Stihl FS 120 200 300 350 400 450 & FR 350 450 Brushcutters Workshop Service Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

STIHL FR 350, 450 2003-04

STIH)

STIHL FS 120, 200, 300, 350, 400, 450,

STIH)

chodina@live.co.uk chodina@live.co.uk

1. Introduction 2

2. Specifications 3

2.1 Engine 3

2.2 Fuel System 3

2.3 Ignition System 4

2.4 Gearhead 4

2.5 Special Accessories 4

2.5.1 For User 4

2.5.2 For Service 4

2.6 Tightening Torques 5

3. Clutch 7

3.1 Removing and Installing 7

3.2 Clutch Carrier 8

4. Engine 9

4.1 Exhaust Muffler/

Spark Arresting Screen 9

4.2 Leakage Test 10

4.2.1 Preparations 10

4.2.2 Pressure Test 11

4.2.3 Vacuum Test 11

4.3 Oil Seals 12

4.4 Exposing the Cylinder 13

4.5 Cylinder and Piston 14

4.5.1 Removal 14

4.5.2 Installation 15

4.6 Piston Rings 17

4.7 Crankcase 17

4.7.1 Removing Crankshaft 17

4.7.2 Installing Crankshaft 20

4.8 Decompression Valve 23

5. Ignition System 23

5.1 Spark Plug Boot 23

5.2 Ignition Lead

(FS 400/450, FR 450) 24

5.3 Ignition Module 25

5.3.1 Ignition Timing 26

5.3.2 Removing and Installing

(FS 120...350, FR 350) 26

5.3.3 Removing and Installing

(FS 400/450, FR 450) 27

5.4 Flywheel 28

5.5 Short Circuit Wire 29

6. Rewind Starter 30

6.1 General 30

6.2 Rewind Spring 30

6.2.1 Replacing 30

6.2.2 Tensioning 31

6.3 Starter Rope/Starter

Grip (ElastoStart) 32

7. Throttle Control 33

7.1 Throttle Trigger/Interlock

Lever (Bike Handle) 33

7.2 Contact Springs/Detent

Spring in Control Handle

(Bike Handle) 34

7.3 Throttle Trigger/Interlock

Lever (Loop Handle) 34

7.4 Slide Control

(Loop Handle) 35

7.5 Throttle Cable 36

7.5.1 Replacing 36

7.5.2 Adjusting 37

8. Fuel System 38

8.1 Air Filter 38

8.2 Carburetor 39

8.2.1 Removing and Installing

(FS 120...350, FR 350) 39

8.2.2 Removing and Installing

(FS 400/450, FR 450) 40

8.2.3 Leakage Test 41

8.2.4 Adjusting

(three screws) 42

8.2.5 Adjusting

(one screw) 43

8.3 Tank Vent 44

8.4 Pickup Body 44

8.5 Fuel Tank/

Hoses 45

8.6 Manual

Fuel Pump 47

9. AV System 47

9.1 Repair

(FS 120/200) 47

9.2 Repair

(FS 300...450) 48

9.3 Repair

(FR 350/450) 50

10. Shaft 51

10.1 Bike Handle

(FS 120/200) 51

10.2 Bike Handle

(FS 300...450) 51

10.3 Loop Handle 52

10.4 Drive Shaft/

Flexible Liner 52

10.5 Flexible Shaft

(FR 350/450) 53

10.6 Drive Tube 54

10.7 Housing

(FR 350/450) 56

11. Cutting Tool

Drive 56

11.1 Gearhead 56

11.2 Clutch Drum 57

12. Support Frame

(FR 350/450) 58

12.1 Repair 58

13. Special Servicing

Tools and Aids 59

13.1 Special Servicing Tools 59

13.2 Servicing Aids 61

© 2000, Andreas Stihl AG & Co., Waiblingen

CONTENTS

qS

FS 120, 200, 300, 350, 400, 450, FR 350, 450 1

chodina@live.co.uk chodina@live.co.uk

This service manual contains de-

tailed descriptions of all the repair

and servicing procedures specific

to this power tool series.

There are separate handbooks for

servicing procedures for stand-

ardized parts and assemblies that

are installed in several STIHL

power tool models. Reference is

made to these handbooks in the

appropriate chapters in this

manual.

As the design concept of models

FS 120, FS 200, FS 300, FS 350,

FS 400, FS 450 and FR 350, FR

450 is almost identical, the descrip-

tions and servicing procedures in

this manual generally apply to all

models. Differences are described

in detail.

You should make use of the

illustrated parts lists while carrying

out repair work. They show the

installed positions of the individual

components and assemblies.

Refer to the latest edition of the

relevant parts list to check the part

numbers of any replacement parts

needed.

Parts lists on microfiche and CD-

ROM are always more up to date

than printed lists.

A fault on the power tool may have

several causes. Consult the

troubleshooting charts for all as-

semblies in the "Standard Repairs,

Troubleshooting" handbook.

Refer to the "Technical Informa-

tion" bulletins for engineering

changes which have been intro-

duced since publication of this

service manual. Technical informa-

tion bulletins also supplement the

parts list until a revised edition is

issued.

The special servicing tools mentio-

ned in the descriptions are

listed in the last chapter of this

manual.

Use the part numbers to identify

the tools in the "STIHL Special

Tools" manual.

The manual lists all special

servicing tools currently available

from STIHL.

Symbols are included in the text

and pictures for greater clarity.

The meanings are as follows:

In the descriptions:

• = Action to be taken as

shown in the illustration

(above the text)

- = Action to be taken that

is not shown in the

illustration

(above the text)

In the illustrations:

= Pointer

= Direction of movement

Service manuals and all technical

information bulletins describing

engineering changes are intended

exclusively for the use of STIHL

servicing dealers. They must not

be passed to third parties.

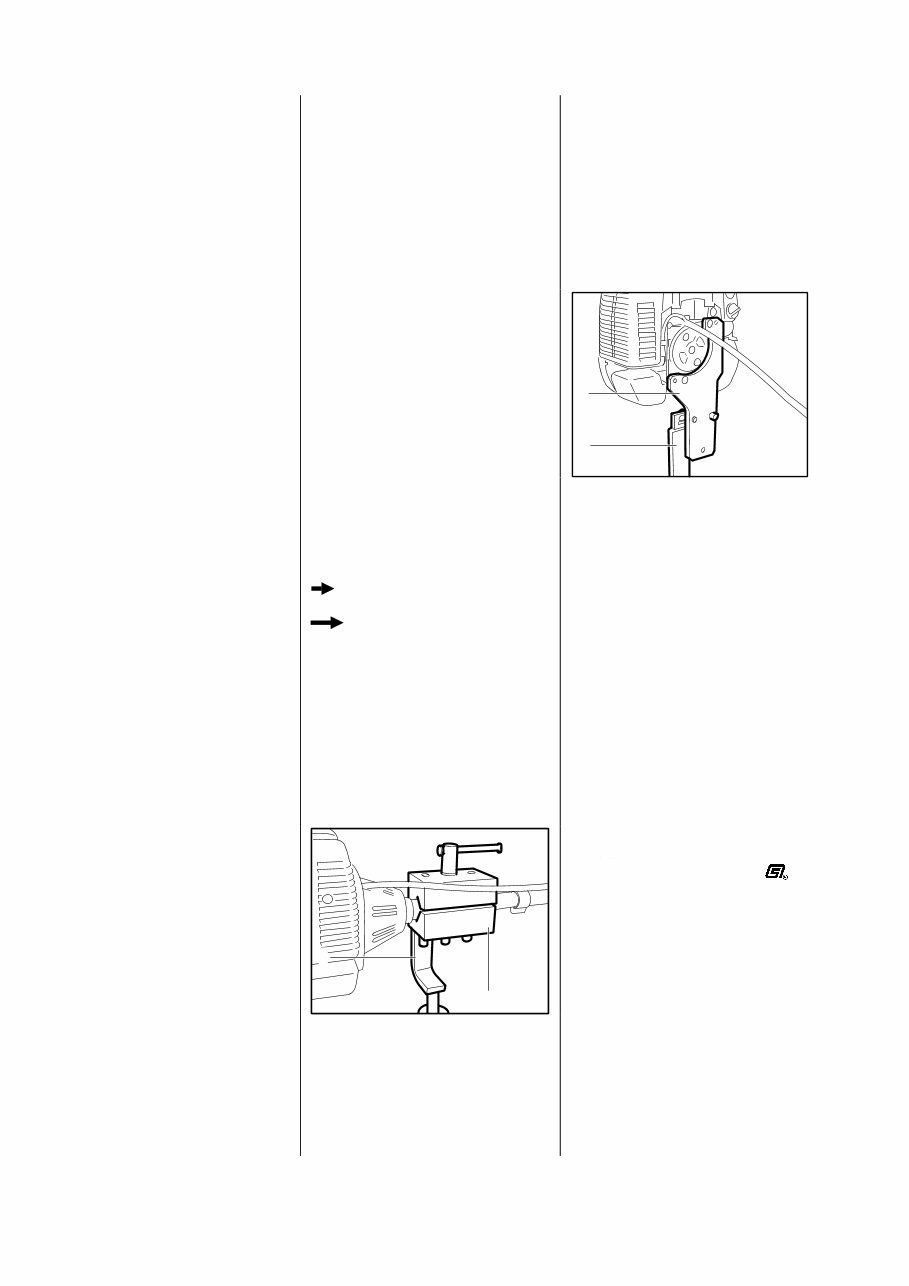

Servicing and repairs are made

considerably easier if the machine

is mounted on assembly stand (2)

5910 890 3100 with the aid of

clamp (1) 5910 890 8800.

Secure the clamp to the assembly

stand with two washers and two

M8 nuts.

Servicing and repairs to the power-

head are considerably easier if it is

mounted on assembly stand (2)

5910 890 3100 with the aid of

clamping plate (1) 5910 890 2101.

First remove the clutch housing

and secure the powerhead to the

stand with two M6x20 and two

M10x25 hex. head screws.

The machine or powerhead can

then be swivelled to the best posi-

tion for the ongoing repair and this

leaves both hands free.

Always use original STIHL

replacement parts.

They can be identified by the

STIHL part number,

the

and the STIHL parts symbol

The symbol may appear alone on

small parts.

1. INTRODUCTION

250RA228

1

2

VA

250RA227 VA

2

1

2 FS 120, 200, 300, 350, 400, 450, FR 350, 450

chodina@live.co.uk chodina@live.co.uk

2.1 Engine

STIHL single cylinder two-stroke engine with special impregnated cylinder bore

FS 120/300 FS 200/350 FS 400 FS 450

FR 350 FR 450

Displacement: 30.8 cm

3

36.3 cm

3

40.2 cm

3

44.3 cm

3

1.88 cu.in 2.21 cu.in 2.45 cu.in 2.70 cu.in

Bore: 35 mm 38 mm 40.0 mm 42.0 mm

1.38 in 1.49 in 1.57 in 1.65 in

Stroke: 32 mm 32 mm 32 mm 32 mm

1.26 in 1.26 in 1.26 in 1.26 in

Power output: 1.3 kW (1.8 bhp) 1.6 kW (2.2 bhp) 1.9 kW (2.6 bhp) 2.1 kW (2.8 bhp)

at 9,000 rpm

Max. permissible engine speed

without cutting tool

(cut-off speed): 12,500 ± 1000 rpm 12,500 ± 800 rpm

Idle speed: 2,800 rpm

Bearings: Crankshaft supported in heavy-duty ball bearings, needle cages on

small and big ends

Piston pin diameter: 10 mm (0.39 in)

Rewind starter: ElastoStart

Pawls: Single pawl system

Reserve pull on rope rotor: min. 1/2 turn

Starter rope: 3.0 mm (0.12 in) dia. x 800 mm (31.5 in)

Clutch: Centrifugal clutch without linings

Clutch engages at: 4,300 rpm

Crankcase leakage

test

at gauge pressure: 0.5 bar (7.25 psi)

under vacuum: 0.5 bar (7.25 psi)

2.2 Fuel System

Carburetor: Diaphragm carburetor

Standard setting on carburetors

with three adjusting screws

High speed screw H: Open approx. 1 turn

Low speed screw L: Open approx. 1 turn

Carburetor leakage test

at gauge pressure: 0.8 bar (11.6 psi)

Function of tank vent

at gauge pressure: ≤ 0.3 bar (4.35 psi)

under vacuum: ≤ 0.05 bar (0.725 psi)

Fuel tank capacity: 0.64 l (1.35 US pt) 0.68 l (1.44 US pt)

Octane rating: min. 90 RON (US/CAN; pump octane min. 87)

Fuel mixture: Regular brand name gasoline

and two-stroke engine oil

Mix ratio: 50:1 with STIHL two-stroke engine oil

25:1 with other brand name two-stroke, air-cooled engine oils

Air filter: Paper filter

2. SPECIFICATIONS

FS 120, 200, 300, 350, 400, 450, FR 350, 450 3

chodina@live.co.uk chodina@live.co.uk

2.3 Ignition System Type: Electronic magneto

ignition (breakerless)

with integral trigger unit

and electronic speed

governor

Air gap: 0.2 - 0.5 mm (0.008 - 0.020 in)

Length of ignition lead: 305 mm * (12 in)*

Spark plug (suppressed): Bosch WSR 6F,

NGK BPMR 7 A or

Champion RCJ 6Y

Electrode gap: 0.5 mm (0.020 in)

Splark plug thread: M14x1.25

Length of thread: 9.5 mm (0.37 in)

2.4 Gearhead Type: Spiral-toothed

bevel gear drive

Gear ratio: 1:1.4 **

1:1.235

Bearings: Deep groove ball bearings

Lubrication: STIHL gear lubricant 0781 120 1117

(7 g / 0.25 oz)

2.5 Special Accessories

2.5.1 For User Full harness

Safety glasses

Transport guard for

metal cutting tools

STIHL gear lubricant (80 g/3 oz tube) 0781 120 1109

STIHL gear lubricant (80 g/3 oz tube) 0781 120 1117

2.5.2 For Service Carburetor parts kit 4134 007 1060

Set of gaskets

for FS 120, 200, 300, 350, FR 350 4134 007 1050

Set of gaskets

for FS 400, 450, FR 450 4128 007 1050

* FS 400/450 only

** FS 120, 200, 350 and 450

4 FS 120, 200, 300, 350, 400, 450, FR 350, 450

chodina@live.co.uk chodina@live.co.uk

DG and P screws (Plastoform) are used in polymer and lightmetal components. These screws form a perma-

nent thread when they are installed for the first time. They can be removed and installed as often as necessary

without detrimentally affecting the strength of the screwed assembly, providing the specified tightening torque is

observed. For this reason it is essential to use a torque wrench.

Fastener Thread For component Torque Remarks

size Nm lbf.ft

Self-tapping screw IS-B3.5x6.5 Rewind spring/fan housing 1.5 1.1

Self-tapping screw IS-B4.2x9.5 Muffler/spark arresting screen 2.5 1.8 1) 2)

Spline screw IS-DG4x20 Ignition module/crankcase 4.5 3.3 3) 4) 5)

Spline screw IS-DG5x24 Ignition module/crankcase 6.0 4.4 1) 2)

Spline screw IS-DG5x12 AV sleeve/drive tube (fixing screw) 2.5 1.8 3)

Spline screw IS-DG5x12 Guard ring/gear housing 5.0 3.7 1) 4)

Spline screw IS-DG5x20 Fan housing/crankcase 6.0 4.4

Spline screw IS-DG5x20 Fan housing/shroud/crankcase 6.0 4.4

Spline screw IS-DG5x20 Carburetor housing/crankcase/

cylinder 6.0 4.4

Spline screw IS-DG5x20 Filter housing/ground wire/

crankcase 6.0 4.4

Spline screw IS-DG5x20 Ground wire/crankcase 6.0 4.4 1) 2)

Spline screw IS-DG5x26 Fuel tank/crankcase 6.0 4.4

Spline screw IS-DG5x24 Bracket/crankcase 6.0 4.4 1)

Spline screw IS-DG5x20 Shroud/clutch housing 6.0 4.4

Spline screw IS-DG5x26 Guard plate/fuel tank/

crankcase 6.0 4.4 1) 2)

Spline screw IS-DG5x28 Cylinder/crankcase 10.5 7.5

Spline screw IS-DG5x24 Muffler/crankcase 8.5 6.3

Spline screw IS-DG5x24 Muffler/cylinder 8.5 6.3

Spline screw IS-DG5x24 Crankcase 8.5 6.3

Spline screw IS-DG5x24 Clutch housing/crankcase 8.5 6.3 1) 2) 4) 5)

Spline screw IS-DG5x24 Clutch housing/crankcase 6.0 4.4 3)

Spline screw IS-DG6x28 Clutch housing/drive tube 12.0 8.8 1) 6)

Spline screw IS-DG5x24 Clutch housing/drive tube 8.5 6.3 4)

Spline screw IS-DG5x24 Gear housing/drive tube 8.5 6.3 2) 3) 5)

Spline screw IS-DG5x25 Gear housing/drive tube

Stage 1 1.5 1.1 1) 4)

Stage 2 7.5 5.5 1) 4)

Collar nut M5 Filter housing/carburetor housing 3.5 2.6

Collar screw M5/P6 Carburetor housing 4.0 3.0

Spline screw IS-M5x12 Clamp/control handle/

drive tube (loop handle) 2.0 1.5 3) 4)

Spline screw IS-M5x16 AV sleeve/drive tube (clamp screw) 5.5 4.0 3)

Spline screw IS-M5x12 Clamp/control handle/drive tube 2.0 1.5 2) 5)

Spline screw IS-M5x16 Clamp/drive tube (for harness) 4.5 3.3 3)

Spline screw IS-M5x30 Control handle (bike handle) 2.0 1.5 6)

2.6 Tightening Torques

FS 120, 200, 300, 350, 400, 450, FR 350, 450 5

chodina@live.co.uk chodina@live.co.uk

Fastener Thread For component Torque Remarks

size Nm lbf.ft

Spline screw IS-M6x25 Clamp/loop handle 4.5 3.3 3)

Spline screw IS-M6x25 Support/drive tube 6.0 4.4 1) 4) 6)

Spline screw IS-M6x35 Clamp moldings/support block

(handle support/bike handle) 4.5 3.3 3)

M8 Carrier 24.0 17.7

Spline screw IS-M6x18 Clutch shoe/carrier 12.0 8.8

M8 Flywheel 32.0 23.6

M10 Decompression valve 14.0 10.3 1) 2) 4) 5)

M14x1.25 Spark plug 20.0 15.0

Screw plug M11x10 Gearhead 8.5 6.3

Spline screw IS-M5x14 Filter cover/filter housing 6.0 4.4 1) 2)

Plastoform screw IS-P4x16 Control handle/handle moldings 1.0 0.75

Collar screw IS-P3.5x10.6 Detent spring/slide control

(bike handle) 1.1 0.80 1) 3) 4)

Nut M12x1.5 L Cutting tool 25.0 18.5

Spline screw IS-M5x16 Cutting tool deflector/gearhead 4.3 3.2

Spline screw IS-M6x14 Spring/support plate 10.0 7.5 2) 5)

Spline screw IS-M6x25 Housing/shaft clamp screw 4.5 3.3 2) 5)

Spline screw IS-M6x14 Bearing housing/support frame 10.0 7.5 2) 5)

Spline screw IS-M10x20 Support plate/ball bearing/

support frame 20.0 15.0 2) 5)

Use the following procedure to fit a DG or P screw in an existing thread:

– Place the DG or P screw in the hole and rotate it counterclockwise until it drops down slightly.

– Tighten the screw clockwise to the specified torque.

This procedure ensures that the screw engages properly in the existing thread and does not form a new thread.

1) FS 400/450

2) FR 450

3) FS 120/200

4) FS 300/350

5) FR 350

6) with washer

Note: Power screwdriver speed settings for polymer: Plastoform screws max. 600 rpm

DG screws max. 500 rpm

6 FS 120, 200, 300, 350, 400, 450, FR 350, 450

chodina@live.co.uk chodina@live.co.uk

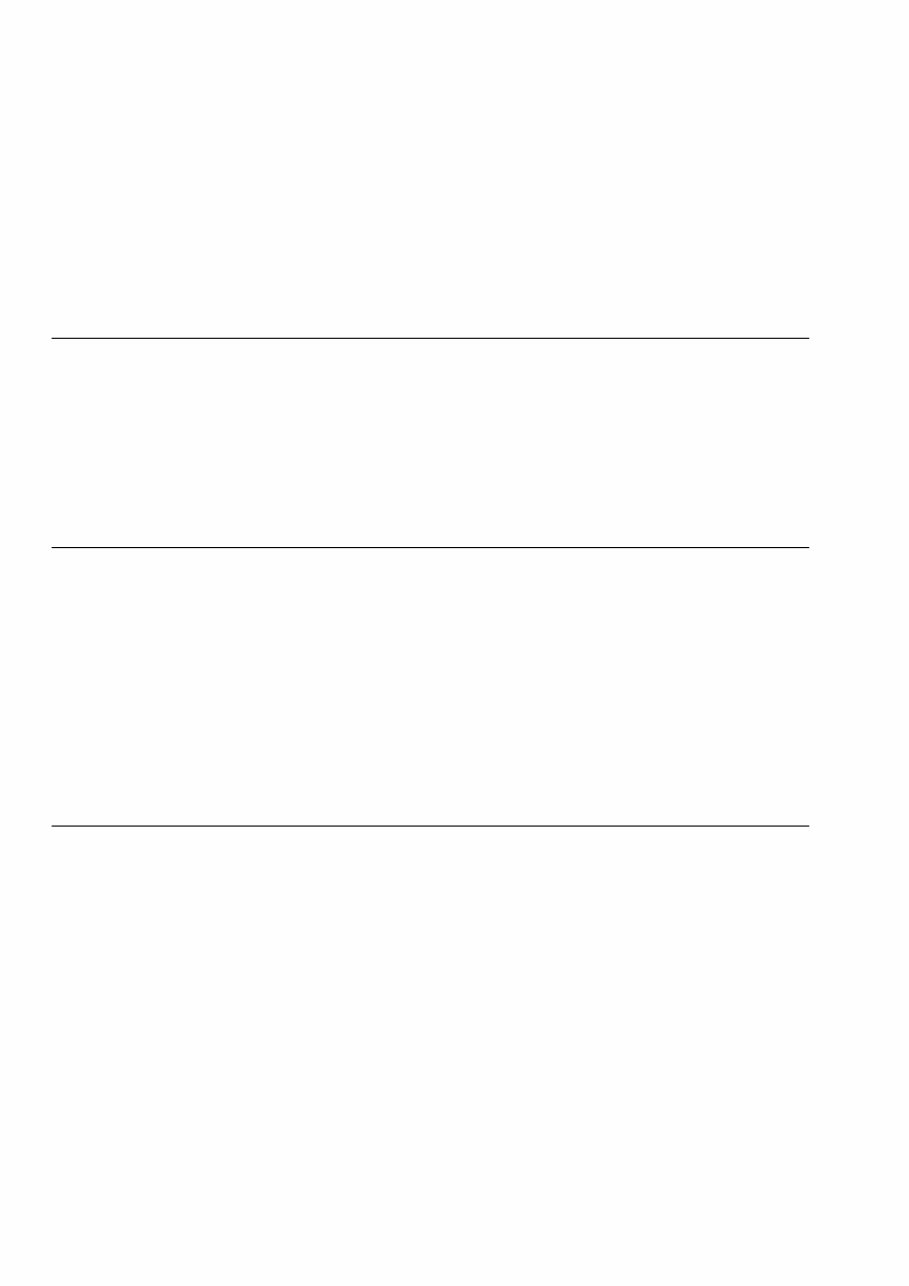

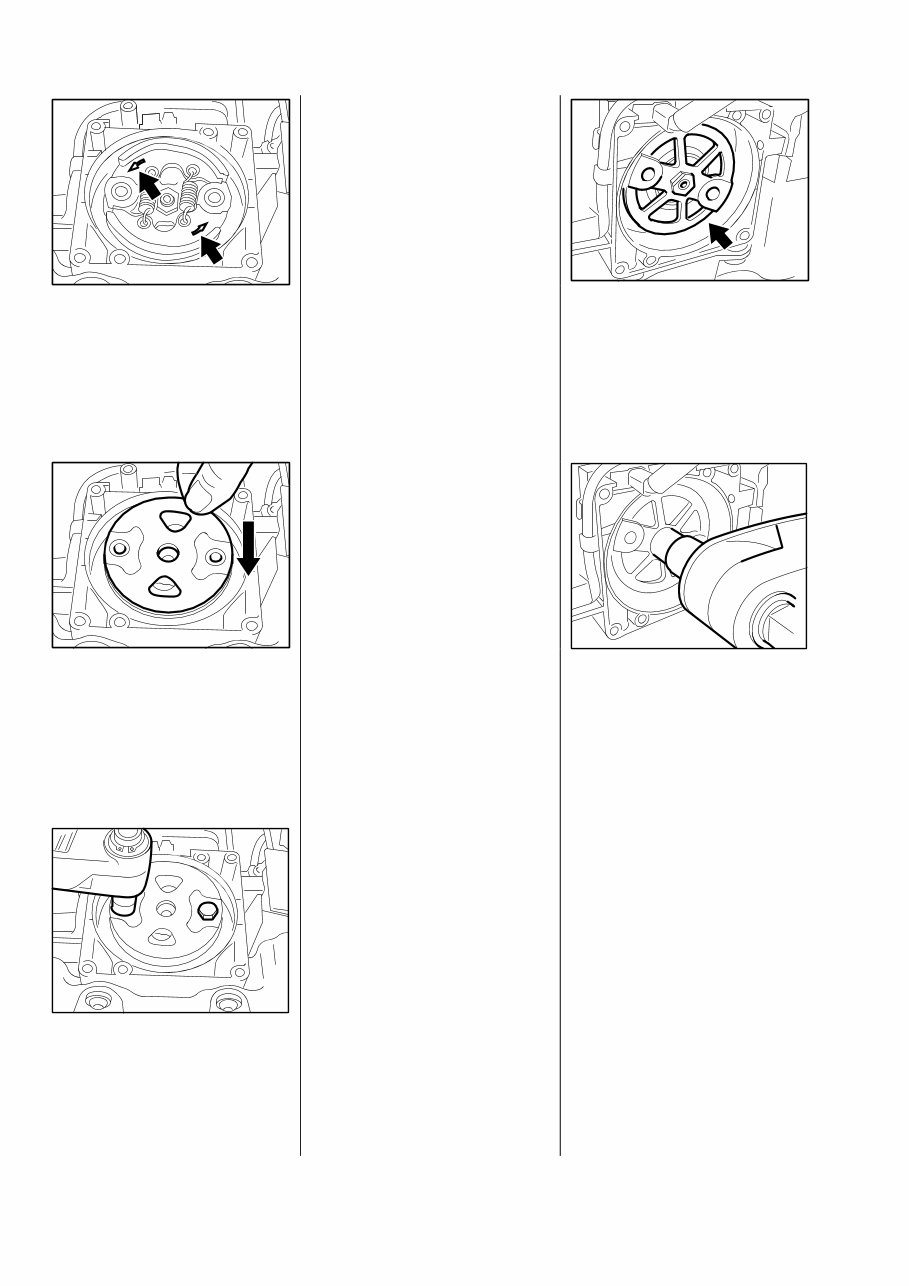

Removal

Troubleshooting chart - see

"Standard Repairs, Trouble-

shooting" handbook.

- Remove clutch housing -

see 9.1 or 11.2.

All models

• Inspect clutch drum. There

should be no scores or signs of

excessive wear.

Important: If there are signs of

serious wear on the inside

diameter, fit a new clutch drum -

see 11.2.

- Remove the shroud - see 4.1.

- Pull off the spark plug boot.

- Unscrew the spark plug.

FS 120...350, FR 350

• Fit locking strip (1)

0000 893 5903.

FS 400/450, FR 450

• Fit locking strip (1)

4221 893 5900.

• Take out screws (1).

• Remove cover (2).

• Remove clutch shoes with

bushings.

• Take bushings out of the clutch

shoes.

• Twist the clutch shoes and

detach the springs.

Important: Clutch shoes and

springs must always be replaced

in pairs.

3. CLUTCH

3.1 Removing and Installing

250RA001

1

VA

250RA002

1

VA

250RA004

1

1

2

VA

250RA003 VA

250RA005 VA

250RA230 VA

250RA229 VA

FS 120, 200, 300, 350, 400, 450, FR 350, 450 7

chodina@live.co.uk chodina@live.co.uk

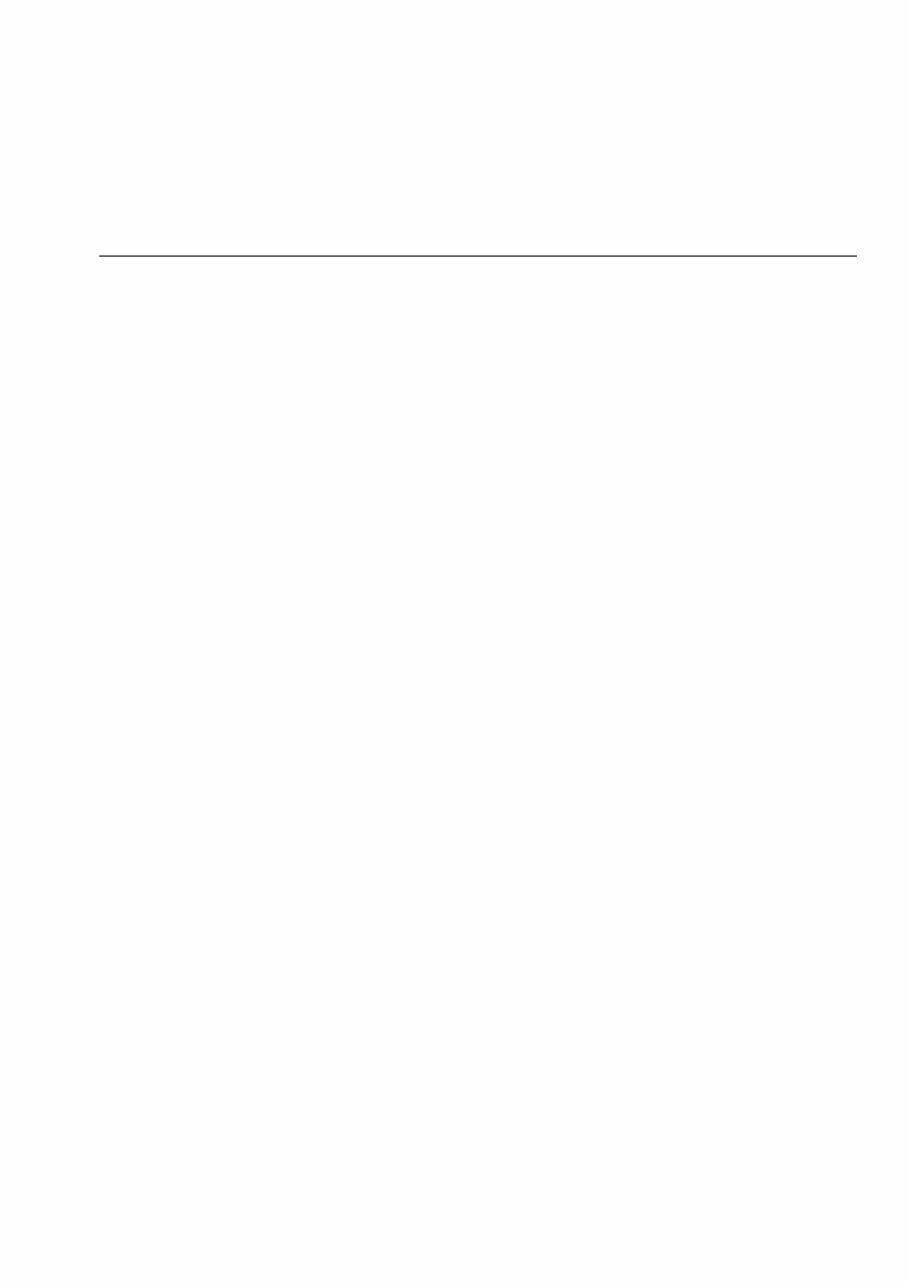

Installation

• Fit clutch shoes with springs and

bushings so that the arrows point

counterclockwise.

• Fit cover in position.

• Insert screws and tighten down

to 12 Nm (8.8 lbf.ft).

- Pull locking strip out of cylinder.

- Fit spark plug and tighten down

to 20 Nm (15 lbf.ft).

Important: If the spark plug

comes with a separate terminal

nut, always fit the nut on the

thread and tighten it down

securely.

- Fit the boot on the spark plug.

- Fit the shroud - see 4.1.

- Fit clutch housing -

see 9.1 or 11.2.

- Remove clutch - see 3.1.

• Unscrew carrier from end of

crankshaft.

• Fit the carrier and tighten it

down to 24 Nm (17.7 lbf.ft).

- Install the clutch - see 3.1.

3.2 Clutch Carrier

250RA232 VA 250RA231 VA

250RA234 VA

250RA235 VA

250RA233 VA

8 FS 120, 200, 300, 350, 400, 450, FR 350, 450

chodina@live.co.uk chodina@live.co.uk

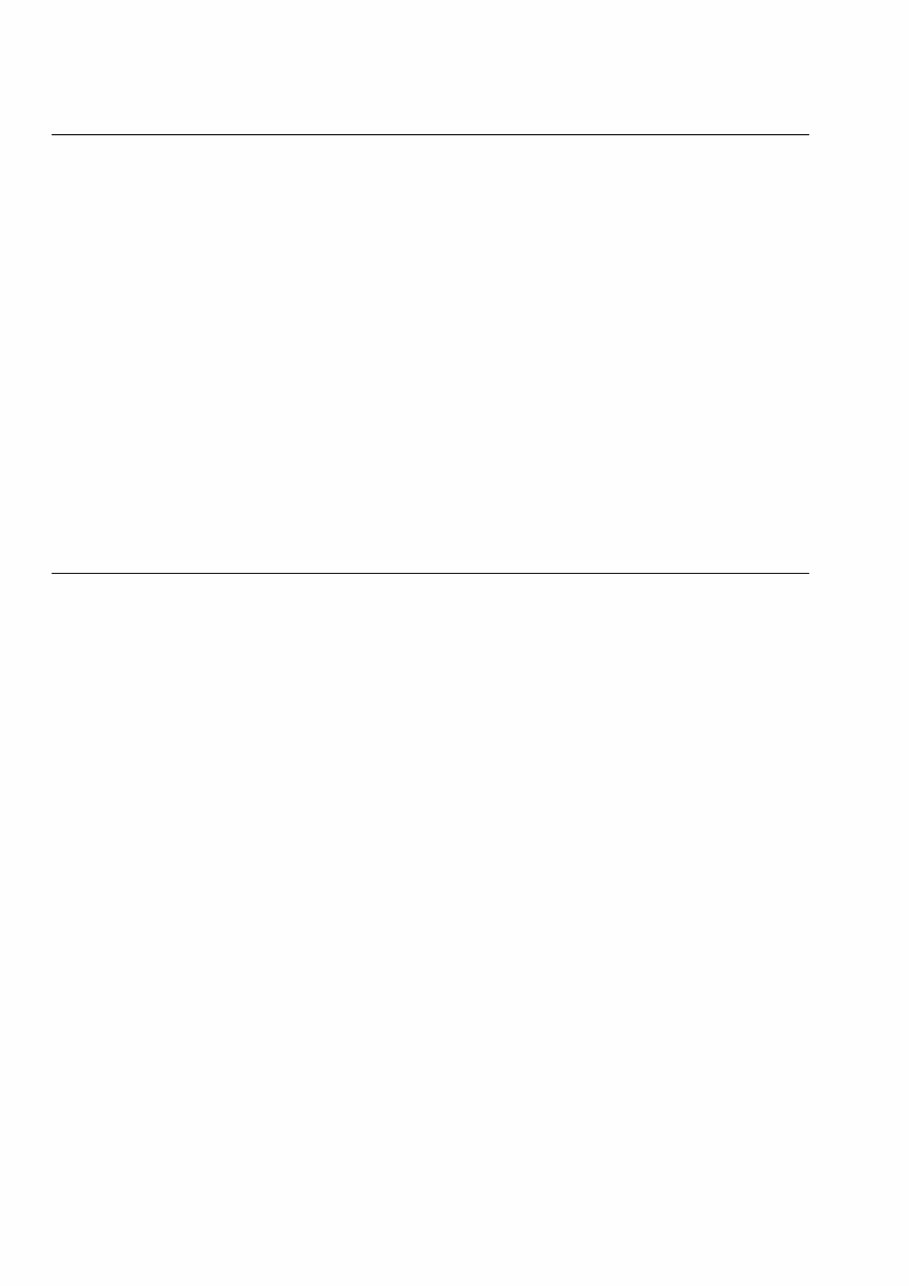

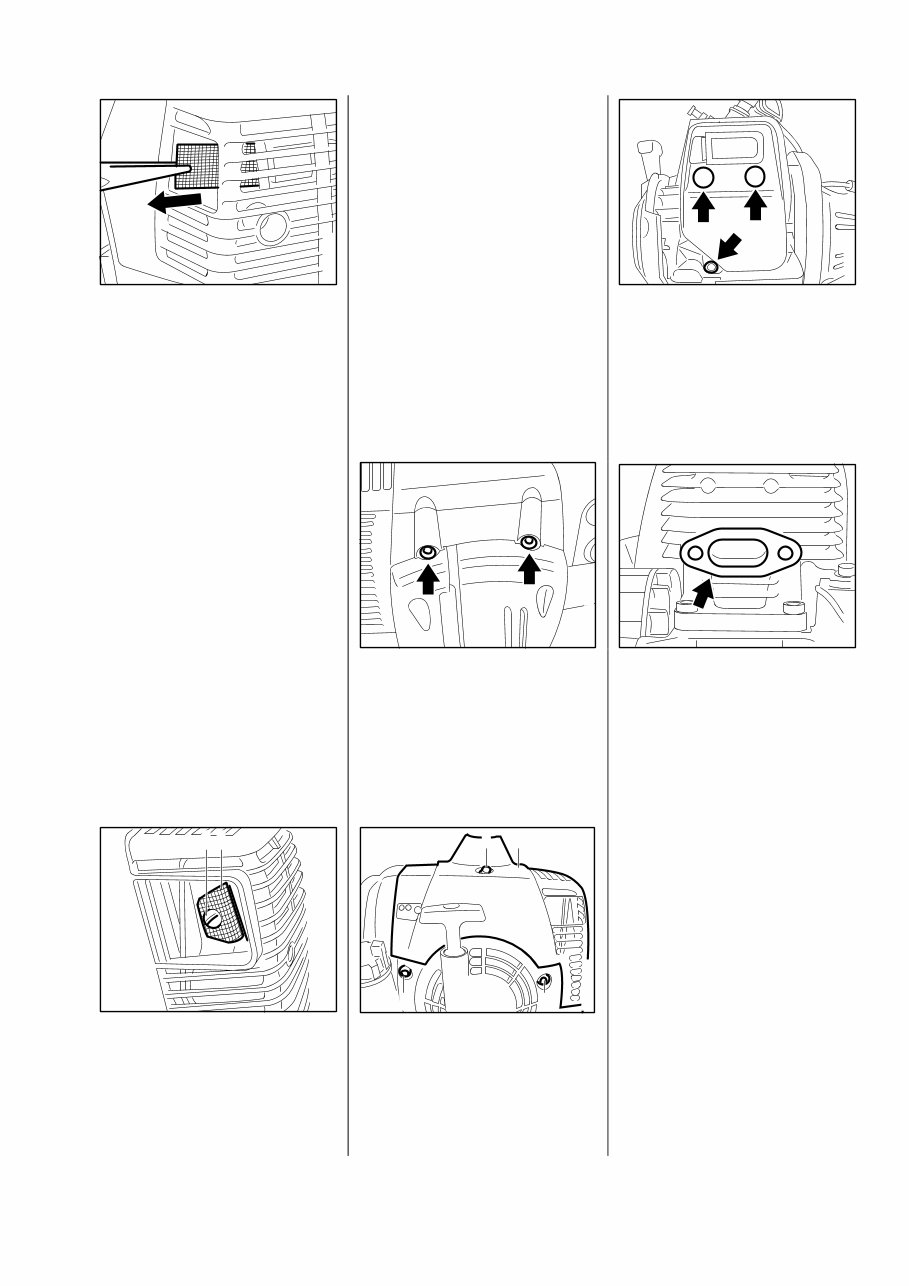

Troubleshooting chart - see

"Standard Repairs, Trouble-

shooting" handbook.

Spark arresting screen

FS 120...350, FR 350

• Pull spark arresting screen out of

the muffler.

- Clean or replace spark arresting

screen if necessary.

FS 400/450, FR 450

• Take out the screw (1).

• Pull spark arresting screen (2)

out of the muffler.

- Clean or replace spark arresting

screen if necessary.

- Tighten down screw to 2.5 Nm

(1.8 lbf.ft).

Muffler

FS 400/450, FR 450

- Remove air filter cover - see 8.1.

All models

• Remove screws from clutch

housing.

• Take out screws (1).

• Press down the decompression

valve (2).

• Remove the shroud (3).

• Take out the screws.

- Lift away the muffler.

• Remove the gasket.

Reassemble in the reverse

sequence.

- Use a new gasket.

- Tighten down screws to 8.5 Nm

(6.3 lbf.ft).

250RA006 VA

250RA011 VA

250RA009 VA

250RA012 VA

250RA007

1 2

VA

1

250RA010

1

3 2

VA

4. ENGINE

4.1 Exhaust Muffler/Spark Arresting Screen

FS 120, 200, 300, 350, 400, 450, FR 350, 450 9

chodina@live.co.uk chodina@live.co.uk

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

$41.99

Viewed 25 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

$41.99

This manual is suitable for both first-time owners and amateur enthusiasts, as well as professional technicians. It is designed in an easy-to-read format and provides all the necessary information to perform procedures correctly.

- Models Covered:

- Stihl FS 120 Brushcutter

- Stihl FS 200 Brushcutter

- Stihl FS 300 Brushcutter

- Stihl FS 350 Brushcutter

- Stihl FS 400 Brushcutter

- Stihl FS 450 Brushcutter

- Stihl FR 350 Brushcutter

- Stihl FR 450 Brushcutter

It is recommended to keep this shop manual accessible and refer to it regularly. Performing routine and preventive maintenance using this manual can save time and money by preventing premature failure and unnecessary repairs.

- Manual Contents:

- Introduction

- Specifications

- Clutch

- Engine

- Ignition System

- Rewind Starter

- AV System

- SHAFT

- CUTTING TOOL DRIVE

- SUPPORT FRAME (FR 350/450)

- Special Servicing Tools And Aids

File Format: PDF

Compatible: All Versions of Windows & Mac

Language: English

Requirements: Adobe Reader