded insert

29. Cap serew

SO. Grease tube

81. Grease fitting

32. Main member

38. Bushings

34. "0" ring

35. "0" ring

36. Thrust washer

37. Pivot pin

as. Main member

\//'

J I CASE (DAVID BROWN)

/'

/'

,/

/'

/'

/'

/'

/'

/'

/'

/'

/'

32

38

/'

885-995-1210-1212-1410-1412

Paragraphs 7-12

7. On alI models except early 995, reo

move axle main member as follows:

Disconnect drag link, or side mounted

steering ram from left steering arm; or

on models with transverse steering

rams, disconnect steering pipes at rear

of axle and place a suitable container

under pipe ends. Loosen cap screw

retaining pivot pin about five turns.

rap head of cap screw to dislodge

threaded insert, then remove cap screw

and threaded insert. Remove expansion

plug from front support casting and

remove pivot pin with slide hammer

threaded into front end of pivot pin.

Remove old bushings and install new

bushings using a suitable driver. New

bushings are pre-sized and should not

require reaming if carefully installed.

Bushings in some models are different

lengths and bushing location should be

noted during removal and installation.

Renew sealing "0" rings. thrust wash-

ers and expansion plug during reassem-

bly.

FRONT SUPPORT

Models 885, 88SN

8. The front support is an integral

part of the main frame casting. To

renew the main frame. first remove

engine as outlined in paragraph 57.

Remove air cleaner and support assem·

bly, battery and battery tray. Remove

front axle pivot pin as outlined in

paragraph 7. then unbolt and remove

main frame from transmission housing.

When reassembling. tighten main

frame to transmission bolts to a torque

of 45 ft.-lbs.

All Models Except 885, 88SN

9. To renew the front support

casting. proceed as outlined in para·

graph 6 and also remove radiator. air

cleaner, battery and battery tray and,

on models so equipped. remove front

mounted hydraulic pump and bracket

assembly.

FRONT AXLE

(FOUR WHEEL

DRIVE)

Model 1210 tractors are available

with a front drive axle which is driven

from the transmission bevel pinion

shaft via a transfer case and a drive

shaft. A shifting mechanism in the

transfer ease allows connecting or

disconnecting power to the front axle

as required.

Front wheel toe·in on tractors

equipped with the front drive axle

should be 0 to 3/64 inch.

FRONT AXLE ASSEMBLY

Model 1210

10. R&R FRONT AXLE. The four

wheel drive front axle can be serv.iced

without removing it from tractor.

However. if removal is required. pro-

ceed as follows:

Disconnect steering ram from left

steering arm and axle housing and

secure to main frame. DisConnect drive

shaft from flange of differential. Loosen

pivot pin retaining cap screw about five

turns, rap head of cap screw to

dislodge threaded insert (lB-Fig. 6),

then remove cap screw and insert.

Attach hoist to front of tractor and

take weight off tractor. Place a rolling

floor jack under front axie to prevent it

from tipping and remove pivot pin.

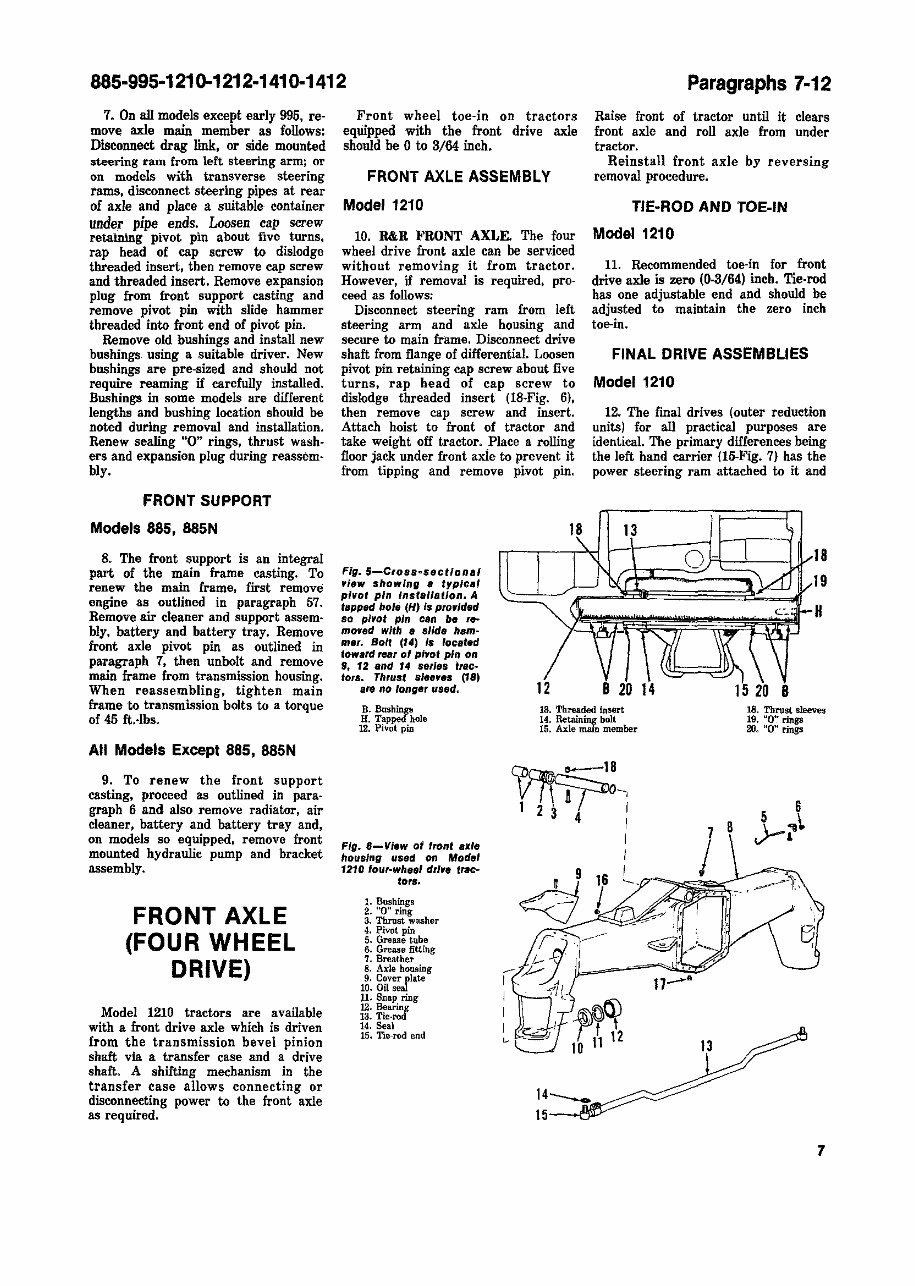

Fig.5-Crossa$ectional

If/ew showing e typlca'

pivot pin Installation. A

tapped hole (H) is prodded

so pivot pin can be re--

moved with a slide ham-

mer. Bolt (14) Is located

toward rear of pivot pin on

9, 12 and 14 series trac-

tors. Thrust sleeves (18)

al'8 no longer used.

18

Raise front of tractor until it clears

front axle and roll axle from under

tractor.

Reinstall front axle by reversing

removal procedure.

TIE-ROD AND TOE-IN

Model 1210

11. Recommended toe-in for front

drive axle is zero (0·3/64) inch. Tie·rod

has one adjustable end and should be

adjusted to maintain the zero inch

toe-in.

FINAL DRIVE ASSEMBLIES

Model 1210

12. The final drives (outer reduction

units) for all practical purposes are

identical. The primary differences being

the left hand carrier (1S-Fig. 7) has the

power steering ram attached to it and

13

o - 18

19

H

B 20 14

15 20 B

B. Bushings 13. Threaded insert 18. Thrust sleeves

H. Tapped hole

12. Pivot pin

Fill. 6-View at front ax'e

housing used on Model

1210 four-wheel drive t,..c~

tors.

1. Bushings

2. "0" ring

3. Thrust washer

4. Pivot pin

5. Grease tube

6. Grease fitting

7. Breather

8. Axle housing

9. Cover plate

10. Oil seal

11. Snap ring

~:~e~l

14. Seal

15. Tie-rod end

14. Retaining bolt

15. Axle main member

14---..

15

19. ~O" rings

20. "0" rings

7

Paragraphs 13·15

the right hand axle shaft is shorter

than the left hand axle shaft.

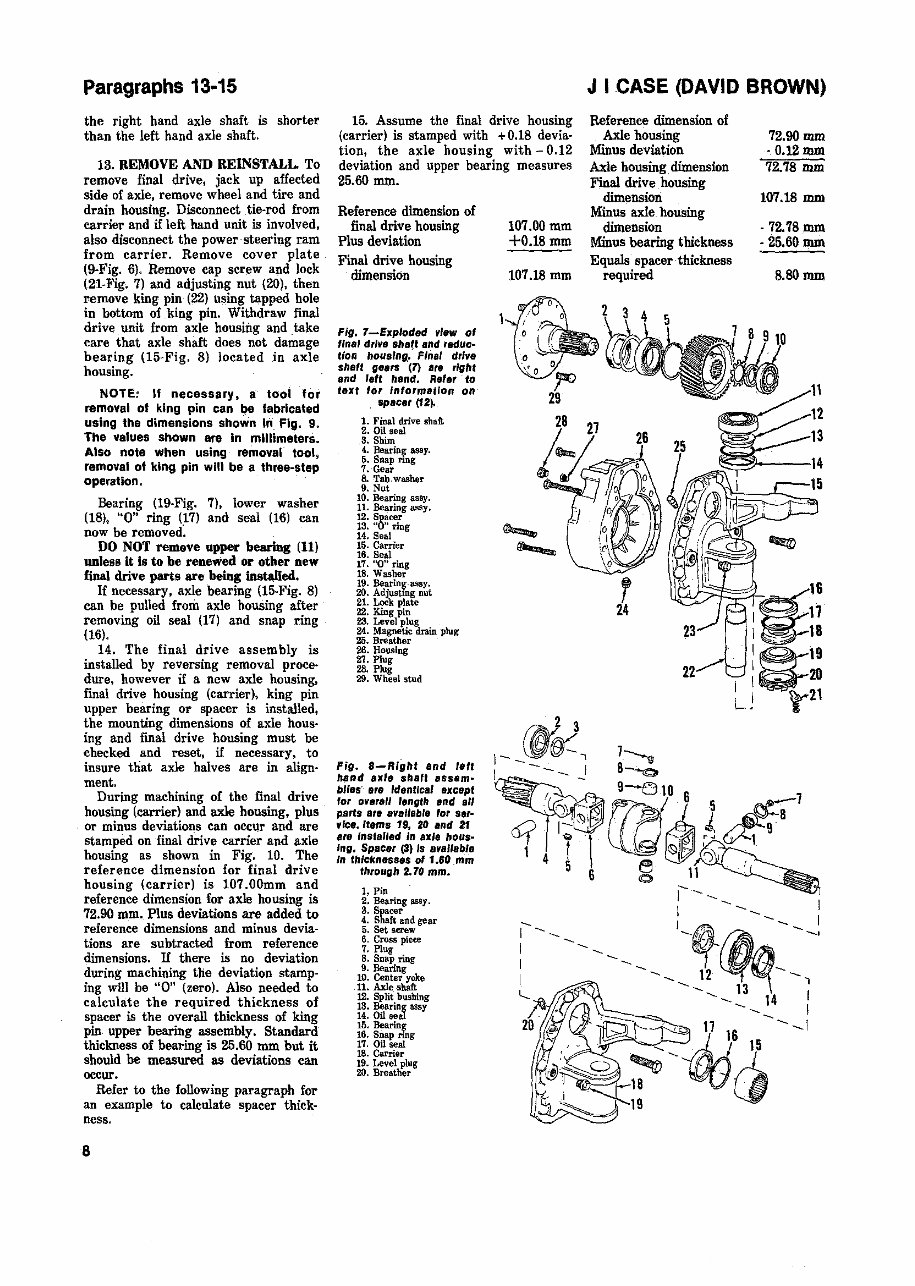

13. REMOVE AND REINSTALL. To

remOVe final drive, jack up affected

side of axle, remove wheel and tire and

drain housing. Disconnect tie·rod from

carrier and if left band unit is involved.

also disconnect the power' steering ram

from carrier. Remove cover plate

(9-Fig. 6). Remove cap screw and lock

(21.Fig. 7) and adjusting nut (20), then

remove king pin (22) using tapped hole

in bottom of king pin. Withdraw final

drive, unit from axle housing and take

care that axle shaft does not damage

bearing (15·Fig. 8) located in axle

housing.

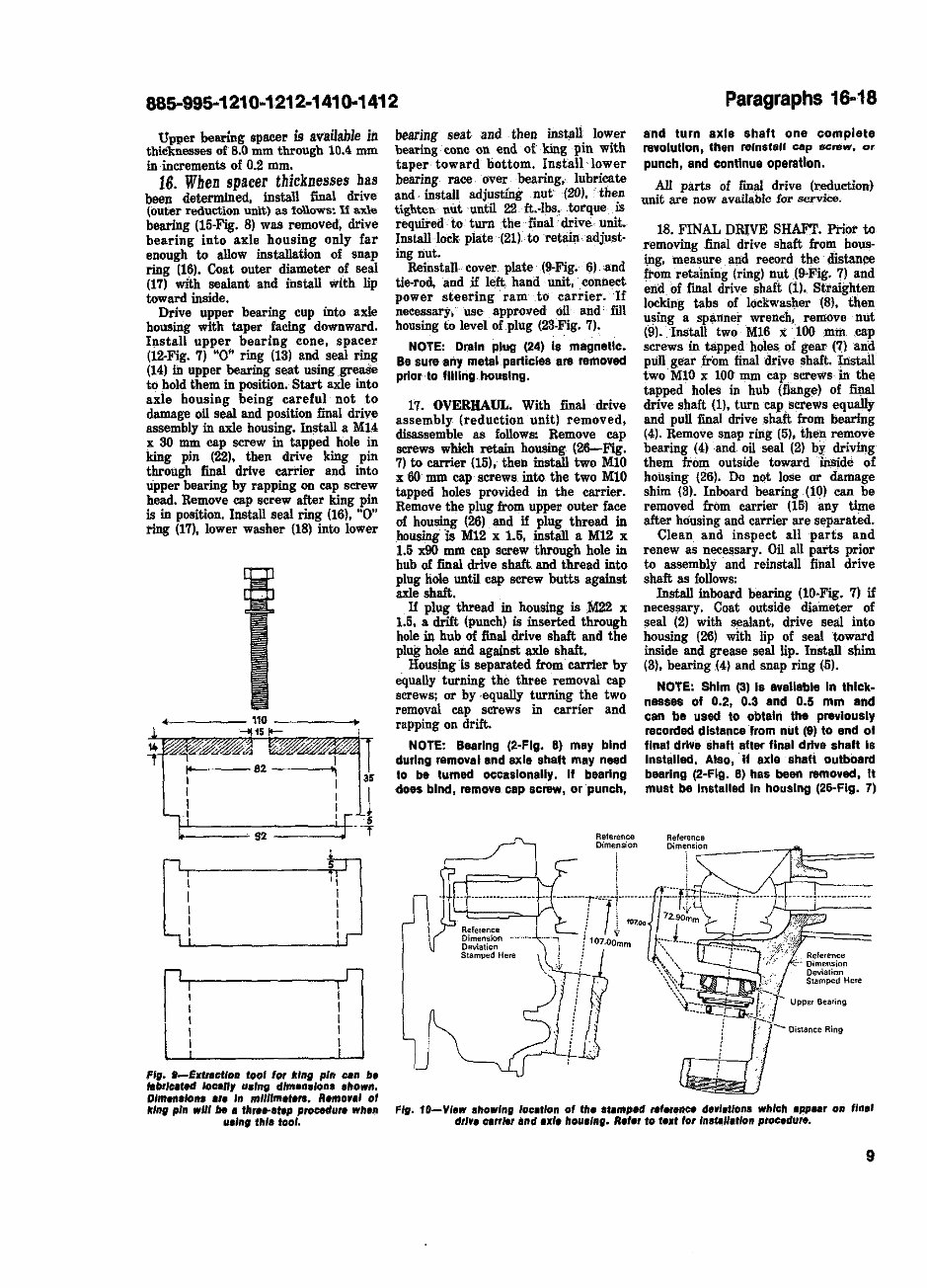

NOTE: If necessary. s- tool for

removal at king pin can I)e fabricated

using the dimensions shown in, Fig. 9.

The values shown are in millimeters.

Also note when using removar tool,

removal of king pin will be a three-step

operation.

Bearing (19-Fig. 7), lower washer

(18), "0" ring (17) and seal (16) can

now be removed.

DO NOT remove upper beariDg (11)

unless it is to be renewed or other new

!inal drive parts are being insWIed.

If necessary, axle hearing (15·Fig. 8)

can be pulled from axle housing after

removing oil seal (17) and snap ring

(16).

14. The final drive assembly is

installed by reversing removal proce·

dure. however if a new axle housing.

final drive housing (carrier), king pin

upper bearing or spacer is installed,

the mounting dimensions of axle hOlls·

ing and final drive honsing must be

ehecked and reset, if necessary. to

insure that axle halves are in align·

ment.

During machining of the final drive

housing (carrier) and axle housing, plus

or minus deviations can occQr and are

stamped on final drive carrier and axle

housing as shown in Fig. 10. The

reference dimension for final drive

housing (carrier) is 107.00mm and

reference dimension for axle housing is

72.90 mm. Plus deviations are added to

reference dimensions and minus devia-

tions are subtracted from reference

dimensions. If there is no deviation

during machining the deviation stamp·

ing will be "0" (zero). Also needed to

calculate the required thickness of

spacer is the overall thickness of king

pin upper bearing assembly. Standard

thickness of bearing is 25.60 mm but it

should he measured as deviations can

occur.

Refer to the following paragraph for

an example to calculate spacer thick-

ness.

8

15. Assume the final drive housing

(carrier) is stamped with + 0.18 devia-

tiOD, the axle housing with - 0.12

deviation and upper bearing measures

25.60 mm.

Reference dimension of

final drive housing

Plus deviation

Final drive housing

dimension

Fig. 7-Exploded view of

"nal drIve shatt and reduc·

lion housIng,' Final drive

shefl gears (7) are right

and leff hand. Re'.r to

text for Information on

spacer (12),

1. Final drive shaft

2. Oil seal

S. Shim

4. BelLrin~ aslIy.

5. Snap rmg

7. Gear

8. Tab, washer

9. Nut

10. Bearing assy.

11. Bejl,ring assy.

12. Spacer

13. "0" ring

14. Seal

15. Carrier

16. Seal

17. "0" ring

18. Washer

111. Bearln~-assy.

20. Adjusting nut

21. Lock plate

22. King pin

23. Level plug

24. Magnetic drain plug

25. Breather

26. Housing

21. Plug

28. Plug

29. Wheel stud

Fig. a-Right and letl

hand axle shari Bss.m~

bliss' Ite Identical except

for 0'l8,all length and all

parts are avallabl, 'or ser-

"le •• Itams 19, 20 end 2f

ere fnstalled In axle hous-

Ing. Spacer (3) Is available

In thlckness.s 01 1.60 mm

through 2. 70 mm.

1. Pin

2. Bearing assy.

3. Spacer

4. Shaft and gear

5. Set screw

6. Cross piece

7. Plug

8. Snap ring

9. Bearing

10. Center yoke

11. Axle slWt

12. Split bushing

13. Bearing assy

14. Oil seal

15. Bearin$

16. Snap nng

17. Oil seal

18. Carrier

19. Level plug

20. Breather

107.00 mm

+0.18mm

107.18 mm

J I CASE (DAVID BROWN)

Reference dimension of

Axle housing

Minus deviation

Axle housing dimension

Final drive housing

dimension

Minus axle housing

dimension

Minus hearing thickness

Equals spacer thickness

required

72.90mm

·O.12mm

72.78 mm

107.18 mm

. 72.78mm

·25.60 mm

8.80mm

g

16

I ~ 17

I ~ 18

1~19

1~20

U t'21

paragraph$ 19-20

ptlor 10 Inslalllng linal drive shalt gear

(7).

Position final drive shaft with wheel

studs down and block under shaft so

wheel studs are not touching. Place

housing (26). over final drive shaft.

Heat.gear (7) to about 100 degrees F,.

start gear on. splines of final drive

shalt. then press or drive. gear and

housing on final drive shaft. Install

loekwasher (8) and nut (9) and tighten

nut securely. Distance from nut to end

of shaft should he the same as that

recorded prior to disassembly. ,about 3

mm (l/8'in.) of final drive shaft thread

should be, exposed with nut tightened.

Retain nut by bending tabs of lock·

washer __ into slots in nut and gear~

. Refer to paragraph 20 for informa·

tion to join housing to carrier.

19. AXLE SHAFT. To remove axle

shaft from carrier, support. carrier and

axle -shaft a_nd drive bearing co,:te

(l,S-Fig. 8)· into carrier far enough to

allow removal of split bushing (12). Use

a soft faced hammer and drive axle

shaft out of hearing and carrier. Seal

(14) and he'l'"ing cup (13) can now be

removed from carrier. Outboard bear

c

ing assembly (2) cannot be removed

unless final drive shaft gear (7-Fig.7)

has heen removed. Spacer (3) should

have been retrieved when housing and

Carrier were separa~

NOTE: Tho axle universal Jolnl can

be ellsalsembled 8& 'oIlOVlS: Remove

snap rings (8·Flg. 8) and pull needle

bearings (9). Tip cro •• plocas (6) oul 01

center yoke (10), remove sa' screws (5),

then remove pins (1) and sallarate axle

halves from cross pieces.

It 135 ---- .... ,

I :- 70------l

fl,. 11-A "old'", cl.mp ca_" N """",.

loc.,,,·to- p~ .. ltt-.x_" ,moqm.iU dUrI"• ...

, .""bl,. Dlm.ii.'on• • r. In mUllm.r.,..

1,0

Clean and inspect all parts and

renew as necessary. Install axle shaft

in carrier as follows: Coat outside

diameter of seal 114) with sealant and

install in carrier (18) with lip toward

inside. Gre ... lip of seal. DriVe hearing

C1;lP into carrier with taper faCing in,

then insert gear end of axle through oil

seal and bearing cup. Hold axle

in- position and drive bearing cone on

axle shaft until the split bushing can be

installed with flat side up. Use a soft

faced hammer and bump end of axle

shaft until axle shaft gear seats on split

bushing.

NOTE:Ca .. should ba token alter

axle -Is Installed to prevent damage to

011 seal (14·Flg. 8) by movement 01 oxle

shaft during subsequent assembly. Use

of a clamp, shown In Fig. 11. is

recommended by the manufacturer and

ciampi. Inatollod bslweon carrier and

universal Jolnl. Clamp muat bo labrl·

caled locally and noto that dimensions

are In'mlilimelers.

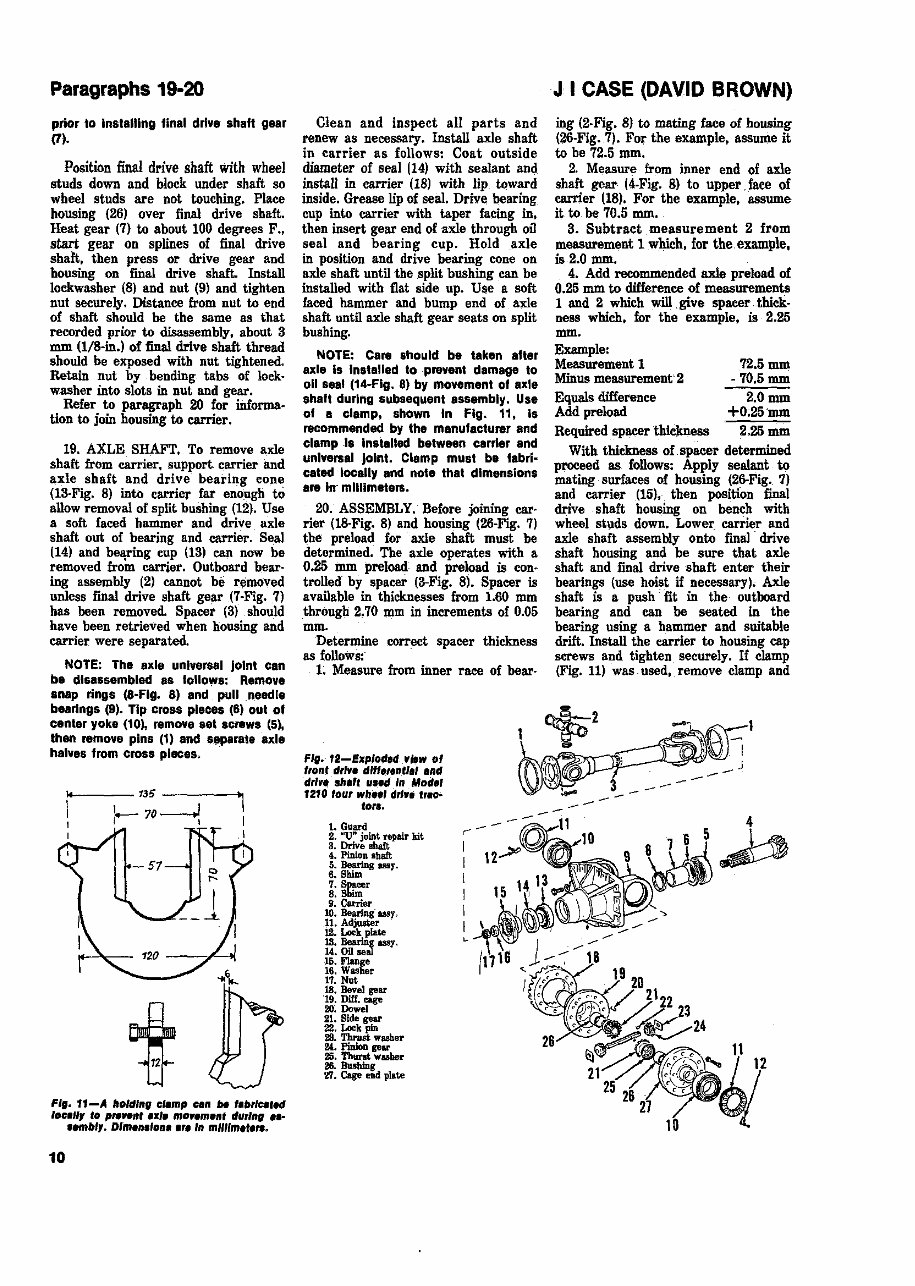

20. ASSEMBLY. Before joining car-

rier (l8'Fig. 8) and housing (26-Fig. 7)

the preload for axle shaft must he

determined. The axle operates with a

0.25 mm preload and preload is con·

trolled by spacer (S-Fig. 8). Spacer is

available in thicknesses from 1.60 mm

through 2.70 mm in increments of 0.05

mID.

Determine correct spacer thi~ess

as follows:

1~ Measure from inner race of bear·

Fig. 12-Exploded "ltw 01

"ont d,I", dln,,,,,u., and

dr'". sh.r, and In Mod.,

1210 'our wh"' drl". t,.c>-

to".

1. Guard

2. "U" joint repair kit

3. Drive sbaft;

4. Pinion shaft

i: ~gBB!lY.

7. Sp,"""

8. Shim

9. Carrier

10. Bearing- usr.

11. A_

12. LoCkpiate

13. Beorliig US'!.

14. on seal

15. Flange

16. Washer

17. Nut

18. Bevel gear

"19. niH. cage

20; Dowel

21. Side gear

22. Loekpin

29. 1'bl'IJst washer

1M. PbUon gear

25. Tbunt washer

26. Busbing

'11. Cage end plate

J I CASE (DAVID BROWN)

ing (2-Fig. 8) to mating face of housing

(26·Fig. 7). Fo~ the example. assume it

to he 72.5 mID.

2. Measure from inner end of axle

shaft gear 14.Fig. 8) to upper face of

carrier (18). For the example. assume

it to he 70.5 mm.

3. Subtract measurement 2 from

measurement 1 which. for the example.

is 2.0 mm.

4. Add recommended axle preload of

0.25 mm to difference of measurements

1 and 2 which will give spacer,thick·

ness which. for the example. is 2.26

mm.

Example:

Measurement 1

Minus measurement'2

Equals difference

Add preload

Required spacer ~

72.5mm

- 70.5 mm

2.0mm

+0;25'mm

2.26mm

With thickness of spacer determined

proceed as follows: Apply sealant to

mating surfaces of housing (26-Fig. 7)

and carrier (15), then position final

drive sboft housing on bench with

wheel st\lds down. Lower_ carrier and

axle shaft assembly onto fmal drive

shaft housing and be sure that axle

shaft and final drive sboft enter their

bearings (use hoist if necessary). Axle

shaft is a push' fit in the outboard

bearing and can he seated in the

bearing using a hammer and suitable

drift. Install the carrier to housing cap

screws and tighten securely. If clamp

(Fig. 11) was -used, remove clamp and

--

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 19 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

- The David Brown 885 Tractor Service & Repair Manual is a comprehensive guide designed to assist in addressing any issues that may arise with your tractor.

- It empowers both professional mechanics and DIY enthusiasts with the knowledge and skills needed to perform troubleshooting and replacement procedures recommended by the manufacturer.

- Regular maintenance is crucial for maintaining the durability of your tractor. This manual provides access to the manufacturer's recommended troubleshooting charts and step-by-step instructions, accompanied by clear images and exploded-view illustrations.

- Its digital format allows for easy navigation, searching, bookmarking, and printing, eliminating the hassle of dealing with greasy, torn, or lost pages.

- Compatible with various electronic devices, including PC and Mac computers, Android and Apple smartphones, and tablets, this manual offers convenience and accessibility.

- Adobe Reader, available for free, is all you need to access this manual on your electronic devices.

- By utilizing this manual, you can save on repairs, reduce downtimes, and ensure the smooth operation of your tractor for years to come.