Oliver Cletrac Model A

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

OLIVER

"Cletracll

GASOLINE

OR DIESEL

POWER

*TRACTORS

OLIVER

"Cletrac"

Noi xiookx‘‘ Imp

0 ff//i/ii/ 1111W

„Novrowo, tlib.!,

4,117/111 1111V

NAAA

.000,/, Mil!:

0 0/7//11/

WAV

„4„.1106,wiml,

0//11117

110%A.V%%1%% /1(([

1: A,

01////// "

.%

lohA.4,1k,..0...

N.V.-

/1

4,P0A%.,

,,{//11l

11

ort/1"

7/ 1 114

IS POWER ON BOTH

OLIVER

"Cletrac"

model "A" mu...

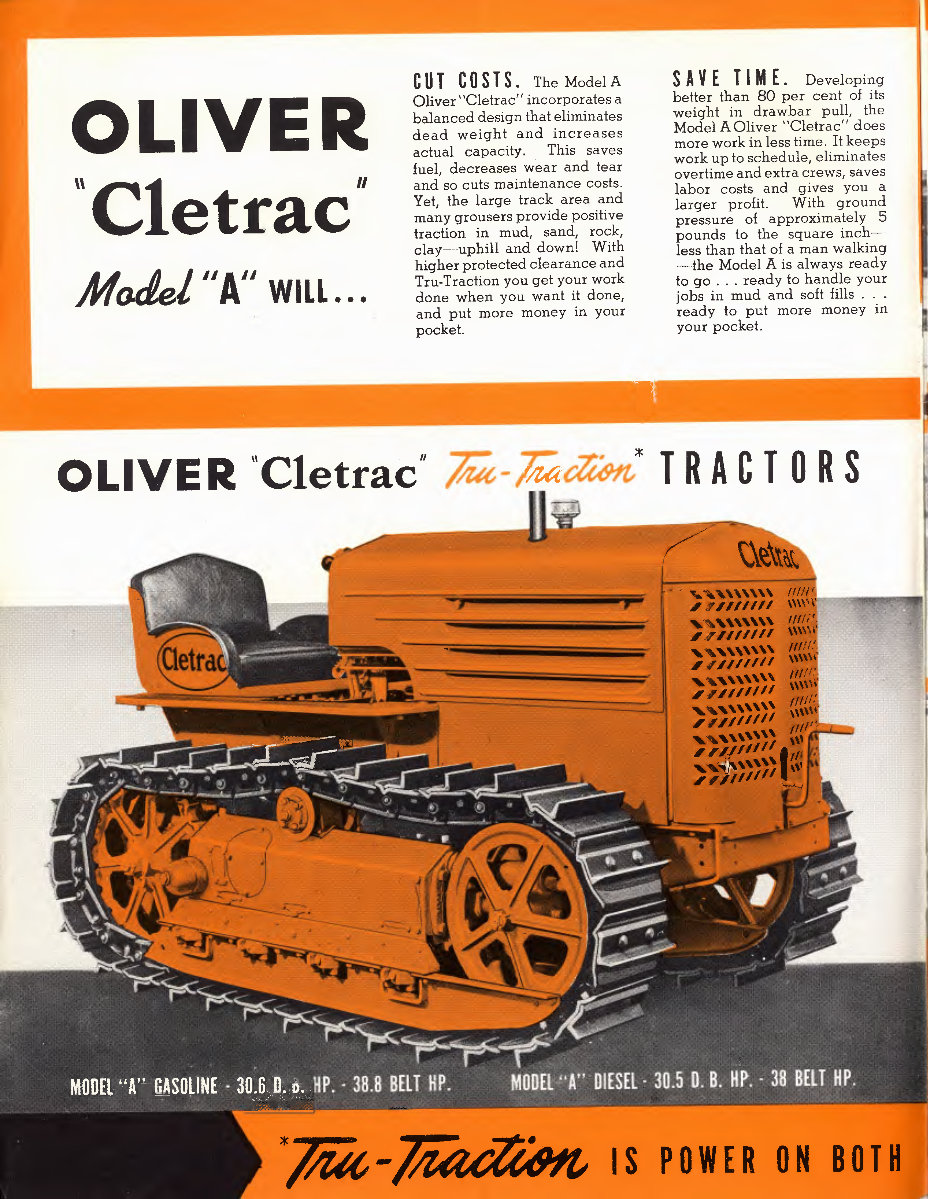

CUT COSTS. The Model A

Oliver "Cletrac" incorporates a

balanced design that eliminates

dead weight and increases

actual capacity. This saves

fuel, decreases wear and tear

and so cuts maintenance costs.

Yet, the large track area and

many grousers provide positive

traction in mud, sand, rock,

clay—uphill and down! With

higher protected clearance and

Tru-Traction you get your work

done when you want it done,

and put more money in your

pocket.

SAVE TIME. Developing

better than 80 per cent of its

weight in drawbar pull, the

Model A Oliver "Cletrac" does

more work in less time. It keeps

work up to schedule, eliminates

overtime and extra crews, saves

labor costs and gives you a

larger profit. With ground

pressure of approximately 5

pounds to the square inch—

less than that of a man walking

the Model A is always ready

to go ... ready to handle your

jobs in mud and soft fills . . .

ready to put more money in

your pocket.

Ili.N1010411

4,./Arir

TI'#/////# NA! VIOL:16,16.

...... •■•■■•:101011.N.

/Or

kNN,:■■■■•■•■•■ .......

1.•\

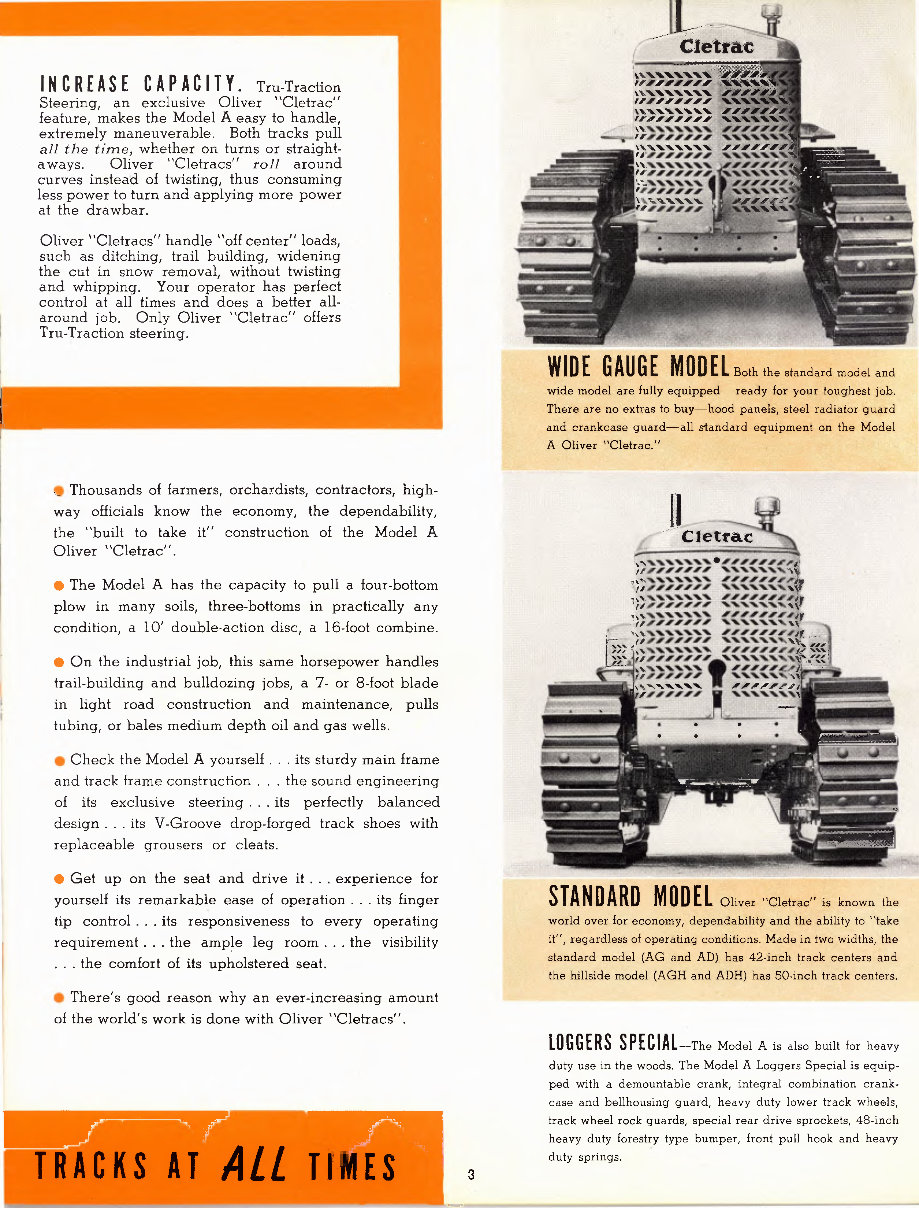

STANDARD MODEL Oliver "Cletrac" is known the

world over for economy, dependability and the ability to "take

it", regardless of operating conditions. Made in two widths, the

standard model (AG and AD) has 42-inch track centers and

the hillside model (AGH and ADH) has 50-inch track centers.

LOGGERS SPECIAL—The Model A is also built for heavy

duty use in the woods. The Model A Loggers Special is equip-

ped with a demountable crank, integral combination crank-

case and bellhousing guard, heavy duty lower track wheels,

track wheel rock guards, special rear drive sprockets, 48-inch

heavy duty forestry type bumper, front pull hook and heavy

duty springs.

3

INCREASE CAPACITY. Tru-Traction

Steering, an exclusive Oliver "Cletrac"

feature, makes the Model A easy to handle,

extremely maneuverable. Both tracks pull

all the time, whether on turns or straight-

aways. Oliver "Cletracs" roll around

curves instead of twisting, thus consuming

less power to turn and applying more power

at the drawbar.

Oliver "Cletracs" handle "off center" loads,

such as ditching, trail building, widening

the cut in snow removal, without twisting

and whipping. Your operator has perfect

control at all times and does a better all-

around job. Only Oliver "Cletrac" offers

Tru-Traction steering.

WIDE GAUGE MODEL Both the standard model and

wide model are fully equipped ready for your toughest job.

There are no extras to buy—hood panels, steel radiator guard

and crankcase guard—all standard equipment on the Model

A Oliver "Cletrac."

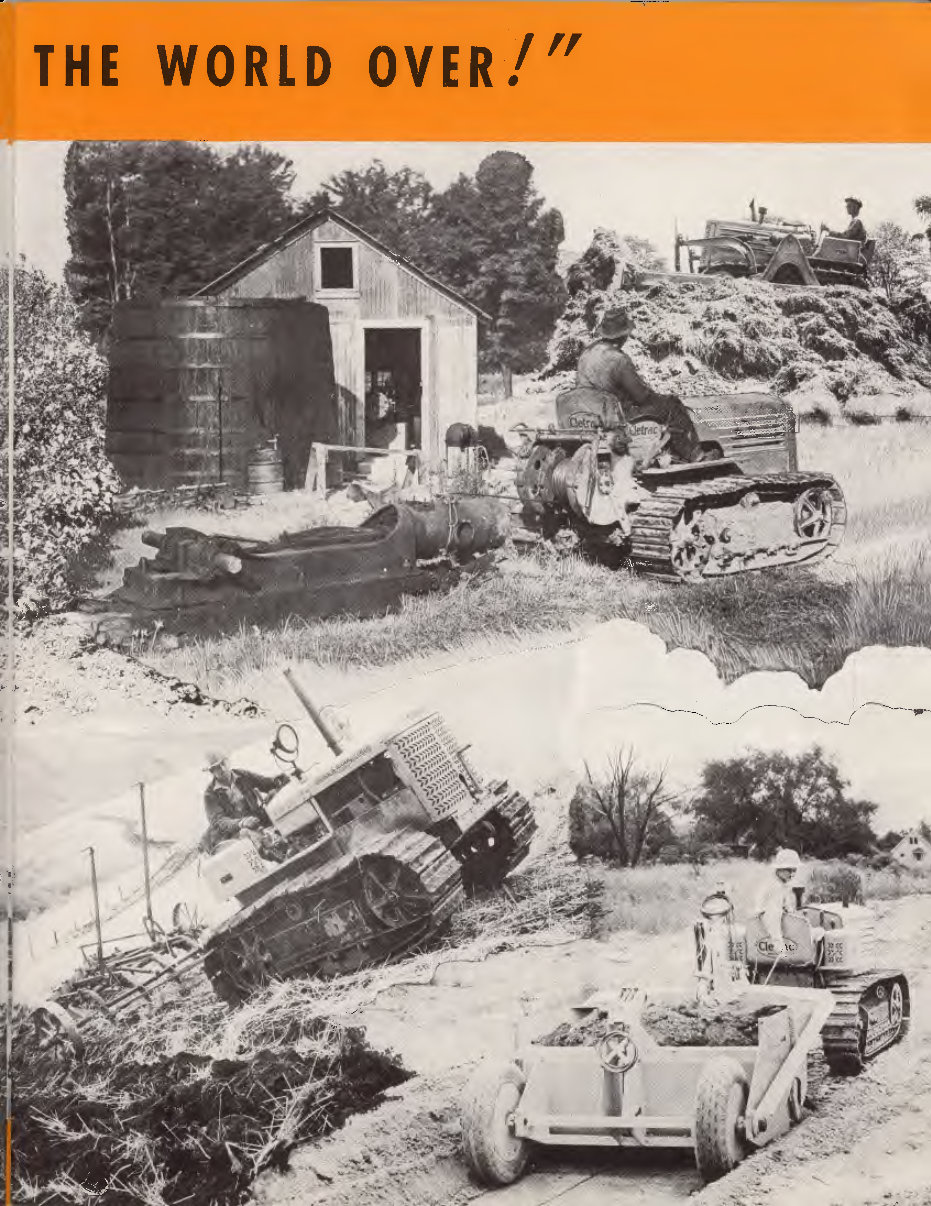

Thousands of farmers, orchardists, contractors, high-

way officials know the economy, the dependability,

the "built to take it" construction of the Model A

Oliver "Cletrac".

• The Model A has the capacity to pull a four-bottom

plow in many soils, three-bottoms in practically any

condition, a 10' double-action disc, a 16-foot combine.

• On the industrial job, this same horsepower handles

trail-building and bulldozing jobs, a 7- or 8-foot blade

in light road construction and maintenance, pulls

tubing, or bales medium depth oil and gas wells.

Check the Model A yourself ... its sturdy main frame

and track frame construction . .. the sound engineering

of its exclusive steering . . . its perfectly balanced

design . . . its V-Groove drop-forged track shoes with

replaceable grousers or cleats.

• Get up on the seat and drive it . . . experience for

yourself its remarkable ease of operation . . . its finger

tip control . . . its responsiveness to every operating

requirement . . . the ample leg room . . . the visibility

. . . the comfort of its upholstered seat.

There's good reason why an ever-increasing amount

of the world's work is done with Oliver "Cletracs".

TRACKS AT

ALL I TIrl

THE WORLD OVER!"

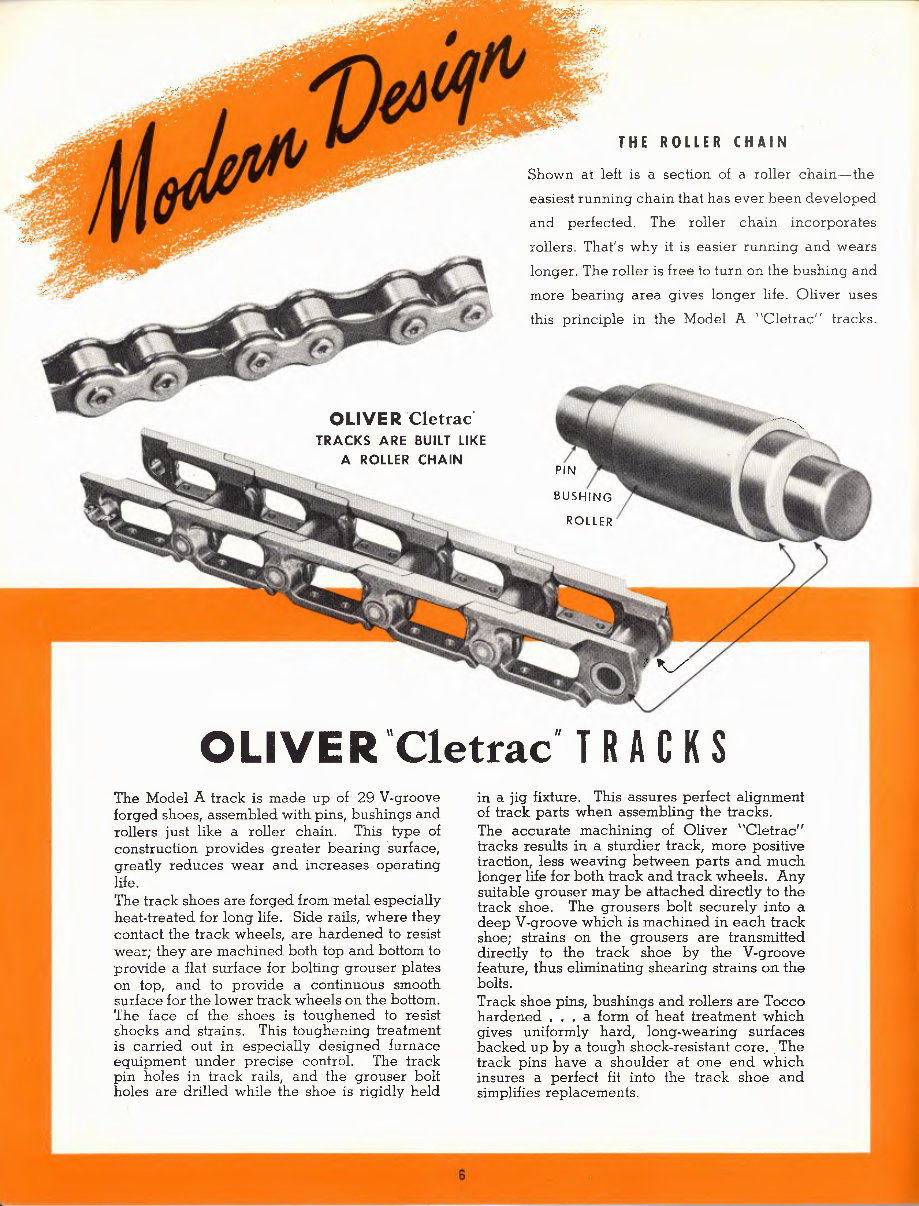

THE ROLLER CHAIN

Shown at left is a section of a roller chain—the

easiest running chain that has ever been developed

and perfected. The roller chain incorporates

rollers. That's why it is easier running and wears

longer. The roller is free to turn on the bushing and

more bearing area gives longer life. Oliver uses

this principle in the Model A "Cletrac" tracks.

OLIVER Cletrac

TRACKS ARE BUILT LIKE

A ROLLER CHAIN

PIN

BUSHING

ROLLER

OLIVER"Cletrac" TRACKS

The Model A track is made up of 29 V-groove

forged shoes, assembled with pins, bushings and

rollers just like a roller chain. This type of

construction provides greater bearing surface,

greatly reduces wear and increases operating

life.

The track shoes are forged from metal especially

heat-treated for long life. Side rails, where they

contact the track wheels, are hardened to resist

wear; they are machined both top and bottom to

provide a flat surface for bolting grouser plates

on top, and to provide a continuous smooth

surface for the lower track wheels on the bottom.

The face of the shoes is toughened to resist

shocks and strains. This toughening treatment

is carried out in especially designed furnace

equipment under precise control. The track

pin holes in track rails, and the grouser bolt

holes are drilled while the shoe is rigidly held

in a jig fixture. This assures perfect alignment

of track parts when assembling the tracks.

The accurate machining of Oliver "Cletrac"

tracks results in a sturdier track, more positive

traction, less weaving between parts and much

longer life for both track and track wheels. Any

suitable grouser may be attached directly to the

track shoe. The grousers bolt securely into a

deep V-groove which is machined in each track

shoe; strains on the grousers are transmitted

directly to the track shoe by the V-groove

feature, thus eliminating shearing strains on the

bolts.

Track shoe pins, bushings and rollers are Tocco

hardened . . . a form of heat treatment which

gives uniformly hard, long-wearing surfaces

backed up by a tough shock-resistant core. The

track pins have a shoulder at one end which

insures a perfect fit into the track shoe and

simplifies replacements.

Sturdy construction and accurate machining of V-groove

track shoes used in the Oliver Model A "Cletrac" tracks is

typical of advanced engineering used throughout the

tractor.

Side rails are forged from alloy steel, heat-treated for

strength. Surfaces which contact the track wheels are

especially hardened to resist wear. Side rails of the track

are machined, both top and bottom, to give a perfectly flat

surface for bolting on grouser plates and to provide a

continuous smooth surface for the lower track wheels.

A deep V-groove is machined in the top of each side rail

and each grouser plate is formed to lock securely into this

V-groove, fitting perfectly. Grouser plates are held securely

to the track by four heat-treated alloy steel bolts, but

strain of traction is taken by the V-groove in the track shoe.

The grousers are designed to give a spring lock when

bolted in place.

GROUSERS BUILT FOR

No. 1. Squart Corner Dirt Grouser, 12 inches wide.

Standard equipment. Also available 14 and 16

inches wide.*

No. 2. Ice Grouser (Used with or without plate.)

No. 3. Pressed Steel Pavement Grouser, 12 inches

wide. (Used with or without plate.)

No. 4. Pressed Steel Street Plate, used with Dirt

Grouser (Fits over Dirt Grouser.) Furnished for

alternate shoes or all shoes.

No. 5. Cast Steel Pavement Grouser, 11 inches wide.

*Plates and grousers over 14 inches available for hillside models only.

Wood blocks and special grousers not shown here can be furnished as special equipment. See price list for full details on plates and grousers.

No. 6. Beveled Corner Dirt Grouser, 12 inches wide.

Also available 14 and 16 inches wide.*

No. 7. Rubber Block.

No. 8. Standard Grouser Plate, 12 inches wide. Also

available 14-16 and 18 inches wide.*

No. 9. Cut-out Plate (Used with Ice or Dirt Grouser)

12 inches wide. Also available 14 inches wide.*

No. 10. Combination Grouser and Plate, 20 inches wide.*

Also available 18 inches wide.*

CRAWLER DESIGN

Track rails are

wide apart for maximum traction

from SIDE to SIDE

Track rails are wide apart so that the weight of the

tractor is spread over a wider area from side to side.

The Oliver "Cletrac" is solidly supported--not

balanced on the track. The front idler wheels are

also wide-spread so that the track is accurately

guided and cannot weave or twist. A minimum part

of the track projects beyond the rails, so that twisting

strains produced by running over rocks or uneven

ground are minimized. This is one reason why the

Oliver "Cletrac" is able to step lightly over soft

soils . . . to give a maximum of positive traction when

the ground is hard and the load heavy . . . to combine

positive traction with lightness in weight and so

develop better than 80 per cent of its weight in draw-

bar pull.

/ . V GROUSER PENETRATES FOR PERFECT TRACTION

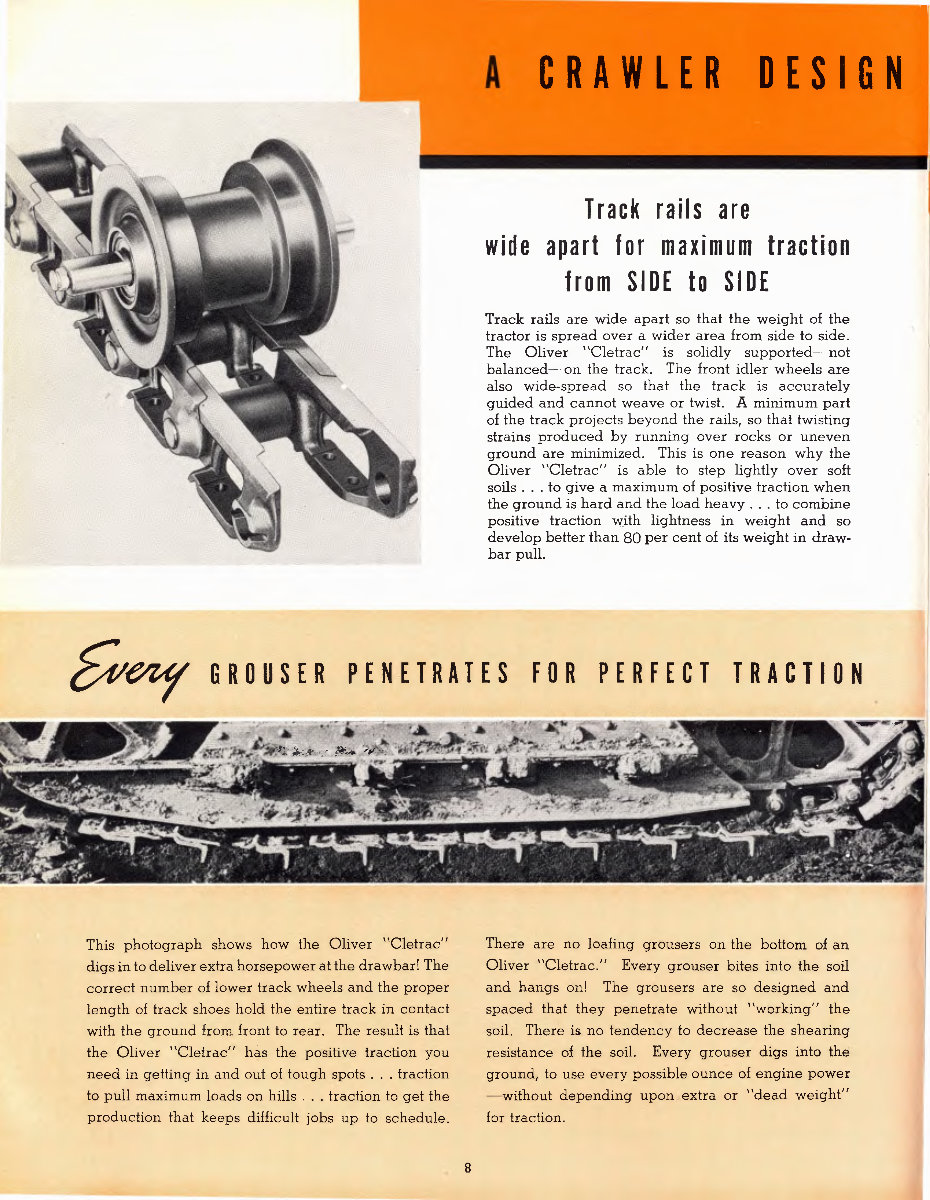

This photograph shows how the Oliver "Cletrac"

digs in to deliver extra horsepower at the drawbar! The

correct number of lower track wheels and the proper

length of track shoes hold the entire track in contact

with the ground from front to rear. The result is that

the Oliver "Cletrac" has the positive traction you

need in getting in and out of tough spots . . . traction

to pull maximum loads on hills ... traction to get the

production that keeps difficult jobs up to schedule.

There are no loafing grousers on the bottom of an

Oliver "Cletrac." Every grouser bites into the soil

and hangs on! The grousers are so designed and

spaced that they penetrate without "working" the

soil. There is no tendency to decrease the shearing

resistance of the soil. Every grouser digs into the

ground, to use every possible ounce of engine power

without depending upon extra or "dead weight"

for traction.

8

THAT'S BUILT FOR

LOWER TRACK WHEEL SHAFT

The lower wheel shaft is especially selected

steel, carburized, hardened and ground. The

upper, or the low pressure side, is milled flat.

This provides for proper distribution of the

oil along the entire length of the shaft and

bearing.

The bushings are of special alloy bronze,

wear resistant and with carefully controlled

bearing qualities. These bushings are

individually replaceable so that when wear

occurs they may be easily and inexpensively

replaced.

9

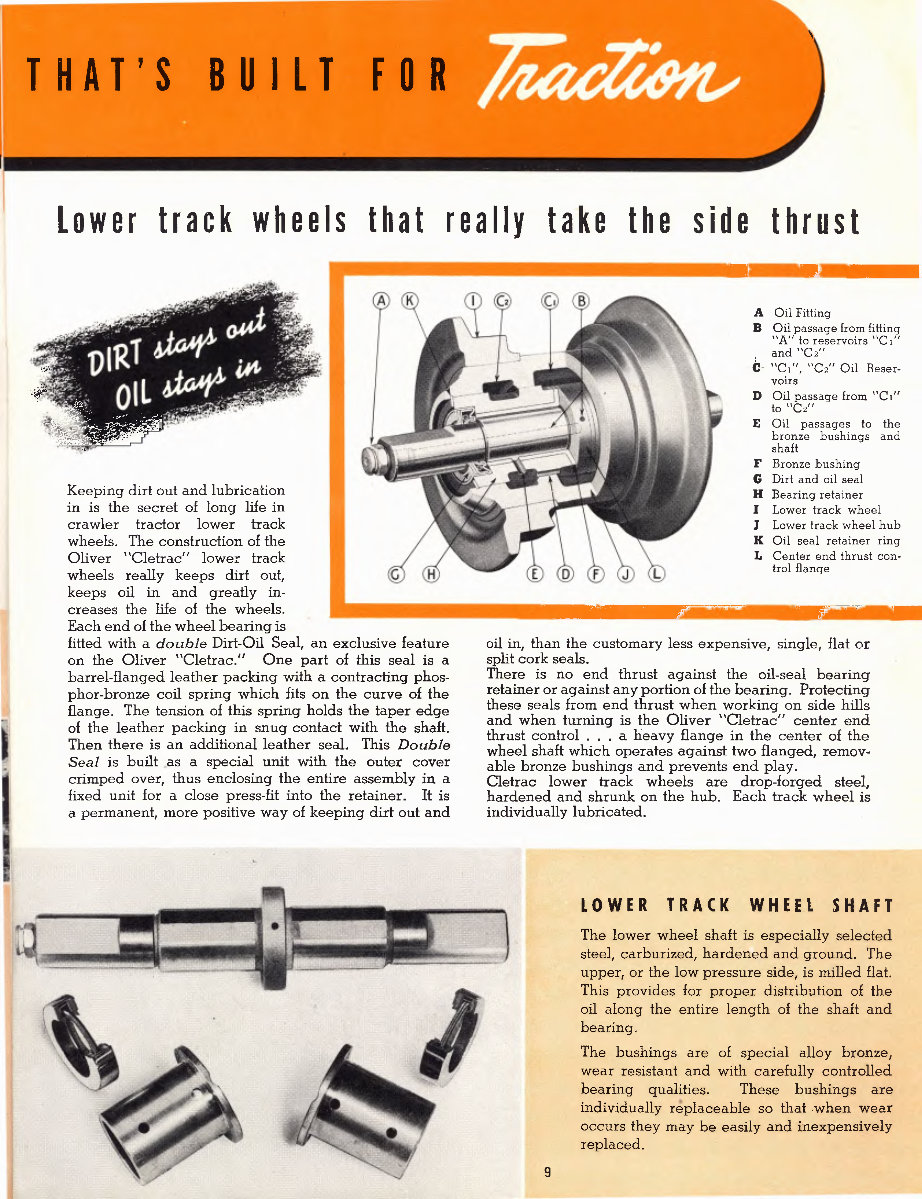

Lower track wheels that really take the side thrust

a RP 11=1111111

Keeping dirt out and lubrication

in is the secret of long life in

crawler tractor lower track

wheels. The construction of the

Oliver "Cletrac" lower track

wheels really keeps dirt out,

keeps oil in and greatly in-

creases the life of the wheels.

Each end of the wheel bearing is

fitted with a double Dirt-Oil Seal, an exclusive feature

on the Oliver "Cletrac." One part of this seal is a

barrel-flanged leather packing with a contracting phos-

phor-bronze coil spring which fits on the curve of the

flange. The tension of this spring holds the taper edge

of the leather packing in snug contact with the shaft.

Then there is an additional leather seal. This Double

Seal is built as a special unit with the outer cover

crimped over, thus enclosing the entire assembly in a

fixed unit for a close press-fit into the retainer. It is

a permanent, more positive way of keeping dirt out and

A Oil Fitting

B Oil passage from fitting

"A" to reservoirs "CI"

and "C2"

C- "Ci", "C2" Oil Reser-

voirs

D Oil passage from "CI"

to "C2"

E Oil passages to the

bronze bushings and

shaft

F Bronze bushing

G Dirt and oil seal

H Bearing retainer

I Lower track wheel

I Lower track wheel hub

K Oil seal retainer ring

L Center end thrust con-

trol flange

oil in, in, than the customary less expensive, single, flat or

split cork seals.

There is no end thrust against the oil-seal bearing

retainer or against any portion of the bearing. Protecting

these seals from end thrust when working on side hills

and when turning is the Oliver "Cletrac" center end

thrust control . . . a heavy flange in the center of the

wheel shaft which operates against two flanged, remov-

able bronze bushings and prevents end play.

Cletrac lower track wheels are drop-forged steel,

hardened and shrunk on the hub. Each track wheel is

individually lubricated.

THERE'S

Shocks and wracking caused by an Oliver "Cletrac"

hitting obstructions or making a short turn is not transmitted

to the final drive sprocket or to any of the gears or shafts.

This is because there is no connection between the drive

sprocket and the track frame.

The track frame of the Oliver "Cletrac" oscillates on a

heavy, fixed track frame shaft. Shocks caused by hitting

an obstruction are cushioned by an enclosed, protected

buffer spring which encircles the front wheel shaft and

works against the stationary track frame shaft. It absorbs

shocks, prevents damage.

/05

-,VJOg)

IR,

-71

IN OLIVER

"Cletrac" MAIN FRAME

OLIVER

Cletracs are designed and built

to withstand these severe

Strains of operation never reach the transmission case or

engine of the Oliver "Cletrac." The engine is carried by

a heavy, rolled one-piece steel frame which rests on two

longitudinal springs properly tapered and free moving in

spring brackets—one on each side of the frame. The

engine is set down in this frame, which is supported and

carried on springs at four points. This general design

relieves the engine and transmission case of harmful,

damaging strain caused by operating the tractor over

uneven ground.

JO-

Any twists that may be set up by the up-and-down oscillating

motion of the tractor when in operation are minimized in

the Oliver "Cletrac" by the two heavy horizontal springs.

The engine bell housing is bolted to the transmission case,

and the front end of the engine is mounted in a trunnion.

Should any twists or strains reach the frame, they are not

passed on to the engine. This safeguards the alignment of

main bearings, crankshaft, pistons and connecting rods.

10

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$26.99

Viewed 77 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$26.99

These digital manuals provide comprehensive technical information for car repair, spanning across 28 pages. They are valuable resources for both professional mechanics and DIY enthusiasts. The manuals are available in .PDF format, offering detailed insights into various aspects of vehicle maintenance and repair.