Bosch Diesel Injection Pumps Size A, B, K and Z Repair

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

BOSCH

WJP 101/1 B EP

Repair 3nsieuclions

Diesel Injection Pumps

Size A, B, K and Z

Table of Contents

Page

I. Introduction 1

II. Initial Examination 2

A) Without pump being removed 2

B) With pump removed 3

III. Dismantling 4

A) Sequence of Operations on Pumps

Type PE 4

B) Sequence of Operations on Pumps

Type PF 13

IV. Repair and Replacement 14

A) Elements 14

B) Delivery Valve 14

C) Roller Tappet or Plunger Guide 14

D) Camshaft 14

E) Ball Bearings 15

F) Control Rod 15

G) Control Quadrant and Sleeve 15

H) Plunger Spring 15

I) Pump Hoys . ing 15

V. Assembly 16

A) Assembly Numbers 16

B) Sequence of Operations for Assembly 16

VI. Special Tools and Appliances 26

VII. Tightening Torques 28

VIII. Explanation of Injection Pump Marks 30

I. Introduction

Detailed information on the design and operating principle of injection pumps with self-contained

drive or with operation by separate camshaft is given in leaflets VDT-UBP 001,5 and .. 6. Before

looking at these repair instructions, it is absolutely essential for you to be fully conversant with the

information contained in the said leaflets.

The data in these repair instructions apply to standard Bosch injection pumps; where they apply

only to certain types this is indicated by a special reference.

Housings and components of injection pumps must be cleaned only in petrol, kerosene, diesel fuel

or test oil (01 61 vii). Trichloroethylene (Tr) should not be used for cleaning pump components.

Before assembling, apply test oil to all sliding parts of the injection pump, and a good quality

engine oil (011 v10) to the governor parts.

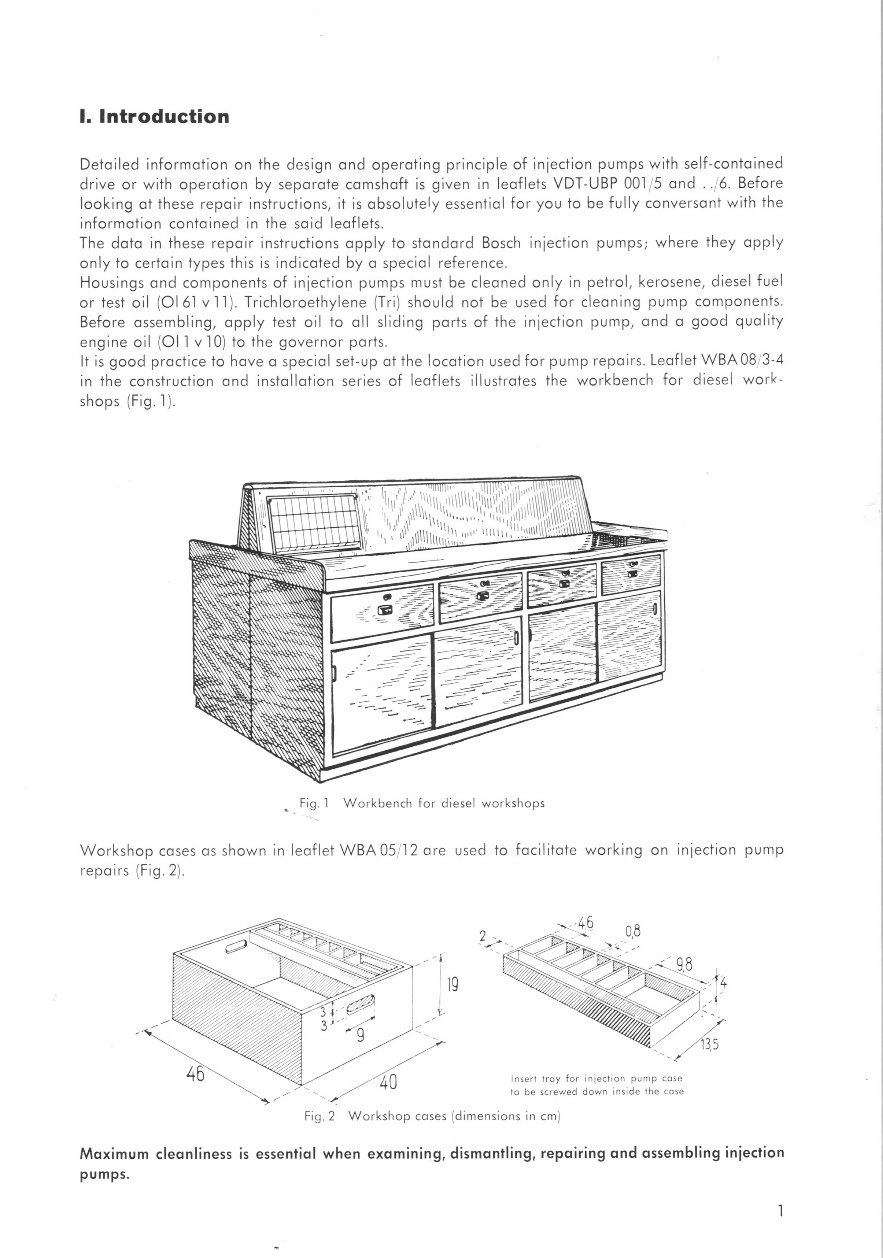

It is good practice to have a special set-up at the location used for pump repairs. Leaflet WBA 08 3-4

in the construction and installation series of leaflets illustrates the workbench for diesel work-

shops (Fig. 1).

Fig. 1 Workbench for diesel workshops

Workshop cases as shown in leaflet WBA 05 12 are used to facilitate working on injection pump

repairs (Fig. 2).

lg

Insert tray for injection pump case

to be screwed down inside the case

Fig. 2 Workshop cases (dimensions in cm)

Maximum cleanliness is essential when examining, dismantling, repairing and assembling injection

pumps.

1

II. Initial Examination

A) Without pump being removed

For tracing trouble and detecting a fault in the injection system of an engine, a test run or trial

trip should be made before removing the injection pump, followed by a visual test. Only then

should a decision be made as to the necessity of removing the injection pump. If it has already

been removed, a check of the pump on the test bench is generally advisable. Only then should

the injection pump be dismantled.

The following sequence of operations is advisable for PE-pumps (this largely applies likewise to

PF-pumps):

1. Before removing it, check whether the pump specified by the engine manufacturer for the

respective engine has been installed. Compare type formula with the design of the pump, check

position of camshaft or cam sequence (watch direction of rotation) and check position of

governor, injection timer and feed pump (for assembly figures see page 30).

2 Check full-load stop on governor and control rod stop on pump for correct setting and sealing

(on pneumatic governors also check stops of Venturi control unit). Check whether fixing screws

of endplate and of governor housing are still secured.

Check whether, when depressing the pedal, the control lever of the centrifugal governor rests

against the full-load stop. Unhinge the linkage and check control rod for smooth action. Un-

screw inspection cover of injection pump, move control lever of governor to FULL and see

whether the deflection of all control sleeves with control quadrants is the same.

Check whether marks on control sleeves and control quadrants coincide and whether clamping

screws are tightened. Check that lock nut of tappet screw is tight. See whether surface of tappet

springs is still satisfactory or if they are damaged.

If any resistance is detected on the control lever of a governor, continue to push with control-

rod stop fixed until the idling springs of the governor are fully compressed and strong resistance

is perceptible. In this position, the control lever should just touch the full-load stop screw.

In case of an automatic (resilient) stop for additional fuel delivery, after reaching the first resis-

tance, hold back the control rod by means of the control sleeves (pushing them strongly upwards),

then continue pushing the lever until the idling springs are compressed. In this position, the

control lever should just touch the full-load stop screw.

On pneumatic governors, the control lever is normally always set to FULL ; check whether here,

too, the deflection of all control sleeves with control quadrants is the same. In normal conditions,

the control rod must rest against the stop at roughly half the control rod travel.

3. In the event of difficulties in starting, the engine should be checked for correct compression and

correct starting speed. If these are found to be in order, look for the defect on the pump.

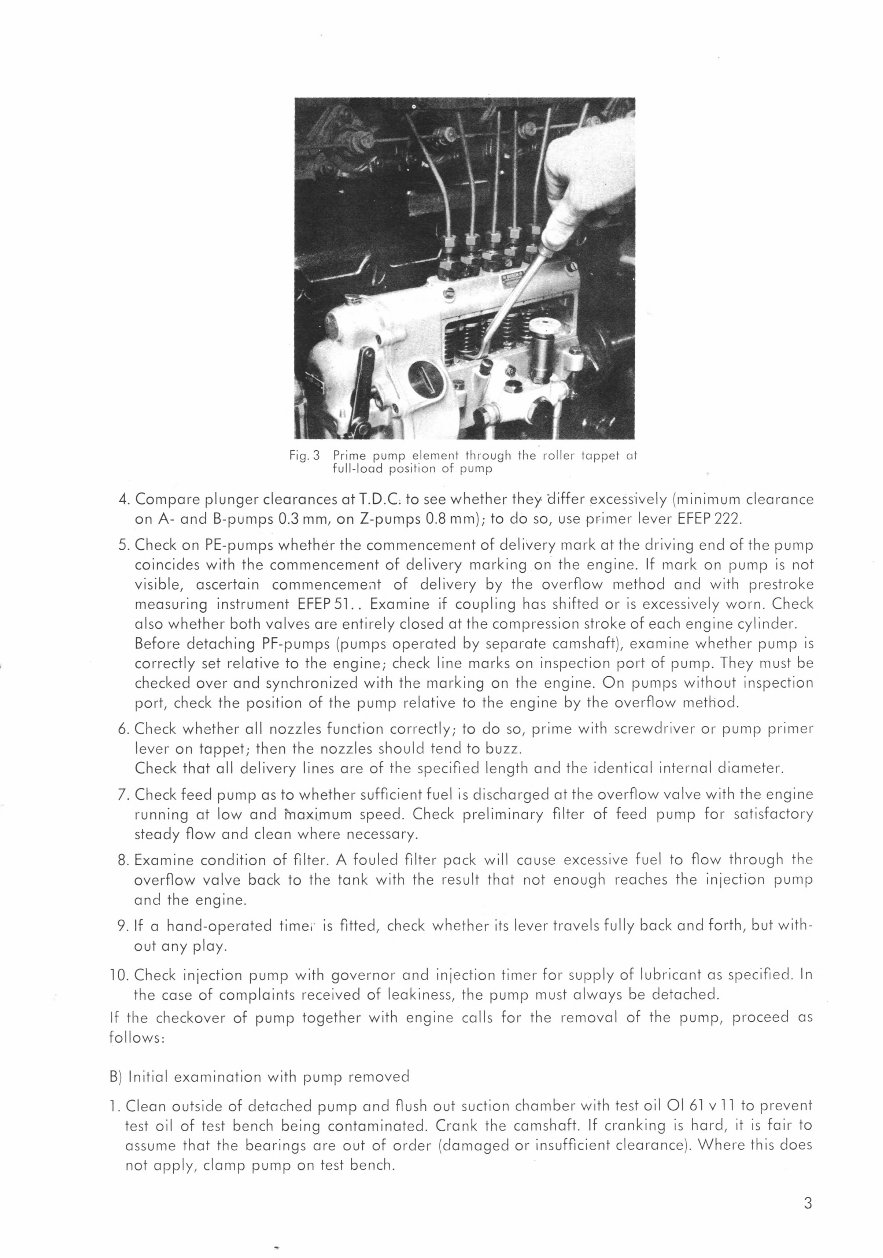

Here a check should be made as to whether the element produces pressure by priming the pump

element through the roller tappet at full-load position of the pump with a broad, non-resilient

screwdriver or better still with pump primer lever EFEP 222 (Fig. 3).

A perceptible resistance when pushing the elements upwards indicates that the elements and

nozzles are in good order. If pushing does not produce any resistance, detach delivery pipe and

close the pump outlets (with pinched-off pipes or with injection tester EFEP 66 A). Repeat this

operation.

If pressure then exists, the nozzle will no longer close. Where no pressure exists, the delivery

valve is jammed (open) or the element is useless.

If, however, everything is in good order, check heater plugs or heating flange and compression.

2

Fig. 3 Prime pump element through the roller tappet at

full-load position of pump

4. Compare plunger clearances at T.D.C. to see whether they differ excessively (minimum clearance

on A- and B-pumps 0.3 mm, on Z-pumps 0.8 mm) ; to do so, use primer lever EFEP 222.

5. Check on PE-pumps whether the commencement of delivery mark at the driving end of the pump

coincides with the commencement of delivery marking on the engine. If mark on pump is not

visible, ascertain commencement of delivery by the overflow method and with prestroke

measuring instrument EFEP 51.. Examine if coupling has shifted or is excessively worn. Check

also whether both valves are entirely closed at the compression stroke of each engine cylinder.

Before detaching PF-pumps (pumps operated by separate camshaft), examine whether pump is

correctly set relative to the engine ; check line marks on inspection port of pump. They must be

checked over and synchronized with the marking on the engine. On pumps without inspection

port, check the position of the pump relative to the engine by the overflow method.

6. Check whether all nozzles function correctly ; to do so, prime with screwdriver or pump primer

lever on tappet ; then the nozzles should tend to buzz.

Check that all delivery lines are of the specified length and the identical internal diameter.

7. Check feed pump as to whether sufficient fuel is discharged at the overflow valve with the engine

running at low and i -naximum speed. Check preliminary filter of feed pump for satisfactory

steady flow and clean where necessary.

8. Examine condition of filter. A fouled filter pack will cause excessive fuel to flow through the

overflow valve back to the tank with the result that not enough reaches the injection pump

and the engine.

9. If a hand-operated time' . is fitted, check whether its lever travels fully back and forth, but with-

out any play.

10. Check injection pump with governor and injection timer for supply of lubricant as specified In

the case of complaints received of leakiness, the pump must always be detached.

If the checkover of pump together with engine calls for the removal of the pump, proceed as

follows:

B) Initial examination with pump removed

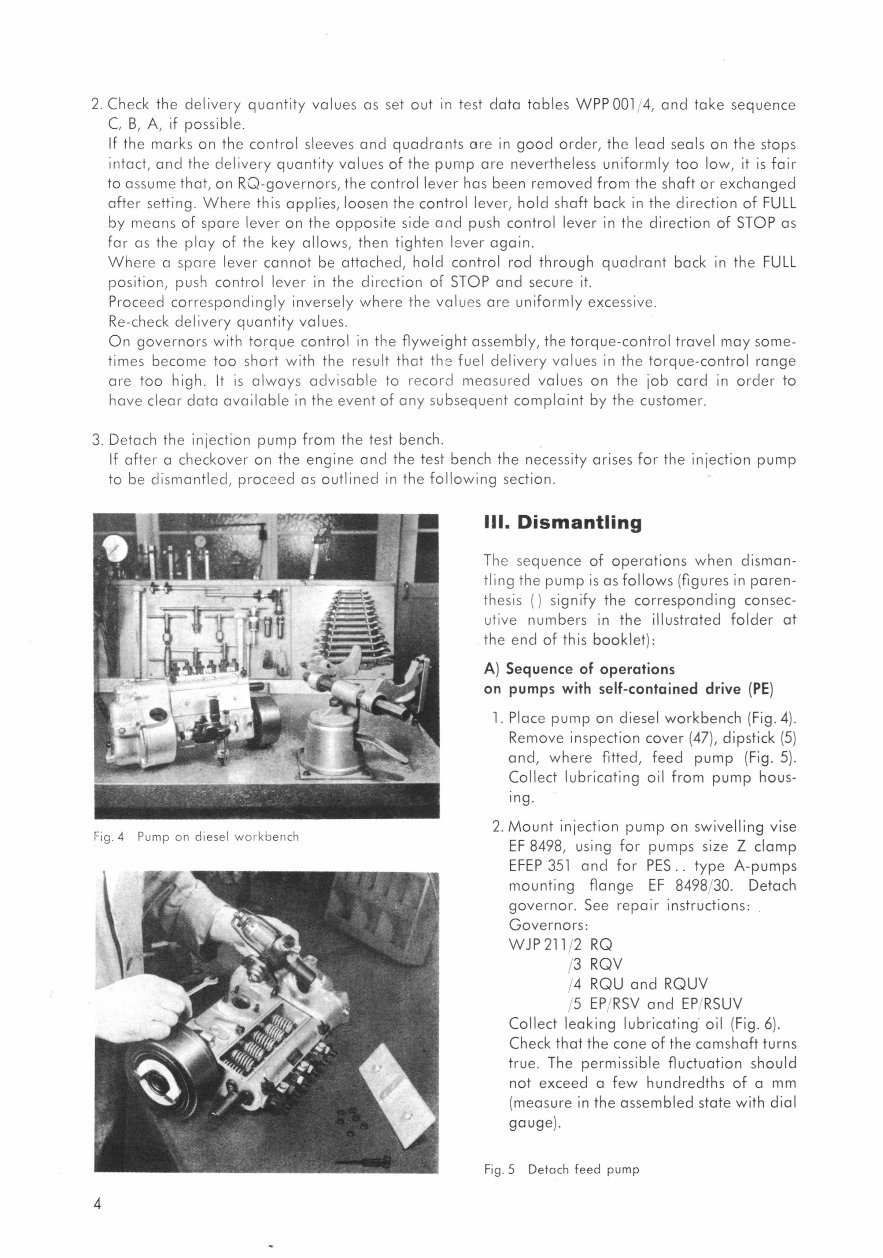

1. Clean outside of detached pump and flush out suction chamber with test oil 01 61 v 11 to prevent

test oil of test bench being contaminated. Crank the camshaft. If cranking is hard, it is fair to

assume that the bearings are out of order (damaged or insufficient clearance). Where this does

not apply, clamp pump on test bench.

3

Fig. 4 Pump on diesel workbench

4

2 Check the delivery quantity values as set out in test data tables WPP 001 4, and take sequence

C, B, A, if possible.

If the marks on the control sleeves and quadrants are in good order, the lead seals on the stops

intact, and the delivery quantity values of the pump are nevertheless uniformly too low, it is fair

to assume that, on RO-governors, the control lever has been removed from the shaft or exchanged

after setting. Where this applies, loosen the control lever, hold shaft back in the direction of FULL

by means of spare lever on the opposite side and push control lever in the direction of STOP as

far as the play of the key allows, then tighten lever again.

Where a spare lever cannot be attached, hold control rod through quadrant back in the FULL

position, push control lever in the direction of STOP and secure it.

Proceed correspondingly inversely where the values are uniformly excessive.

Re-check delivery quantity values.

On governors with torque control in the flyweight assembly, the torque-control travel may some-

times become too short with the result that the fuel delivery values in the torque-control range

are too high. It is always advisable to record measured values on the job card in order to

have clear data available in the event of any subsequent complaint by the customer.

3. Detach the injection pump from the test bench.

If after a checkover on the engine and the test bench the necessity arises for the injection pump

to be dismantled, proceed as outlined in the following section.

Ill. Dismantling

The sequence of operations when disman-

tling the pump is as follows (figures in paren-

thesis ( ) signify the corresponding consec-

utive numbers in the illustrated folder at

the end of this booklet):

A) Sequence of operations

on pumps with self-contained drive (PE)

1. Place pump on diesel workbench (Fig. 4).

Remove inspection cover (47), dipstick (5)

and, where fitted, feed pump (Fig. 5).

Collect lubricating oil from pump hous-

ing.

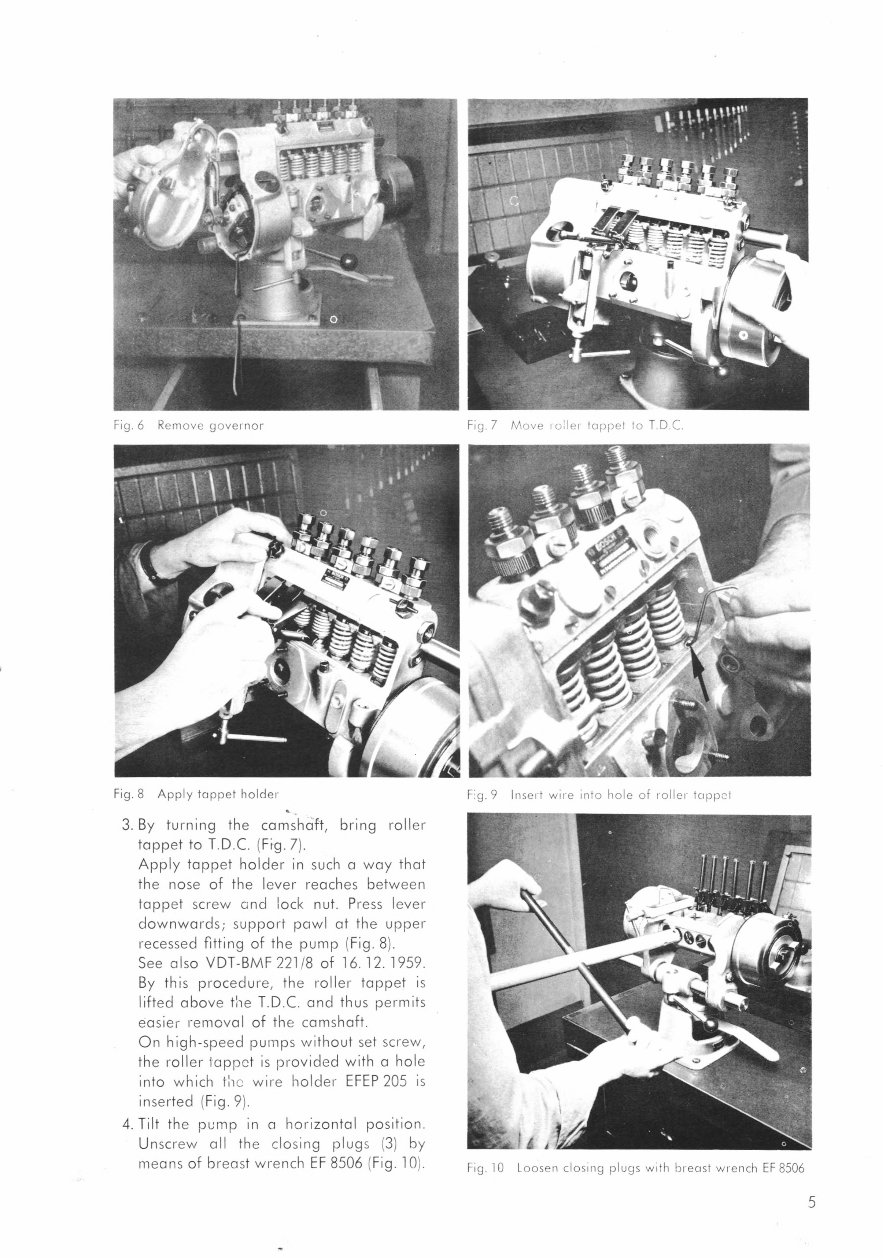

2. Mount injection pump on swivelling vise

EF 8498, using for pumps size Z clamp

EFEP 351 and for PES .. type A-pumps

mounting flange EF 8498'30. Detach

governor. See repair instructions:

Governors:

WJP 211/2 RQ

/3 RQV

4 RQU and RQUV

5 EP RSV and EP RSUV

Collect leaking lubricating . oil (Fig. 6).

Check that the cone of the camshaft turns

true. The permissible fluctuation should

not exceed a few hundredths of a mm

(measure in the assembled state with dial

gauge).

Fig. 5 Detach feed pump

41 -

F g. 9 Insert wire into hole of roller toppei Fig. 8 Apply tappet holder

Fig. 6 Remove governor Fig. 7 Move roIler tappet to T.D.C.

3. By turning the camshaft, bring roller

tappet to T.D.C. (Fig. 7).

Apply tappet holder in such a way that

the nose of the lever reaches between

tappet screw cnd lock nut. Press lever

downwards ; support pawl at the upper

recessed fitting of the pump (Fig. 8).

See also VDT-BMF 221/8 of 16.12. 1959.

By this procedure, the roller tappet is

lifted above the T.D.C. and thus permits

easier removal of the camshaft.

On high-speed pumps without set screw,

the roller lappet is provided with a hole

into which thc wire holder EFEP 205 is

inserted (Fig. 9).

4. Tilt the pump in a horizontal position.

Unscrew all the closing plugs (3) by

means of breast wrench EF 8506 (Fig. 10).

Fig. 10 Loosen closing plugs with breast wrench EF 8506

5

Fig. 11 Loosen round nut

Fig. 12 Detach injection timer

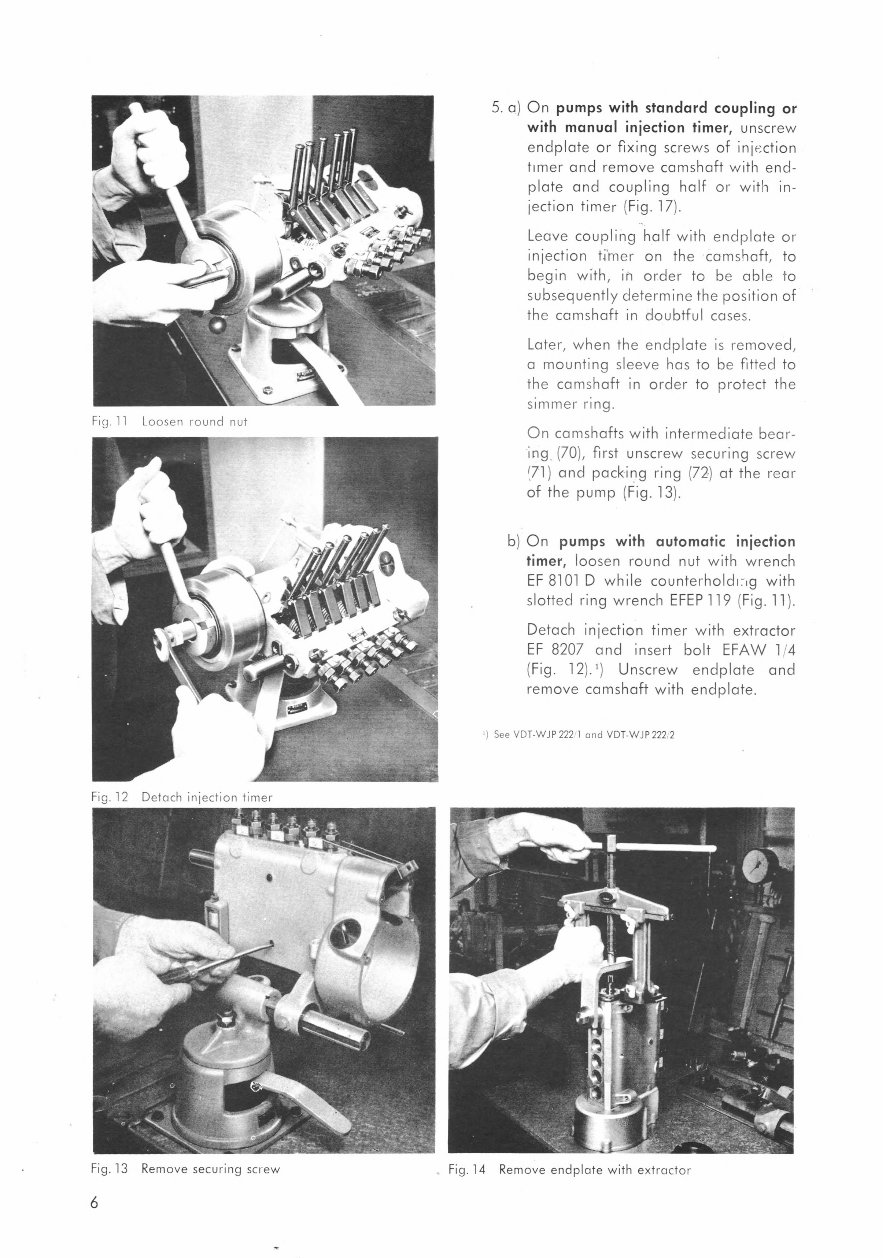

5. a) On pumps with standard coupling or

with manual injection timer, unscrew

endplate or fixing screws of injection

timer and remove camshaft with end-

plate and coupling half or with in-

jection timer (Fig. 17).

Leave coupling half with endplate or

injection timer on the camshaft, to

begin with, in order to be able to

subsequently determine the position of

the camshaft in doubtful cases.

Later, when the endplate is removed,

a mounting sleeve has to be fitted to

the camshaft in order to protect the

simmer ring.

On camshafts with intermediate bear-

ing (70), first unscrew securing screw

(71) and packing ring (72) at the rear

of the pump (Fig. 13).

b) On pumps with automatic injection

timer, loosen round nut with wrench

EF 8101 D while counterholdr - ig with

slotted ring wrench EFEP 119 (Fig. 11).

Detach injection timer with extractor

EF 8207 and insert bolt EFAW 1/4

(Fig. 12).9 Unscrew endplate and

remove camshaft with endplate.

See VDT-WJP 222 1 and VDT-WJP 222 , 2

Fig. 13 Remove securing screw Fig. 14 Remove endplate with extractor

6

Fig. 16 Modification on extractor jaws

Extractor

EF 366

Commercial-type

extractor

Fig. 17 Detach camshaft

Fig. 18 Remove tappet holder

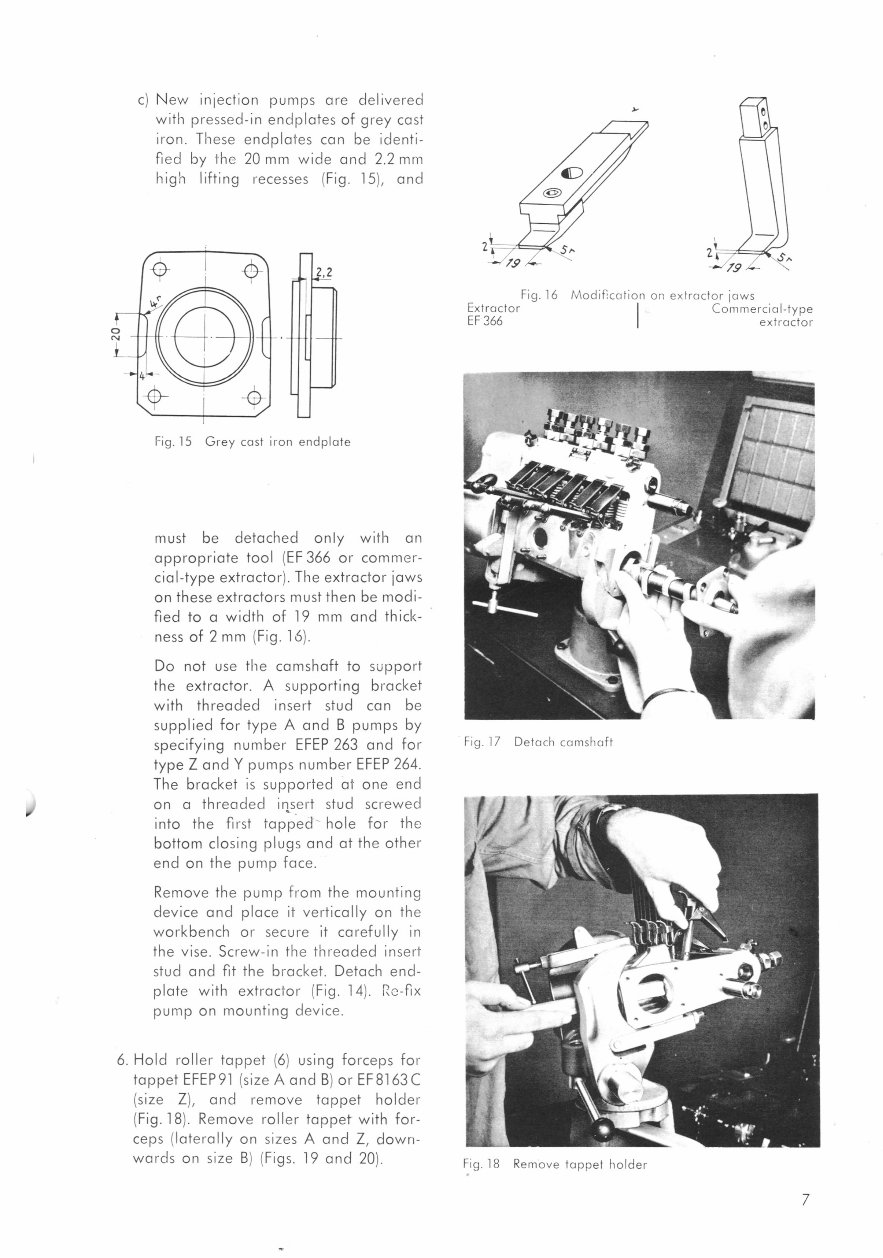

c) New injection pumps are delivered

with pressed-in endplates of grey cast

iron. These endplates can be identi-

fied by the 20 mm wide and 2.2 mm

high lifting recesses (Fig. 15), and

1,2

Fig. 15 Grey cast iron endplate

must be detached only with an

appropriate tool (EF 366 or commer-

cial-type extractor). The extractor jaws

on these extractors must then be modi-

fied to a width of 19 mm and thick-

ness of 2 mm (Fig. 16).

Do not use the camshaft to support

the extractor. A supporting bracket

with threaded insert stud can be

supplied for type A and B pumps by

specifying number EFEP 263 and for

type Z and Y pumps number EFEP 264.

The bracket is supported at one end

on a threaded insert stud screwed

into the first tapped hole for the

bottom closing plugs and at the other

end on the pump face.

Remove the pump from the mounting

device and place it vertically on the

workbench or secure it carefully in

the vise. Screw-in the threaded insert

stud and fit the bracket. Detach end-

plate with extractor (Fig. 14). Re-fix

pump on mounting device.

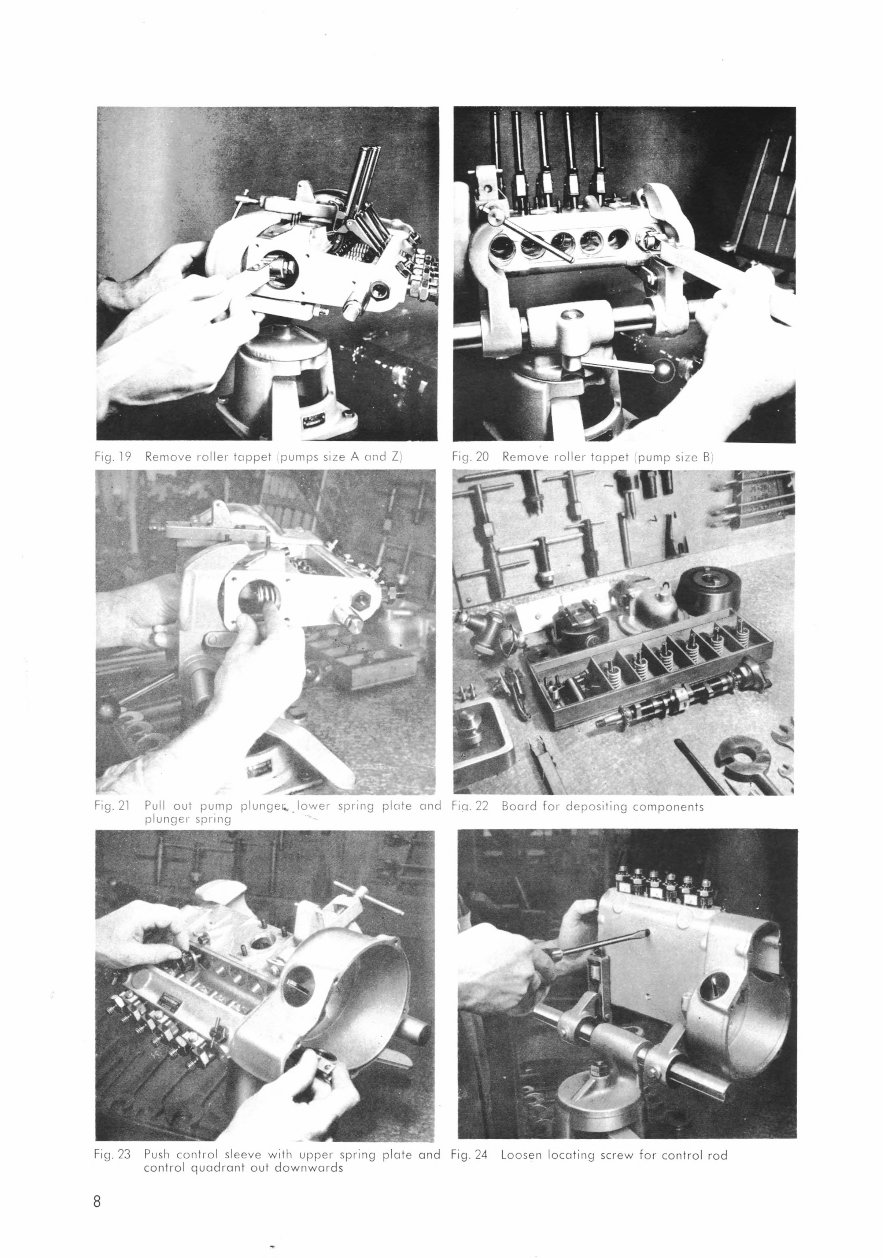

6. Hold roller tappet (6) using forceps for

tappet EFEP 91 (size A and B) or EF 8163 C

(size Z), and remove tappet holder

(Fig. 18). Remove roller tappet with for-

ceps (laterally on sizes A and Z, down-

wards on size B) (Figs. 19 and 20).

Fig. 20 Remove roller tappet pump size B) Fig. 19 Remove roller tappet .pumps size A and Z)

• •,.< .

„ -

4

„

Fig. 21 Pull out pump plungec . lower spring plate and Fia. 22 Board for depositing components

plunger spring

Fig. 23 Push control sleeve with upper spring plate and Fig. 24 Loosen locating screw for control rod

control quadrant out downwards

8

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 33 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

These digital manuals provide comprehensive guidance for car repair, catering to the needs of both professional mechanics and DIY enthusiasts. The manuals cover a wide range of topics, including initial examination, dismantling, repair and replacement, assembly, special tools and appliances, tightening torques, and explanation of injection pump marks.

- Introduction

- Initial Examination

- Without pump being removed

- With pump removed

- Dismantling

- Sequence of Operations on Pumps Type PE

- Sequence of Operations on Pumps Type PF

- Repair and Replacement

- Elements

- Delivery Valve

- Roller Tappet or Plunger Guide

- Camshaft

- Ball Bearings

- Control Rod

- Control Quadrant and Sleeve

- Plunger Spring

- Pump Housing

- Assembly

- Assembly Numbers

- Sequence of Operations for Assembly

- Special Tools and Appliances

- Tightening Torques

- Explanation of Injection Pump Marks

These manuals are available in .PDF format, providing valuable insights and instructions for efficient car repair and maintenance.