KUBOTA BH65 BACKHOE ATTACHMENT Workshop Service Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

BH65. WSM SAFETY INSTRUCTIONS

SAFETY FIRST

This symbol, the industry's "Safety Alert Symbol", is used throughout this manual and on labels on

the machine itself to warn of the possibility of personal injury. Read these instructions carefully.

It is essential that you read the instructions and safety regulations before you attempt to repair or use

this unit.

A DANGER : Indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury.

A WARNING : Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

A CAUTION : Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury.

• IMPORTANT : Indicates that equipment or property damage could result if instructions are not

followed.

: Gives helpful information.

BEFORE SERVICING AND REPAIRING

• Read all instructions and safety instructions in this

manual and on your machine safety decals.

• Clean the work area and machine.

• Park the machine on a firm and level ground. and set

the parking brake.

• Lower the implement to the ground.

• Stop the engine, and remove the key.

• Disconnect the battery negative cable.

• Hang a NOT OPERATE" tag in operator

station.

BH65, WSM SAFETY INSTRUCTIONS

SAFETY STARTING

• Do not start the engine by shorting across starter

terminals or bypassing the safety start switch.

• Do not alter or remove any part of machine safety

system.

• Before starting the engine, make sure that all shift

levers are in neutral positions or in disengaged

positions.

• Never start the engine while standing on ground.

Start the engine only from operator's seat.

SAFETY WORKING

• Do not work on the machine while under the influence

of alcohol, medication, or other substances or while

fatigued.

• Wear close fitting clothing and safety equipment

appropriate to the job.

• Use tools appropriate to the work. Makeshift tools,

parts, and procedures are not recommended.

• When servicing is performed together by two or more

persons, take care to perform all work safely.

• Do not work under the machine that is supported

solely by a jack. Always support the machine by

safety stands.

• Do not touch the rotating or hot parts while the engine

is running.

• Never remove the radiator cap while the engine is

running, or immediately after stopping. Otherwise, hot

water will spout out from radiator. Only remove

radiator cap when cool enough to touch with bare

hands. Slowly loosen the cap to first stop to relieve

pressure before removing completely.

• Escaping fluid (fuel or hydraulic oil) under pressure

can penetrate the skin causing serious injury. Relieve

pressure before disconnecting hydraulic or fuel lines.

Tighten all connections before applying pressure.

• Do not open high-pressure fuel system.

High-pressure fluid remaining in fuel lines can cause

serious injury. Do not disconnect or attempt repair

fuel lines, sensors, or any other components between

the high-pressure fuel pump and injectors on engines

with high pressure common rail fuel system.

• High voltage exceeding 100 V is generated in the

ECU, and is applied to the injector.

Pay sufficient caution to electric shock when

performing work activities.

2

BH65, WSM

SAFETY INSTRUCTIONS

•

+

-

AVOID FIRES

• Fuel is extremely flammable and explosive under

certain conditions. Do not smoke or allow flames or

sparks in your working area .

• To avoid sparks from an accidental short circuit,

always disconnect the battery negative cable first and

connect it last.

• Battery gas can explode. Keep sparks and open

flame away from the top of battery, especially when

charging the battery.

• Make sure that no fuel has been spilled on the engine.

VENTILATE WORK AREA

• If the engine must be running to do some work, make

sure the area is well ventilated. Never run the engine

in a closed area. The exhaust gas contains poisonous

carbon monoxide.

PREVENT ACID BURNS

• Sulfuric acid in battery electrolyte is poisonous. It is

strong enough to burn skin, clothing and cause

blindness if splashed into eyes. Keep electrolyte

away from eyes, hands and clothing. If you spill

electrolyte on yourself, flush with water, and get

medical attention immediately.

DISPOSE OF FLUIDS PROPERLY

• Do not pour fluids into the ground, down a drain, or

into a stream, pond, or lake. Observe relevant

environmental protection regulations when disposing

of oil, fuel, coolant, electrolyte and other harmful

waste.

3

BH65, WSM SAFETY INSTRUCTIONS

PREPARE FOR EMERGENCIES

• Keep a first aid kit and fire extinguisher handy at all

times.

• Keep emergency numbers for doctors, ambulance

service, hospital and fire department near your

telephone.

4

BH65, WSM SAFETY INSTRUCTIONS

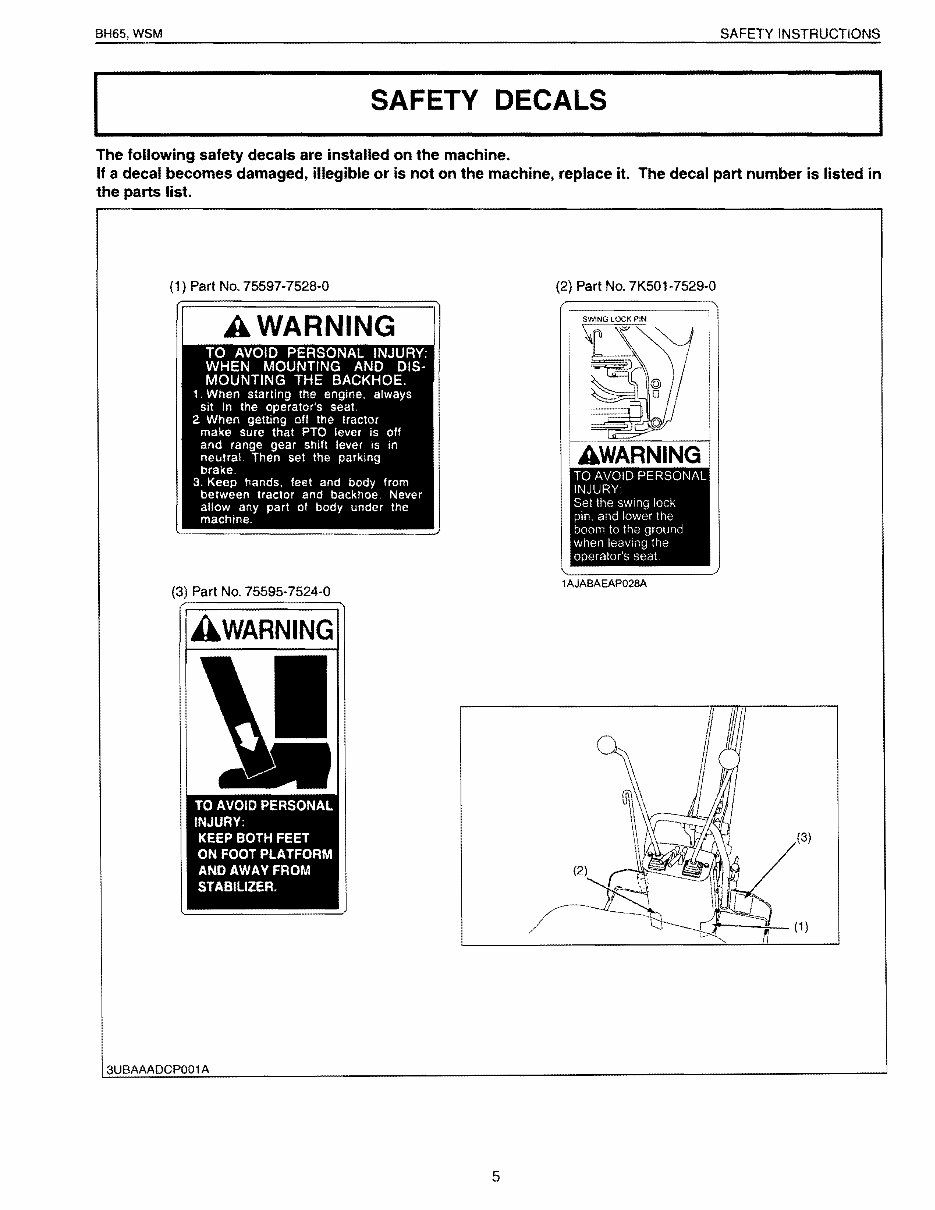

SAFETY DECALS

The following safety decals are installed on the machine.

If a decal becomes damaged, illegible or is not on the machine, replace it. The decal part number is listed in

the parts list.

(1) Part No. 75597-7528-0 (2) Part No. 7K501-7529-0

1AJABAEAP028A

(3) Part No. 75595-7524-0

AWARNING

(1)

(3)

(2)

3UBAAADCP001 A

5

BH65. WSM

SAFETY INSTRUCTIONS

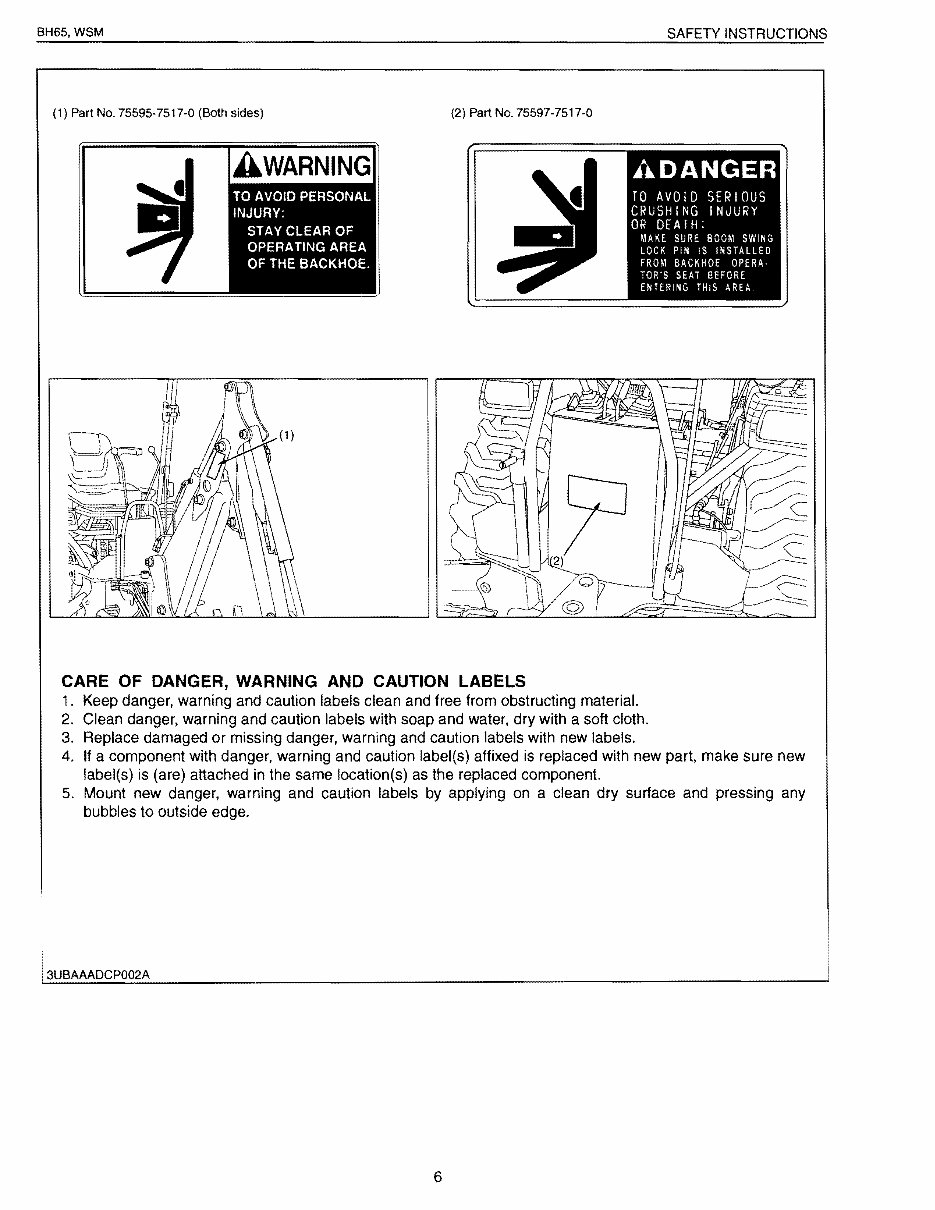

(1) Part No. 75595-7517-0 (Both sides) (2) Part No. 75597-7517-0

r

2)

CARE OF DANGER, WARNING AND CAUTION LABELS

1. Keep danger, warning and caution labels clean and free from obstructing material.

2. Clean danger, warning and caution labels with soap and water, dry with a soft cloth.

3. Replace damaged or missing danger, warning and caution labels with new labels.

4. If a component with danger, warning and caution label(s) affixed is replaced with new part, make sure new

label(s) is (are) attached in the same location(s) as the replaced component.

5. Mount new danger, warning and caution labels by applying on a clean dry surface and pressing any

bubbles to outside edge.

13UBAAADCP002A

6

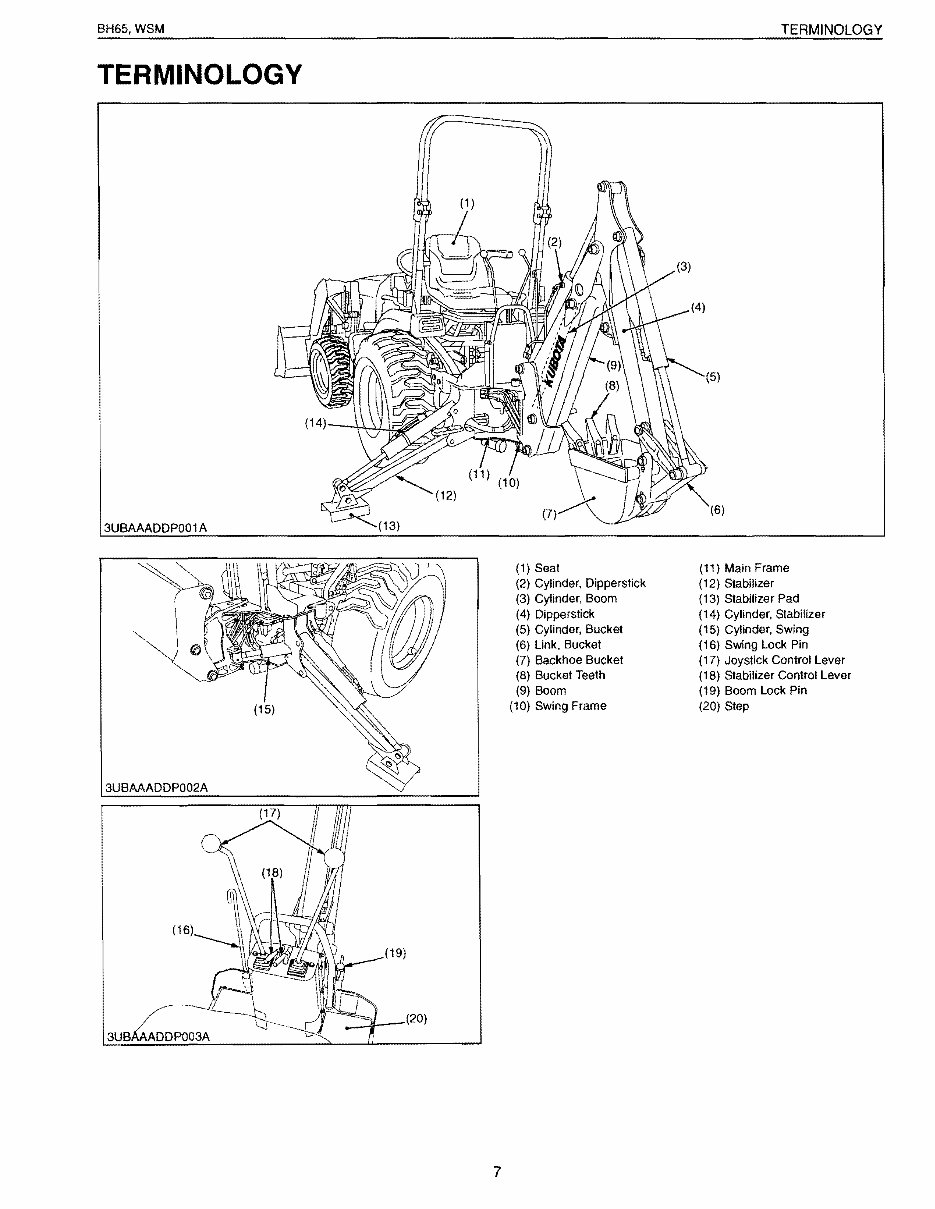

BH65. WSM TERMINOLOGY

TERMINOLOGY

3UBAAADDP001 A

3UBAAADDP002A

__.,...-_ (20)

(1) Seat

(2) Cylinder. Dipperstick

(3) Cylinder, Boom

(4) Dipperstick

(5) Cylinder. Bucket

(6) Link, Bucket

(7) Backhoe Bucket

(8) Bucket Teeth

(9) Boom

(10) Swing Frame

(11) Main Frame

(12) Stabilizer

(13) Stabilizer Pad

(14) Cylinder, Stabilizer

(15) Cylinder, Swing

(16) Swing Lock Pin

(17) Joystick Control Lever

(18) Stabilizer Control Lever

(19) Boom Lock Pin

(20) Step

7

BH65, WSM

SPECIFICATIONS

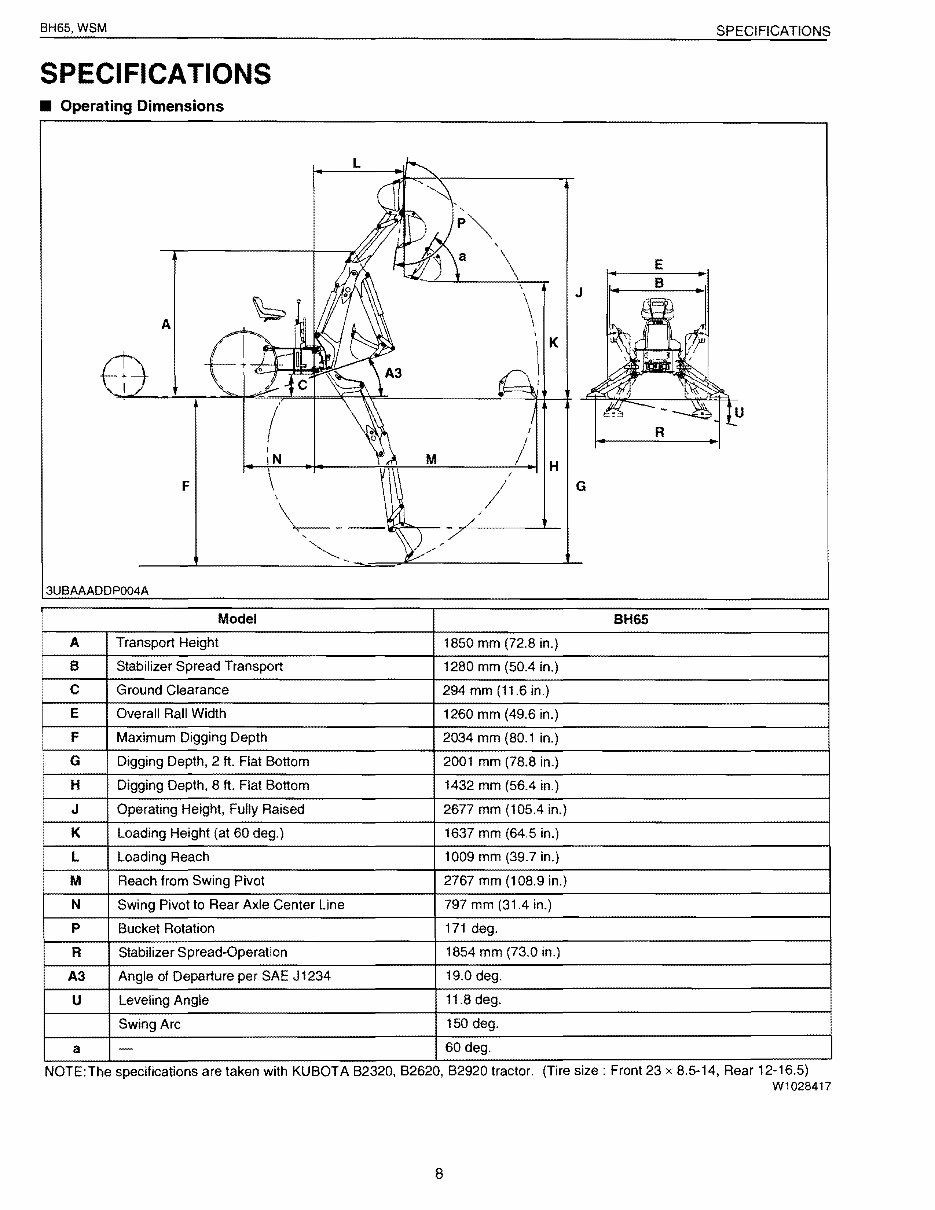

SPECIFICATIONS

• Operating Dimensions

L

A

F \

M /

H

/

G

3UBAAADDP004A

Model BH65

1850 mm (72.8 in.)

1280 mm (50.4 in.)

294 mm (11.6 in.)

1260 mm (49.6 in.)

F Maximum Digging Depth 2034 mm (80.1 in.)

G Digging Depth, 2 ft. Flat Bottom 2001 mm (78.8 in.)

H Digging Depth, 8 ft. Flat Bottom 1432 mm (56.4 in.)

2677 mm (105.4 in.)

1637 mm (64.5 in.)

1009 mm (39.7 in.)

2767 mm (108.9 in.)

797 mm (31.4 in.)

171 deg.

1854 mm (73.0 in.)

Operating Height. Fully Raised

Loading Height (at 60 deg.)

Loading Reach

Reach from Swing Pivot

Swing Pivot to Rear Axle Center Line

ilizer Spread-Operation

Angle of Departure per SAE J1234

nsport Height

ilizer Spread Transport

und Clearance

19.0 deg.

11.B deg.

150 deg.

60 deg.

NOTE: The specifications are taken with KUBOTA B2320, B2620, B2920 tractor. (Tire size: Front 23 x 8.5-14. Rear 12-16.5)

W1028417

B

BH65, WSM

SPECIFICATIONS

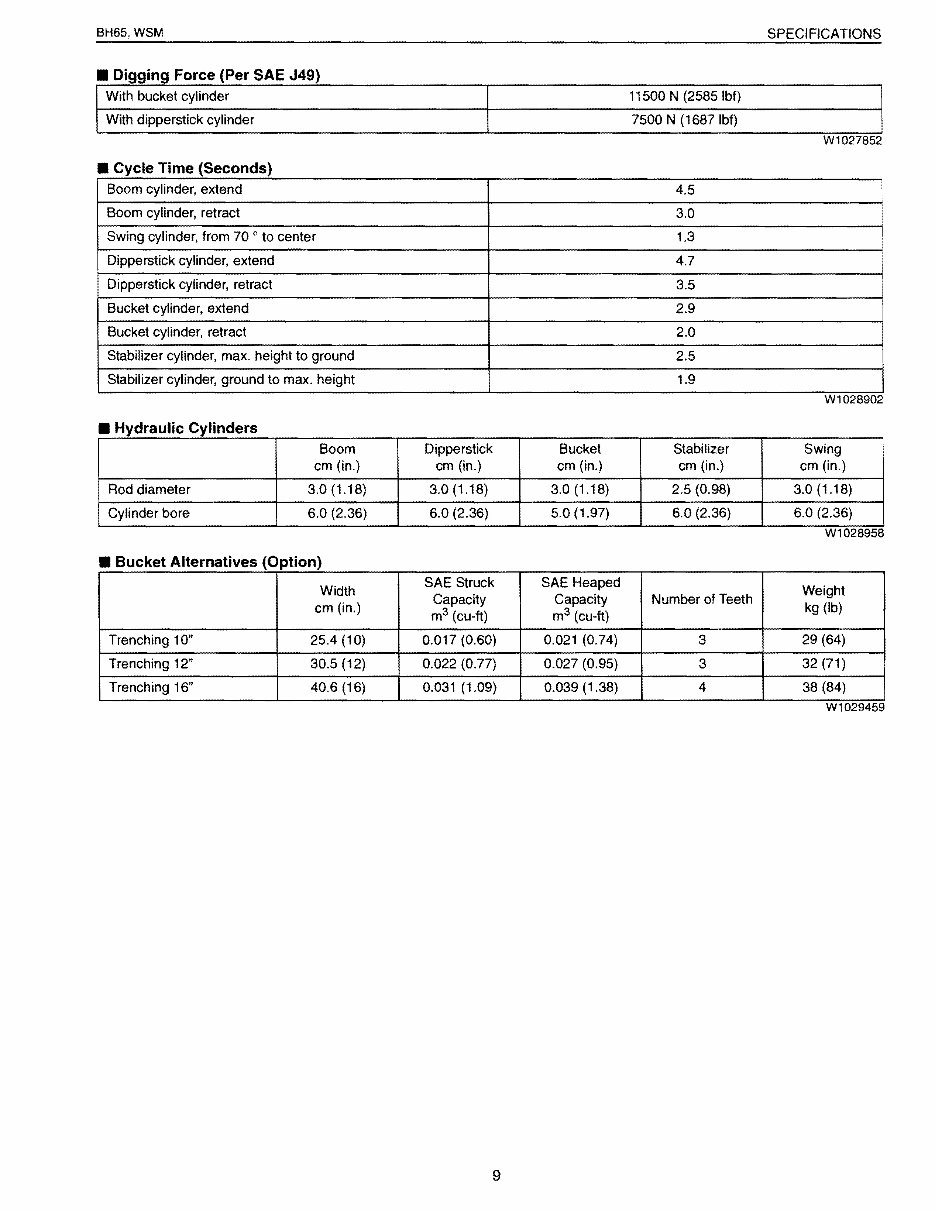

• Digging Force (Per SAE J49)

With bucket cylinder 11500 N (2585 Ibf)

With dipperstick cylinder 7500 N (1687Ibf)

W1027852

• Cycle Time (Seconds)

Boom cylinder, extend 4.5

I

Boom cylinder, retract 3.0

I

Swing cylinder, from 70 0 to center 1.3

Dipperstick cylinder, extend 4.7

Dipperstick cylinder, retract 3.5

Bucket cylinder, extend 2.9

Bucket cylinder, retract 2.0

Stabilizer cylinder, max. height to ground 2.5

Stabilizer cylinder, ground to max. height 1.9

W1028902

• Hydraulic Cylinders

Boom

cm (in.)

Dipperstick

cm (in.)

Bucket

cm (in.)

Stabilizer

cm (in.)

Swing

cm (in.)

Rod diameter 3.0 (1.18) 3.0 (1.18) 3.0(1.18) 2.5 (0.98) 3.0 (1.18)

Cylinder bore 6.0 (2.36) 6.0 (2.36) 5.0 (1.97) 6.0 (2.36) 6.0 (2.36)

W1028958

• Bucket Alternatives (Option)

Width

cm (in.)

SAE Struck

Capacity

m

3

(cu-ft)

SAE Heaped

Capacity

m

3

(cu-ft)

Number of Teeth

Weight

kg (Ib)

Trenching 10" 25.4 (10) 0.017 (0.60) 0.021 (0.74) 3 29 (64)

Trenching 12" 30.5 (12) 0.022 (0.77) 0.027 (0.95) 3 32 (71)

Trenching 16" 40.6 (16) 0.031 (1.09) 0.039 (1.38) 4 38 (84)

W1029459

9

BH65, WSM

SPECIFICATIONS

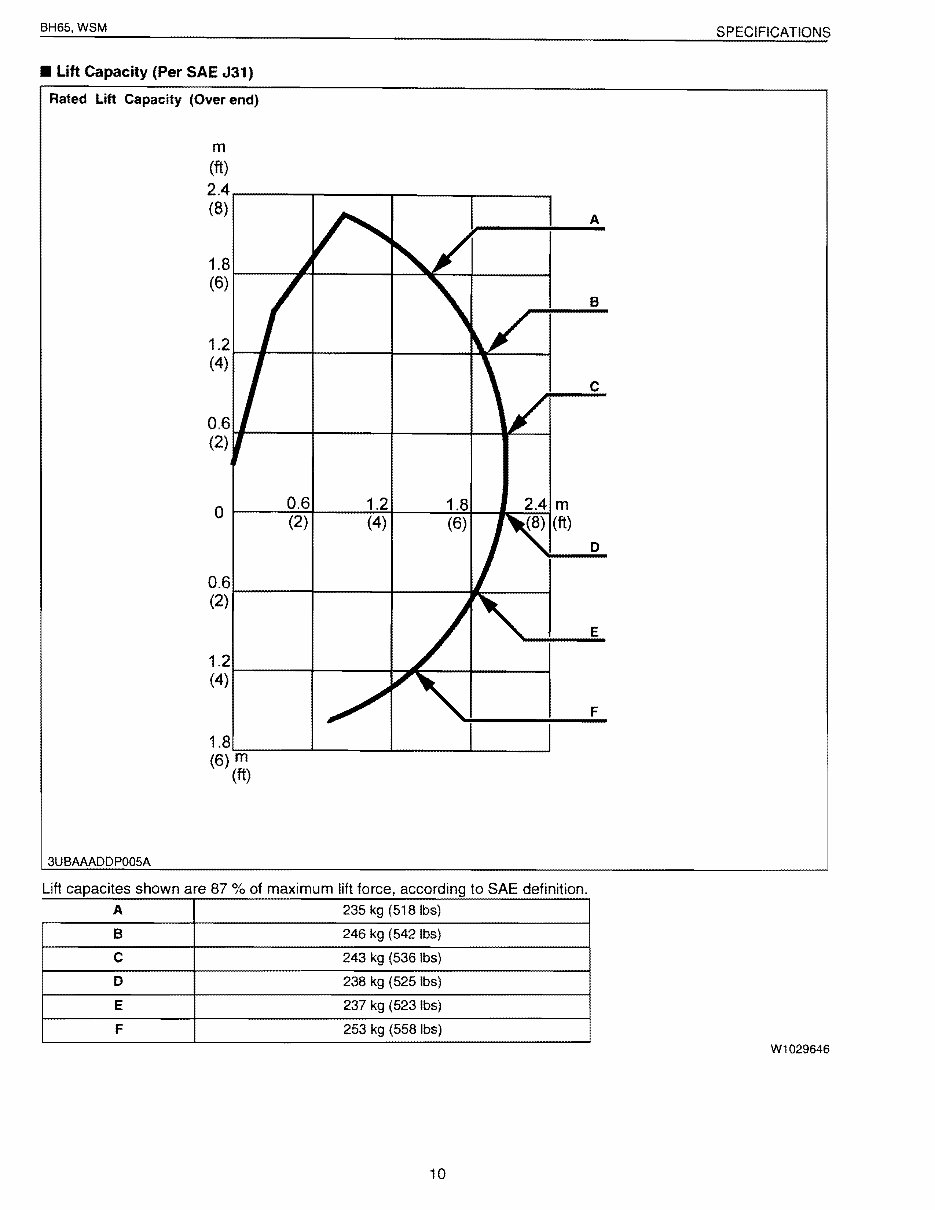

• Lift Capacity (Per SAE J31)

Rated Lift Capacity (Over end)

m

(ft)

2.4;--__-,-__--.__---,__----,

0

(8)

A

1.8

(6)

B

1.21--I---t----+------f¥_--I

(4)

C

0

0.6 1.2 1.8

(2) (4)

(6)

0.6

(2)

E

1.2

(4)

F

1.8

(6)

3UBAAADDP005A

Lift capacites shown are 87 % of maximum lift force, according to SAE definition.

A 235 kg (518Ibs)

B 246 kg (542 Ibs)

C 243 kg (536 Ibs)

0 238 kg (525 Ibs)

E 237 kg (523 Ibs)

F 253 kg (558Ibs)

W1029646

10

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 10 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

The Workshop Service Manual is a comprehensive guide offering detailed servicing instructions for Kubota equipment. It provides complete step-by-step information on repair, servicing, preventative maintenance, and troubleshooting procedures. This manual includes photos and illustrations to assist both professional mechanics and DIY enthusiasts through the repair process.

- Pages: 66

- Format: PDF

- Compatibility: Adobe Reader 9.0 or newer

Ensure to use Adobe Reader 9.0 or newer to view this file. You can access the current version of Adobe Reader for free at get.adobe.com. Satisfaction Guaranteed!