CASE 580C 580CK BACKHOE Loader Tractor Workshop Service Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

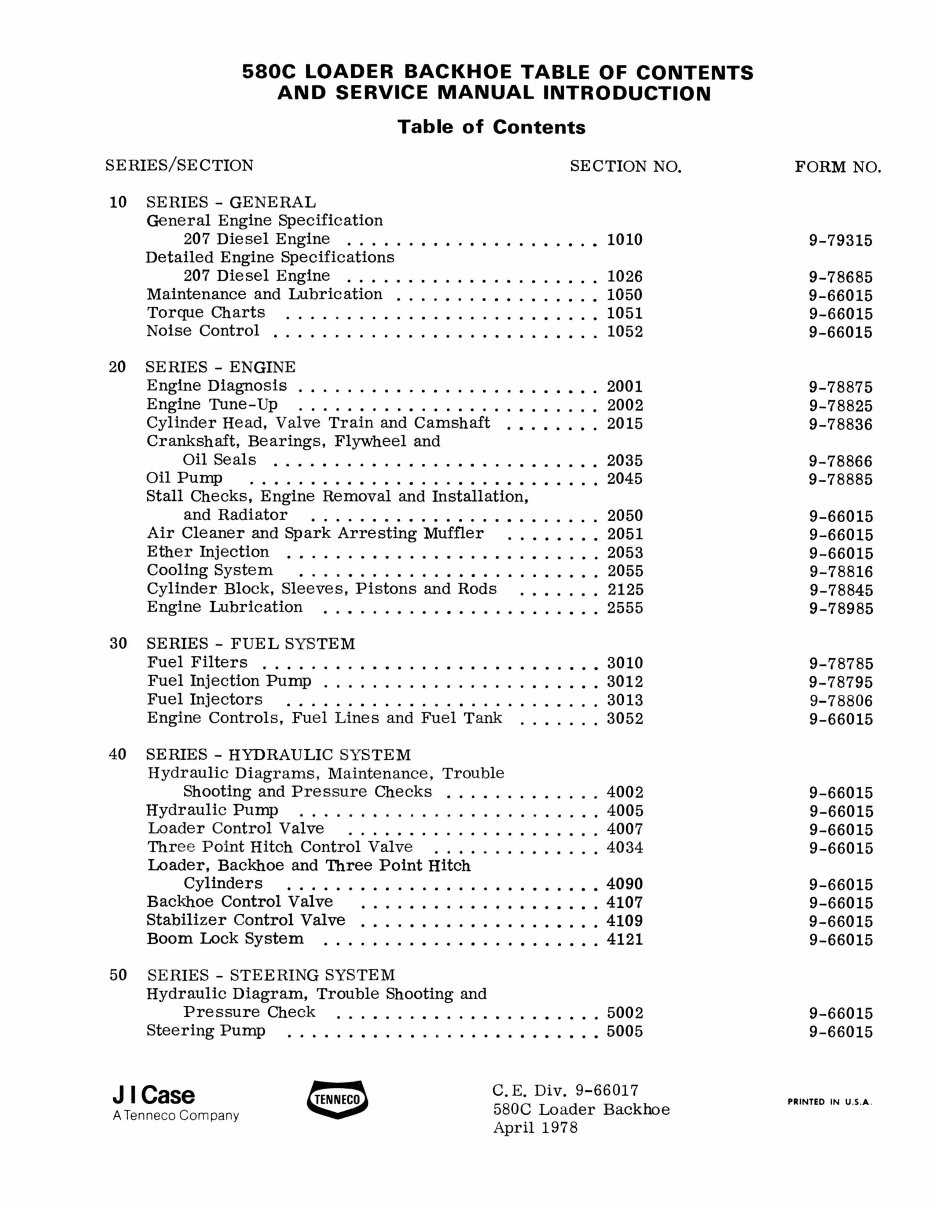

580C LOADER BACKHOE TABLE OF CONTENTS

AND SERVICE MANUAL INTRODUCTION

Table of Contents

SERIES/SE CTION

10 SERIES - GENERAL

General Engine Specification

SECTION NO.

207 Diesel Engine ...... • ........... •.• 1010

Detailed Engine Specifications

207 Diesel Engine ............. • ....... 1026

Maintenance and Lubrication ................. 1050

Torque Charts .......................... 1051

Noise Control ................... • ...... . 1052

20 SERIES - ENGINE

Engine Diagnosis . . . . . . • . . . . . . . . . . . • . • • • . . 2001

Engine Tune-Up ......................... 2002

Cylinder Head, Valve Train and. Camshaft .•.•..•. 2015

Crankshaft, Bearings, Flywheel and

Oil Seals ........ • ....... • .... •..•.. 2035

Oil PuInp ....... •••.•.•...•...•• ...... 2045

Stall Checks, Engine Removal and Installation,

and Radiator ...... • ......... •• ...... 2050

Air Cleaner and Spark Arresting Muffler ...••••. 2051

Ether Injection ....... • ...... • ..... •.. . .. 2053

Cooling System ............. •• ..... •••.. 2055

Cylinder. Block, Sleeves, Pistons and Rods ....... 2125

Engine Lubrication ..• ..... •.•• ........ •.. 2555

30 SERIES - FUEL SYSTEM

Fuel Filters ............... •...• ..... ••• 3010

Fuel Injection PuInp ..................... •. 3012

Fuel Injectors .......................... 3013

Engine Controls, Fuel Lines and Fuel Tank ....... 3052

40 SERIES - HYDRAULIC SYSTEM

Hydraulic Diagrams , Maintenance, Trouble

Shooting and Pressure Checks ............. 4002

Hydraulic PUInp ...... • .................. 4005

Loader Control Valve ..................... 4007

Three Point Hitch Control Valve ............. . 4034

Loader, Backhoe and Three Point Hitch

Cylinders ............ •• ...... ••..•• 4090

Backhoe Control Valve ............ •.•.•.•. 4107

Stabilizer Control Valve .... •..• ...... •••... 4109

Boom Lock System ..... •..•.•.•...• ...... 4121

50 SERIES - STEERING SYSTEM

Hydraulic Diagram, Trouble Shooting and

Pressure Check ................. • .... 5002

Steering Pump ................... •.•.•.• 5005

J I Case

A Tenneco Company

C. E. Div. 9-66017

580C Loader Backhoe

April 1978

FORM NO.

9-79315

9-78685

9-66015

9-66015

9-66015

9-78875

9-78825

9-78836

9-78866

9-78885

9-66015

9-66015

9-66015

9-78816

9-78845

9-78985

9-78785

9-78795

9-78806

9-66015

9-66015

9-66015

9-66015

9-66015

9-66015

9-66015

9-66015

9-66015

9-66015

9-66015

PRINTED IN U.S.A .

2

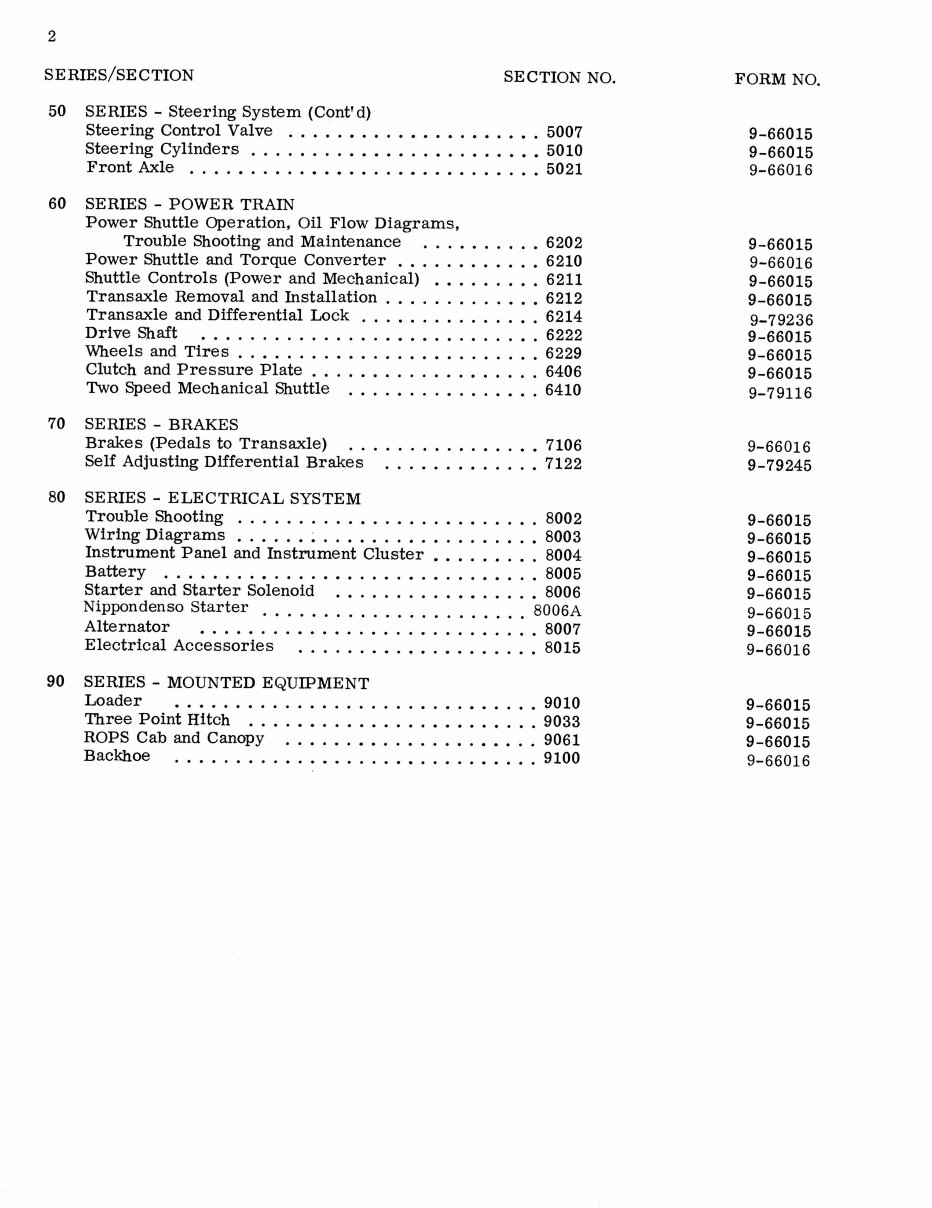

SERIES/SECTION SECTION NO.

50 SERIES - Steering System (ContI d)

Steering Control Valve ..... ••..•••.•.•••••. 5007

Steering Cylinders ........ •••••..•..•.•••• 5010

Front Axle ..•.• ..... •••••..••••• ....... 5021

60 SERIES - POWER TRAIN

Power Shuttle Operation, Oil Flow Diagrams,

Trouble Shooting and Maintenance ...•• ..... 6202

Power Shuttle and Torque Converter .•...•.••..• 6210

Shuttle Controls (Power and Mechanical) •••• ..... 6211

Transaxle Removal and Installation .......... •.• 6212

Transaxle and Differential Lock ...• ........ ••. 6214

Drive Shaft ..• ............. • ......... •. 6222

'Wheels and Tires ..•• ............ •• ....... 6229

Clutch and Pressure Plate ............ ••• .... 6406

Two Speed Mechanical Shuttle .... •...•.•.•... 6410

70 SERIES - BRAKES

Brakes (Pedals to Transaxle) .. ....... •.•..•. 7106

Self Adjusting Differential Brakes ...•...• .... • 7122

80 SERIES - ELECTRICAL SYSTEM

Trouble Shooting .......... • ............ •. 8002

Wiring Diagrams • .... • ~ ....... •.• ..... •.• 8003

Instrument Panel and Instrument Cluster •••..•... 8004

Battery ........ • .... •••..•.•.•...•••.. 8005

Starter and Starter Solenoid .• ....... ••• .... • 8006

Nippondenso Starter ...................... 8006A

Alternator • . • • . . . . . . . • . . . . . . . . . . . . . . . . 8007

Electrical Accessories ....... •.•..• ....... 8015

90 SERIES - MOUNTED EQUIPMENT

Loader •.•..• .............. •.•.•••..• 9010

Three Point Hitch ..•.•••••••••..•••..•.•. 9033

ROPS Cab and Canopy ..•.•.••..•...•.•••.. 9061

Backhoe ..... •...•..• .... ••• .......... 9100

FORM NO.

9-66015

9-66015

9-66016

9-66015

9-66016

9-66015

9-66015

9-79236

9-66015

9-66015

9-66015

9-79116

9-66016

9-79245

9-66015

9-66015

9-66015

9-66015

9-66015

9-66015

9-66015

9-66016

9-66015

9-66015

9-66015

9-66016

3

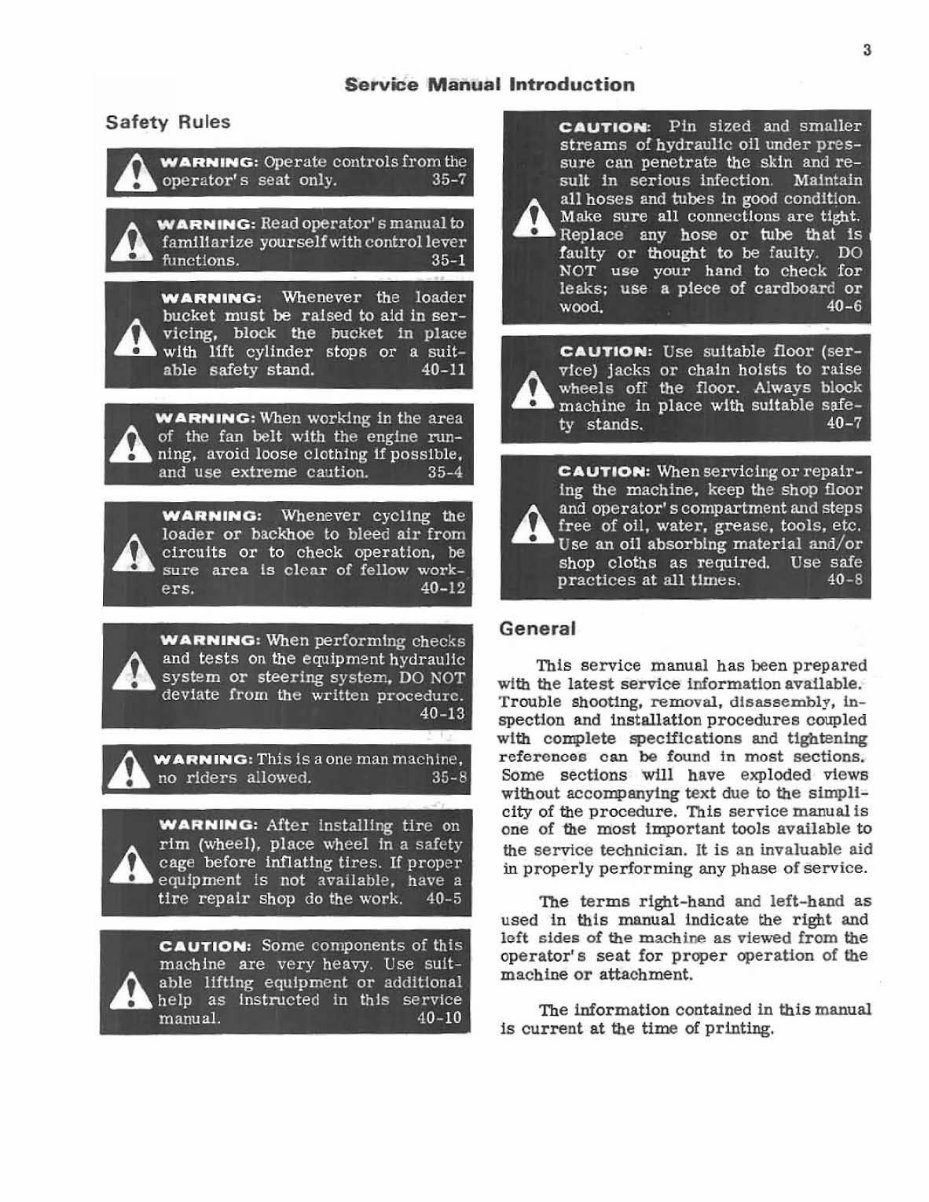

Service Manual Introduction

Safety Rules

/). WARNING: Operatt:! controls from the

.. ope r ato r's seat only. 35-;

/). WARNING: Read operator' s manual to

.. faromarize yourseJfwith controllevcr

functions. 35-1

WARNING : Whenever the loader

bucket must be rai sed to a1d in ser-

r... vicing. block the bucket In place

.. with 11ft cyl1nder stops or a suit-

able safety stand. 40-11

WARNING : When working in the area

/). of the fan belt with the engine run-

.. ning. avoid loose clothing If pOSSIble .

and use extreme C3'.1tion. 35-4

WARNING: Whenever cyCl1ng Ute

A

l oade r or backhoe to bleec air from

circuits or to check operation, be

sure area Is clcnr of fellow work-

ers. 40 -12

WARNING: When performtng ch ec~s

A and tests on the equtpm2nt hydraultc

.. system or steering systel1"., DO l'\OT

devIa te from the wr itten procedure.

40-13

~ WARNING : ThiS is a one man machine,

.. no riders allowed. 3!J - t'

WARNING: After Installlng tire on

A

riro (wheel), place wh ee l In a saft:ty

cage before inflaUng tires. If proper

equIpment Is not available, ha\'e a

tir e repair shop do the work. 40-5

CAUTION: Some components of this

machine are very heavy. ese sult-

h ab le lifting equipment or additional

.. help as Instructed in this service

manuaL 40-10

General

'Ibis service manual has been prepared

with the latest service information avaUable.

Trouble Shooting, removal, disass e mbl y. in -

spection and installation procedures coupled

with complete specific ations a!ld tightening

referonces oan be found In most sections .

Some sections will have exploded views

without accompanying text due to the simpl1-

city of the procedure. This service manual1s

one of the most Important tools available to

the servi ce technician. It is an invaluable aid

in properly performing any phase of service.

The terms right-band and le ft - hand as

used In this manual indicate the right and

left sides of the mach ine as viewed from the

operator' 6 seat for proper operation of the

machine or attachment .

The information contained in this manual

is current at the time of printing.

http://stores.ebay.com/UsefulCDs

4

Table of Contents

The preceedlng pages contain a Table of

Contents wblcb 118t the Series number and

title, and the sections contained in each series.

The individual sections, where required. will

have a Table of Contents on the second page

of that section.

Page Numbers

All page numbers consist of two sets of

digits separated by a daSh, such as 4002-9.

The digits preceeding the daSh identify the

section. The digits following the dasb repre-

sent the conaecutive page mllnber within that

section. Page numbers will be found at the

upper right or left of each page.

Text

If this manual covers more than one

machine, or different models of component

parts (planetary axles, gear boxes, control

valves, etc.) the procedures will apply to all

unless otherwise noted.

Illustrations

Where possible, Ulustrations are placed

as close as possible to the accompanying

text and should be used as part of the text.

Serial and Model Numbers

When requisitioning repair or replace-

ment parts as it may be necessary tofurn1Sh

the parts department with one or both num-

bers Serial and model numbers will be

found in the following locations.

Machine - Plate fastened to left front

cab or canopy mounting bracket. Also

stamped on top of chassis behind left-

hand hydraulic reservoir.

Engine - Right-hand side of block below

starter.

COIT4>onent parts - plate attached to part

or number stamped in part.

Torque References

Essentially two grades of fasteners

(bolts, nuts and screws) are used on Case

machinery. They a...~ grade 5 and grade 8.

Refer to Section 1051 for torque spe cific a-

tions and means of Identification.

The specifications in Section 1051 are

standard torque values and Should be used

on all fasteners during assembly and in-

stallation unless special torque values are

noted in a particular section.

Classification of Lubricants

Oils, lubricants, and grease are classi-

fied and graded accordlngto standards recom-

mended by the Society of Automotive Engi-

neers (SAE). the American Petroleum Insti-

tute (APl), and the National Lubricating

Grease Institute (NLGI).

Engine Oil

The SAE number indicates the viscosity

of engine oils, for example, SAE ao, a single

grade oU. Engine oils are also identified by

dual numbers, SAE lOWaO, a multigrade 011.

The API clauification (MS DS SD CAl

defines 011 performance in terms of engine

usage. Only olls specified in Section 1050

should be used. These oils contain sufficient

chemical additives to provide maximum en-

gine protection. Both the SAE grade and API

designation must be found on the container.

Gear Lubricant

The SAE grade mlmber also indicates the

viscosity of gear lubricantsdeflnedbyMIL-L

-2105B. An example is SAE 90, a medlumvi8-

cosity lubricant.

Grease

Semi - soUd lubricants specified for pivot

points must be that specified in Section 1050.

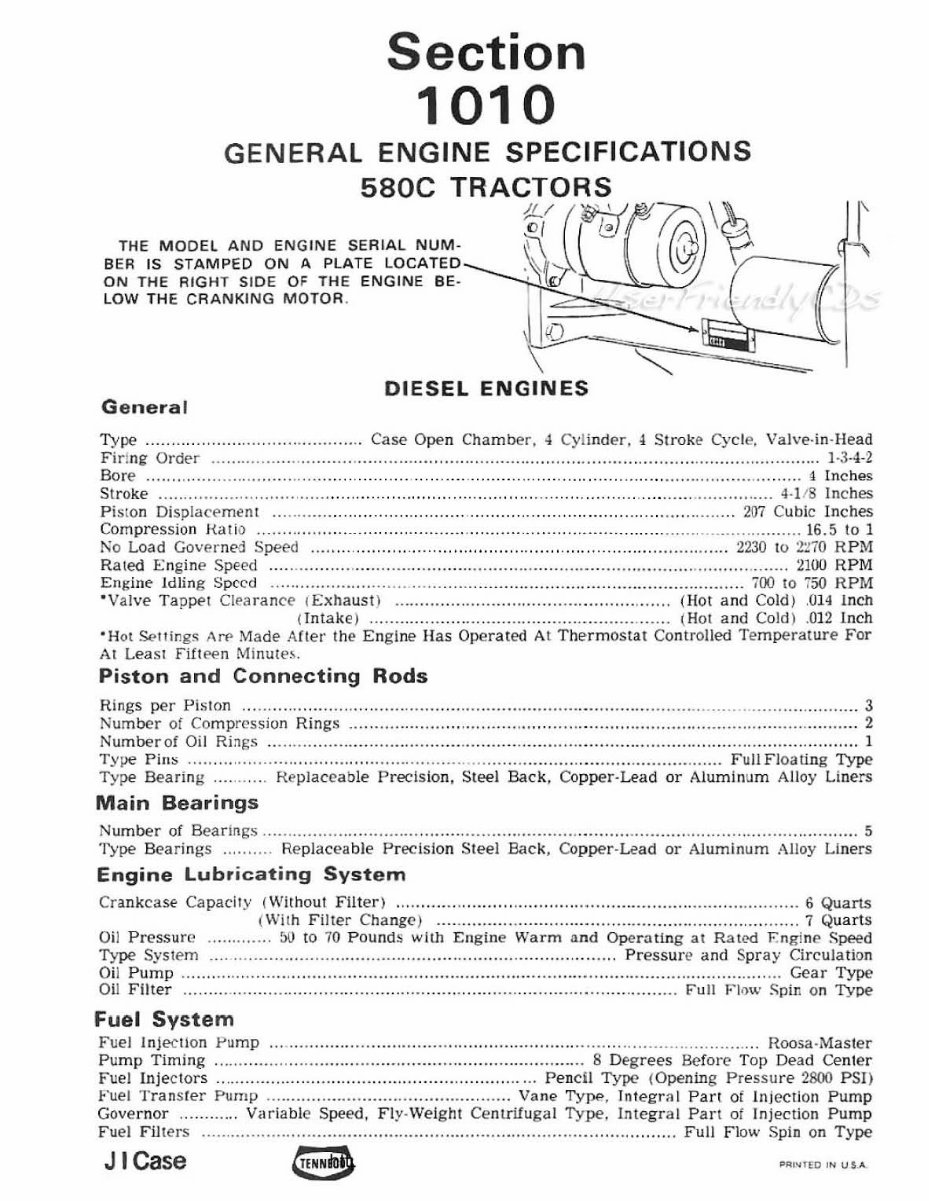

Section

1010

GENERAL ENGINE SPECIFICATIONS

580C TRACTORS

THE MODEL AND ENGINE SERIAL NUM-

BER IS STAMPED ON A PLATE LOCATED

ON THE RIGHT sIDe OF THE ENGINE BE·

lOW THE CRANKING MOTOR .

%( (~~ \~ I'

~~ I@---" ' I'

~ ,

~

iO

DIESEL ENGINES

General

Type ........ . ....... . ....... ..... ........ ..... CasE" O pen Cham ber, ..J Cylinder, ~ S t ro k~ Cycle. Valve· in-Hea d

Firing Order ... .... ...... ..... ......... .. .................... . .. ........... .......... . .................. .... .............. . ......... 1·3· 4-2

Bo re ....... ... ", ... ... n ... ...... .. .... . . ... . .. .... . . .. .... .. . .. . .. .. .. . .... .. .. ... ...... .. . ...... . . . ... .......... ... . .. ... . . .... . 4 Inches

Stroke .......... ........... ..... .. ...... ............... .............. ..... ....... .. ...... ............ .... ......... ............. 4·1/8 Inches

Pi ston Displacement ... ... ...... ....... ...... . ............ . ............ . .... .... ......... .......... .... .. ...... 207 Cubic In c hes

Com pre ssion Harlo ........................................... ............... .. ........ ............ , .... ..... ... ... ..... 16 .5 to 1

t\o Load Governed Speed ..... .. .... .. ... ........................ .. ............................... .. .. .... 2230 to 2:170 R PM

Rated Engine Speed ....... .. .......... .. ....... .. ... .. ............ .. .. .. ............................... .. ............... . 2100 RPM

Engine Idling S pc' cd ......... ..... ......... ... .. .. .. .... .. ................. ..... ....... .. ............. ... ...... 700 to 750 RPM

·Valve TappE't Clea r ance I£ xhaust) ..................... . ........... .. .. . ......... .... ... (Hot a nd COl d) ,014 In ch

(Intake) ...... ... .......... ................. ....... . ........ . ...... ( Ho t and Cold ) . 01 2 lnch

-H ot Settir!g!> AN' Made After the En gi ne Ha s Operated At The rm ostat Controlled Te m perature For

At Least Fifteen Min ute s.

Piston and Connecting Rods

R ings per Pis ton .... ................. . .......... ,............. ..................... . ............. ... .... .... ... ...... ... ..... ........... 3

Number of Com pression Rings .. ................................. .. ............................................................... 2

Num berof Oil Rings ......... ......... .. ...................... .. ...... .. ................... .. ..... .. .... .. .. ................. .. ......... 1

Type Pill S ..... .. .................................................... .................. . ................... ....... Full Floating Type

T ype Beari ng ....... ... . Replace a ble Precision. Stee l Back. Copper ·Lead or Alumi num Alloy Liners

Main Bearings

Number of Bear ings .. ................. .. ...... .. ... .......... .................. .. .. ... . .......... ..... .... ......... .. ........... . ....... 5

Type Bea rings .... . .. ... Replaceable Pr ecisio n Steel Back . Cop per · Lead or Alum i num Alloy Li ners

Engine Lubricating System

Crankcase Capacity (Without Filter) ............ ... ... ..... ...... ..... .................................. . .......... 6 Quarts

( With Filler Cha ng(' ) .... . ........ ......... .... ... ................ . ................... ... .. . 7 Qua rts

Oi l Pressure ..... .. ... . .. 50 to 70 Pounds with Engine Warm a. nd Operati ng at R atoo F. ng in £> Speed

1'ypI? System ...... .. ..................................... .. ... .. . ... ...... .. ...... , ... ..... Pres sure and S pr ay Ci r cu lati on

Oil Pump ........... ..... . ...... ... . ......... . ...... ...... ..................... . ............ . ............................... ... Gear Type

Oil Filter ..... ...................... .... ...... .... .............. .... .. ...... .. ... . .......... . .......... ... Full F lnw Spir , on Type

Fuel System

Fuel In je-c tion Pump ...... . ............. .. ........... .............. .............. ....... ............. ... . ...... .... Roosa· Mast er

Pump Timing ..................... ..... ............. ... ................ .. ............ . 8 Degrees Before Top Dead Center

Fuel [nject ors ................ ......... ...... .. ............. ........... ...... Pen cil Type ( Opening Pressure 2800 PSI)

Fuel Tran sr er Pump ... ............... .. ....................... ..... Vane TypP , Inlegr;)1 Part of In jection Pump

Gove rn or ....... .. ... Vilfiable Speed, Fly·Wei ght Centrifuga l Ty pe . In tegral Part of I njection Pump

Fuel Fi Jters ................................................ . ........ . ........ . ..... .. ...... .. ..... Full Flow Spin on Type

J I Case ~~''''E D 'N us .. .

http://stores.ebay.com/UsefulCDs

This Page is Blank

http://stores.ebay.com/UsefulCDs

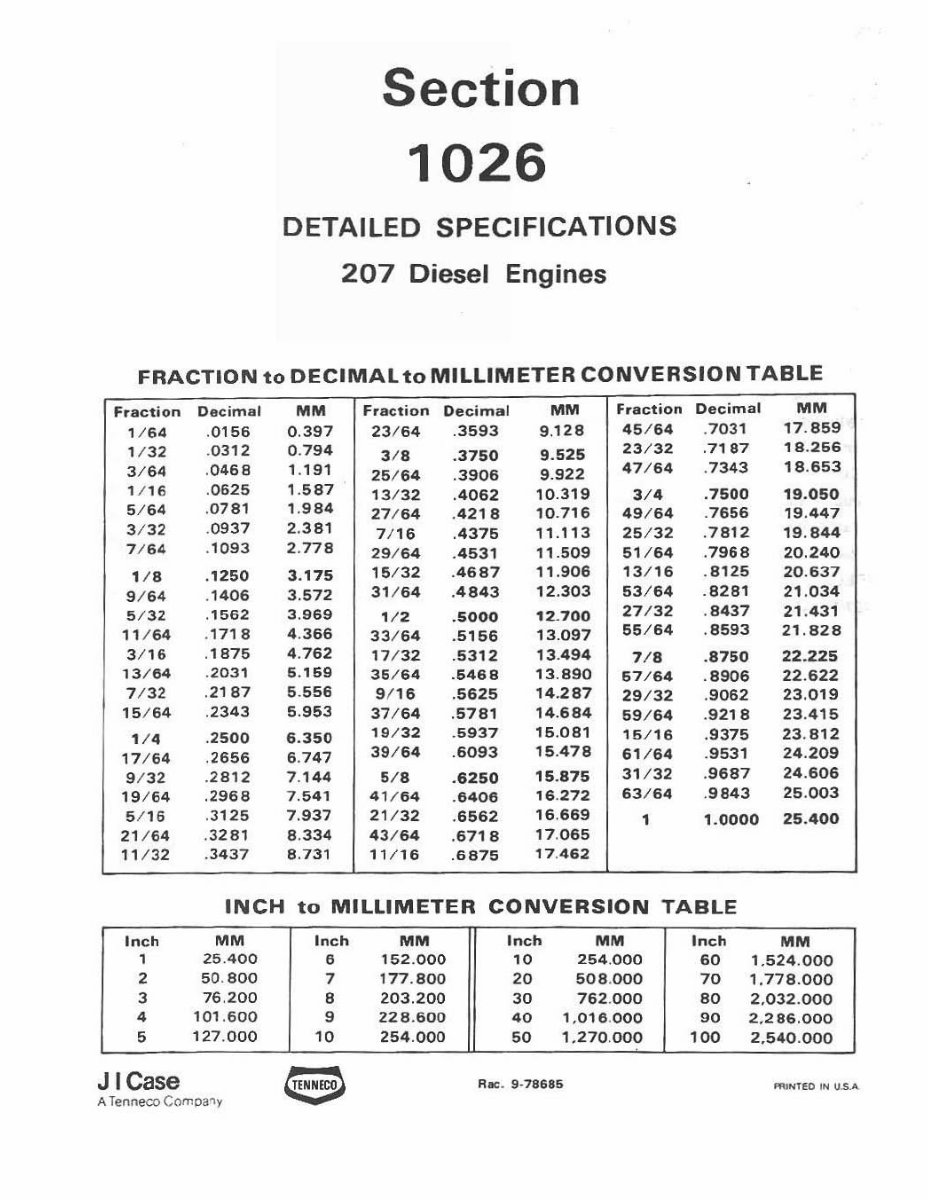

Section

1026

DETAILED SPECIFICATIONS

207 Diesel Engines

FRACTION to OECIMALto MILLIMETER CONVERSION TABLE

fraction Decimal MM Fraction Decimal MM Fraction Decimal MM

1/ 64 . 0156 0. 397 23 / 64 .3593 9.128

45 / 64 .70 31 17. 859

1/32

. 0312 0. 794

3/8 . 3750 9.525

23/32 .7187 19. 266

3/ 64

. 0468 1.191

26 / 64 . 3906 9.922

47 / 64 . 7343

18. 653

1/ 16 . 0625 , . 587

13 / 32 .4062 10.319

3/'

.7500 19.050

5/ 64 .0 781 1. 984

27 / 64 . 4218 10.716 49 / 64 . 7656 19.447

3 /32 .0937 2. 381

7/ 16 .4376 11.113 25/32 . 7812 19 . B44

7/ 64 , 1093 2. 778

29/ 64 . 4531 '1.509

61 / 64 . 7968 20.240

1/8 . 1250 3. 175

15 / 32 . 4687 11.906 13 / 16 . SUS 20 . 637

9/ 64 .1 406 3.572

31 / 64 . 4843 12.303 53/64 .8281 21 . 034

5/ 32 . 1562 3. 969

1/ '

.5000 12. 700

27 / 32 . 8437 21 . 431

11 / 64 . 1718 4. 366

33 / 64 . 5166 13.097

55/64 . 8593 21,828

3/ 16 . 1875 4. 762

17 / 32 .5312 13.494

7/8 . 8750 22 . 225

13 / 84 .20 31 5. 159

35 / 64 .5468 13.890

67 / 64 . 8906 22 . 622

7/32 . 2187 5. 556

9/ 16 . 5625 14.287

29 / 32 . 9062 23 . 019

15 / 64 . 2343 5.953

37 / 64 . 5781

14.684

59 / 64 .9 218 23 . 415

1/, . 2500 6.350

19 / 32 . 6937 16 . 081

16/16 .9375 23 . 812

17 / 54 . 2655 5. 747

39 / 64 .6093 15 . 478

61 / 64 . 9531 24 . 209

9/ 32 .2 B12 7. 144 5/ 8 .6250

15.875

31 / 32 . 9687 24 . 606

19 / 54 .296B 7.541 41 / 64 . 6406

16 .272 63 / 64 . 9843 26 . 003

5/ 16 .3 125 7.937 21 / 32 . 6562

16 .669

1 1. 0000 25.400

21 / 54 . 3281 8. 334 43 / 64 . 6718

17. 065

11 /3 2 . 3437 8. 731 11 / 16 .6875

, 7 .462

INCH to MILLIMETER CONVERSION TABLE

Inch MM Inch MM Inch MM Inch MM

,

25.400

•

, 52 . 000

10 254 .000 60 1.524 . 000

2 50. 800

7 177 . 800 20 508 .000 70 1.778.000

3 76 .200 8 203 . 200 30 762 .000 80 2, 032.000

,

101 . 600 9 228 . 600 40 , .016 .000 90 2,286.000

5

127 . 000

'0

254.000 50 1, 270 .000 100 2.540 . 000

J I Case

Rae. 9·78686

........ ED IN \I.s. ..

A Tenneco C omOa~y

1026-2

TABLE OF CONTENTS

RUN·lN INSTR UCf ION S ................ ........................... ............................................................... 3,':1

DETAILED ENGINE SPECIFICATIONS ................................................................................ 5-10

Cylinder Sleeves ....................... .. ................ ........... ..... ..................... .. ............. ........ .................. 5

Pi s lon ............. .... ... .................................................................................................................. 5

Pis ton Rings ................................. ......................................................... .......... ............ ... ..... .. 5.6

Piston Pin ..... .. ..... . ......................... .................................................................................. ...... . 6

Connecting Rod .............. . .. .. .............................................................................................. .. ..... 6

Crankshaft ...................... ........................ .................................................................. ............ 6,7

Camshaft .................................... .......................................................................... .................... 7

ValvE' Push Rod Lifters ................. ............ ............................... ......... ............................. .... .... 7

Gear Train ............................................................................................................................... 8

011 Pump ............................ ....................... ....... ................................ ........................................ 8

Cyllnder Head ....... ............................ ........ ......... ..... ............ ................. ..................... .............. 8

Intake Valve ......................... .. ................ ......... . ................. .................... ......................... .......... 8

Exhaust Valve ................. ...... ................ ................... ....................... ........................................ 9

Intake and Exhaust Valve Guides ............................................................................................ 9

Valve Spring ............................................................................................................................ 9

Rocker Arm Assembly ............................................................................................................ 10

SPECIAL TORQUES ....................... ..... ........... .......... ................ ............ .... ............... .................. 10

GENERAL TORQUE SPECIFICATION TABLE ........................................................................ 11

http://stores.ebay.com/UsefulCDs

1026-3

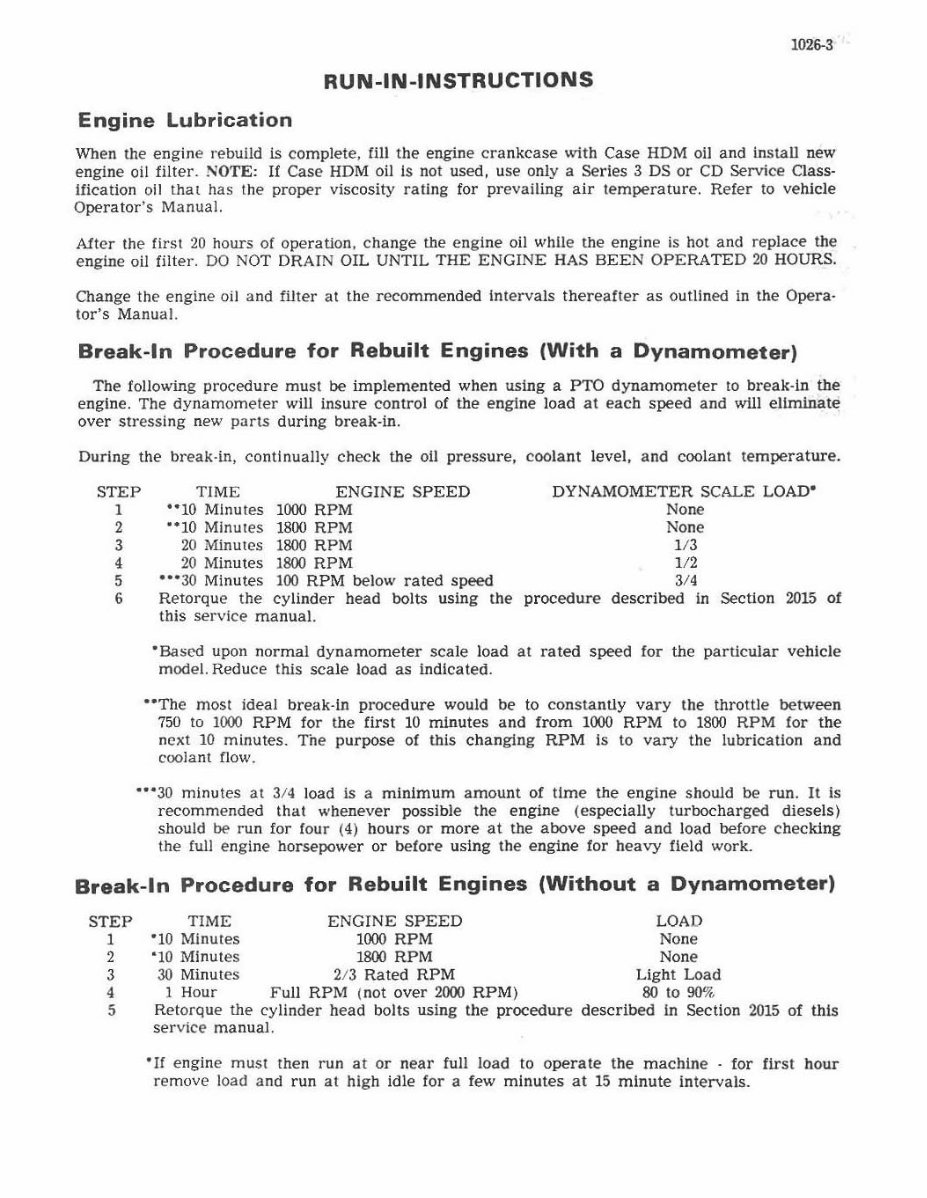

RUN-IN-INSTRUCTIONS

Engine Lubrication

Wh en tile engine rebuild is complete, fi ll the engine cra nkcase with Case HOM oil and install new

engine oil filter. NOTE: If Case HDM oil Is not used, use only a Series 3 DS or CD Service Gass-

Ification oll thaI has Ihe proper viscosity ra ting for prevailing air temperature. Refer to vehicle

Ope rator 'S Manual.

Alter the first 20 hours of operati on, change the engine oil while the engine is hot and re place the

engine oil filter. DO NOT DRAIN OIL UNTIL THE ENGINE HA S BEEN OPERATED 20 HOURS.

Change the engine oil and filter at the recomme nded intervals thereafter as outlined in the Opera·

lor's Manual.

Break-In Procedure for Rebuilt Engines (With a Dynamometer)

The following procedure must be imp lemented when usi ng a PTO dynamometer to break-in tbe

engine. The dynamometer will insure control of the engine load a l eac h speed and will e liminate

over stressing new parts during break·in.

During the break·in, continually check the 011 pressure, c oo lant level, and coolant temperature.

STEP

I

TIME ENGINE S PEED

'·10 Minutes 100.1 RPM

DYNAMOMETER SCALE LOAD-

None

2

3

4

5

6

"10 Minutes 1800 RPM

20 Minutes 1800 RPM

20 Minutes 1800 RPM

.0° 30 Minutes 100 RPM below rated speed

Ret orque the cylinder head bolts using the

this service manual.

No ne

1 /3

IJ2

3/.

procedure described In Section 2015 of

°Based upon normal dy namometer sca le load at r ated speed for the particular vehicle

model. Reduce this scale load as indicated.

"The most ideal break·in procedure would be to constantly var y the throttle between

750 to 1000 RPM for the first 10 minutes and from 1000 RPM to 1800 RPM for the

next 10 minutes. Tile purpose of this chan ging RPM is to vary the lubrication and

coolant flow.

'0' 30 minutes at 3/4 load is a minimum amount of time the engine should be run. It is

recommended that whenever possible the engine (especially tur bocharged d iesels)

should be run for four (4) hours or more at the above speed and load before chec king

the full eng ine horsepower or before using the engine for heavy field work.

Break-In Procedure for Rebuilt Engines (Without a Dynamometer)

STEP

1

2

3

•

5

TIME ENGINE SPEED

°10 Minutes 1000 RPM

' 10 Minutes 1800 RPM

30 Minutes 213 Rated RPM

1 Hour Fu ll RPM i not over 2000 RPM)

Retorque the cyUnder head bolts using the procedure

ser vice manual.

LOAD

None

None

Light Load

80 to 9O' li •

described in Section 2015 of thts

'If engine must then run at or n ea r full load to operate the mach ine - for first hour

remo ve load and run at high idle for a few minutes at 15 minute intervals.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 74 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

This manual is suitable for both first-time owners and amateur enthusiasts, as well as professional technicians. It is designed in an easy-to-read format and provides comprehensive information necessary for accurate procedure execution. It is recommended to keep this shop manual accessible and refer to it regularly. Adhering to routine and preventive maintenance outlined in the manual will contribute to time and cost savings by averting premature failure and unnecessary repairs.

- General

- Engine

- Fuel system

- Hydraulic system

- Steering system

- Power train

- Brakes

- Electrical system

File Format: PDF

Compatible with all versions of Windows & Mac

Language: English

Requirements: Adobe Reader