Bolens Large Frame Tractors Workshop Service Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

j!1:~:~n

------____,.;1

Balens

LARGE

FRAME

) TRACTORS

SERVICE MANUAL

)

FORM 552665·5 REV. 3/85

L

F

MODEL

E

ME

CTORS

1886s-05

1886s .. o6 (HT 18)

2086 (HT 20)

2087 (HT 20)

2288 (HT 22)

2289 (HT 20)

2389 (HT 23)

2388s {HOT 1 000)

2389s (HT 23)

I. GENERAL II

II. ELECTRICAL SYSTEM

Ill. DRIVETRAIN ~

IV. FUEL SYSTEM II

V.CHASSIS m

-

VI. HYDRAULIC SYSTEM m

VII. ENGINE ~

VII I. TRACTOR ATTACHMENTS l: ~

.ARGE FRAME TRACTOR

Rev. 3/85

TABLE OF CONTENTS

PAGE

GROUP I. GENERAL . . . . . . . . . . . . . 1-1

SERIAL NUMBER

INFORMATION . . . . . . . . . . . 1-1

SPECIFICATIONS . . . . . . . . . . . 1-2

TORQUE ................... 1~

MAINTENANCE CHART

KOHLER ................ 1-4

MAINTENANCE CHART

(WISCONSIN/DUCATTI) .... 1-5

LUBRICATION POINTS . . . . . . . 1-6

LUBRICATION CHART ....... 1-7

MAINTENANCE CHART

(MITSUBSHI) . . . . . . . . . . . . . 1-8

LUBRICATION CHART . . . . . . . 1-9

GROUP II. ELECTRICAL SYSTEM

TROUBLE SHOOTING GUIDE .

WIRING DIAGRAM - 18865-05

2-1

2-1

and 06 .................. 2-3

LIGHT CIRCUIT DIAGRAM 2-4

START/RUN CIRCUIT . . . . . . 2-4

CHARGING CIRCUIT . . . . . . 2-5

WIRING DIAGRAM - 2086 and

2087 S/N 01/03 . . . . . . . . . . . 2-6

WIRING DIAGRAM - 2087-04

and 2389 ............... .

LIGHT CIRCUIT .......... .

START/RUN CIRCUIT -

2-6A

2-7

2086 and 2087-01/03 . . . . . . 2-7

START/RUN CIRCUIT -

2389, 2087-04 and 23895 .. .

CHARGING CIRCUIT ..... .

CRUISE CONTROL CIRCUIT

WIRING DIAGRAM - 23895 ...

WIRING DIAGRAM - 2288

and 2289 ............... .

CHARGING CIRCUIT ..... .

SEAT CIRCUIT .......... .

START CIRCUIT ......... .

LIGHT CIRCUIT .......... .

WIRING DIAGRAM - 23885 .. .

START CIRCUIT ......... .

RUN CIRCUIT ........... .

LIGHT CIRCUIT .......... .

CRUISE CONTROL CIRCUIT

PREHEAT CIRCUIT ...... .

TESTING ELECTRICAL

SYSTEM ............... .

2-8

2-8

2-9

2-6B

2-10

2-11

2-12

2-13

2-13

2-14

2-15

2-15

2-16

2-16

2-17

2-15

GROUP Ill. DRIVE TRAIN ......... 3-1

TROUBLE SHOOTING GUIDE 3-1

PRINCIPLES OF HYDROSTATIC

OPERATION ............. 3-2

HYDROSTATIC TRANSMISSION

FLOW CHART . . . . . . . . . . . . 3-3

IDENTIFICATION ............ 3-4

TESTING HYDRO

(SUNDSTRAND) . . . . . . . . . . 3-6

HYDRO REMOVAL AND

INSTALLATION

(SUNDSTRAND) . . . . . . . . . . 3-7

TESTING HYDRO (EATON) 3-11A

HYDRO REMOVAL AND

INSTALLATION (EATON) ... 3-11 B

HYDROSTATIC REPAIR PAGE

(SUNDSTRAND) .......... 3-12

CHARGE PUMP SECTION .... 3-12

PUMP SECTION ............ 3-15

CENTER SECTION .......... 3-18

MOTOR SECTION . . . . . . . . . . . 3-20

TRANSAXLE REMOVAL ...... 3-21A

ASSEMBLY PROCEDURE OF

CARRIER AND AXLE . . . . . . 3-24

TRANSAXLE ASSEMBLY . . . . . 3-26

TRANSAXLE ASSEMBLY

PROCEDURE . . . . . . . . . . . . 3-28

TWO SPEED TRANSAXLE

ASSEMBLY 2389, 2288, 23895,

23885, and 2289 . . . . . . . . . . 3-30

GROUP IV. FUEL SYSTEM ........ 4-1

TROUBLE SHOOTING GUIDE . 4-1

FUEL TANK AND VALVE ..... 4-3

FUEL FILTER . . . . . . . . . . . . . . . 4-4

AIR CLEANER . . . . . . . . . . . . . . 4-4

CARBURETOR ADJUSTMENTS 4-5

GROUP V. CHASSIS .. ~ .......... 5-1

FRONT AXLE ............... 5-1

FRONT WHEEL ALIGNMENT . . 5-2

TURNING RADIUS . . . . . . . . . . . 5-2

FRONT WHEEL BEARINGS . . . 5-3

TIRES ..................... 5-3

BRAKES ................... 5-4

POWER TAKE-OFF LEVER

AND BELTS . . . . . . . . . . . . . . 5-5

REAR WHEELS . . . . . . . . . . . . . 5-6

TRAVEL PEDAL . . . . . . . . . . . . . 5-6

FOOT BRAKE AND SEAT

INTERLOCK SWITCH . . . . . . 5-7

GROUP VI. HYDRAULIC SYSTEM .. 6-1

TROUBLE SHOOTING GUIDE . 6-1

PRINCIPLE OF OPERATION . . 6-2

TI:STING HYDRAULIC SYSTEM 6-4

CHECKING IMPLEMENT

RELIEF VALVE ........... 6-4

HYDRAULIC POWER LIFT . . . . 6-4

REPAIRING HYDRAULIC

SYSTEM ................ 6-6

DISASSEMBLY . . . . . . . . . . . . . . 6-6

ASSEMBLY . . . . . . . . . . . . . . . . . 6-7

OIL COOLER . . . . . . . . . . . . . . . 6-8

POWER STEERING .......... 6-10

ADJUSTMENT OF STEERING

NUT . . . . . . . . . . . . . . . . . . . . 6-11

GROUP VII. ENGINE . . . . . . . . . . . . . 7-1

TROUBLE SHOOTING GUIDE 7-1

ENGINE REMOVAL . . . . . . . . . . 7-3

GROUP VIII. TRACTOR ATTACH·

MENTS ...................... 8-1

MOWERS .................. 8-1

SNOW THROWER ........... 8-3

TILLERS . . . . . . . . . . . . . . . . . . . 8-6

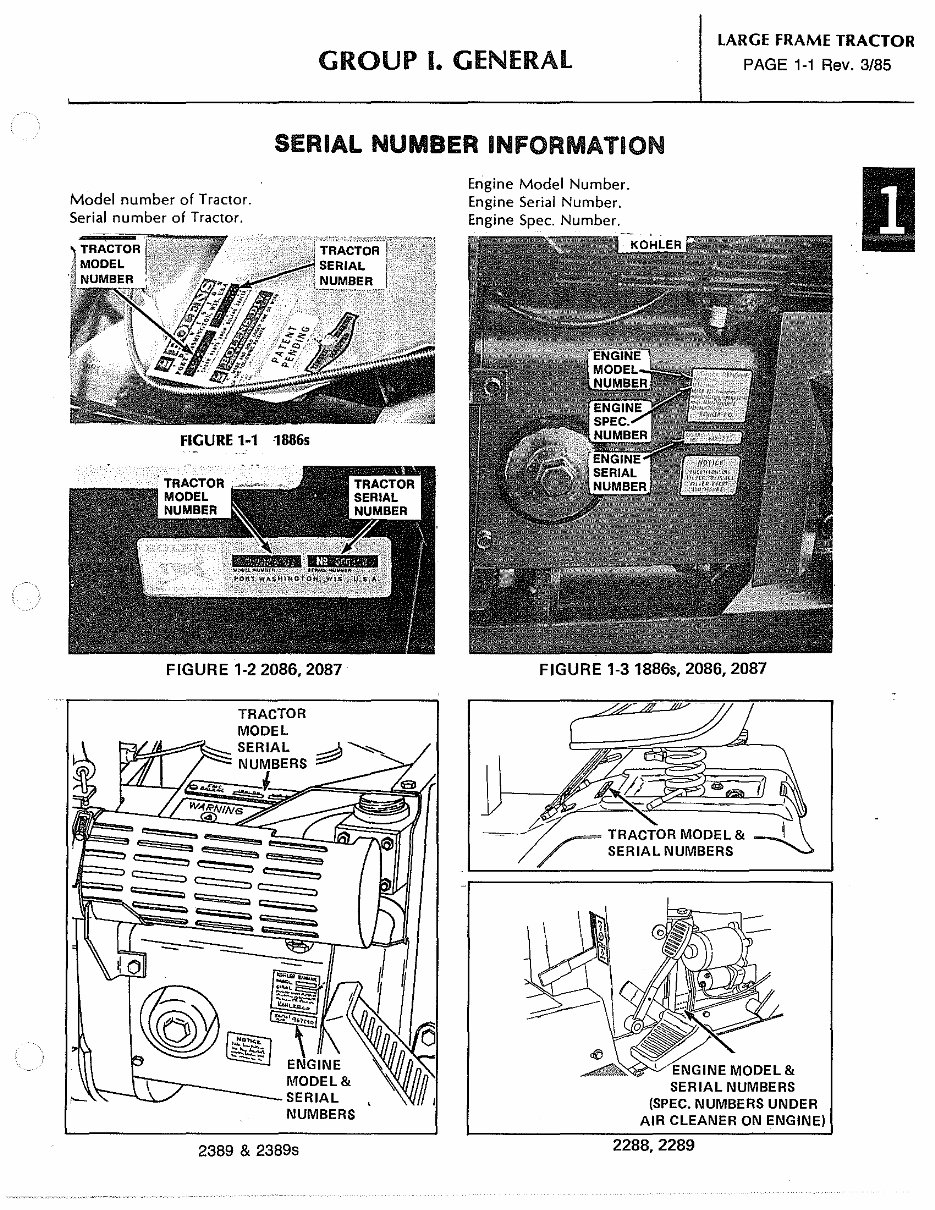

GROUP I. GENERAL

SERIAL NUMBER INFORMATION

Model number of Tractor.

Serial number of Tractor.

FIGURE 1-1 ·1886s

Engine Model Number.

Engine Serial Number.

Engine Spec. Number.

LARGE FRAME TRACTOR

PAGE 1-1 Rev. 3/85

FIGURE 1-2 2086,2087 FIGURE 1-3 1886s, 2086, 2087

2389 & 23895

2288,2289

1\RGE FRAME TRACTOR

PAGE 1-2 Rev. 3/85

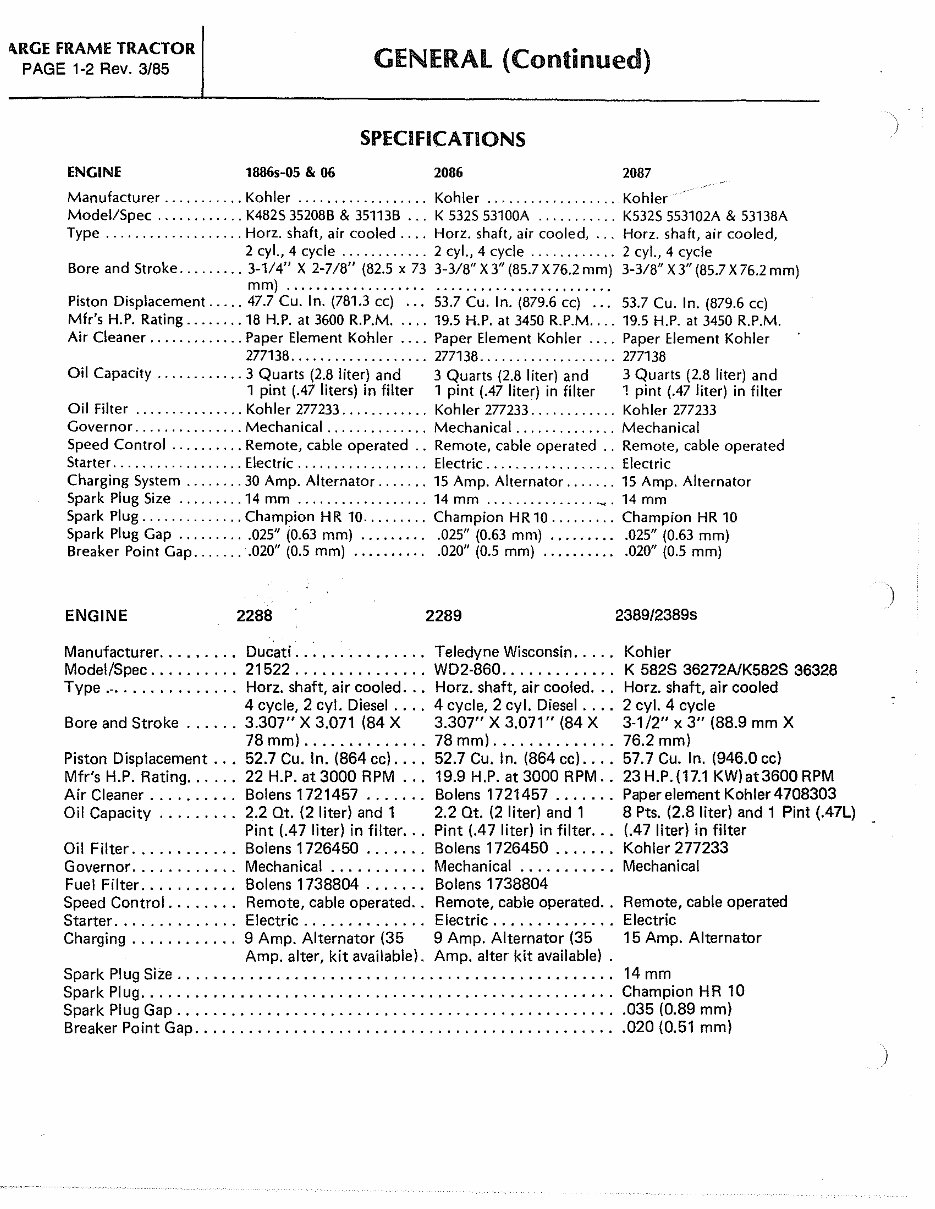

ENGINE 1886s-05 & 06

GENERAL(Continued)

SPECIFICATIONS

2086 2087

Manufacturer ........... Kohler .................. Kohler .................. Kohler

Model/Spec ............ K482S 35208B & 35113B ... K 5325 53100A ........... K532S 553102A & 53138A

Type ................... Harz. shaft, air cooled .... Harz. shaft, air cooled, ... Harz. shaft, air cooled,

2 cyl., 4 cycle ............ 2 cyl., 4 cycle ............ 2 cyl., 4 cycle

Bore and Stroke ......... 3-1/4" X 2-7 /8" (82.5 x 73 3-3/8" X 3" (85.7 X 76.2 mm) 3-3/8" X 3" (85.7 X 76.2 mm)

mm) .......................................... .

Piston Displacement ..... 47.7 Cu. ln. (781.3 cc) ... 53.7 Cu. ln. (879.6 cc) ... 53.7 Cu. ln. (879.6 cc)

Mfr's H.P. Rating ........ 18 H.P. at 3600 R.P.M ..... 19.5 H.P. at 3450 R.P.M .... 19.5 H.P. at 3450 R.P.M.

Air Cleaner ............. Paper Element Kohler .... Paper Element Kohler .... Paper Element Kohler

277138 . . . . . . . . . . . . . . . . . . . 277138. . . . . . . . . . . . . . . . . . . 277138

Oil Capacity ............ 3 Quarts (2.8 liter) and 3 Quarts (2.8 liter) and 3 Quarts (2.8 liter) and

1 pint (.47 liters) in filter 1 pint (.47 liter) in filter 1 pint (.47 liter) in filter

Oil Filter ............... Kohler 277233 ............ Kohler 277233 ............ Kohler 277233

Governor ............... Mechanical .............. Mechanical .............. Mechanical

Speed Control .......... Remote, cable operated .. Remote, cable operated .. Remote, cable operated

Starter .................. Electric .................. Electric .................. Electric

Charging System ........ 30 Amp. Alternator ....... 15 Amp. Alternator ....... 15 Amp. Alternator

Spark Plug Size ......... 14 mm .................. 14 mm ............... ·~. 14 mm

Spark Plug .............. Champion HR 10 ......... Champion HR 10 ......... Champion HR 10

Spark Plug Gap .......... 025" (0.63 mm) . . . . . . . . . . 025" (0.63 mm) . . . . . . . . . . 025" (0.63 mm)

Breaker Point Gap ........ 020" (0.5 mm) . . . . . . . . . . .020" (0.5 mm) . . . . . . . . . . . 020" (0.5 mm)

ENGINE

Manufacturer .... •.•..

Model/Spec ......... .

Type ..• .... • ........

2288 2289 2389/23895

Ducati ........ •• .... • Teledyne Wisconsin ..... Kohler

21522 ...• ........... WD2·860 .•.•..• ...... K 5828 36272AIK582S 36328

Harz. shaft, air cooled. . • Harz. shaft, air cooled. . . Harz. shaft, air cooled

4 cycle, 2 cyl. Diesel .... 4 cycle, 2 cyl. Diesel .... 2 cyl. 4 cycle

Bore and Stroke ...... 3.307" X 3.071 (84 X 3.307" X 3.071" (84 X 3-1/2" x 3" (88.9 mm X

Piston Displacement ..•

Mfr's H.P. Rating • .....

Air Cleaner ......... .

Oil Capacity ..... •...

Oil Filter ........... .

Governor .......... •.

Fuel Filter .......... .

Speed Control ....... .

Starter .• ............

Charging ........... .

78 mm) ..... • ........ 78 mm) ........ •• .... 76.2 mm)

52.7 Cu. ln. (864 cc) .... 52.7 Cu. ln. (864 cc) .... 57.7 Cu. ln. (946.0 cc)

22 H.P. at 3000 RPM ... 19.9 H.P. at 3000 RPM .. 23 H.P.(17.1 KW)at3600 RPM

Bolens 1721457 ....... Bolens 1721457 ....... Paper element Kohler4708303

2.2 Ot. (2 liter) and 1 2.2 Ot. (2 liter) and 1 8 Pts. (2.8 liter) and 1 Pint (.47L)

Pint (.47 liter) in filter ... Pint (.47 liter) in filter ... (.47 liter) in filter

Bolens 1726450 . . . • . . . Bolens 1726450 ....... Kohler 277233

Mechanical .• .... •..•. Mechanical ...•• ...... Mechanical

Bolens 1738804 . . . . . . . Bolens 1738804

Remote, cable operated. . Remote, cable operated ..

Electric ............ •. Electric ............. .

9 Amp. Alternator (35 9 Amp. Alternator (35

Amp. alter, kit available). Amp. alter kit available) .

Remote, cable operated

Electric

15 Amp. Alternator

Spark Plug Size ................................................ . 14mm

Spark Plug ......... • ........ • .... • ......................... •...

Spark Plug Gap ....... • .........................................

Breaker Point Gap ......................... • .....................

Champion HR 10

. 035 (0.89 mm)

. 020 (0.51 mm)

)

)

GENERAL (Continued)

LARGE FRAME TRACTOR

PAGE 1-3 Rev. 3/85

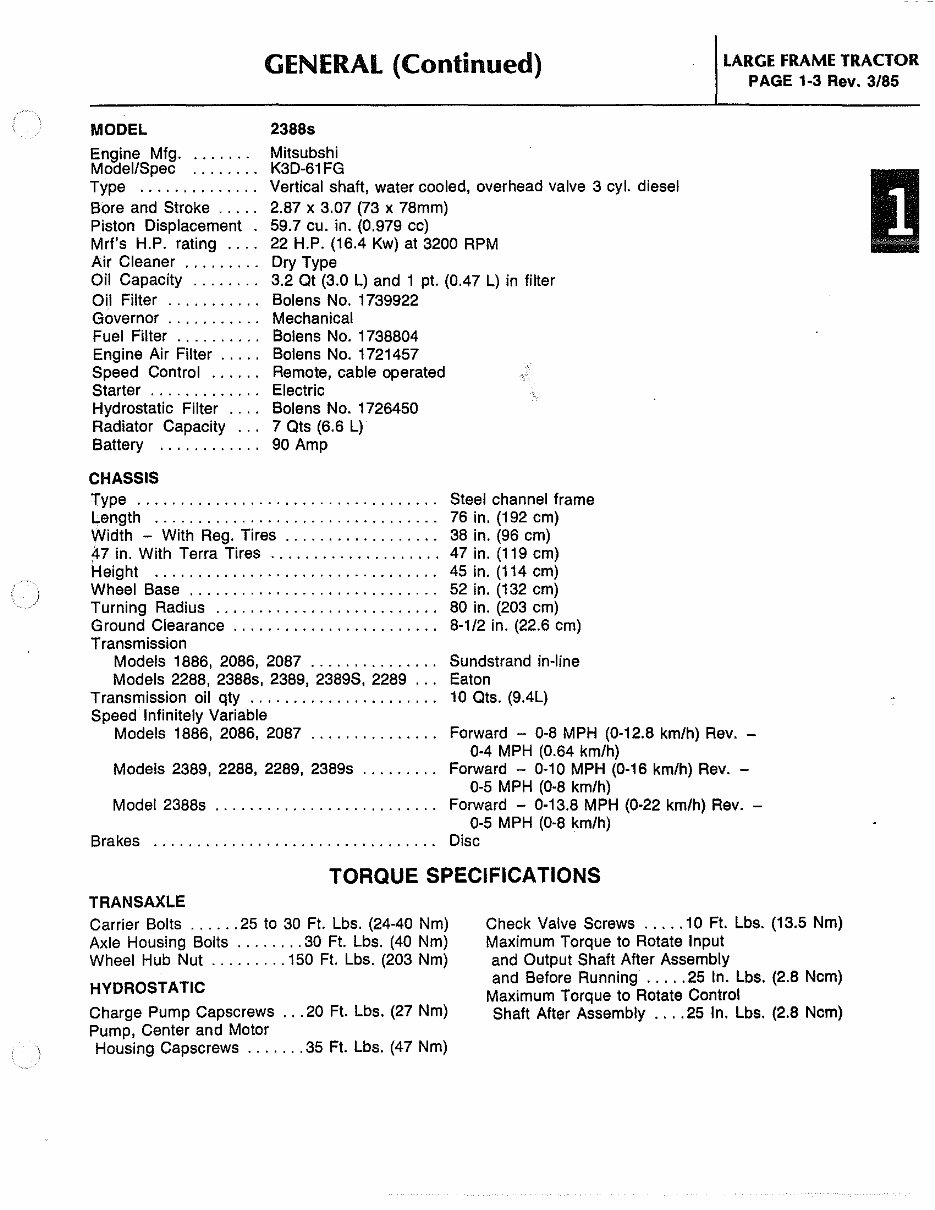

MODEL 2388s

Engine Mfg. . . . . . . . Mitsubshi

Model/Spec . . . . . . . . K3D·61 FG

Type . . . . . . . . . . . . . . Vertical shaft, water cooled, overhead valve 3 cyl. diesel

Bore and Stroke . . . . . 2.87 x 3.07 (73 x 78mm)

Piston Displacement . 59.7 cu. in. (0.979 cc)

Mrf's H.P. rating .... 22 H.P. (16.4 Kw) at 3200 RPM

Air Cleaner . . . . . . . . . Dry Type

Oil Capacity . . . . . . . . 3.2 Qt (3.0 L) and 1 pt. (0.47 L) in filter

Oil Filter . . . . . . . . . . . Bolens No. 1739922

Governor . . . . . . . . . . . Mechanical

Fuel Filter . . . . . . . . . . Bolens No. 1738804

Engine Air Filter . . . . . Bolens No. 1721457

Speed Control . . . . . . Remote, cable operated

Starter . . . . . . . . . . . . . Electric

Hydrostatic Filter . . . . Bolens No. 1726450

Radiator Capacity . . . 7 Qts (6.6 L)

Battery . . . . . . . . . . . . 90 Amp

CHASSIS

Type .................................. .

Length ................................ .

Width - With Reg. Tires ................. .

47 in. With Terra Tires ................... .

H~g~ ................................ .

Wheel Base ............................ .

Turning Radius ......................... .

Ground Clearance ....................... .

Transmission

Models 1886, 2086, 2087 .............. .

Models 2288, 2388s, 2389, 2389S, 2289 .. .

Transmission oil qty ..................... .

Speed Infinitely Variable

Models 1886, 2086, 2087 .............. .

Models 2389, 2288, 2289, 2389s ........ .

Model 2388s ......................... .

Brakes

Steel channel frame

76 in. (192 em)

38 in. (96 em)

47 in. (119 em)

45 in. (114 em)

52 in. (132 em)

80 in. (203 em)

8-1/2 in. (22.6 em)

Sundstrand in-line

Eaton

10 Qts. (9.4L)

Forward - 0-8 MPH (0-12.8 km/h) Rev. -

0-4 MPH (0.64 km/h)

Forward - 0-10 MPH (0-16 km/h) Rev. -

0-5 MPH (0·8 km/h)

Forward - 0-13.8 MPH (0-22 km/h) Rev. -

0-5 MPH (0·8 km/h)

Disc

TORQUE SPECIFICATIONS

TRANSAXLE

Carrier Bolts ...... 25 to 30 Ft. Lbs. (24-40 Nm)

Axle Housing Bolts ........ 30 Ft. Lbs. (40 Nm)

Wheel Hub Nut ......... 150 Ft. Lbs. (203 Nm)

HYDROSTATIC

Charge Pump Capscrews ... 20 Ft. Lbs. (27 Nm)

Pump, Center and Motor

Housing Capscrews ....... 35 Ft. Lbs. (47 Nm)

Check Valve Screws ..... 10 Ft. Lbs. (13.5 Nm)

Maximum Torque to Rotate Input

and Output Shaft After Assembly

and Before Running ..... 25 ln. Lbs. (2.8 Ncm)

Maximum Torque to Rotate Control

Shaft After Assembly .... 25 ln. Lbs. (2.8 Ncm)

II

LARGE FRAME TRACTOR

PAGE 1-4 Rev. 3/85

GENERAL (Continued)

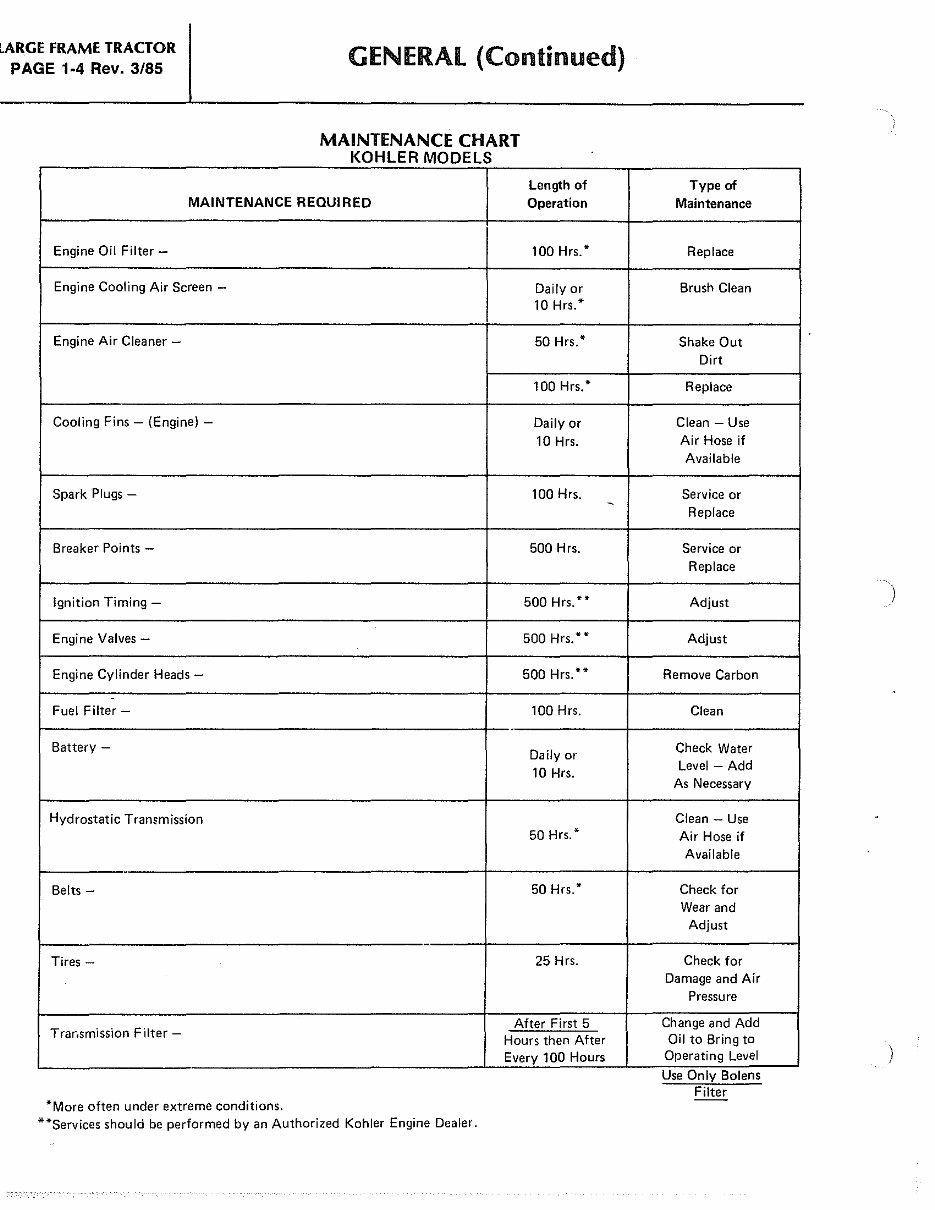

MAINTENANCE CHART

KOHLER MODELS

Length of

MAINTENANCE REQUIRED Operation

Engine Oil Filter- 100 Hrs. *

Engine Cooling Air Screen -

Dally or

10 Hrs. *

Engine Air Cleaner- 50 Hrs. *

100 Hrs. *

Cooling Fins- (Engine)- Daily or

10 Hrs.

Spark Plugs- 100 Hrs.

Breaker Points - 500 Hrs.

Ignition Timing- 500 Hrs.**

Engine Valves- 500 Hrs.**

Engine Cylinder Heads- 500 Hrs.**

-

Fuel Filter- 100 Hrs.

Battery -

Daily or

10 Hrs.

Hydrostatic Transmission

50 Hrs. •

-

Belts - 50 Hrs. *

-

Tires- 25 Hrs.

Transmission Filter-

After First 5

Hours then After

Every 100 Hours

*More often under extreme conditions.

**Services should be performed by an Authorized Kohler Engine Dealer.

'

Type of

Maintenance

Replace

Brush Clean

Shake Out

Dirt

Replace

Clean- Use

Air Hose if

Available

Service or

Replace

Service or

Replace

Adjust

Adjust

Remove Carbon

Clean

Check Water

Level- Add

As Necessary

Clean- Use

Air Hose if

Available

Check for

Wear and

Adjust

Check for

Damage and Air

Pressure

Change and Add

Oil to Bring to

Operating Level

Use Only Bolens

Filter

GENERAL (Continued)

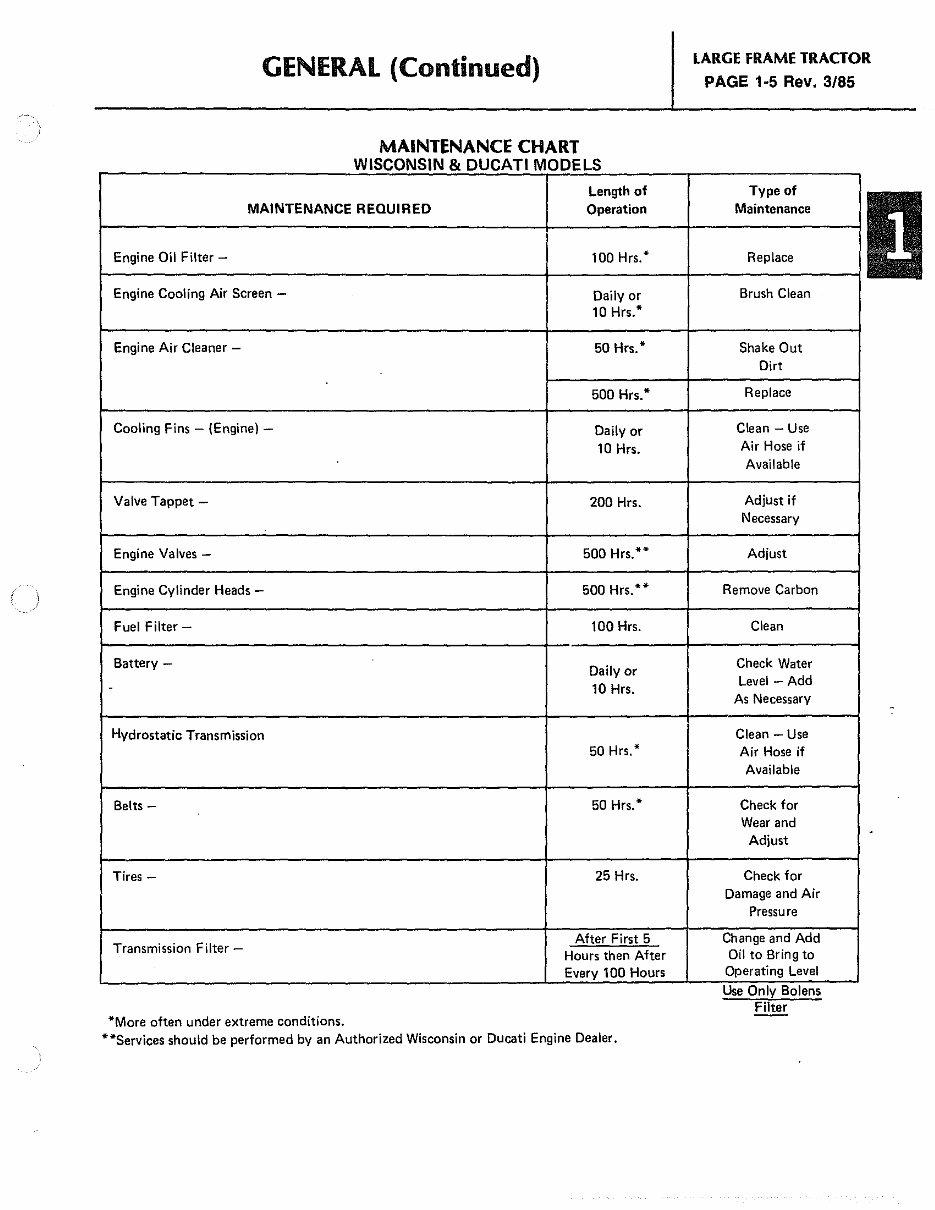

MAINTENANCE CHART

WISCONSIN & DUCATI MODELS

Length of

MAINTENANCE REQUIRED Operation

Engine Oil Filter- I 00 Hrs.*

Engine Cooling Air Screen -

Daily or

10 Hrs.*

Engine Air Cleaner- 50 Hrs.*

500 Hrs.*

Cooling Fins- (Engine)-

Daily or

10 Hrs.

Valve Tappet- 200 Hrs.

Engine Valves - 500 Hrs.**

Engine Cylinder Heads - 500 Hrs. **

Fuel Filter- 100 Hrs.

Battery -

Daily or

.

10 Hrs .

Hydrostatic Transmission

50 Hrs.*

Belts- 50 Hrs.*

Tires- 25 Hrs.

Transmission Filter-

After First 5

Hours then After

Every 100 Hours

*More often under extreme conditions.

**Services should be performed by an Authorized Wisconsin or Ducati Engine Dealer.

LARGE FRAME TRACTOR

PAGE 1·5 Rev. 3/85

Type of

Maintenance

Replace

D

Brush Clean

Shake Out

Dirt

Replace

Clean- Use

Air Hose if

Available

Adjust if

Necessary

Adjust

Remove Carbon

Clean

Check Water

Level- Add

As Necessary

Clean- Use

Air Hose if

Available

Check for

Wear and

Adjust

Check for

Damage and Air

Pressure

Change and Add

Oil to Bring to

Operating Level

Use Only Bolens

~

LARGE FRAME TRACTOR

PAGE 1·6 Rev. 3/85

GENERAL (Continued)

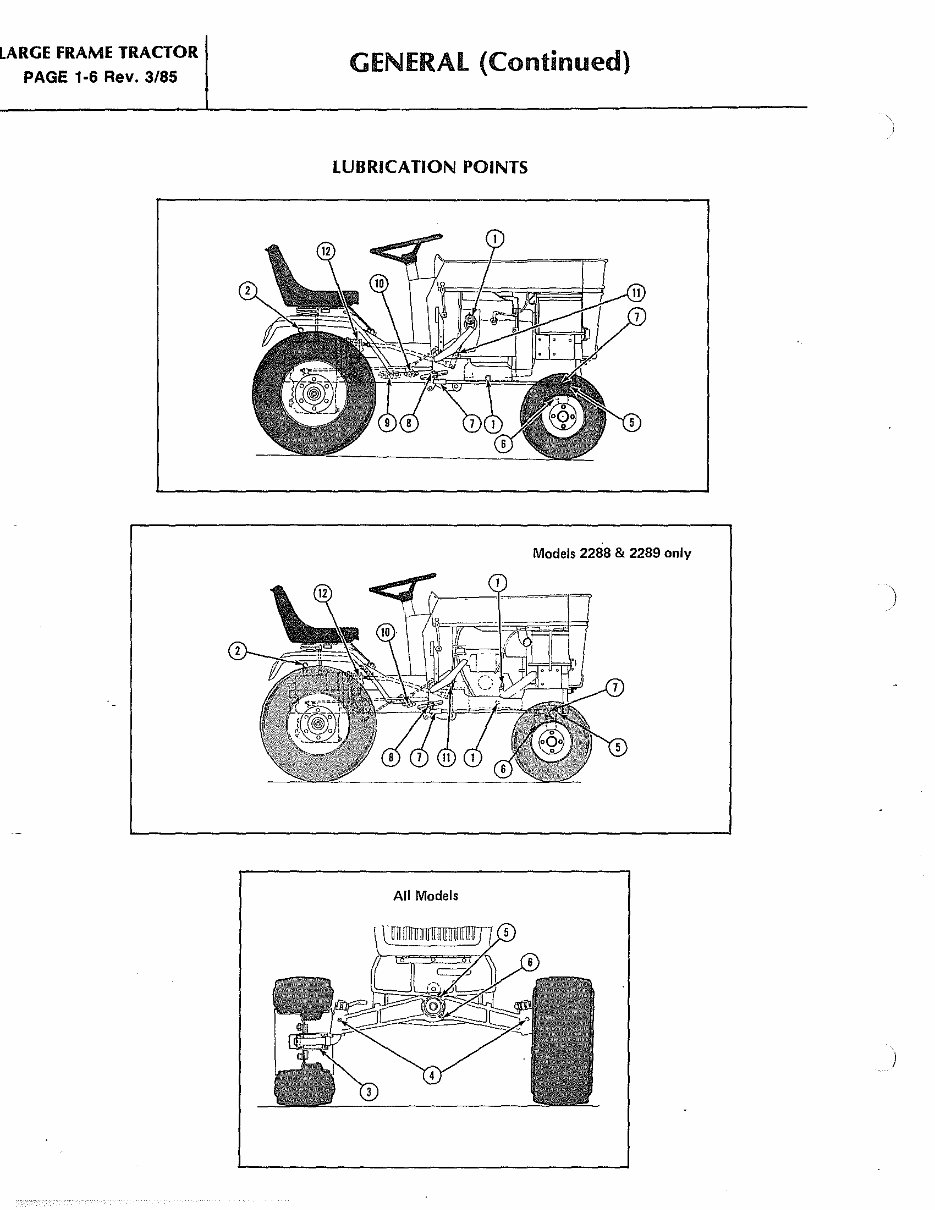

LUBRICATION POINTS

Models 22S8 & 2289 only

All Models

)

)

GENERAL(Continued)

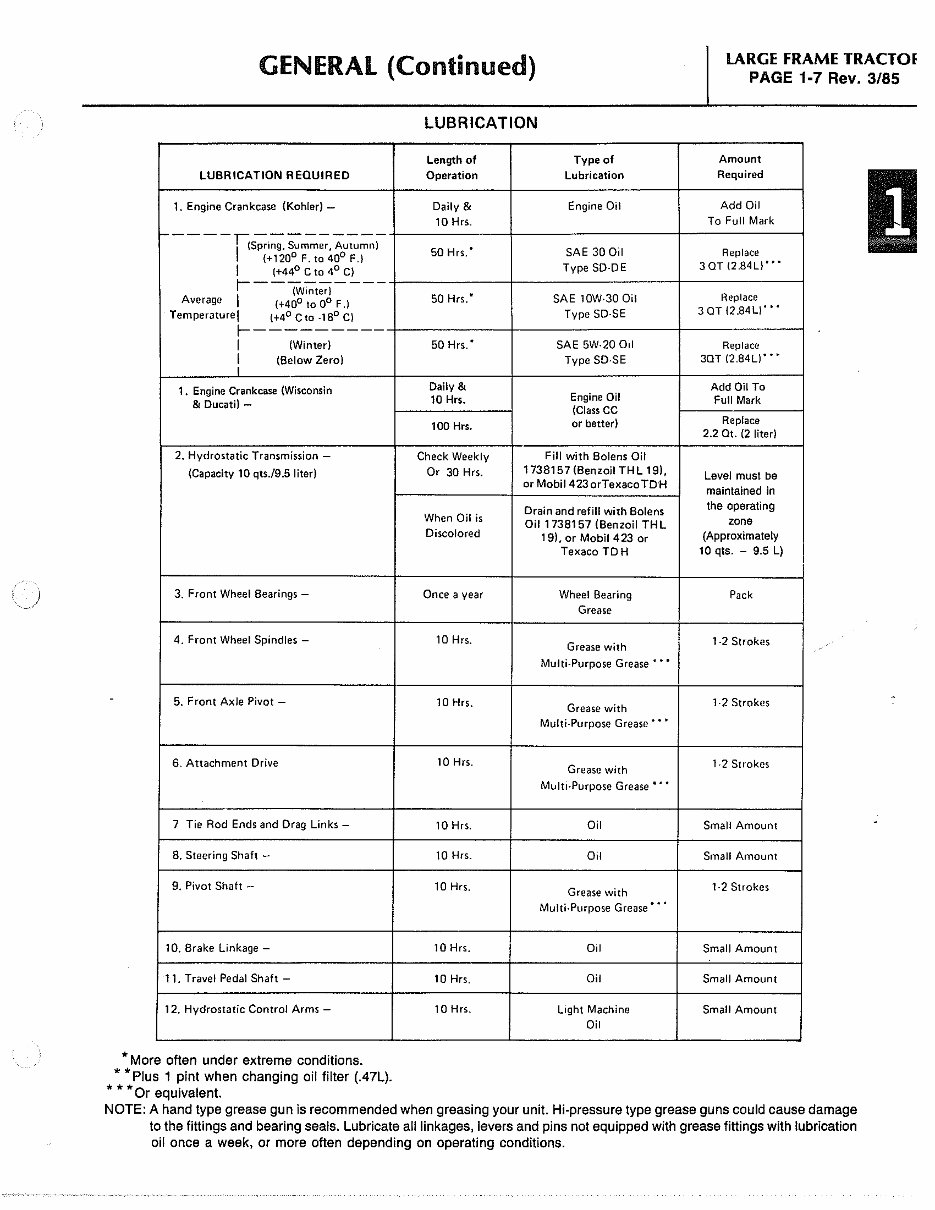

LUBRICATION REQUIRED

1. Engine Crankcase {Kohler) -

1

---- ftsprmg, Sum~;, Au~mn)

(+120° F. to 40° F.)

I (+44° C to 4° C)

Average

r---Twi;ter)--

I (+40° to 0° F.)

Temperature!

(+4° Cto -18° Cl

1--------

I

(Winter)

i

(Below Zero)

1. Engine Crankcase (Wisconsin

& Ducati)-

2. Hydrostatic Transmission -

{Capacity 10 qts./9.5 titer)

3. Front Wheel Bearings-

4. Front Wheel Spindles-

5. Front Axle Pivot-

6. Attachment Drive

7 Tie Rod Ends and Drag Links -

8. Steering Shaft -

9. Pivot Shaft -

10. Brake Linkage -

11. Travel Pedal Shaft -

12. Hydrostatic Control Arms -

*More often under extreme conditions.

**Plus 1 pint when changing oil filter (.47L).

* * *Or equivalent.

LUBRICATION

Length of Type of

Operation Lubrication

Daily & Engine Oil

10 Hrs.

50 Hrs.

4

SAE 30 Oil

Type SO-DE

50 Hrs. • SAE lOW-30 Oil

Type SD-SE

50 Hrs. * SAE SW-20 Oil

Type SD-SE

Daily&

10 Hrs.

Engine Oil

(Class CC

100 Hrs.

or better)

Check Weekly Fill with Bolens Oil

Or 30 Hrs.

173815 7 (Benzolt TH L 19),

or Mobil 423 orTexaco TDH

Drain and refill with Botens

When Oil is

Oil 1738157 (Benzoit TH L

Discolored

19). or Mobil 423 or

Texaco TDH

Once a year Wheel Bearing

Grease

10 Hrs.

Grease with

Multi-Purpose Grease ' • •

10 Hrs.

Grease with

Multi-Purpose Grease • • •

10 Hrs.

Grease with

Multi-Purpose Grease • • •

10 Hrs. Oil

10 Hrs. Oil

10 Hrs.

Grease with

Multi-Purpose Grease

...

10 Hrs.

0"

10 Hrs. Oil

10 Hrs. l1ght Machine

Oil

LARGE FRAME TRACTOI

PAGE 1-7 Rev. 3/85

Amount

Required

Add Oil

To Full Mark

Replace

JOT (2.84L)' ..

Replace

3 OT {2.84LI' ''

Replace

JOT (2.84L)'' •

Add Oil To

Full Mark

Replace

2.2 Ot. (2 liter)

Level must be

maintained in

the operating

zone

(Approximately

10 qls. - 9.5 L)

Pack

1-2 Strokes

1-2 Strokes

1-2 Strokes

Small Amount

Small Amount

1·2 Strokes

Small Amount

Small Amount

Small Amount

NOTE: A hand type grease gun is recommended when greasing your unit. Hi·pressure type grease guns could cause damage

to the fittings and bearing seals. Lubricate all linkages, levers and pins not equipped with grease fittings with lubrication

oil once a week, or more often depending on operating conditions.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$33.99

Viewed 28 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$33.99

The Bolens Large Frame Tractors Workshop Service Repair Manual is a comprehensive resource covering models 1886S (HT18), 2086 (HT20), 2087 (HT20), 2288 (HT22), 2289 (HT20), 2389 (HT23), 2388S (HDT1000), and 2389S (HT23). This factory repair manual is designed to assist both professional mechanics and DIY enthusiasts in addressing all repair needs for these tractors, including coverage of engines. It contains a wealth of pictures, diagrams, and illustrations to facilitate the repair process.